A comprehensive treatment method for tailings slurry containing cyanide

A comprehensive treatment and slurry technology, applied in sludge treatment, metallurgical wastewater treatment, water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

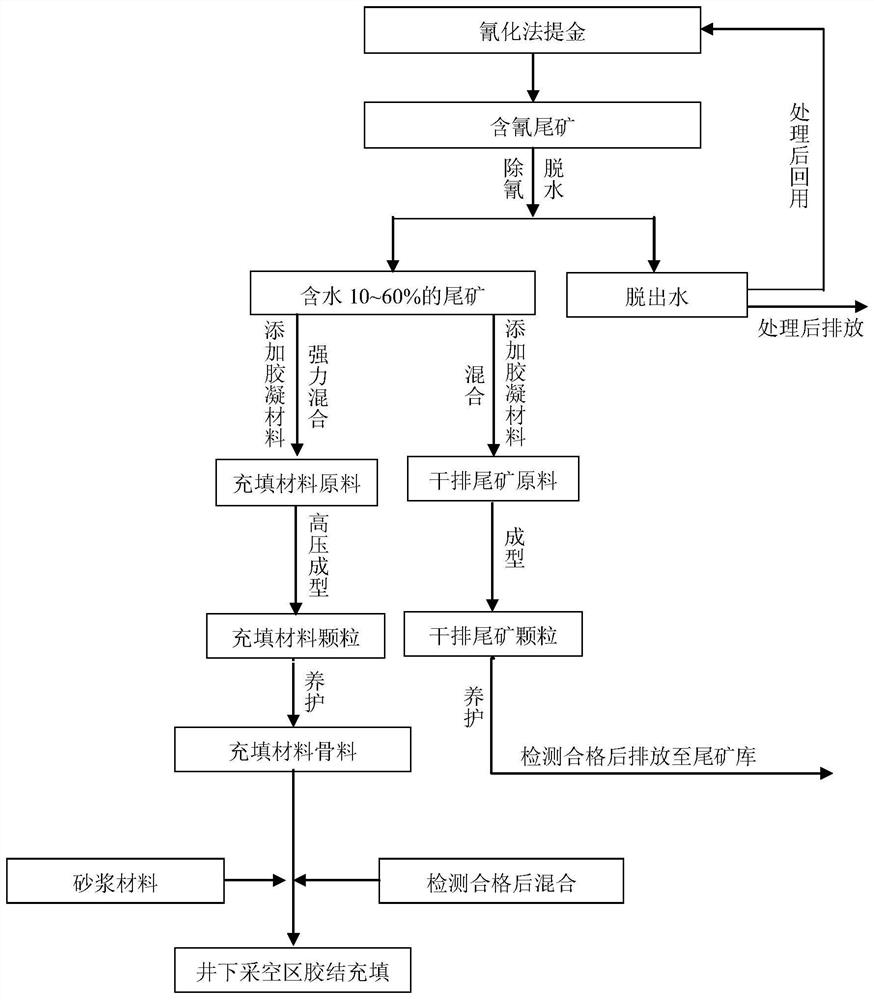

[0048] A comprehensive treatment method for tailings slurry containing cyanide, the process flow chart is as follows figure 1 shown, including the following steps:

[0049] Step 1: Take the cyanide-containing tailings slurry discharged from the cyanidation gold extraction process, first filter and dehydrate it, put sodium metabisulfite into the cyanide-containing tailings slurry and fully stir to remove cyanide, and use slaked lime to adjust the pH of the reaction in real time To achieve the best cyanide removal effect, obtain water-containing tailings and extracted water. The water-containing tailings has a water mass ratio of 10%, a cyanide concentration of 5ml / L, and the extracted water is treated to remove the effects of gold leaching. The components are reused in the gold leaching process or discharged after removing cyanide and other pollutants in the water;

[0050] Step 2, filling the underground goaf with the water-containing tailings, the steps are as follows:

[0...

Embodiment 2

[0065] A comprehensive treatment method for tailings slurry containing cyanide, the process flow chart is as follows figure 1 shown, including the following steps:

[0066] Step 1, take the cyanide-containing tailings slurry discharged from the cyanide gold extraction process, first perform centrifugal dehydration on it, put sodium metabisulfite into the cyanide-containing tailings slurry and fully stir to remove cyanide, use slaked lime to adjust the pH of the reaction in real time to To achieve the best cyanide removal effect, obtain water-containing tailings and extracted water. The water-containing tailings have a water mass ratio of 30%, a cyanide concentration of 10ml / L, and the extracted water is treated to remove components that affect the effect of gold leaching It is reused in the gold leaching process or discharged after removing cyanide and other pollutants in the water;

[0067] Step 2, filling the underground goaf with the water-containing tailings, the steps ar...

Embodiment 3

[0072] A comprehensive treatment method for tailings slurry containing cyanide, the process flow chart is as follows figure 1 shown, including the following steps:

[0073] Step 1: Take the cyanide-containing tailings slurry discharged from the cyanide gold extraction process, first evaporate and dehydrate it, then put chlorine dioxide into the cyanide-containing tailings slurry and fully stir to remove cyanide, and use slaked lime to adjust the pH of the reaction in real time In order to achieve the best cyanide removal effect, obtain the water-containing tailings and the extracted water. The water-containing tailings has a water mass ratio of 50%, a cyanide concentration of 10ml / L, and the extracted water is treated to remove the effects of gold leaching. The components are reused in the gold leaching process or discharged after removing cyanide and other pollutants in the water;

[0074] Step 2, filling the underground goaf with the water-containing tailings, the steps are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com