A Clearance Evaluation Method for Rock Misaligned Fracture Surfaces

An evaluation method and crack technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of evaluation gap, inability to evaluate crack surface gap, inability to apply a group of crack surfaces, etc., to achieve improved accuracy, feasibility and efficiency. The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0032] A method for evaluating gaps of rock fracture surfaces, the specific steps are as follows:

[0033] (1) Split the formation core to obtain two corresponding fracture surfaces A and B. Two new surfaces are produced when the rock splits or fractures under the action of formation stress. These two surfaces have a certain corresponding relationship, which we call the corresponding fracture surface.

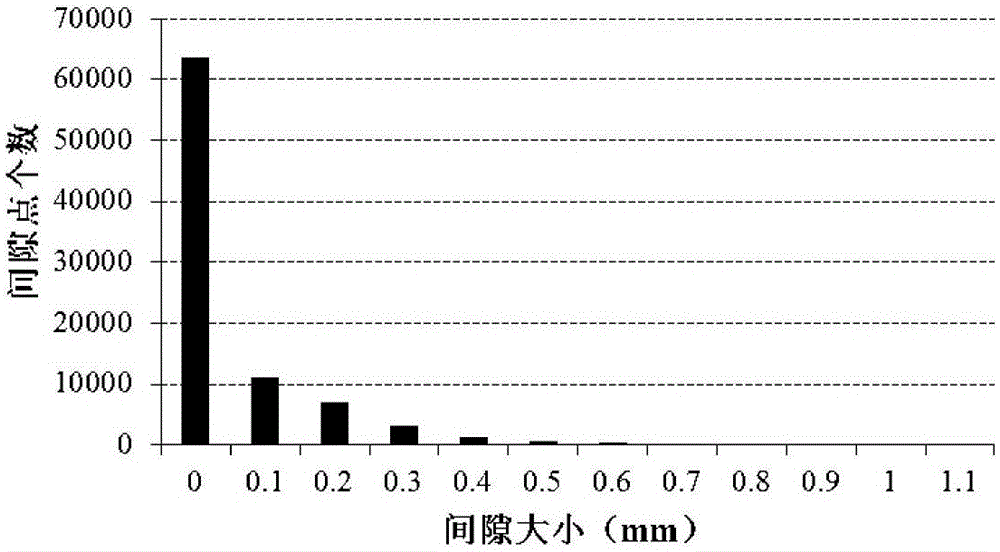

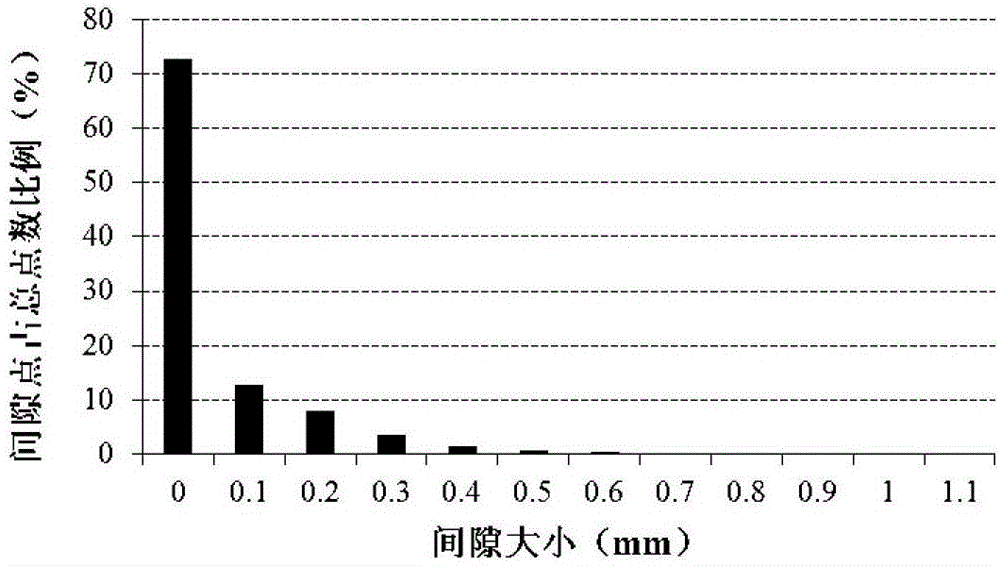

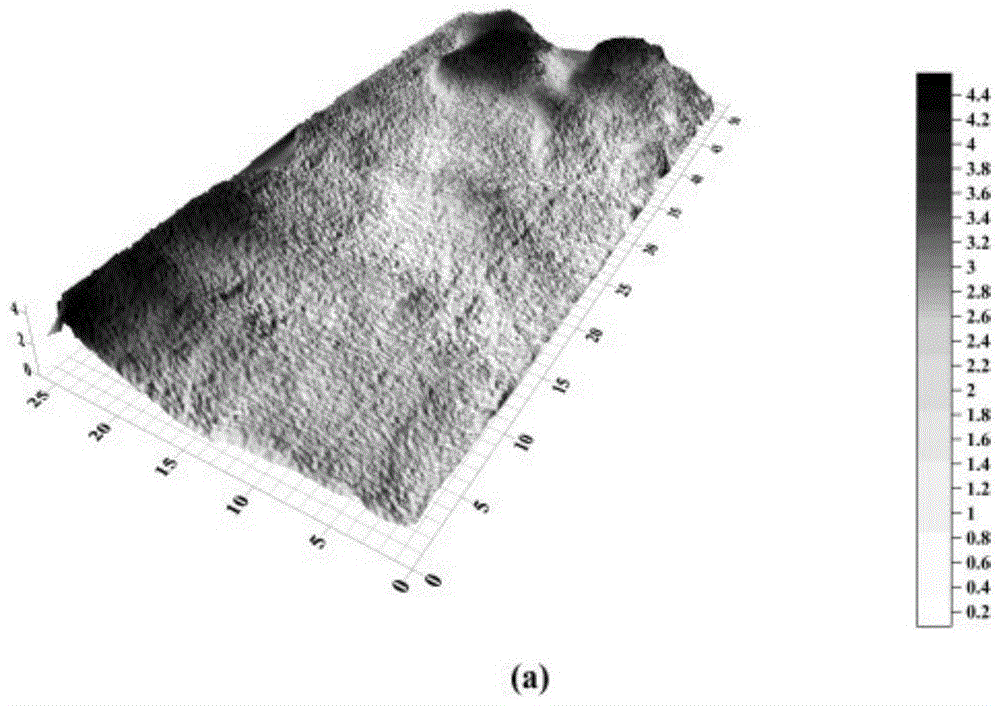

[0034] (2) Use a high-precision 3D laser scanner to scan the corresponding fracture surfaces of the two rock cores to obtain the original 3D geometric data of the fracture surfaces of the two rocks, and the spatial points are represented by (x, y, z). For example, after the core is split, the fracture area is 25mm×30mm=750mm2. If the scanner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com