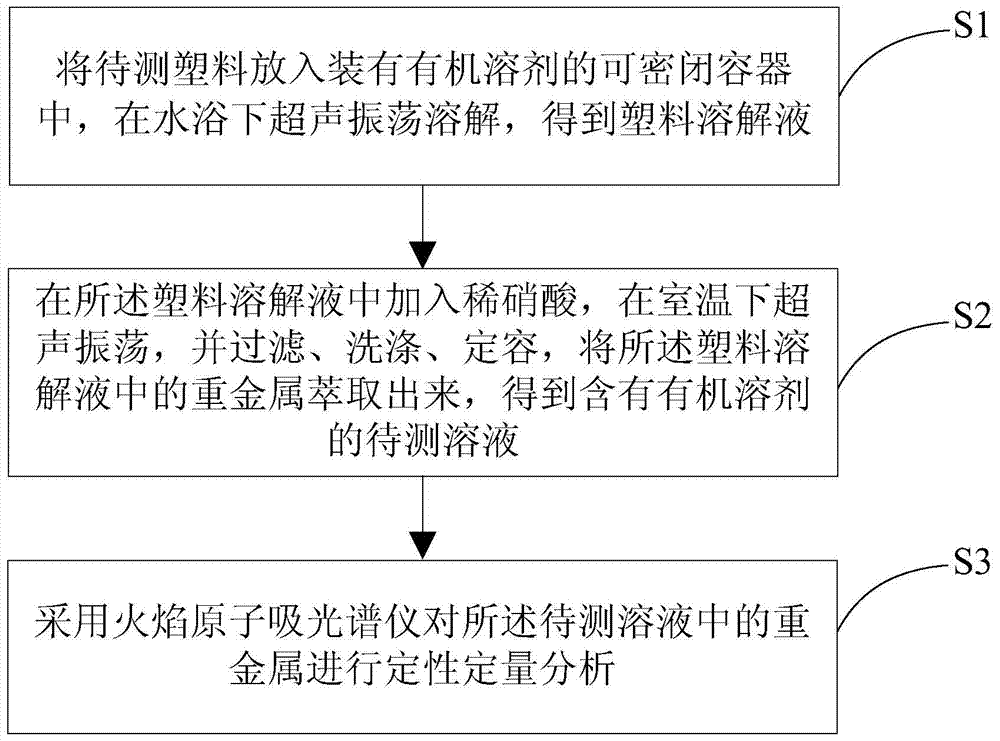

Detection method of heavy metals in plastics

A detection method, heavy metal technology, applied in the field of heavy metal detection, can solve the problems of long digestion time, cross-contamination, non-discovery, etc., achieve good stability, high recovery rate, and ensure the effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Crush 0.1-0.2g of the PVC or PE plastic sample to be tested and put it into a sealable container, add 10mL of tetrahydrofuran, and ultrasonically shake for 60min in a water bath at 80°C to fully dissolve the sample. Then, 10 mL of 20% (V / V) nitric acid was added to the obtained solution, and ultrasonic vibration was performed at room temperature for 30 min. Then the above-mentioned shaken solution was filtered and washed with 20% (V / V) nitric acid, and finally the volume was adjusted to 50 mL to prepare a solution to be tested containing an organic solvent.

Embodiment 2

[0052] Crush 0.1-0.2g of the PVC or PE plastic sample to be tested and put it into a sealable container, add 10mL of tetrahydrofuran, and ultrasonically shake for 45min in a water bath at 85°C to fully dissolve the sample. Then, 10 mL of 15% (V / V) nitric acid was added to the obtained solution, and ultrasonic vibration was performed at room temperature for 30 min. Then the above shaken solution was filtered and washed with 15% (V / V) nitric acid, and finally the volume was adjusted to 50 mL to prepare a solution to be tested containing an organic solvent.

Embodiment 3

[0054] Crush 0.1-0.2g of the PVC or PE plastic sample to be tested and put it into a sealable container, add 10mL of tetrahydrofuran, and ultrasonically shake for 30min in a water bath at 90°C to fully dissolve the sample. Then, 10 mL of 10% (V / V) nitric acid was added to the obtained solution, and ultrasonic vibration was performed at room temperature for 30 min. Then the above-mentioned shaken solution was filtered and washed with 10% (V / V) nitric acid, and finally the volume was adjusted to 50 mL to prepare a solution to be tested containing an organic solvent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com