Electrooptical modulator

A technology of electro-optic modulator and electrode, which is applied in the direction of instruments, optics, nonlinear optics, etc., and can solve problems such as the decrease of extinction ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

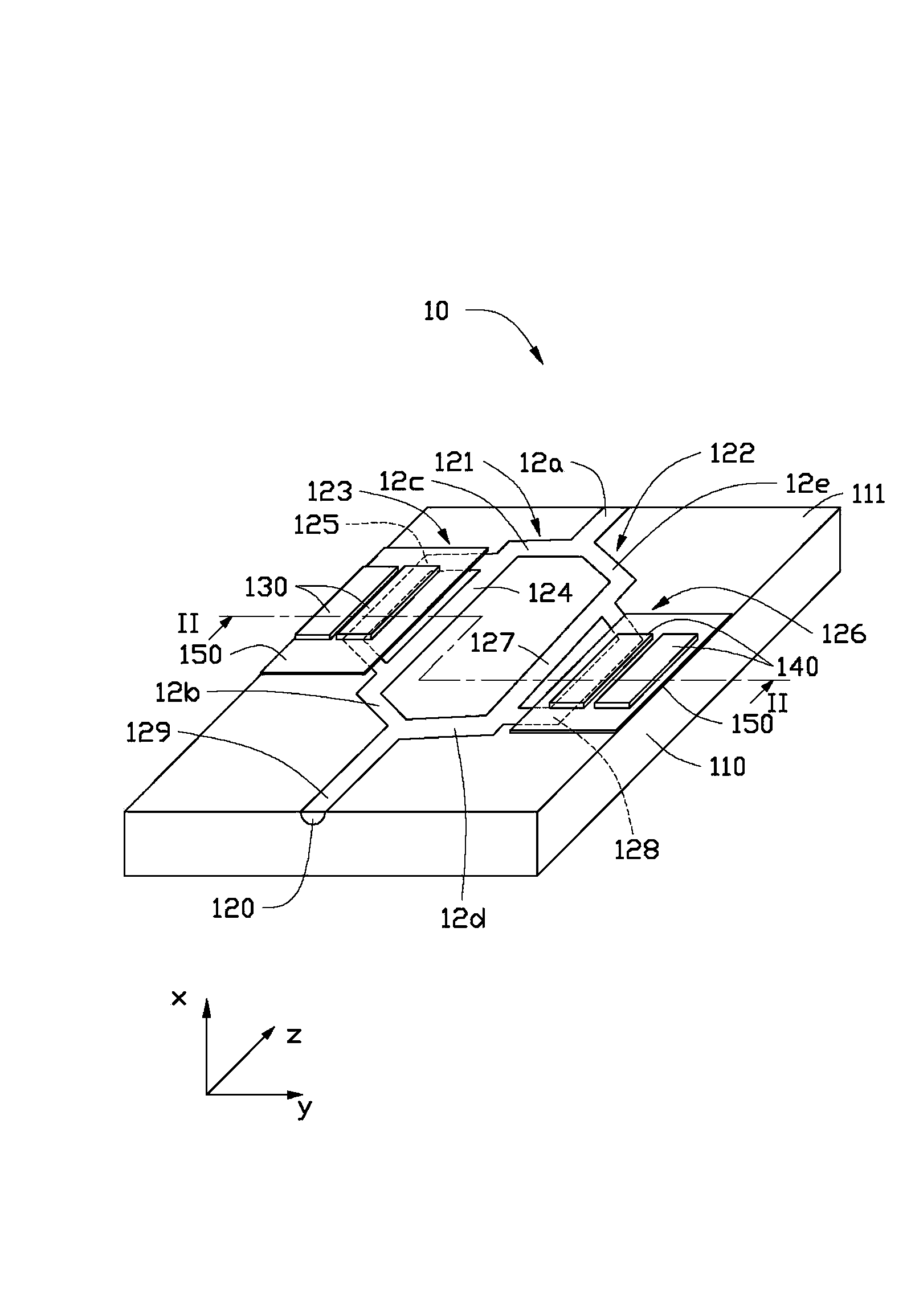

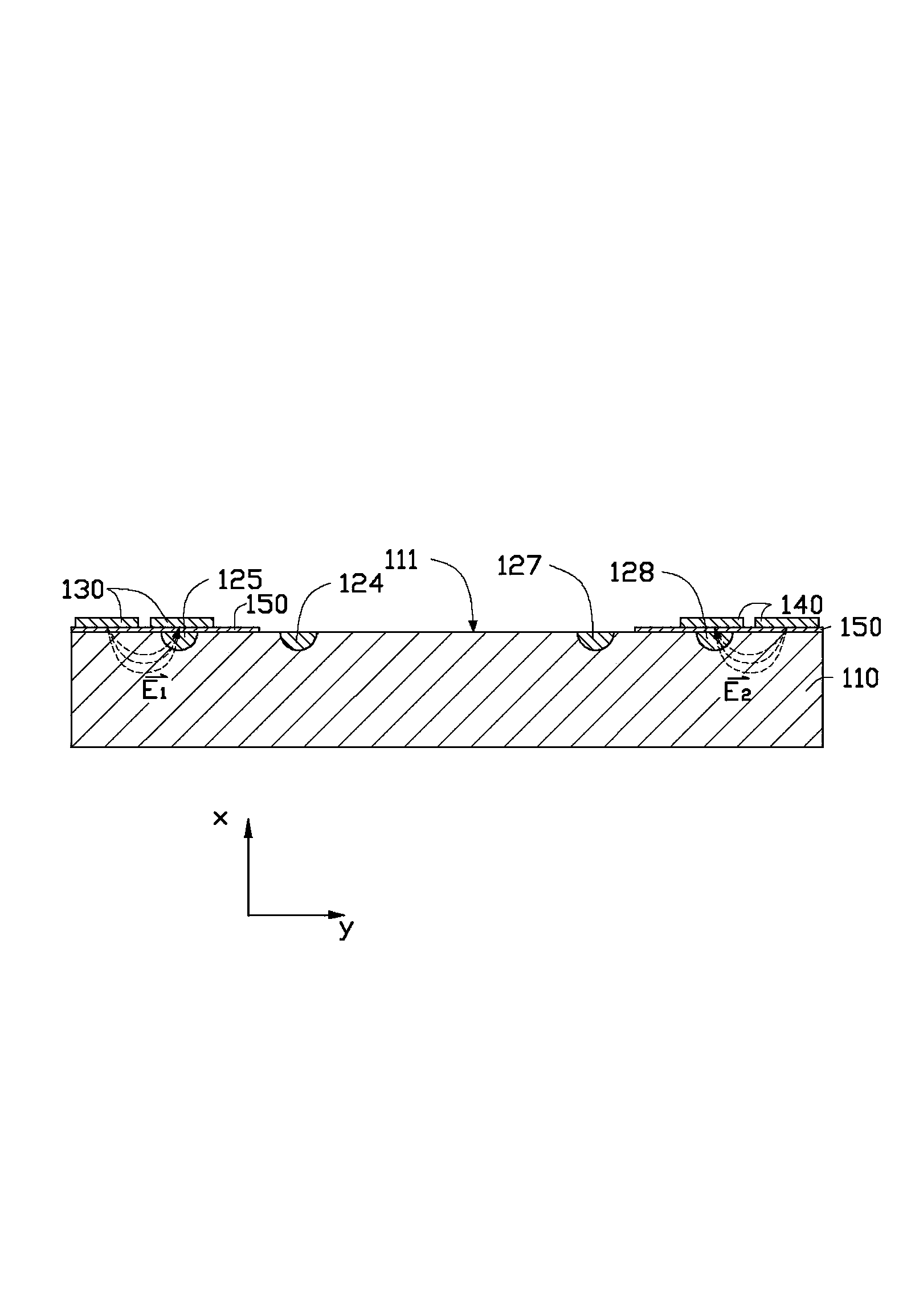

[0016] See figure 1 and figure 2 The electro-optical modulator 10 of the preferred embodiment of the present invention includes a substrate 110, a Y-shaped optical waveguide 120, a first electrode 130, and a second electrode 140. The Y-shaped optical waveguide 120 is formed on the substrate 110 and includes a first branch 121 and a second branch 122. The first branch 121 includes a first sub-Y-type optical waveguide 123, the first sub-Y-type optical waveguide 123 includes a first sub-branch 124 and a second sub-branch 125, and the second branch 122 includes a second sub-branch The Y-shaped optical waveguide 126 includes a third sub-branch 127 and a fourth sub-branch 128. The second sub-branch 125 and the fourth sub-branch 128 are located on both sides of the first sub-branch 124 and the third sub-branch 127 respectively. The pair of first electrodes 130 are disposed on the substrate 110, and respectively cover the second sub-branch 125 and parallel to the second sub-branch 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com