Connector

A technology of connectors and terminals, applied in the field of connectors, can solve the problems of not being able to fully ensure positional accuracy and holding force, and not being able to hold the housing 525, and achieve the effects of precise positioning and holding, and high sealing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

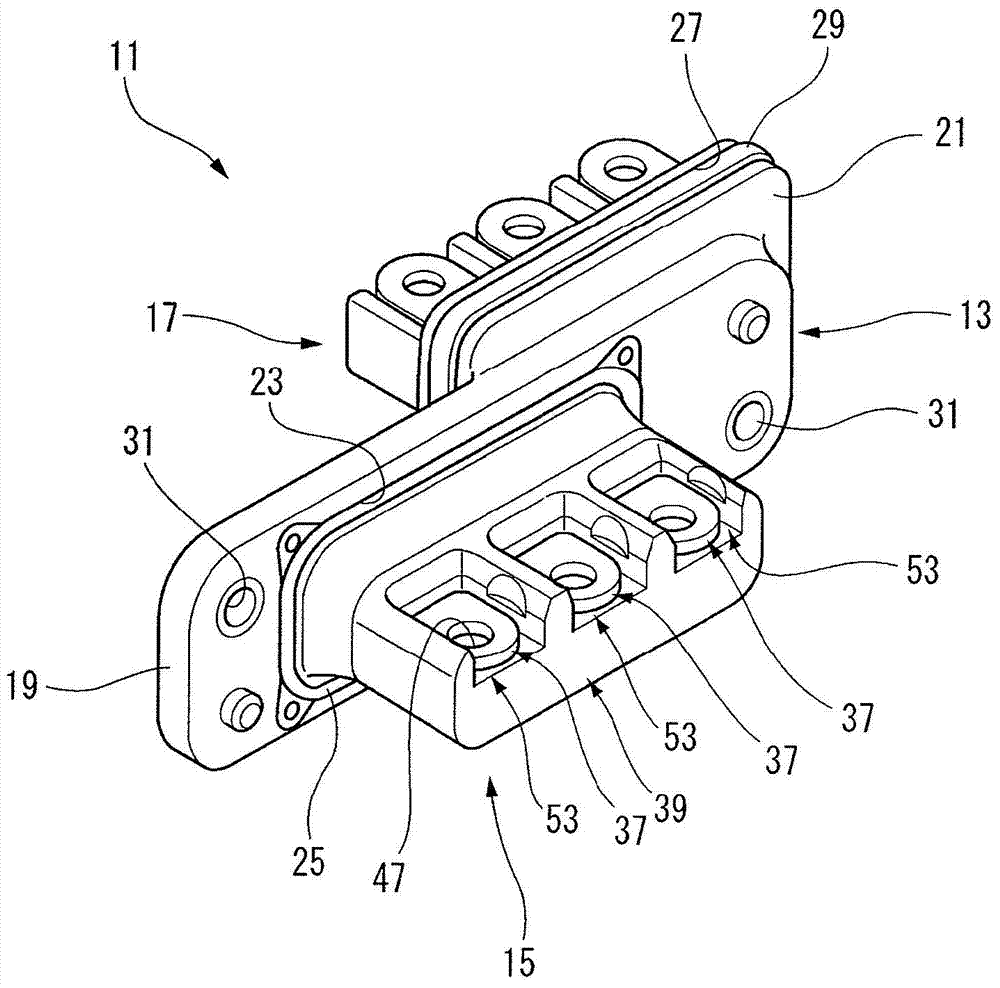

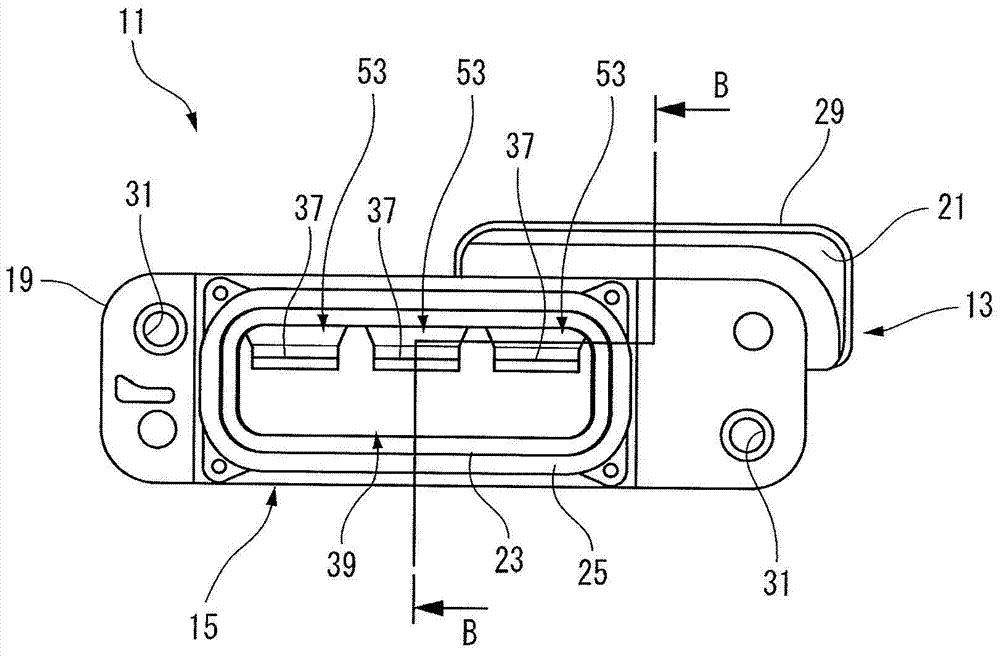

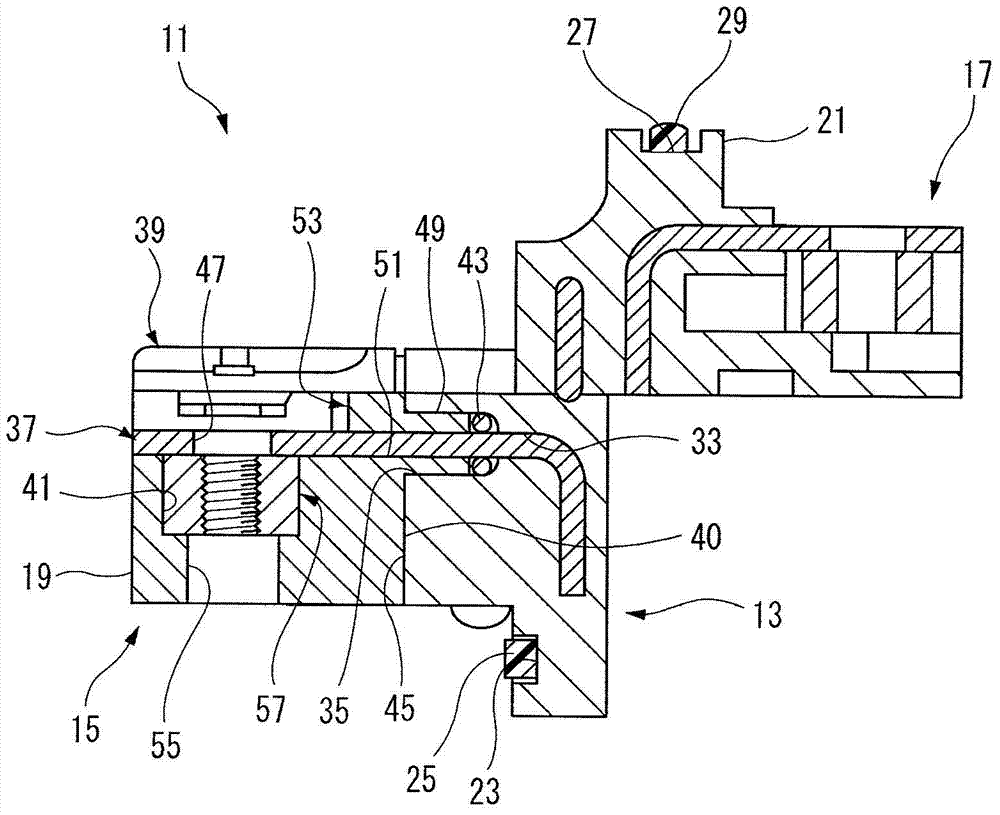

[0035] Embodiments of the present invention are described below with reference to the drawings.

[0036] Such as figure 1 As shown, the connector 11 according to the embodiment of the present invention is mounted to a motor side panel (not shown) and an inverter side panel (not shown).

[0037] The connector 11 includes a housing 13 (also referred to as a terminal block) formed of a synthetic resin having insulating properties. The housing 13 is provided with a motor-side connecting portion 15 on the mounting side mounted to the motor-side panel. The housing 13 is provided with an inverter-side connecting portion 17 on the mounting side mounted to the inverter-side panel.

[0038]Inside the housing 13, a motor-side flange 19 and an inverter-side flange 21 are formed parallel to each other. The motor side flange 19 and the inverter side flange 21 are attached to a motor side mounting hole (not shown) formed in the panel on the motor side and an inverter mounting hole formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com