FTF-based complex product quality loss network analysis method

A technology of network analysis and complex products, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of unscientists on the network research of fault quality loss and failure to quantitatively analyze fault loss, etc., and achieve great guiding significance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

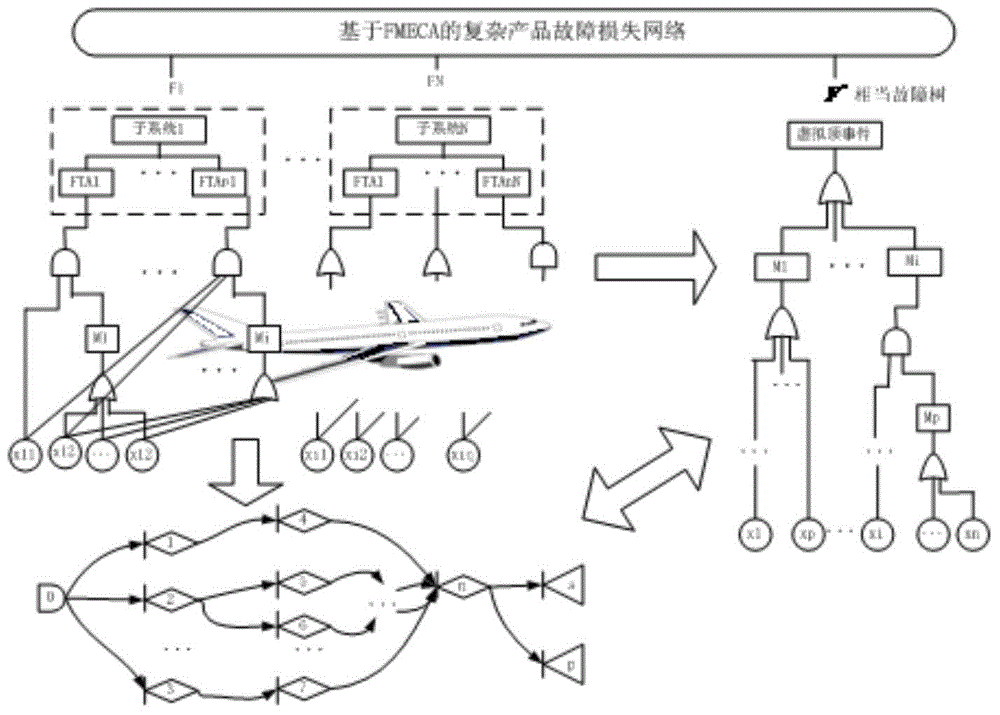

[0018] figure 1 Shown, relate to a kind of complex product quality loss network analysis method based on FTF of the present invention, comprise the steps:

[0019] 1) With the help of the forward FMECA-FTA method, using the severity level in the product FMECA results, select one or several failure modes corresponding to the severity level as the top event of the fault tree, and establish the fault tree distribution diagram of the system , and then use the bottom event failure rate data and failure loss data obtained from the hazard analysis results in FEMCA to conduct qualitative and quantitative analysis;

[0020] 2), using the fault tree distribution diagram established above, analyze different network structures;

[0021] 3) Using the principle of minimum cut set, draw a corresponding fault tree containing virtual top events, and calculate the loss based on the perspective of fault mode;

[0022] 4) Construct the conversion rules between FTA and GERT, and convert the mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com