Assembly structure of insulator and external flange

A technology for assembling structures and insulators, which is applied in switchgear, switchgear setting, electrical components, etc., can solve the problems of difficult assembly, and achieve the effects of simple assembly operation, increased reliability, and simple assembly structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

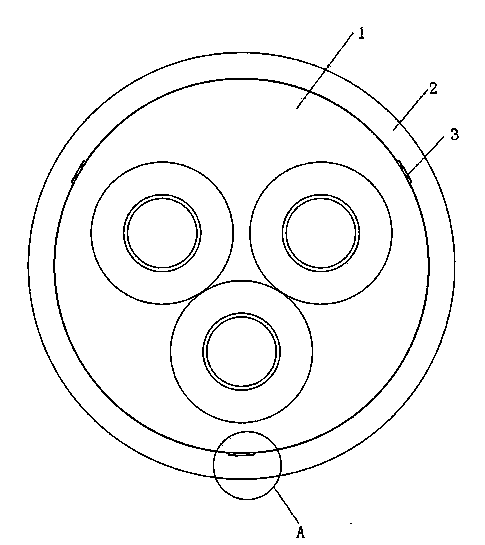

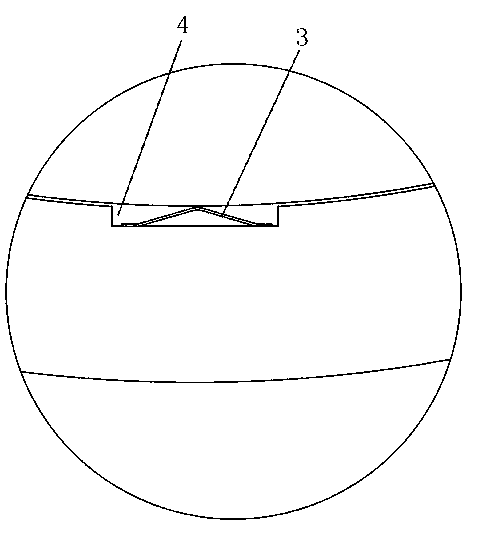

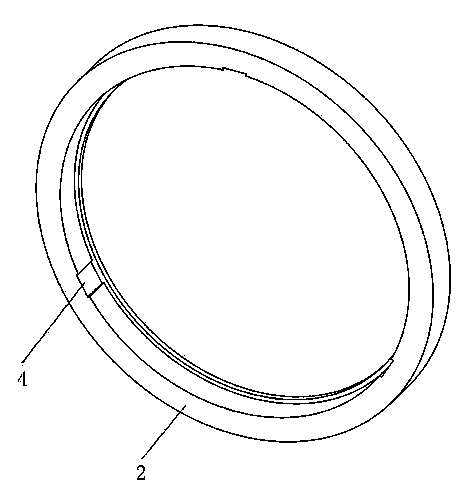

[0011] Embodiment 1 of the assembly structure of the insulator and the outer flange of the present invention, such as Figure 1-4 Shown: The assembly structure of the insulator and the outer flange, including a concentric disc-shaped insulator 1 and a circular outer flange 2, the outer flange 2 is set on the periphery of the insulator 1, and the inner periphery of the outer flange 2 There is a gap between the outer surface of the outer flange 2 and the outer peripheral surface of the insulator 1, and there are four flanges evenly distributed along the circumferential direction between the inner peripheral surface of the outer flange 2 and the outer peripheral surface of the insulator 1, which are used to provide radial The pressing force is to make the insulator 1 tightly fix the leaf spring 3 located in the center of the outer flange 2. The leaf spring 3 is a bow-shaped structure. The leaf spring 3 has a convex part and two supporting parts that are respectively matched with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com