System of vibration-damping control for crane and method of vibration-damping control for crane

A vibration suppression and control system technology, which is applied to cranes, trolley cranes, transportation and packaging, etc., can solve the problems of insufficient and difficult to cope with large earthquakes, and achieve the effect of easy vibration suppression transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

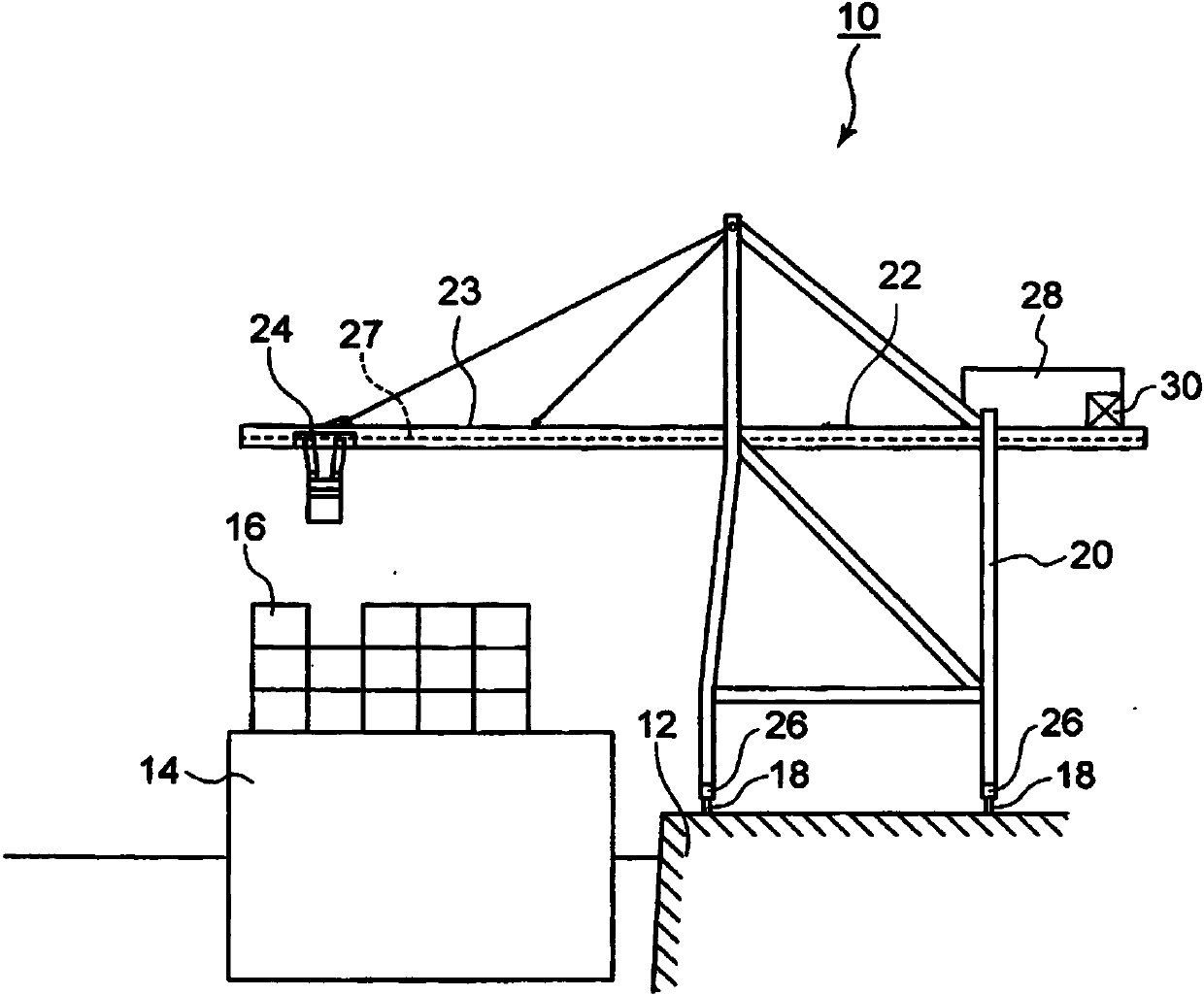

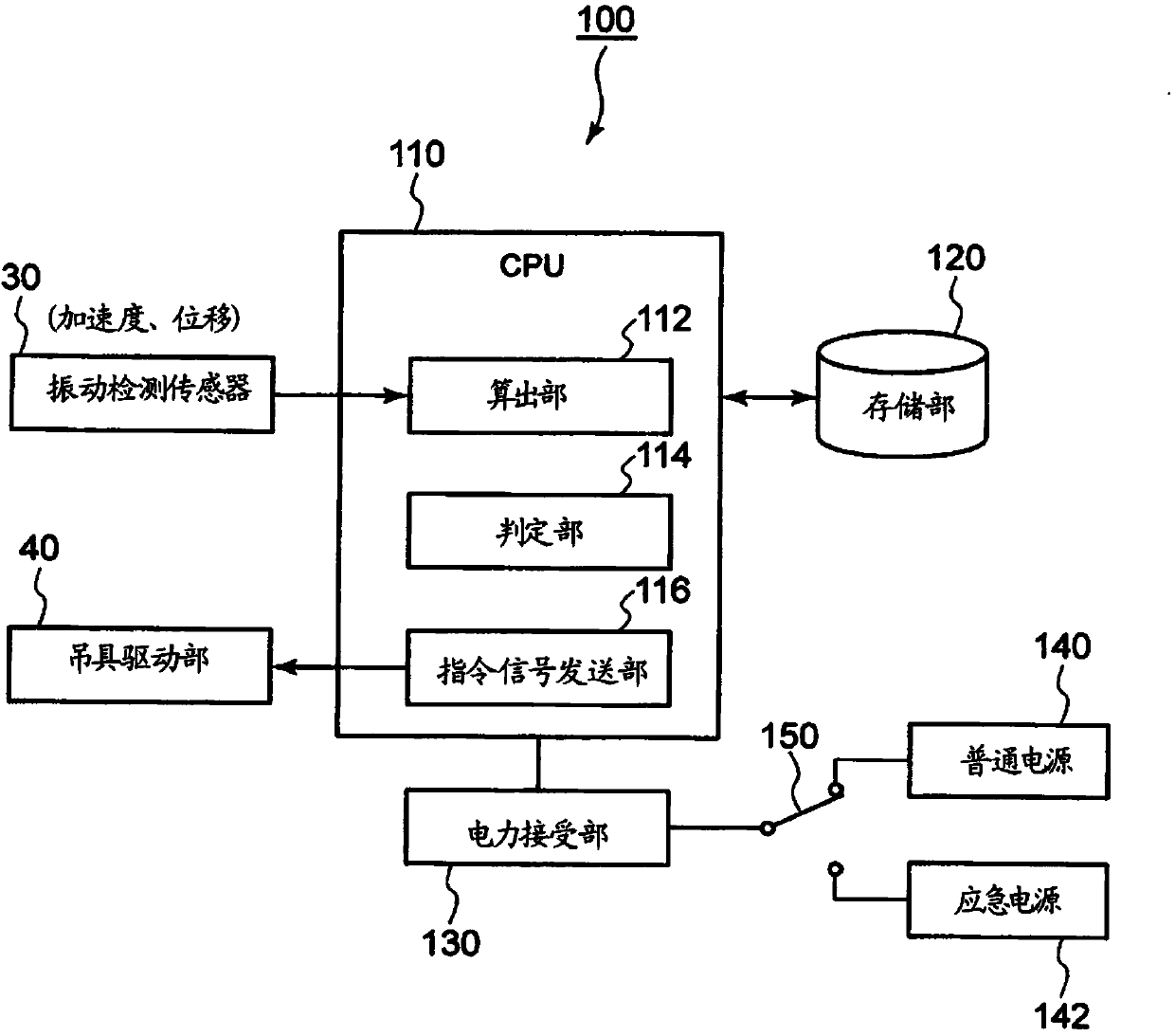

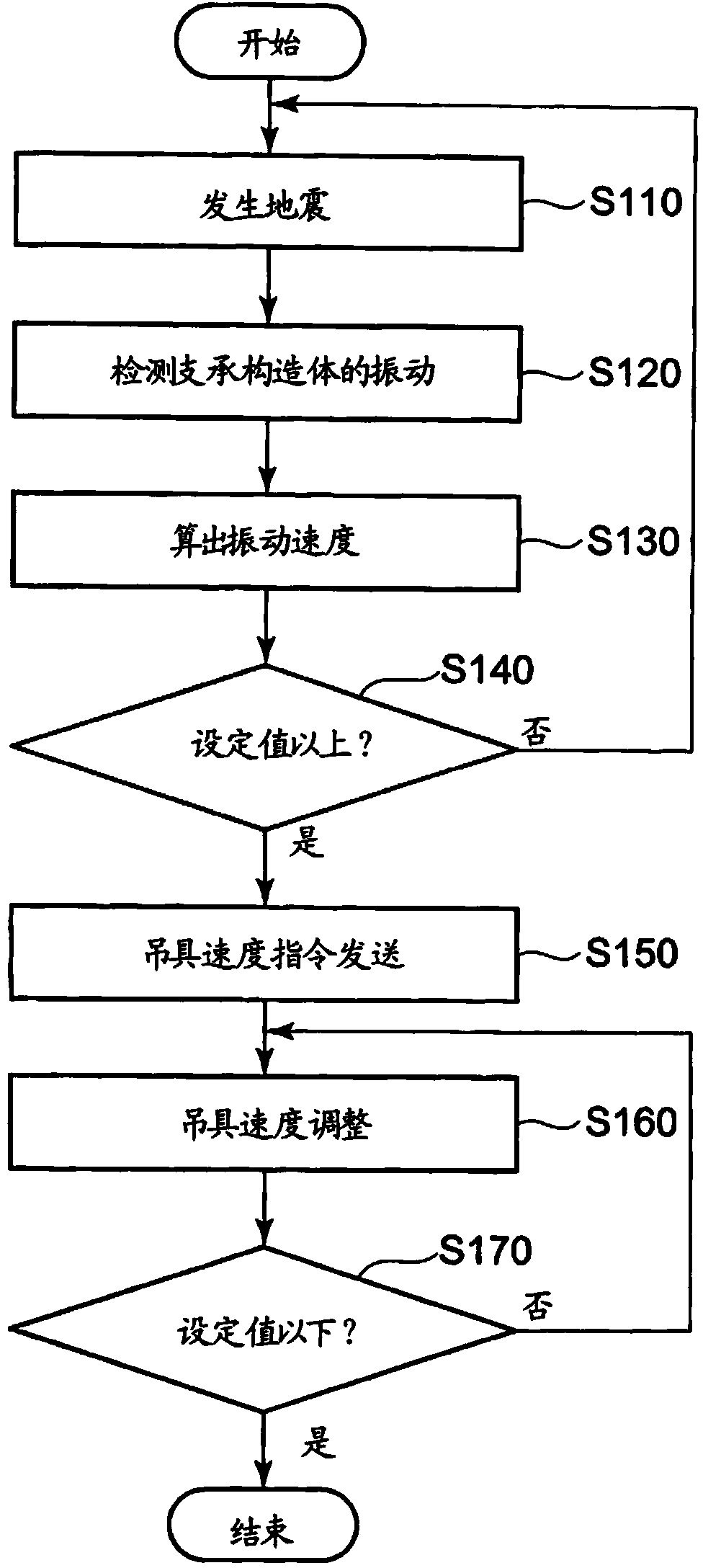

[0029] First, the crane structure of the first embodiment of the vibration suppression control system applied to the crane of the present invention will be described with reference to the drawings. figure 1 It is a front view showing the outline of the structure of a crane to which the first embodiment of the vibration suppression control system for a crane according to the present invention is applied.

[0030] The container crane 10 is to unload the container 16 carried on the container ship 14 approaching the port 12 on the land, and load the container 16 on the land to the container ship 14, and travels along the port 12 and between the land and the hatch of the container ship 14. Cranes that move back and forth. The container crane 10 has: a support structure 20 movably installed on the walking rail 18 laid along the port 12; a girder 22 provided on the top side of the support structure 20; A boom 23 extending in a substantially horizontal direction; a hanger 24 that mov...

no. 2 approach

[0056] Next, the structure of the crane in the second embodiment of the vibration suppression control system applied to the crane of the present invention will be described with reference to the drawings. Figure 4 It is a front view showing an outline of a crane structure to which a second embodiment of the vibration suppression control system for a crane according to the present invention is applied.

[0057] Such as Figure 4As shown, the container crane 50 of the present embodiment is a crane in which a shock absorber 70 such as a damper is attached to a running part or the like provided on the bottom side of the support structure 60 of the container crane 50 . That is, the crane vibration suppression control system of this embodiment is applied to a container crane equipped with a shock absorber, and performs vibration suppression control on the support structure 60 when vibrating based on the operation start signal of the shock absorber 70 . Furthermore, similarly to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com