Electrorheological fluid damper with magnetic rotation and axial movement

An electro-variable and magnetic rotation technology, applied in non-rotational vibration suppression, vibration suppression adjustment and other directions, can solve the problems of fluid leakage in the fluid damper and the use restriction of the fluid damper, and achieves vibration suppression and large magnetic force. , the effect of large damping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

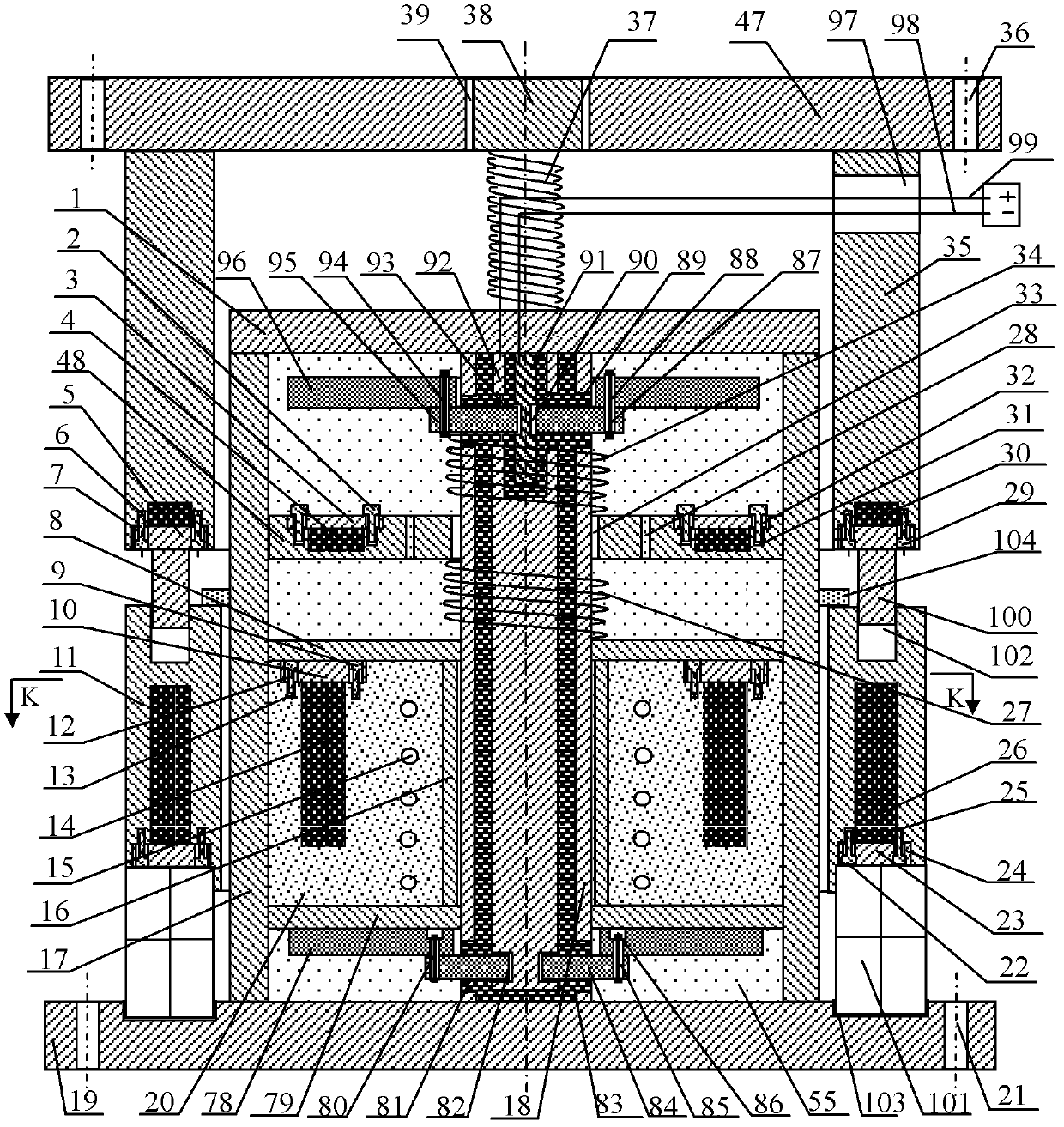

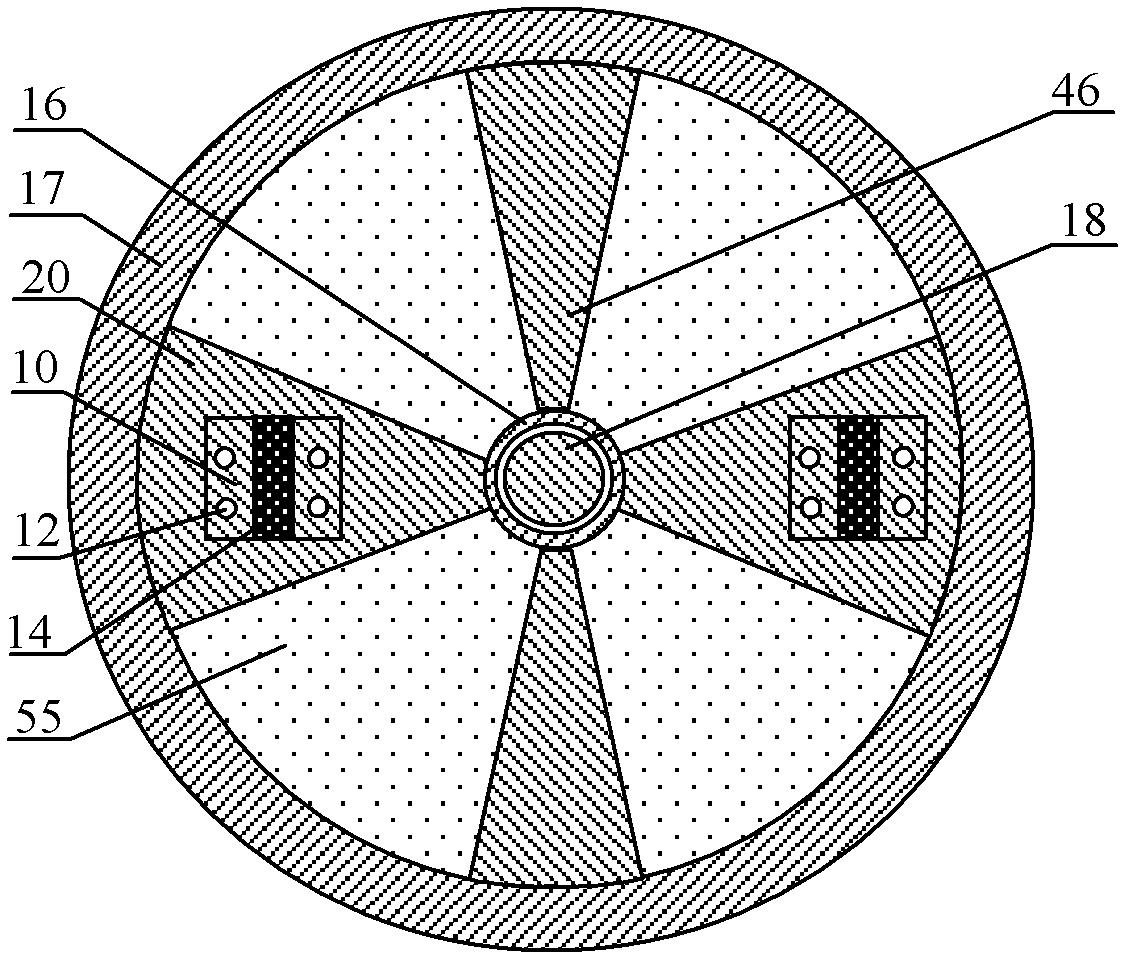

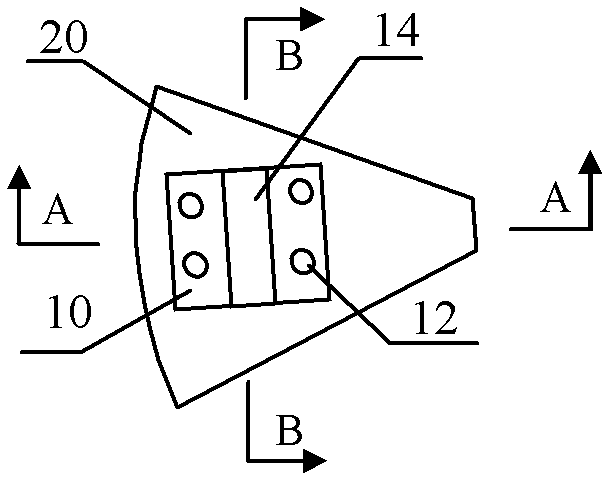

[0046] The present invention will be further described below in conjunction with the accompanying drawings.

[0047] The present invention proposes a magnetic force rotation and axial motion electrovariant damper, which uses magnetic force to push the blades in the damper to rotate and the piston shaft to move. When the blades rotate (piston shafts), the damping fluid flows through the blades (pistons). Small round through hole (damping hole), energy is consumed when the damping fluid flows through the small round hole (damping hole) on the vane (piston), which has the effect of controlling vibration.

[0048] The following descriptions of embodiments of the invention are merely exemplary in nature, and are in no way intended to limit the application or uses of the invention.

[0049] The characteristic of the magnetic rotation and axial dynamic EPR damper is that the second circular spring 34 and the first circular spring 27 are removed simultaneously, and an effective magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com