A crane assembly

A crane and assembly technology, applied in the field of crane assembly, can solve the problems of relying on manual work, vibration at the top of the crane, deviation between the placement position and the target position, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the drawings and implementations.

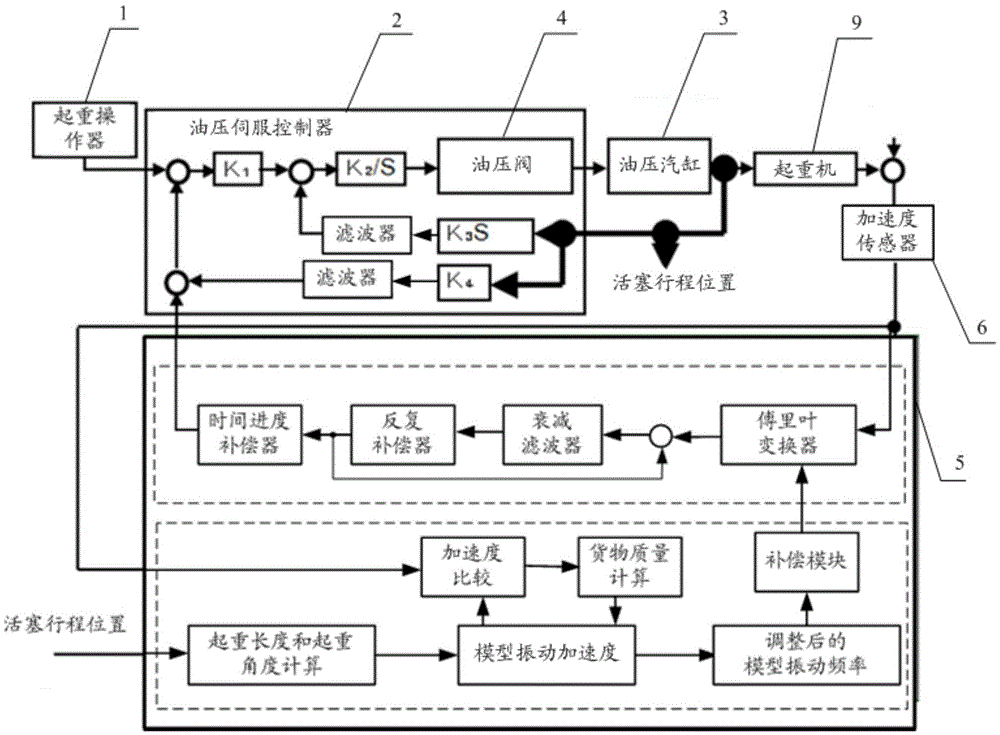

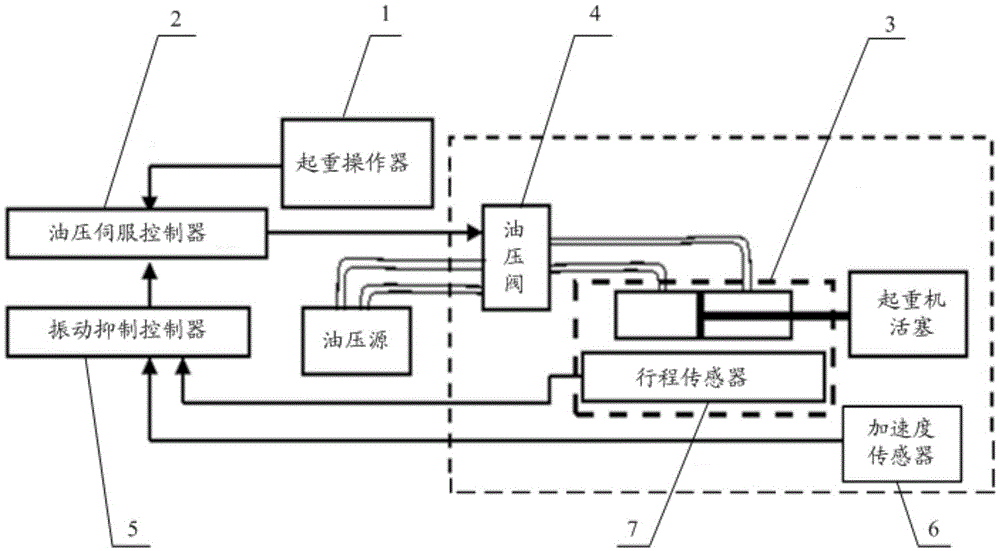

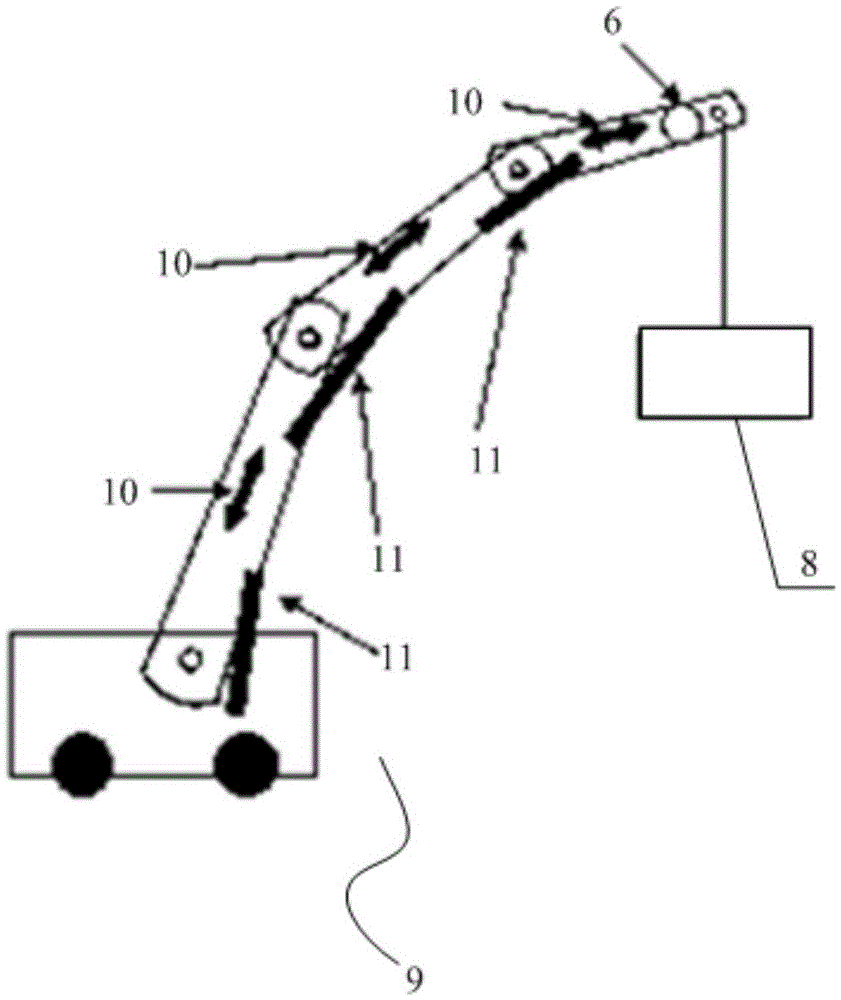

[0033] Such as figure 1 with figure 2 As shown, a crane assembly may include: a lifting operator 1, an oil pressure servo controller 2 and a plurality of oil pressure cylinders 3 arranged on the body of the crane 9, and oil pressure cylinders 3 are provided with oil pressure valves 4 , can also include: a vibration suppression controller 5 and an acceleration sensor 6; wherein, the acceleration sensor 6 can collect the actual acceleration during the lifting process of the crane 9; the vibration suppression controller 5 can generate vibration suppression that can offset the actual acceleration according to the actual acceleration signal, so that the hydraulic servo controller 2 controls the hydraulic valve 4 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com