Rotary piston

A rotary piston, rotary piston pump technology, applied in rotary piston pumps, rotary piston machines, pistons, etc., can solve the problems of wear and tear of elastomer material strips, failure of rotary piston pumps, etc., and achieve the effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

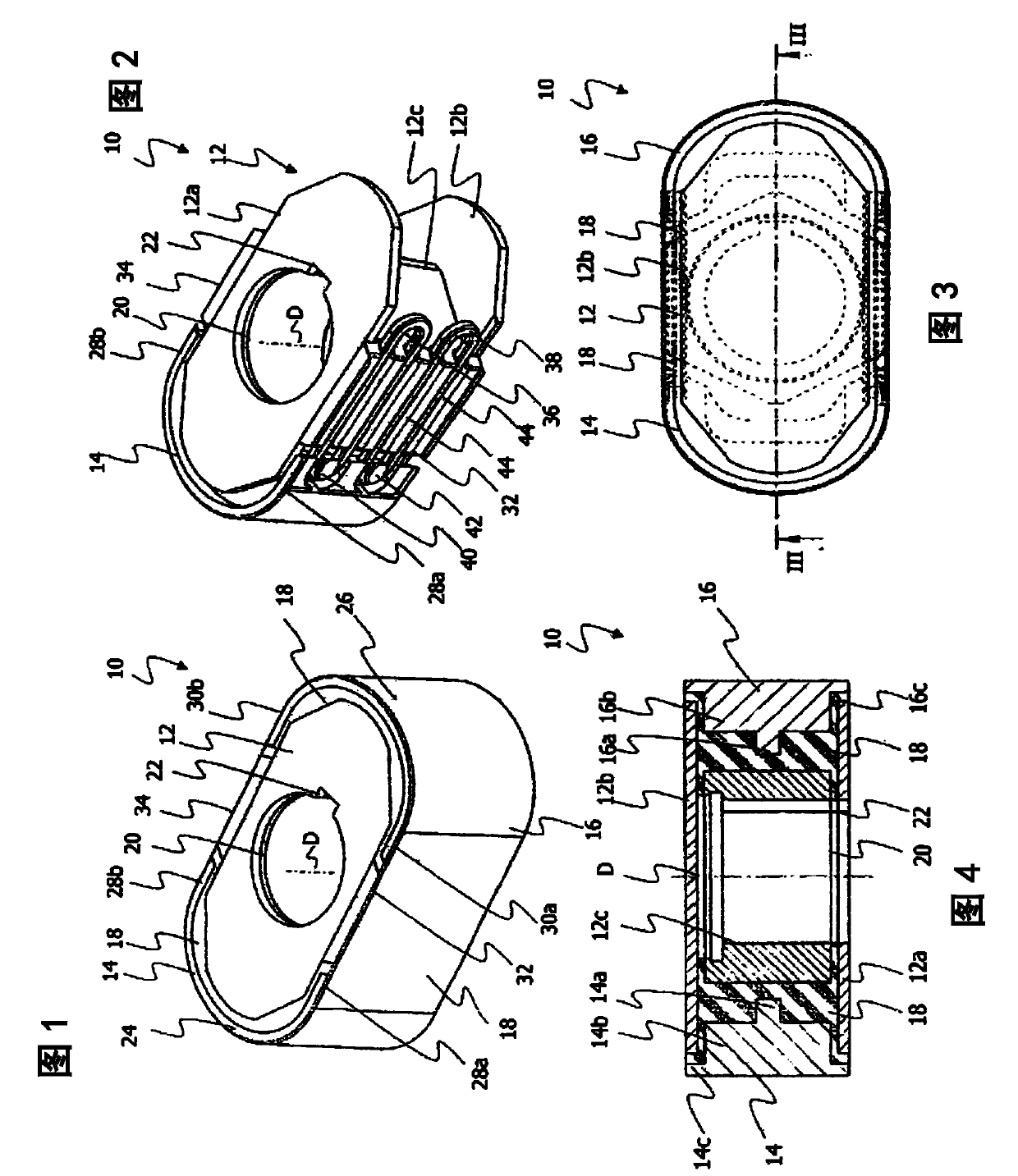

[0039] figure 1 A perspective view of a rotary piston 10 according to a first embodiment of the invention is shown. Such a rotary piston 10 can be used, for example, in a rotary piston pump as described in document DE 10 2010 014 248 A1.

[0040] The rotary piston 10 comprises a support body 12 and an end cover part 14 and 16 each radially outside the support body. The support body 12 is connected to the end caps 14 , 16 by an elastomeric cushioning layer 18 . Elastomeric cushioning layer 18 such as figure 1 As shown, it is formed around the support body 12 .

[0041] The support body 12 also comprises an opening 20 forming the hub of the rotary piston 10, which opening accommodates a shaft (not shown) for driving the rotary piston 10 when the rotary piston 10 is in the installed state in the rotary piston pump. In order to enable the connection to the shaft (not shown) of the rotary lobe pump, the opening or hub 20 comprises a recess 22 in which a driver part or a matin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com