Flue gas dust-removing method and device

A dust removal device and flue gas technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as environmental and personnel injuries, and achieve obvious effects, good practicability and economy, and simple principles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail in conjunction with the accompanying drawings, but not as any limitation to the present invention.

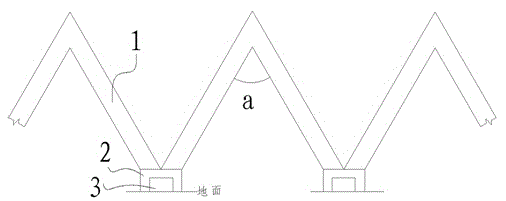

[0016] Embodiment of the present invention: a flue gas dedusting method, the method is to use flue gas and solid dust under the same thrust to continuously change the movement direction of flue gas and fixed dust to cause different energy losses per unit weight of flue gas and fixed dust , and in the process of repeatedly changing the gravitational potential energy, when the initial kinetic energy lost per unit weight of the flue gas and fixed dust cannot overcome the gravitational potential energy, they will be deposited at the bottom of the exhaust pipe to separate the flue gas from the dust, thereby realizing the Air dust removal purpose.

[0017] Specifically, the exhaust tube is a bent structure and placed vertically. The angle of the exhaust tube at the bend is 30° to 60°. The flue gas and solid dust are dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com