Method and device for stirring ink for printed circuit board

A technology of printed circuit boards and stirring methods, which is applied in chemical instruments and methods, transportation and packaging, mixers with rotating containers, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

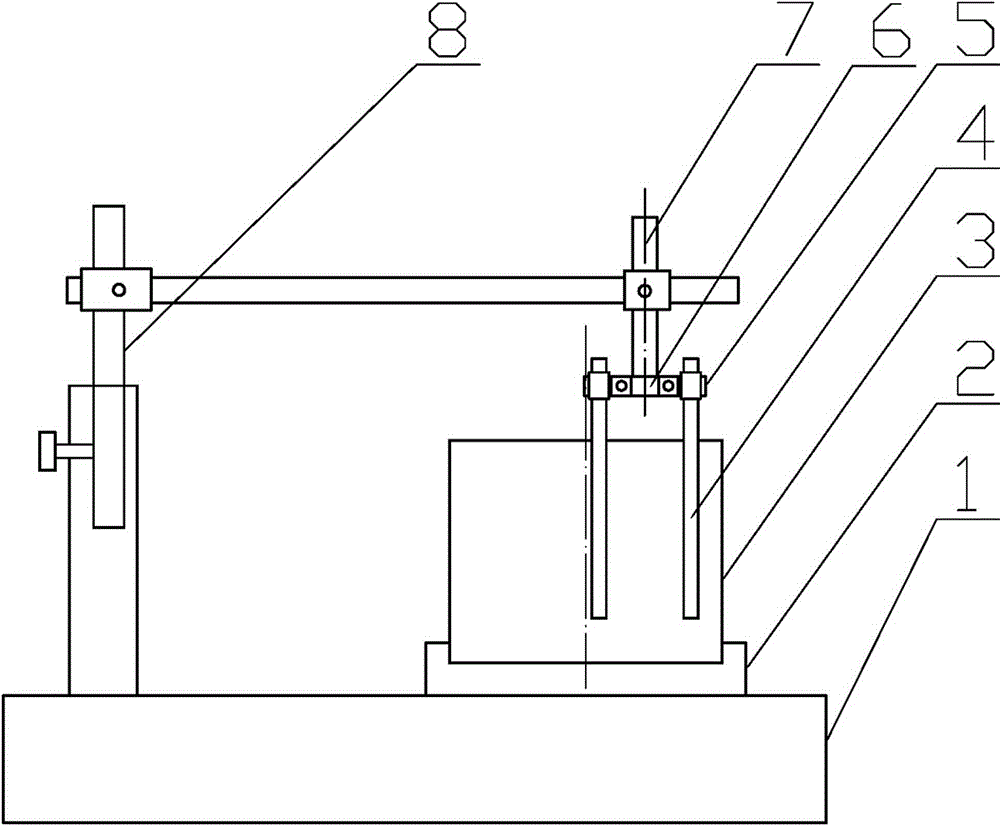

[0020] The present invention will be further described below with reference to the drawings and embodiments.

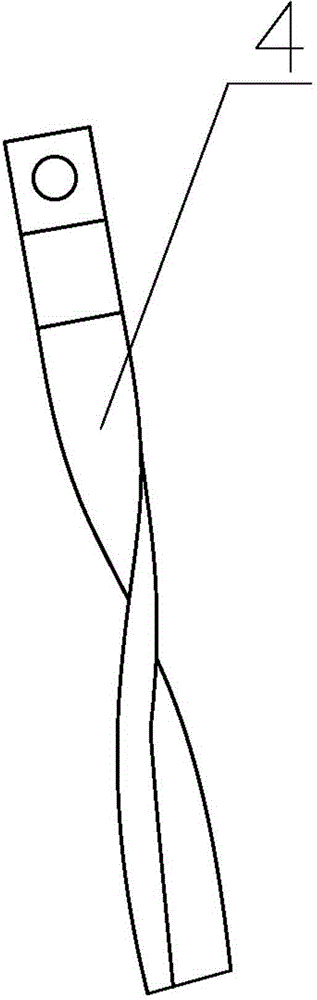

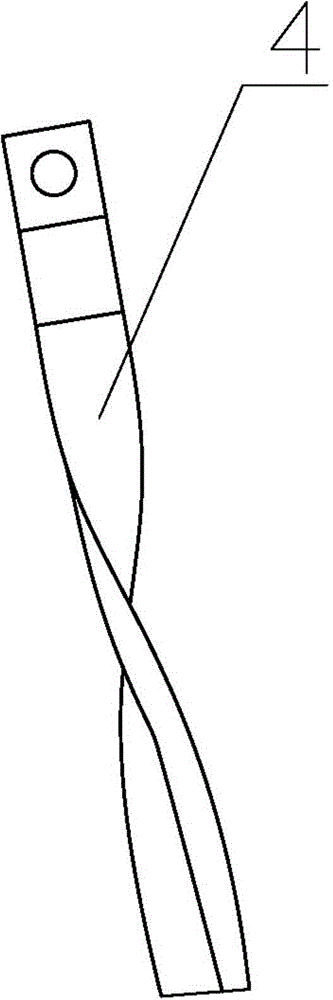

[0021] A method for stirring ink for printed circuit boards, which comprises a rotating ink bucket, a stirring blade installed on a fixed stirring shaft extends into the ink tank, and two stirring leaves are arranged on the stirring shaft. When rotating, the paddles and the ink produce relative movement, and the paddles rotate around the paddle shaft due to the resistance in the relative movement of the paddles.

[0022] In order to increase the relative speed of the stirring blade and the ink, and to make the ink at the inner edge and the center of the ink tank be stirred, the center of the stirring shaft of the present invention is not at the same position as the center of the ink tank, and the distance between the two is less than Equal to 1 / 2 the radius of the ink bucket.

[0023] In order to improve the stirring effect, two stirring blades are symmetrically arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com