Laser cutting head for strip steel

A technology of laser cutting head and cutting head, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of reducing cutting speed and cutting quality, and small laser cutting kerf, so as to improve feasibility and processing accuracy , prolong life and ensure cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

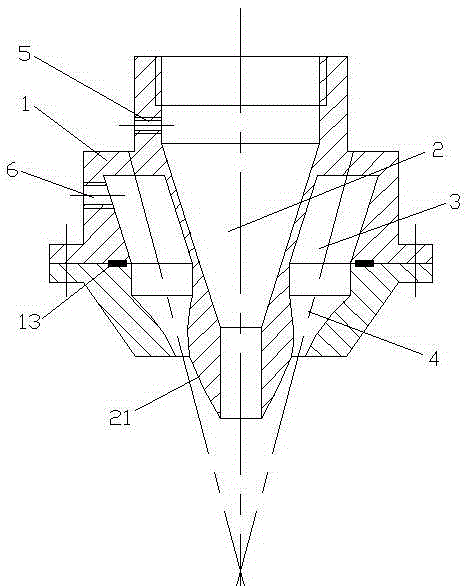

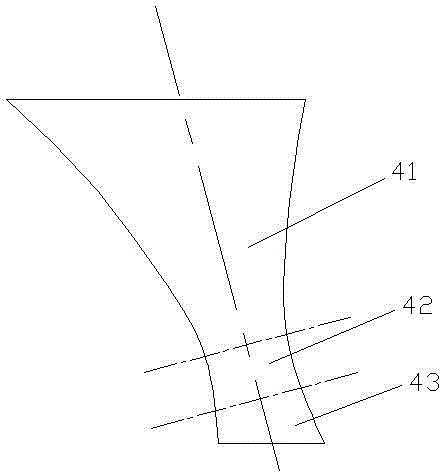

[0026] Such as figure 1 , 2 As shown, a laser cutting head for strip steel includes a cutting head body 1, the axis of the cutting head body 1 is provided with a laser passage 2, and a ring-shaped laser passage 2 is provided in the cutting head body 1. The air injection chamber 3, the purpose of the air injection chamber 3 is to assist the air flow to maintain a uniform pressure before entering the air injection structure 4, so in order to better achieve this purpose, the volume of the air injection chamber 3 is larger than the air injection structure 4 in the present invention The volume of the cutting head body 1 is provided with a pressure maintaining air inlet 5 and an injection air inlet 6, the pressure maintaining air inlet 5 communicates with the laser passage 2, and the injection air inlet 6 is connected with the air injection chamber 3 connected, the airflow entering the pressure-holding air inlet 5 provides a certain positive pressure for the laser passage 2, which ...

Embodiment 2

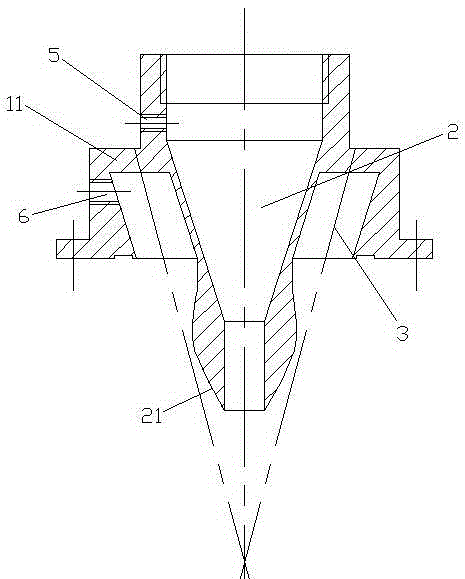

[0031] Such as Figure 5 , 6 , 7, and 8, a laser cutting head for strip steel, the difference between embodiment 2 and embodiment 1 is that the cutting head body 1 is composed of two parts, an upper structure 11 and a lower structure 12, and the The laser passage 2 and the upper structure 11 are integrated, the lower structure 12 is set outside the laser passage 2, the lower structure 12 is sealed and fixedly connected to the lower end surface of the upper structure 11, and a sealing seal is arranged between the upper structure 11 and the lower structure 12. circle 13, the air injection structure 4 is composed of a number of air injection holes provided on the lower structure 12, and the number of air injection holes is an annular array centered on the axis of the laser passage 2. In this embodiment, there are four air injection holes. indivual.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com