Improved structure of locking mechanism between vertical tube and adjusting tube for fitness equipment

A technology of locking mechanism and fitness equipment, applied in the connection of rods, connecting components, gymnastics equipment, etc., can solve the problems of loose riser, thread wear of bolts, safety accidents, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

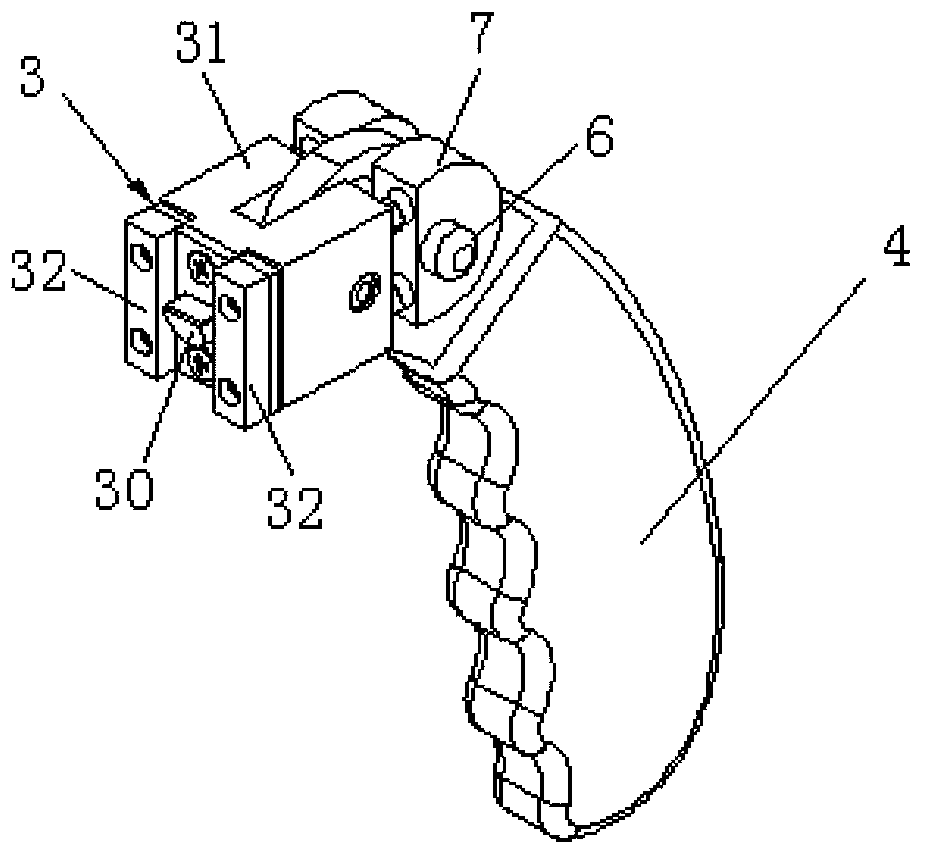

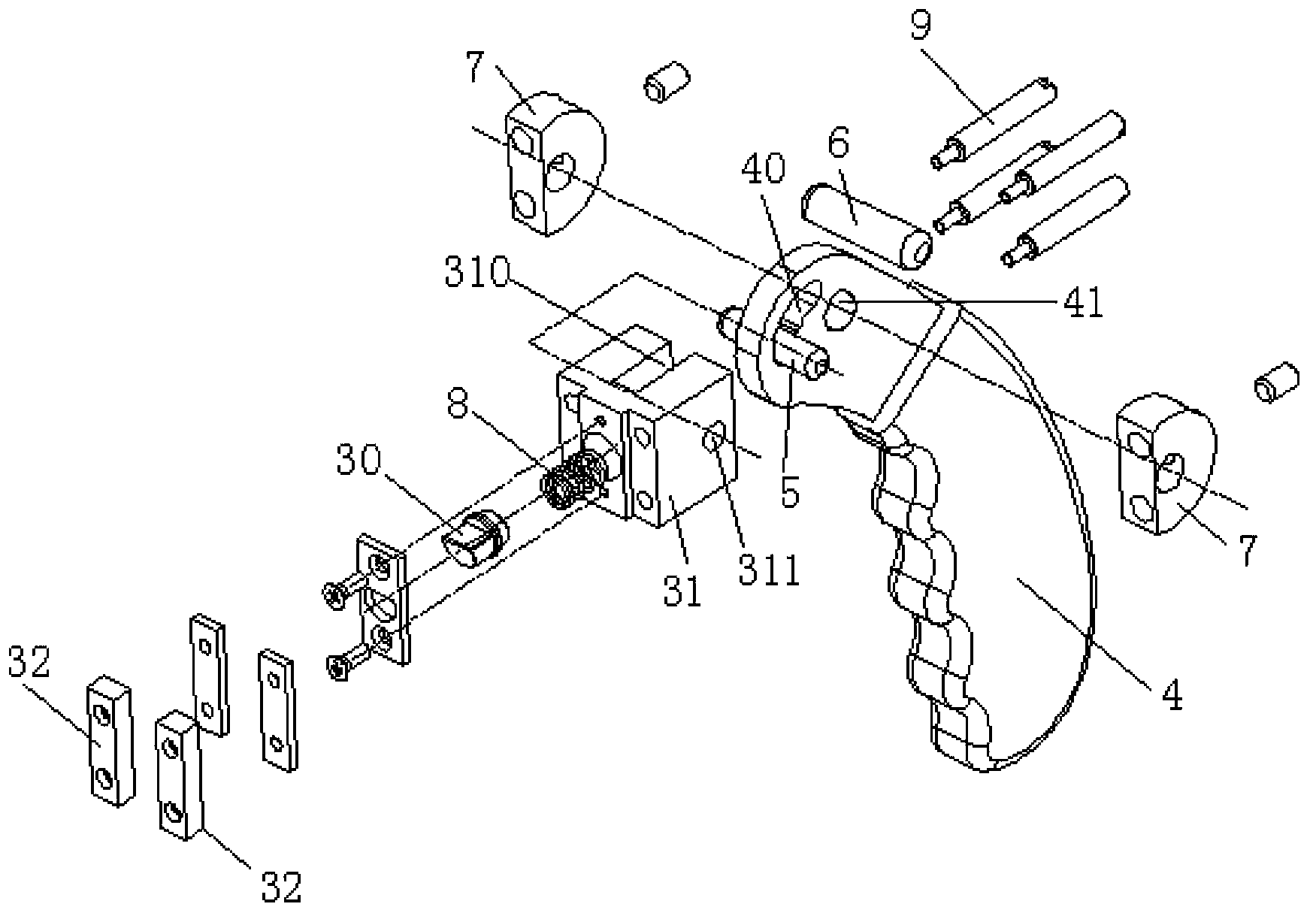

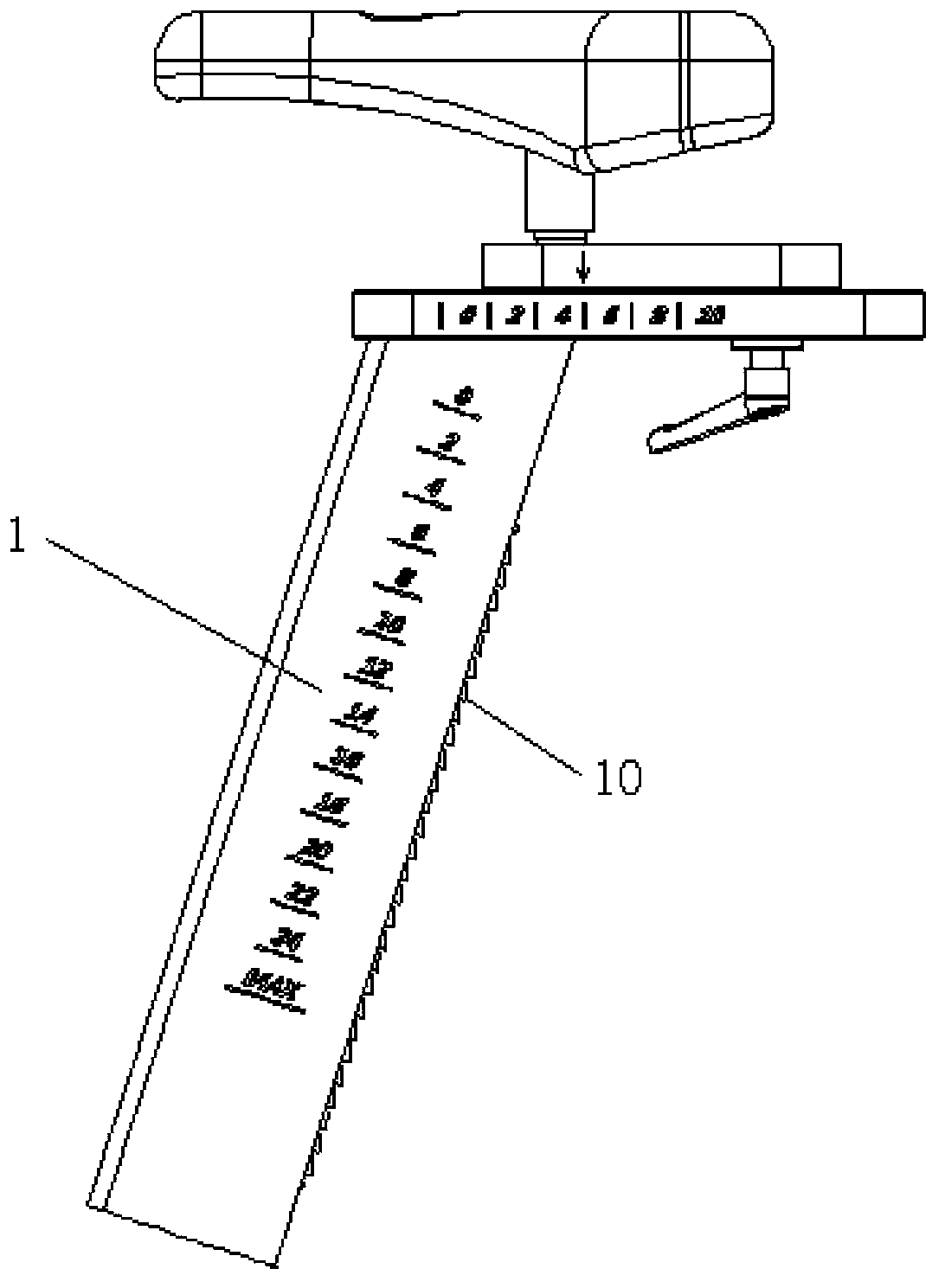

[0028] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] The improved structure of the locking mechanism between the standpipe and the adjustment pipe for fitness equipment provided by the present invention, the standpipe 1 is freely inserted in the adjustment pipe 2, and the position of the standpipe 1 relative to the adjustment pipe 2 is fixed by the locking mechanism , the locking mechanism includes a sliding block 3, the adjustment tube is provided with a sliding tube for the sliding block 3 to move freely, and the sliding block 3 can move freely in the sliding tube along the axial direction of the sliding tube In addition, the sliding pipe opens to the standpipe 1, and the sliding block 3 can just break away from and press against the standpipe 1; the sliding block 3 includes a lock tongue 30 and a pressing block 31, and the lock tongue 30 is elastically stretchable and positioned On the side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com