Magnetic pole group automatic matching unit and assembly line

A magnetic pole and grouping technology, which is applied in the direction of magnets, electrical components, magnetic objects, etc., can solve the problems of small size, difficult manual assembly, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

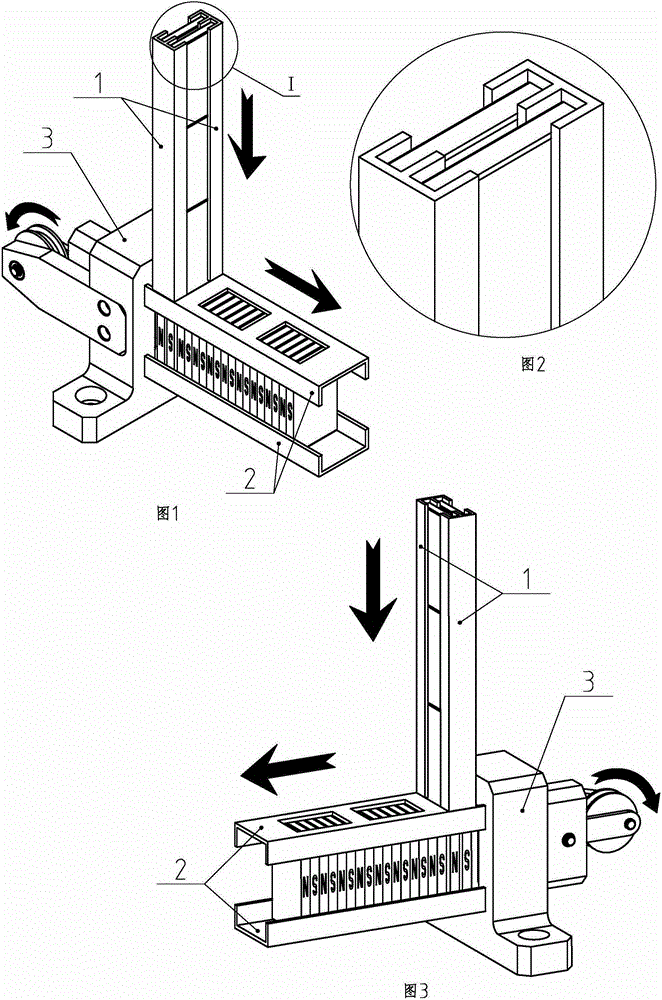

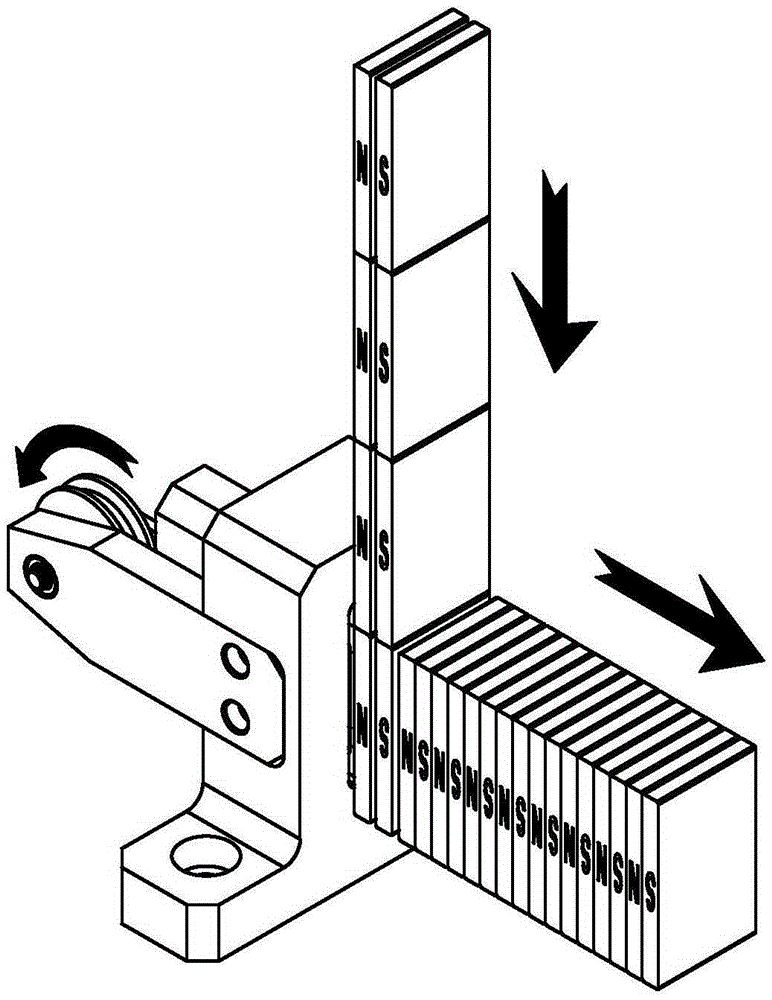

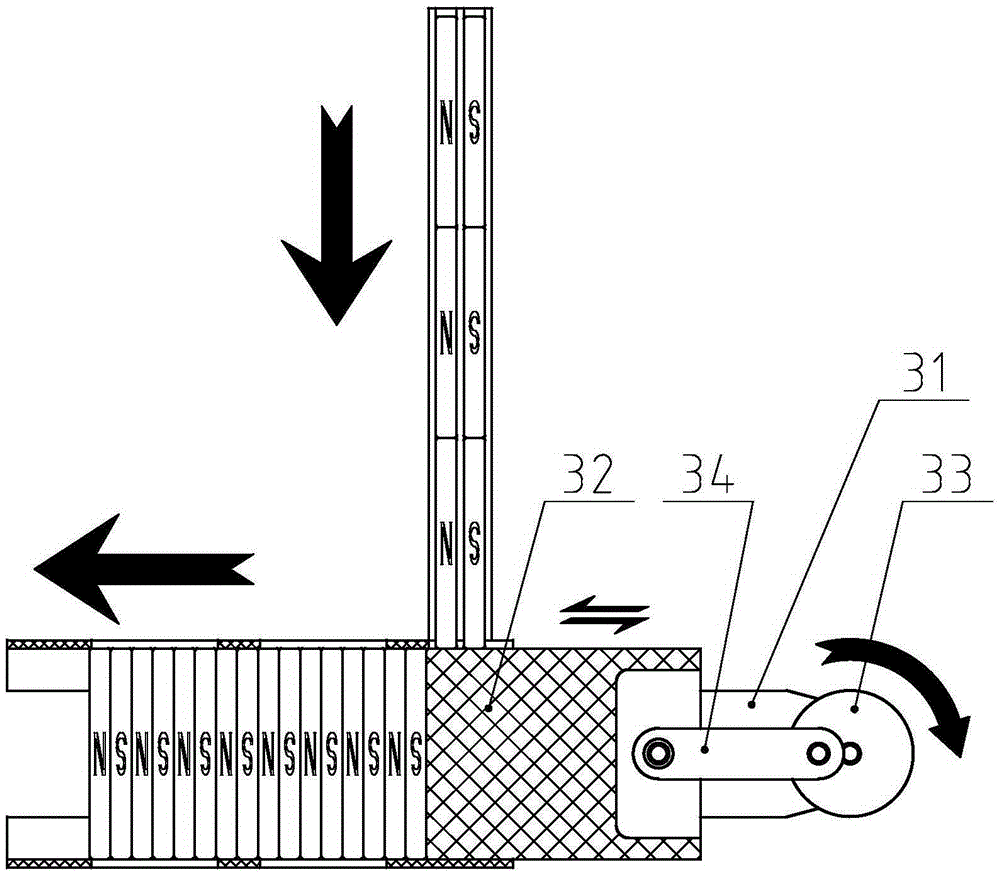

[0028] Such as figure 1 , 3 A magnetic pole group automatic matching unit is shown, which includes N, S conveying track 1, output track 2, fixed frame (not shown) and push assembly 3, N, S conveying track 1 is vertically set, output track 2 Horizontal setting, N, S conveying track 1 and output track 2 are vertically intersected with a push assembly 3 .

[0029] The permanent magnets in the N, S delivery track 1 continuously move downward under the action of gravity, and the permanent magnets on the output track 2 are continuously assembled and output in the form of alternating magnetic poles under the push of the push component 3.

[0030] Such as figure 2 As shown, the N and S conveying tracks 1 are set opposite to each other by two "E" shaped tracks, the upper half of the two "E" shaped tracks form the N conveying track, and the lower half of the two "E" shaped tracks form the S conveying track The tracks, N Conveyor Track and S Conveyor Track are parallel and separated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com