Material distributing unit for magnetic pole assembling line

A technology of batching unit and production line, applied in electrical components, manufacturing stator/rotor body, generator/motor, etc., can solve problems such as unhealthy, error-prone, small size, etc., and achieve the effect of reducing labor intensity and increasing production capacity

Active Publication Date: 2014-10-29

宁波伊玛磁业有限公司

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Patent document PCT / CN2014 / 081921 discloses a magnetic energy turntable, which is equipped with numerous magnetic pole group arrays, and each magnetic pole group is composed of 16 pieces of permanent magnets arranged alternately with adjacent magnetic poles. At present, each magnetic pole group Manual assembly is adopted. Due to the small size and thin thickness of each permanent magnet, manual assembly is difficult, inefficient, and error-prone, resulting in multiple permanent magnets attracting each other.

Because the operator maintains a posture for a long time and repeats the same thing, it is not conducive to health, and the production capacity is related to the working time of the worker

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

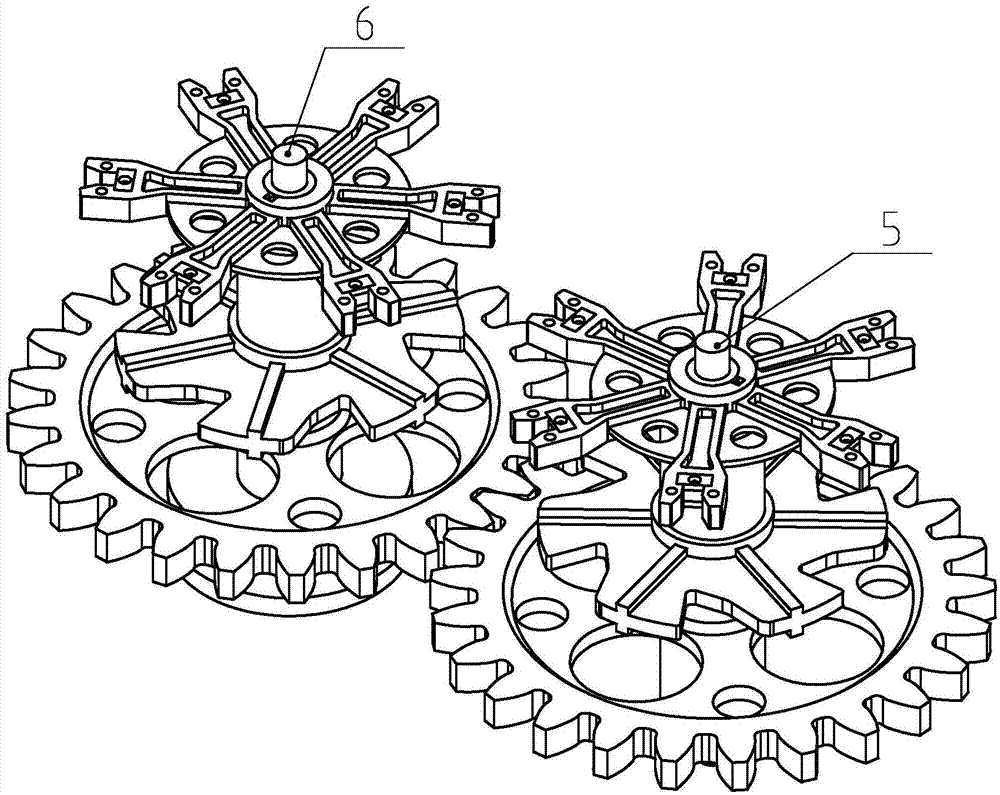

[0028] The power input disc 12 on the S pole rotating shaft 6 in the embodiment one is moved to the N pole rotating shaft 5 and can realize the same effect of the embodiment one, that is, the permanent magnets with the N poles up and the permanent magnets with the S poles up are staggered The way is transported to the output track 3.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

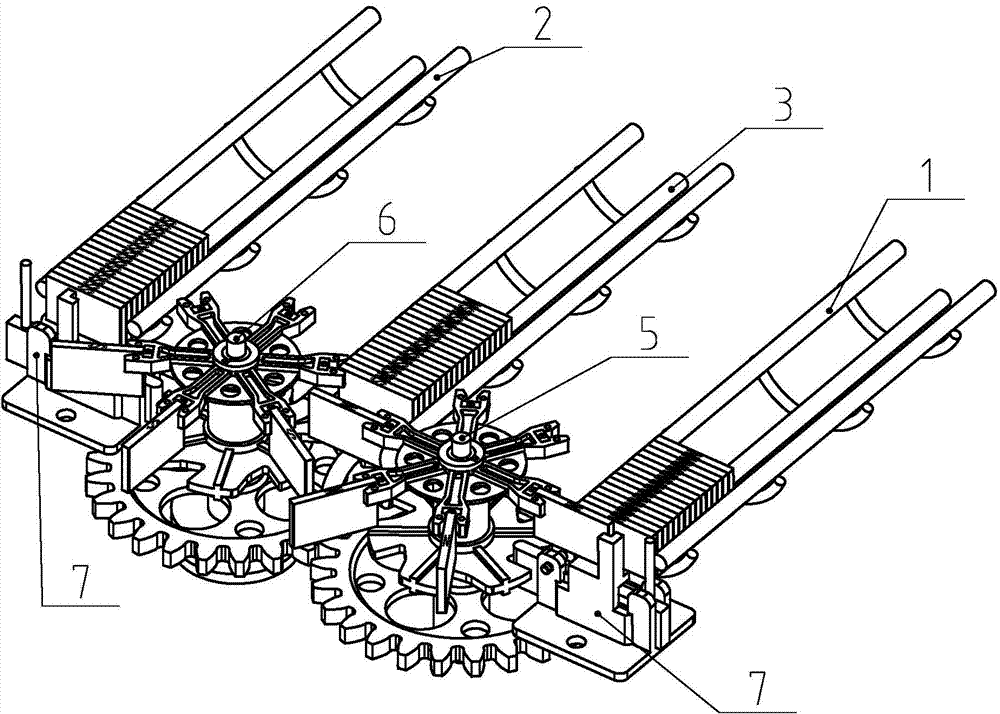

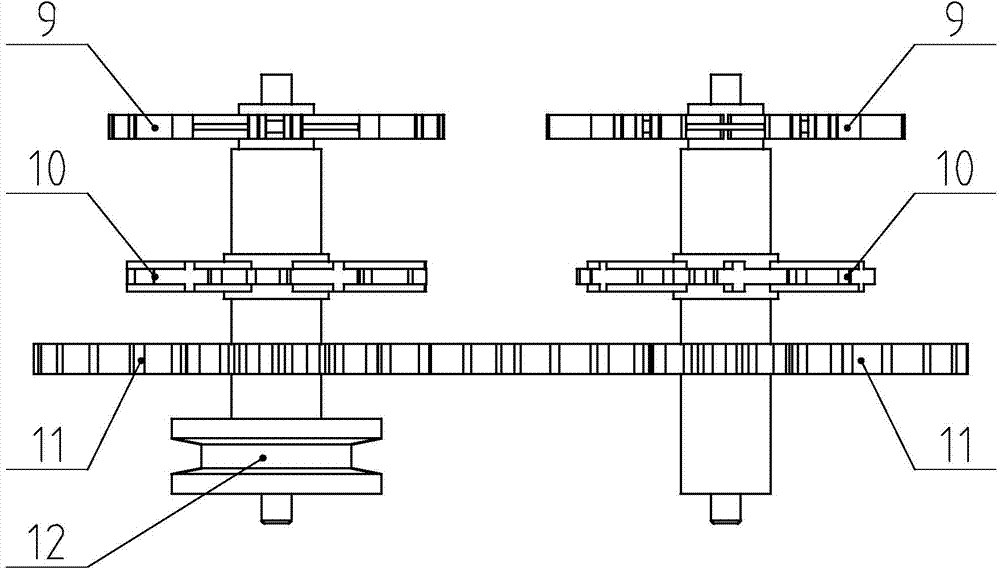

The invention relates to the field of automatic assembly lines, particularly to a material distributing unit for a magnetic pole assembling line. The material distributing unit for the magnetic pole assembling line comprises a N(north)-pole conveying track, an S(south)-pole conveying track, an output track and a material shifting unit and is characterized in that the material distributing unit further comprises an N-pole rotating shaft and an S-pole rotating shaft, a clamping jaw of a rotating plate on the N-pole rotating shaft and a clamping jaw of a rotating plate on the S-pole rotating shaft are arranged in a staggered mode, and the N-pole rotating shaft and the S-pole rotating shaft perform equal ratio transmission through gear engagement and are opposite in rotating directions. The material shifting unit stores energy and quickly triggers a shifting rod through a cam, and the shifting rod enables a single permanent magnet to fly into the clamping jaws of the rotating plates by striking the permanent magnet and enables the permanent magnet to be steadily transferred to the output track with the aid of magnetoconductivity fixing blocks arranged on the clamping jaws. The material distributing unit for the magnetic pole assembling line can efficiently and accurately assemble a plurality of permanent magnets in a mode that the magnetic poles are alternately arranged to reduce labor intensity of workers and improve productivity. The invention further provides an assembly line comprising the material distributing unit.

Description

technical field [0001] The invention relates to the field of automatic assembly lines, in particular to a batching unit for a magnetic pole group assembly line. Background technique [0002] Patent document PCT / CN2014 / 081921 discloses a magnetic energy turntable, which is equipped with numerous magnetic pole group arrays, and each magnetic pole group is composed of 16 pieces of permanent magnets arranged alternately with adjacent magnetic poles. At present, each magnetic pole group Manual assembly is adopted. Due to the small size and thin thickness of each permanent magnet, manual assembly is difficult, inefficient, and error-prone, resulting in multiple permanent magnets attracting each other. Because the operator keeps a posture for a long time and does the same thing repeatedly, it is not good for health, and the production capacity is related to the working hours of the workers. Contents of the invention [0003] In order to solve the above problems, the object of th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H02K15/03H02N11/00

Inventor 龚柱

Owner 宁波伊玛磁业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com