Assembling tool for nozzle of breaker and positioning assembly of assembling tool

A technology for assembling tooling and positioning components, which is applied in the direction of circuits, electrical components, emergency protection devices, etc., can solve problems such as bolts falling out, transmission frame smashing operators, workpiece scratches, etc., to achieve reliable positioning, simple and convenient positioning, and reduce The effect of the number of people required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

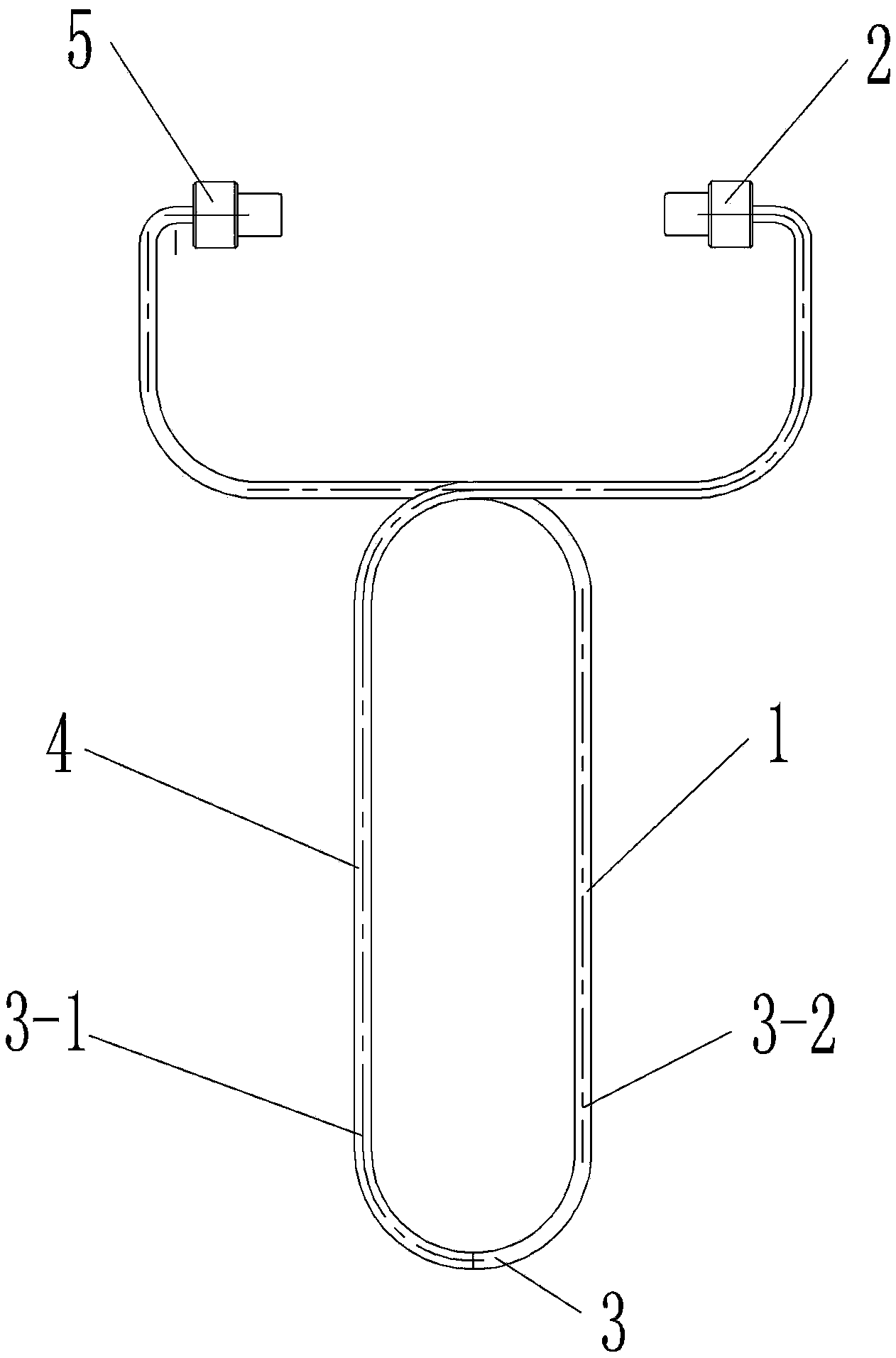

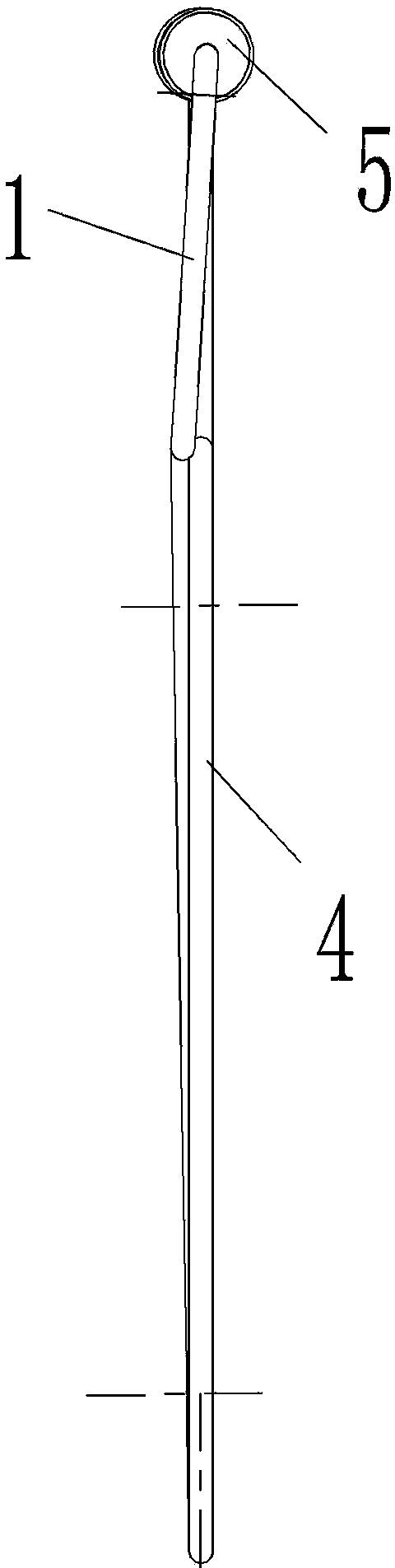

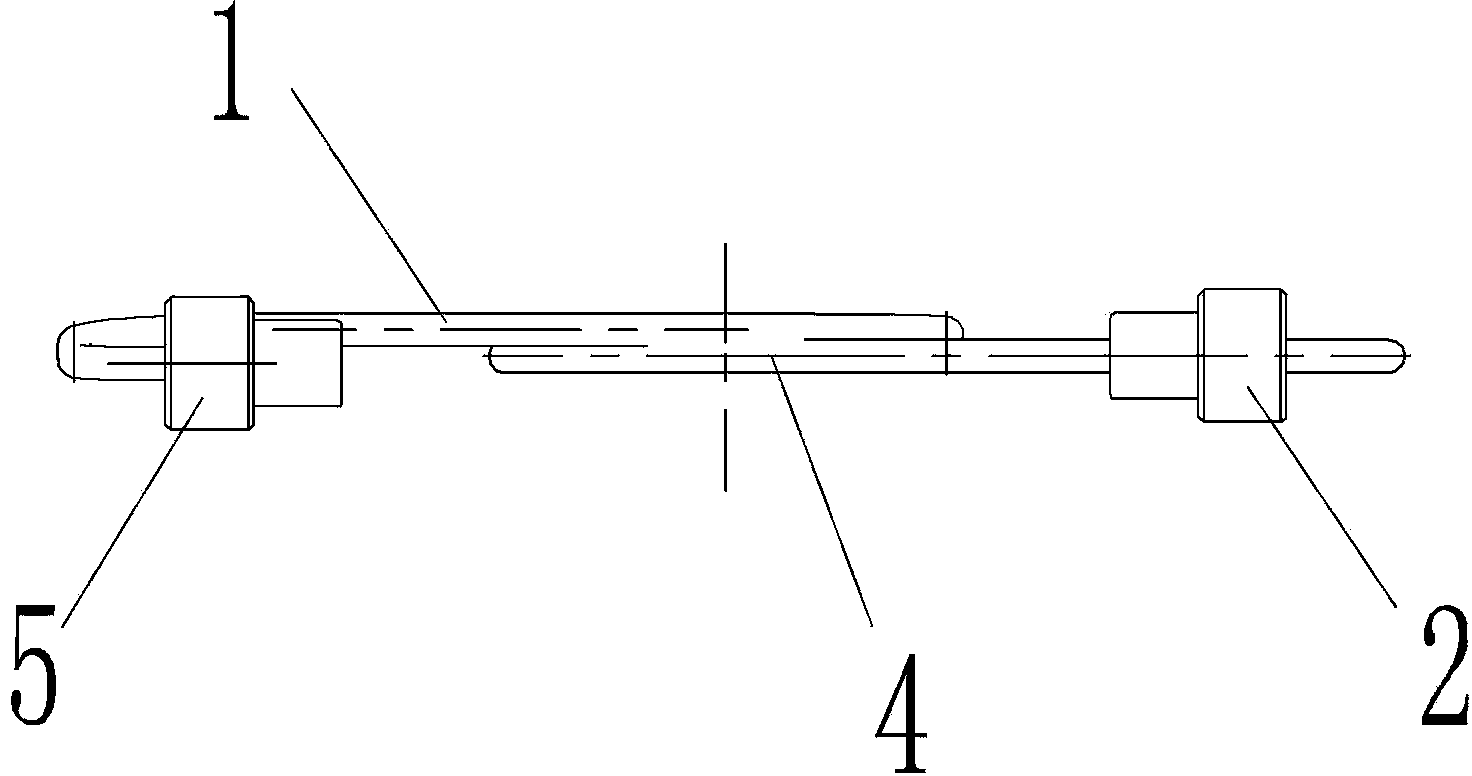

[0025] An embodiment of an assembly tool for a circuit breaker spout such as Figures 1~7 Shown: it includes a transmission frame that is used to fit around the periphery of the corresponding spout 6 when in use, the transmission frame is a sleeve 7, and the sleeve has an inner hole for guiding and matching with the outer peripheral cylindrical surface of the upper end of the spout, and the lower end of the sleeve is sleeved Two weight-reducing grooves 7-1 extending to the lower end face of the sleeve are symmetrically arranged on the wall of the cylinder in the circumferential direction. The problem of excessive labor intensity of the operator will not be caused by the excessive weight of the sleeve. The sleeve wall between the two weight-reducing grooves is provided with a reinforcing rib 7-2 with a length extending in the up-down direction, and the lower end of the sleeve wall between the two weight-reducing grooves is provided with two diameters respectively corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com