Rotor milling cutter and blade fixing structure

A fixed structure, rotor milling technology, used in milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of loose displacement, unstable machining accuracy, and time difference between rotor machining accuracy, so as to achieve firm and reliable positioning and ensure machining. Accuracy and stability, not easy to loosen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

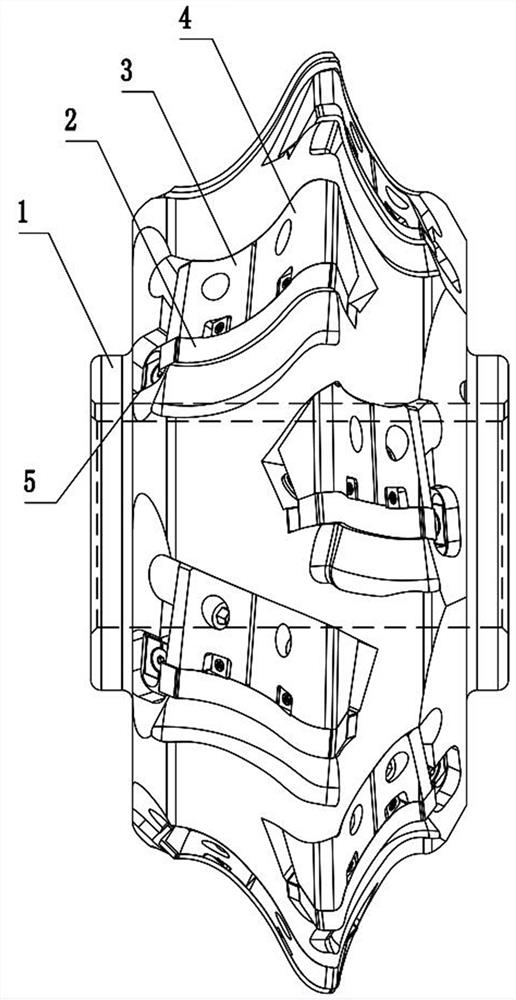

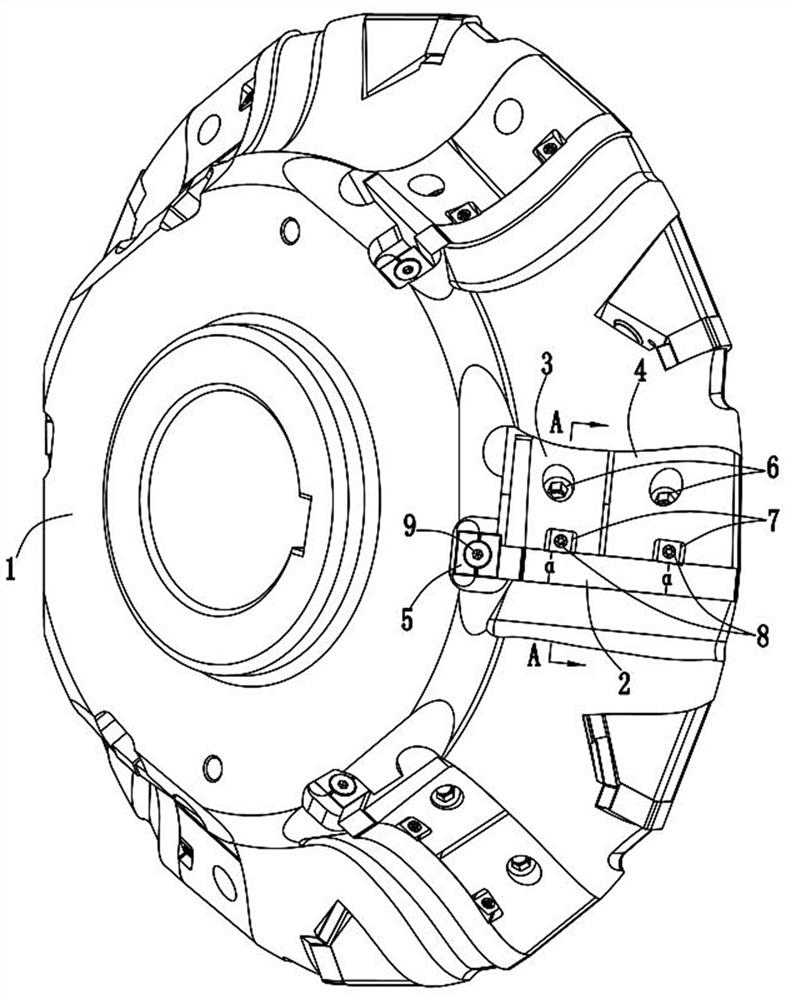

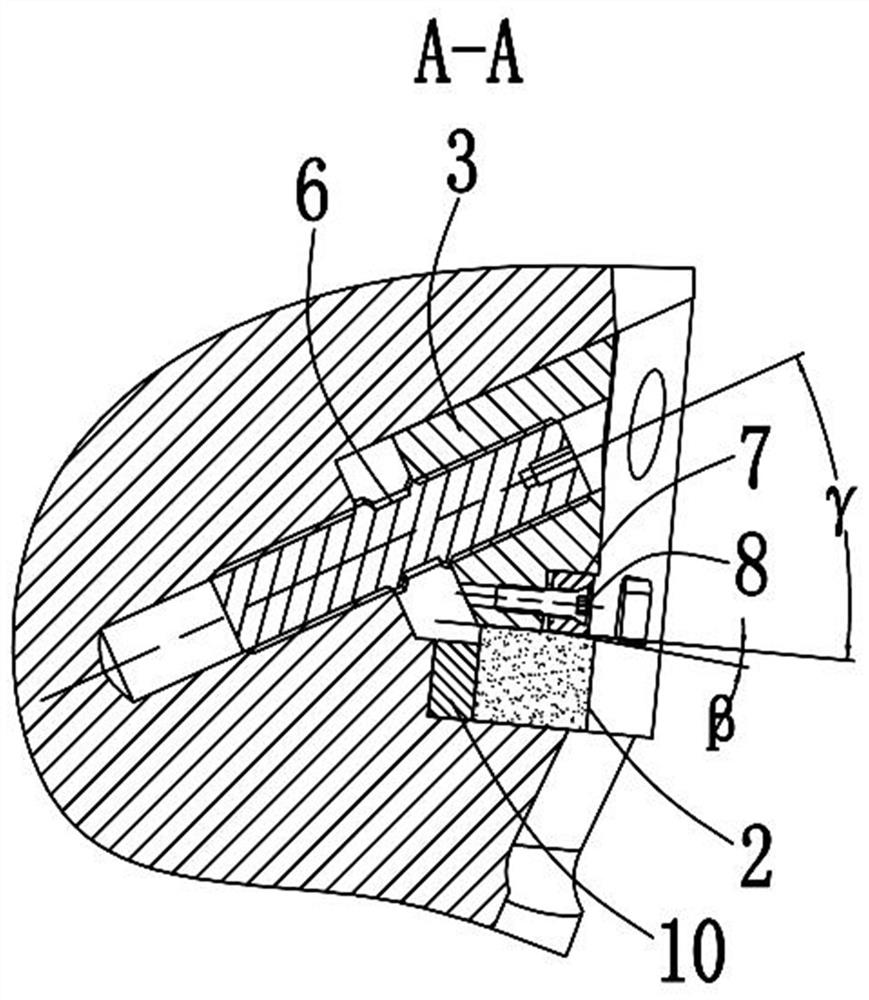

[0037] Such as Figure 1-10 Shown:

[0038] The invention provides a rotor milling cutter and a blade fixing structure, including a cutter body 1, a blade 2 and a pressing block; wherein:

[0039] The cutter body 1 is provided with a plurality of blade grooves,

[0040] Blocks 10 are installed on each of the blade slots,

[0041] Be provided with the briquetting groove 16 that is used for installing briquetting beside described blade groove,

[0042] The blade 2 is fixed on the spacer 10 through a pressing block to form a complete cutting edge 11 of the rotor milling cutter,

[0043] The blade positioning surface 22 of the blade 2 is provided with an adjusting block groove 13,

[0044] An adjusting block 5 for adjusting the angle of the blade 2 is installed on the adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com