Ultra-high-speed operating mechanism of gunpowder gas-driven circuit breaker

A gas-driven, operating mechanism technology, applied in the protection switch operation/release mechanism, etc., can solve the problems of broken shells, inability to realize fast opening, unfavorable operating speed of the operating mechanism, etc., and achieve high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

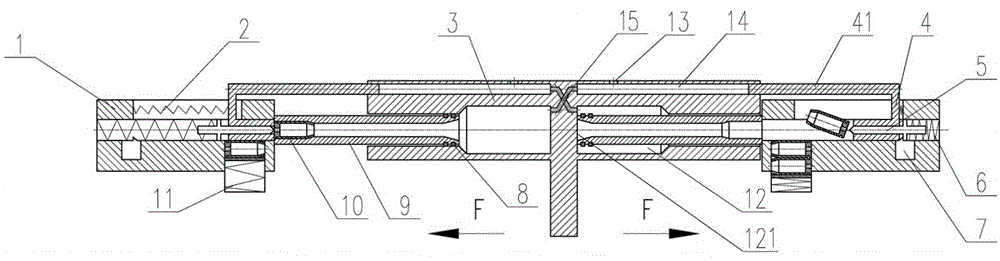

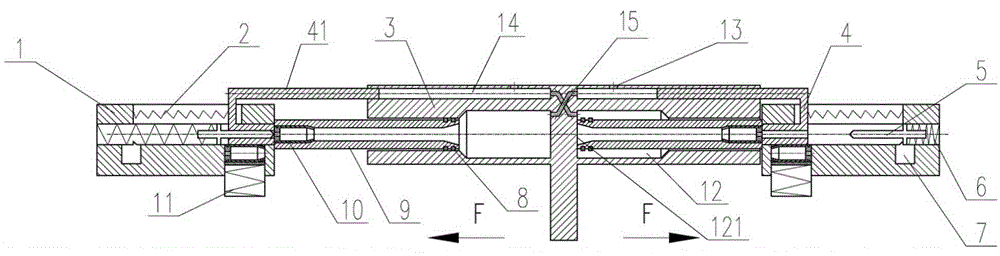

[0017] An embodiment of the ultra-high-speed operating mechanism of the gunpowder gas-driven circuit breaker of the present invention is as follows Figure 1~Figure 2 As shown, a single-break DC circuit breaker for a class above 200KV includes a transmission member 3 which is guided and moved along the left and right directions of the opening and closing movement, and empty shell launchers arranged on the left and right sides of the transmission member 3 .

[0018] Each blank bullet launching device has the same structure, and can refer to the structure of existing automatic firearms, and can realize loading, percussion and shell ejection of blank bullets 10, including casing 1, ammunition supply, and being arranged at the front end of casing 1. Form the gun barrel 9 of ejection port, and the ejection port of each gun barrel 9 is all towards transmission part 3; For ammunition adopt magazine 11, certainly, also can adopt bullet chain or magazine etc. in other embodiments; In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com