High-efficiency durable-type stirrer

A durable and agitator technology, applied in mixers with rotating agitation devices, chemical instruments and methods, dissolution, etc., can solve problems that affect the quality of agitation and production and processing efficiency, the agitation mechanism is stuck, and the agitation effect is poor. Achieve the effects of improving the mixing quality and production and processing efficiency, ensuring the safety of use, and improving the crushing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

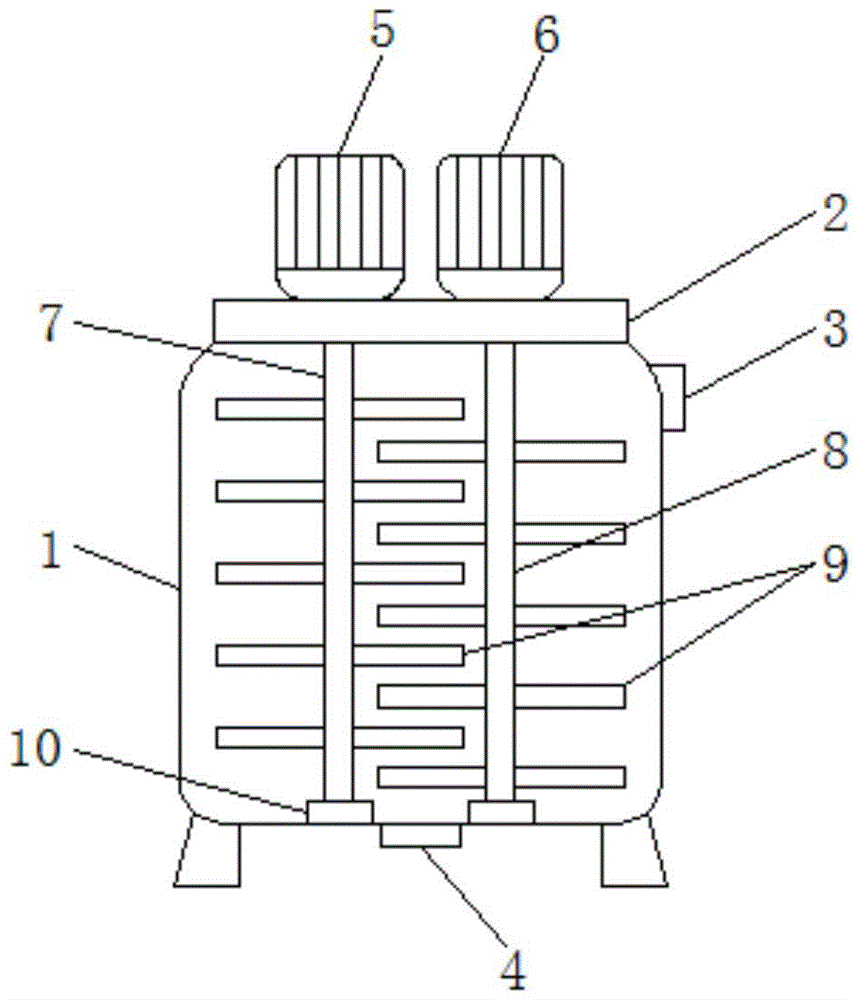

[0010] Such as figure 1 As shown, a high-efficiency and durable agitator includes a stirring tank 1, the top of the stirring tank 1 is provided with a mounting seat 2, the upper side wall is provided with a feed port 3, the bottom is provided with a discharge port 4, and the upper edge of the mounting seat 2 is The agitating tank is symmetrically provided with a first drive motor 5 and a second drive motor 6 that rotate in opposite directions, and the output ends of the first and second drive motors 5 and 6 are respectively connected with a first rotating shaft extending into the agitating tank 1. 7 and the second shaft 8, the first shaft 7 and the second shaft 8 are evenly spaced with a number of stirring rods 9, and the number of stirring rods 9 on the first shaft 7 and the second shaft 8 are arranged alternately.

[0011] The lower ends of the first rotating shaft 7 and the second rotating shaft 8 both extend to the bottom of the mixing tank 1 and are rotatably mounted on a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com