Deformation correcting device for welded tubes

A welded pipe and orthopedic technology, applied in the field of welded pipe orthopedic devices, can solve the problems of affecting the orthopedic effect, shortening the life of the orthopedic roller, large flexural stress, etc., and achieve the effect of good orthopedic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

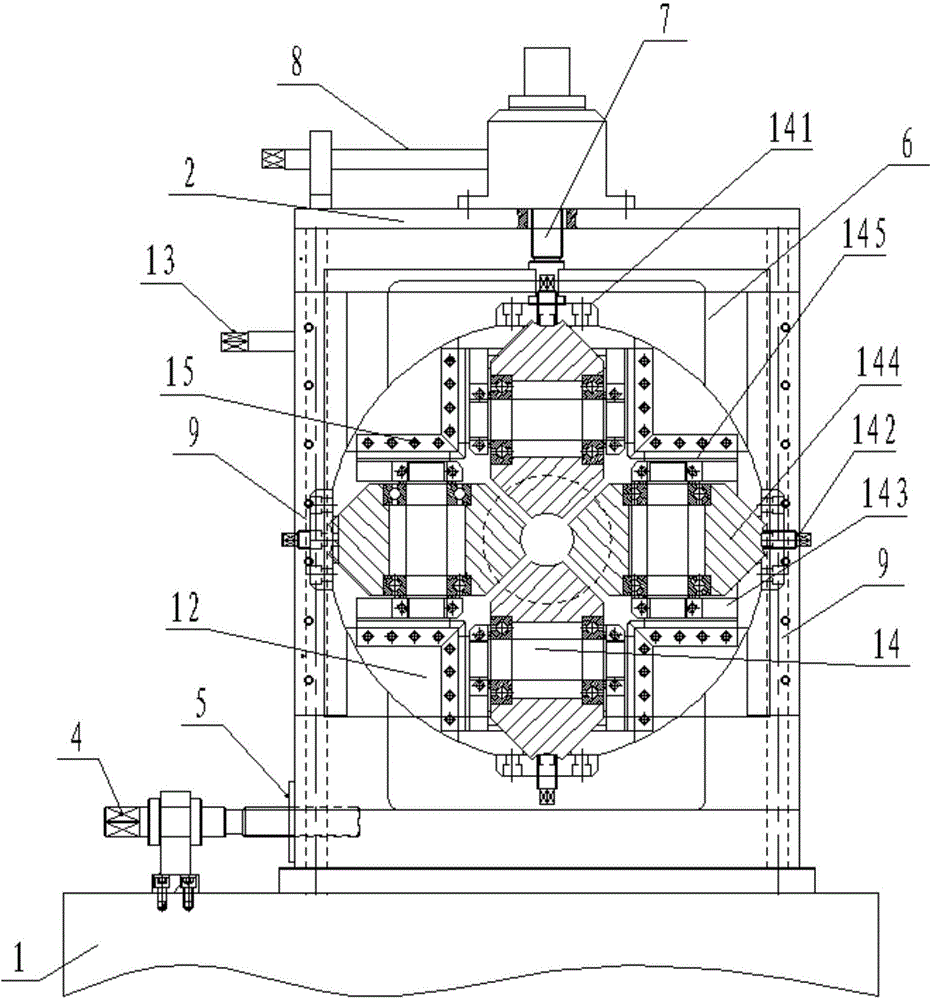

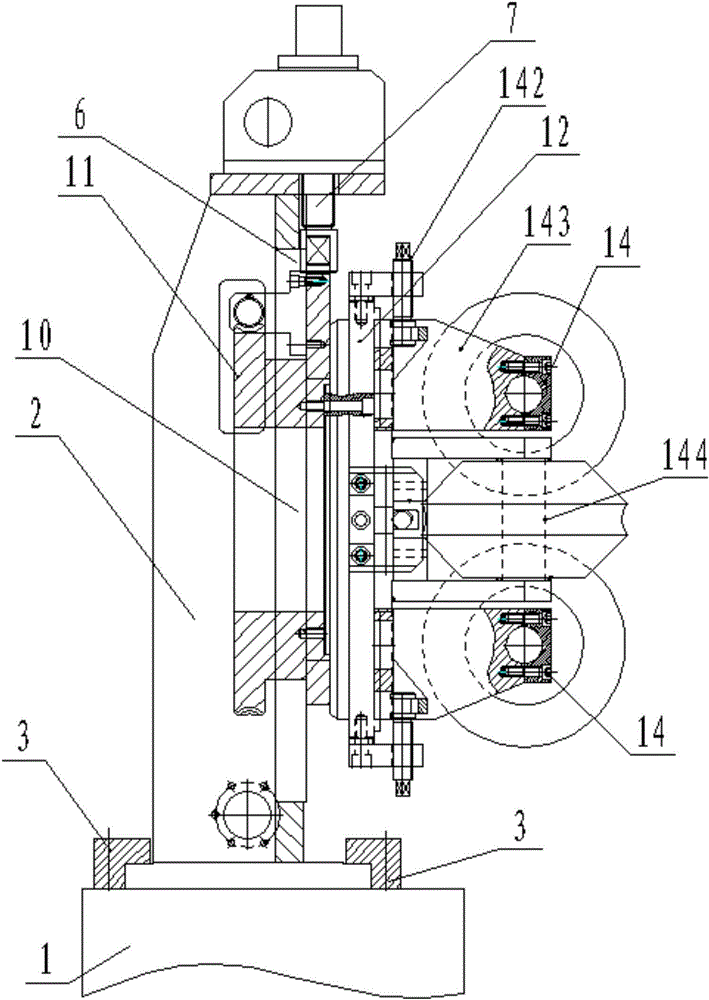

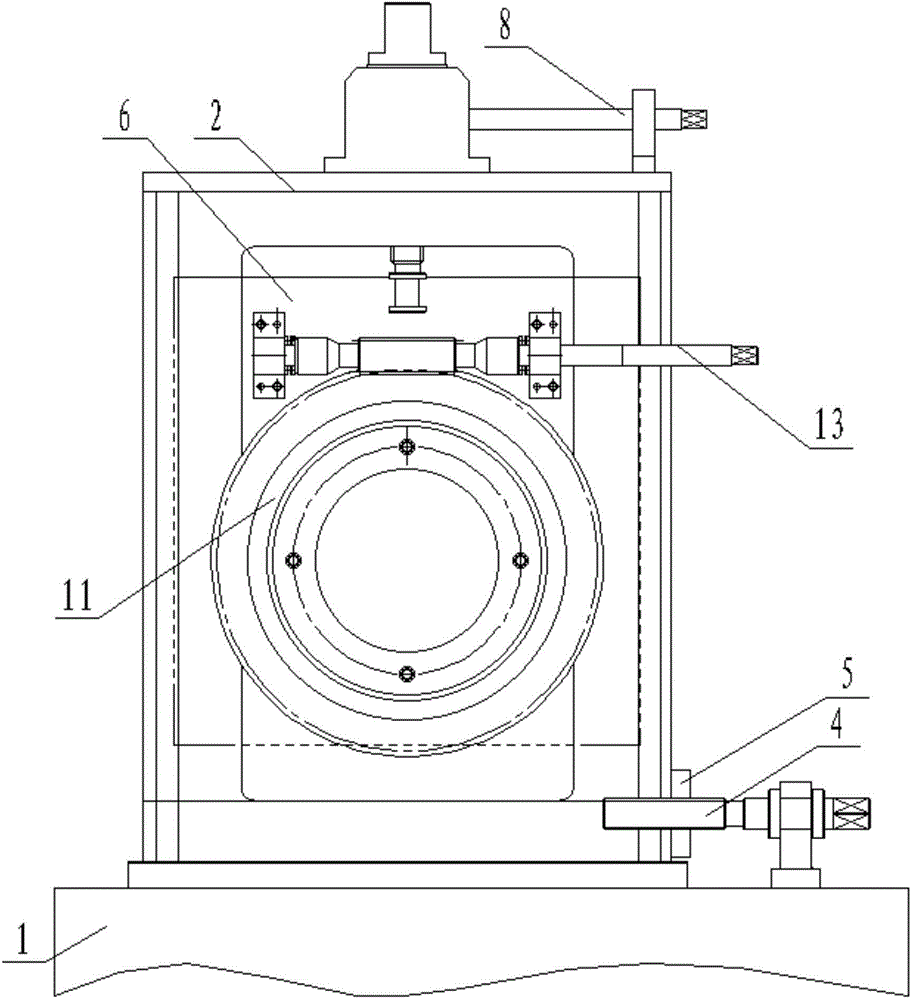

[0019] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0020] like Figure 1-3 As shown, a welded pipe orthopedic device includes a gantry 2 movably arranged on an installation base 1, the installation base 1 is provided with pressure plates 3 covering both sides of the bottom plate of the gantry 2, and the installation base 1 is on the gantry frame. 2 is provided with a lead screw 4, the lead screw 4 is connected with the gantry frame 2 through threads, and an adjusting nut 5 is provided on the lead screw 4 on the outer casing of the gantry frame 2.

[0021] The gantry frame 2 is movably provided with a movable seat 6 that can move up and down, the upper part of the movable seat 6 is provided with a screw 7, and the part of the upper part of the screw 7 that passes through the top plate of the gantry frame 2 is sleeved with a worm gear (not shown in the figure), and the gantry The top plate of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com