A carburized thin-walled ring gear combined pressure quenching tooling

A thin-walled ring gear and combined technology, applied in the direction of quenching devices, manufacturing tools, furnaces, etc., can solve the problem that the correction effect cannot meet the requirements of machining, and achieve the best correction effect and the effect of clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

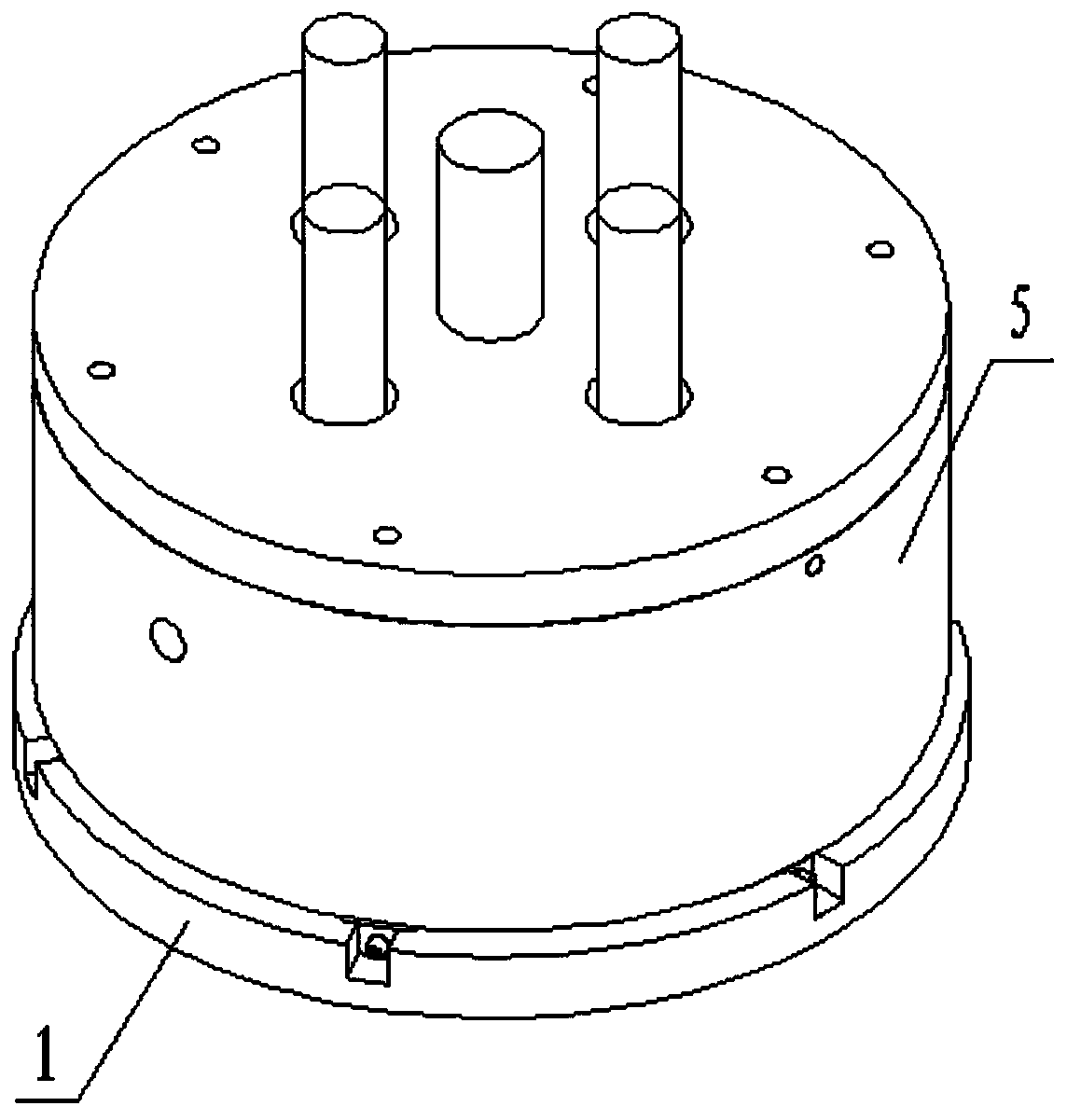

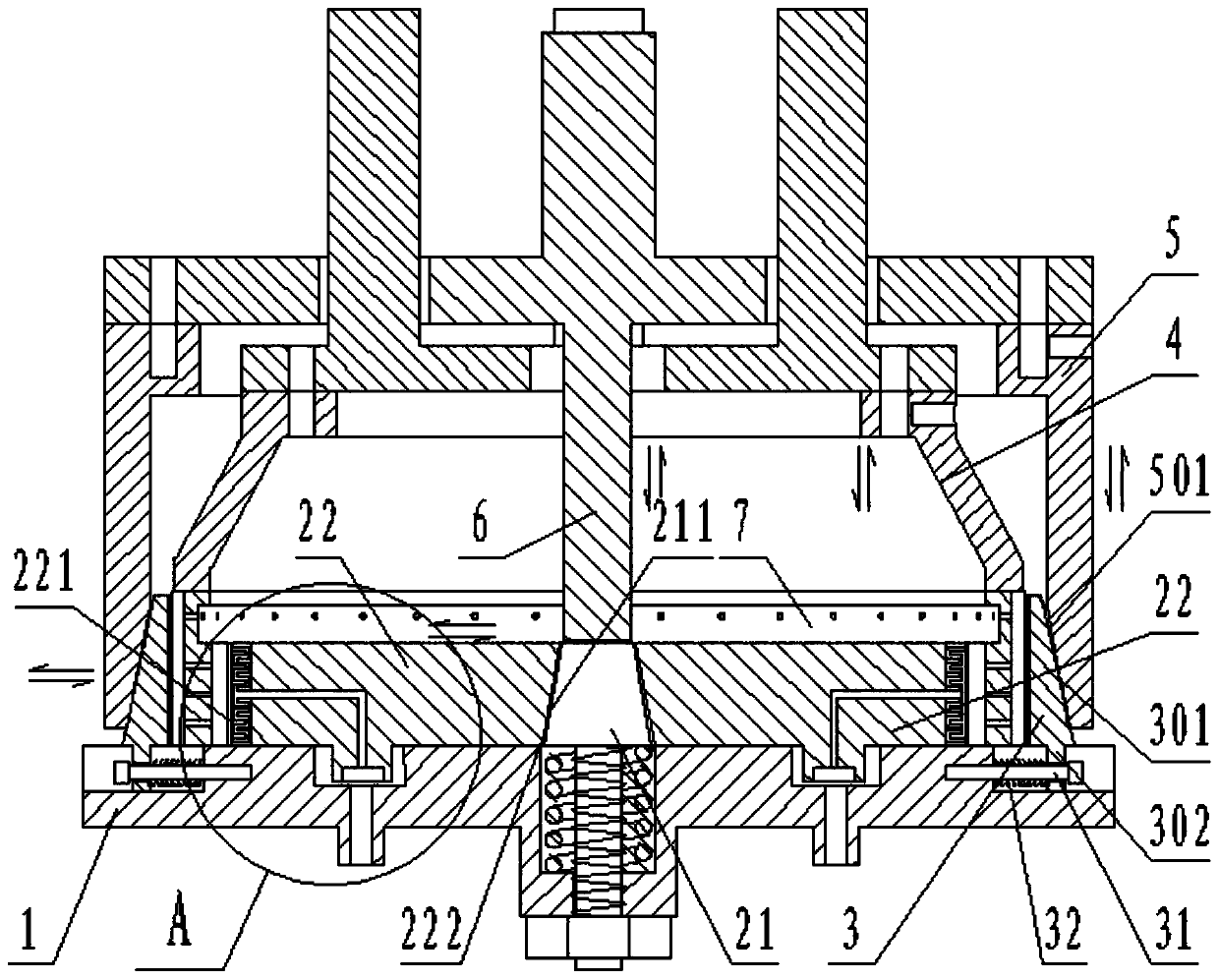

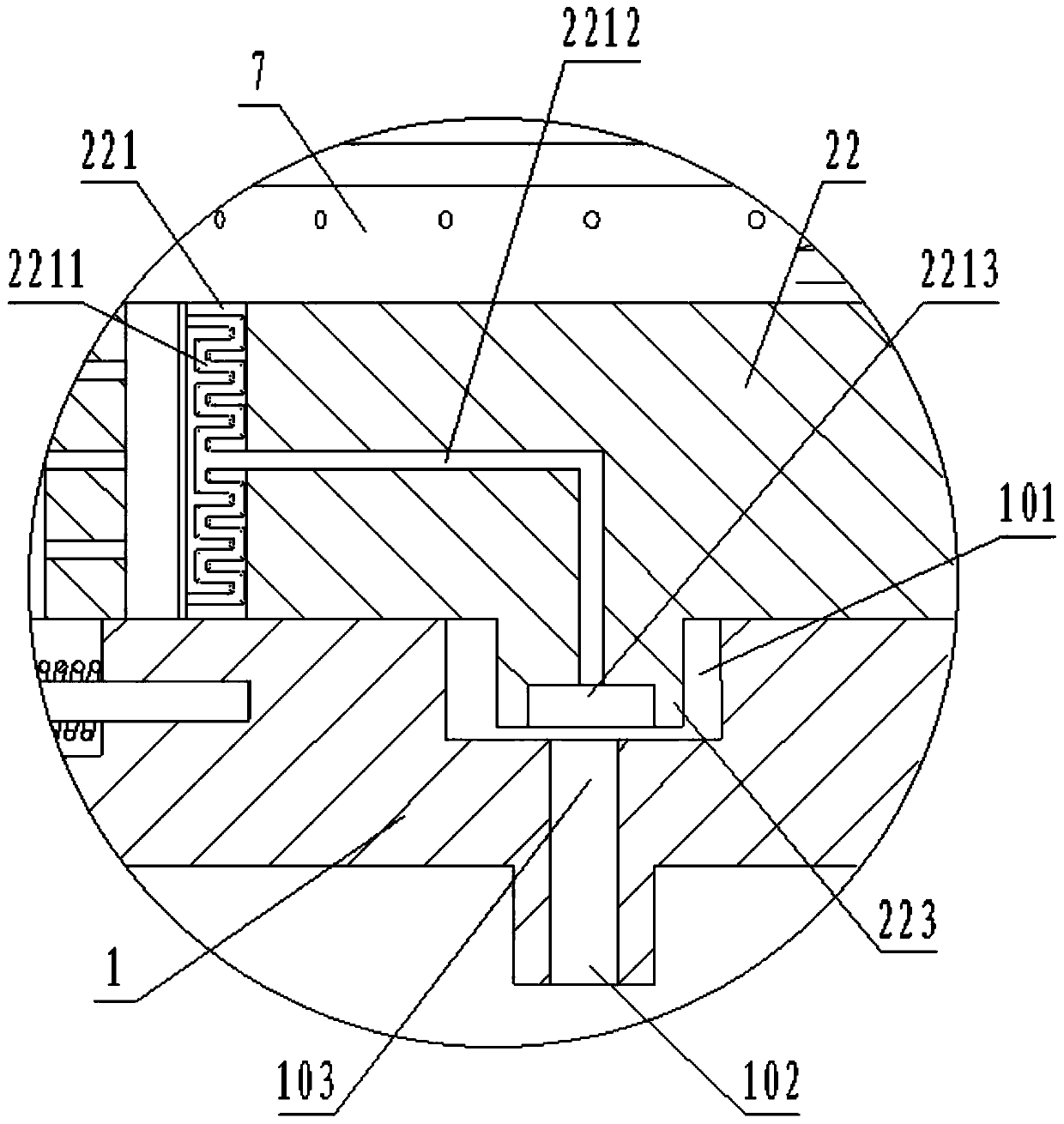

[0029] Such as Figure 1-5 As shown, the specific structure of the present invention is: a carburized thin-walled ring gear combined pressure quenching tool, including a bottom mold 1, the upper end of the bottom mold 1 is provided with a core mold 2, and the core mold 2 includes a A movable mandrel 21 on the mold 1 and a plurality of sliders 22 uniform around the axis of the mandrel 21, when the mandrel 21 moves along its axial direction, the sliders 22 move radially along the mandrel 21; One end of 22 is provided with a slider tooth 221 matching the internal gear ring to be quenched, and the other e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com