Multi-head punching device

A punching head and punching technology, applied in the field of sheet metal processing, can solve the problems of cumbersome adjustment of punching head position and slow processing speed, and achieve the effects of good adaptability, easy operation and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

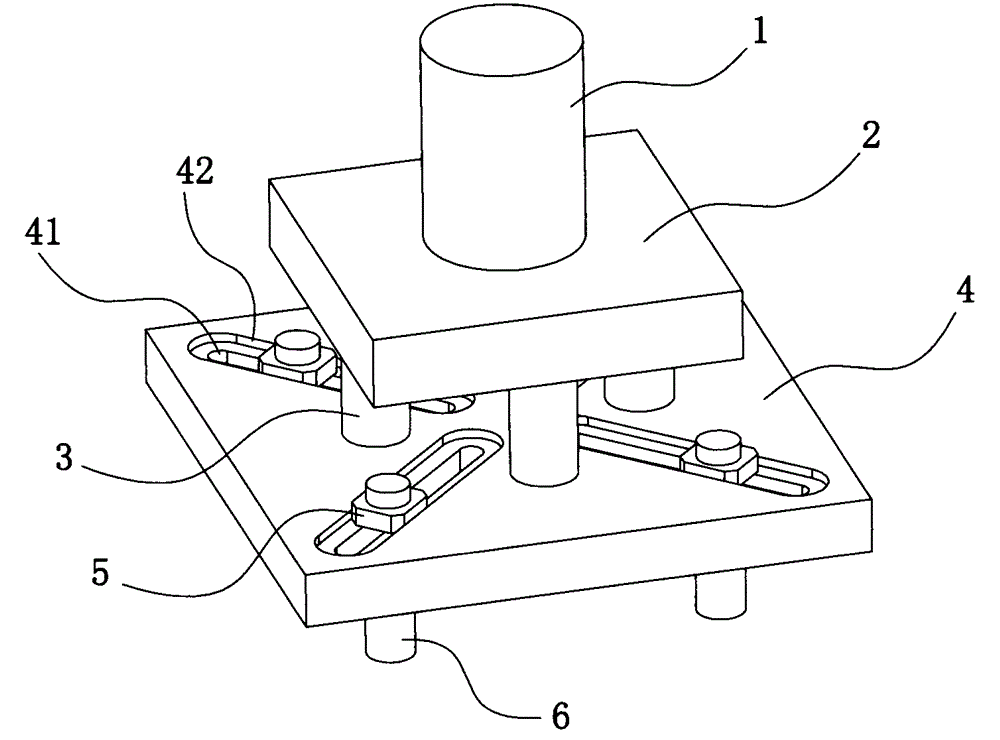

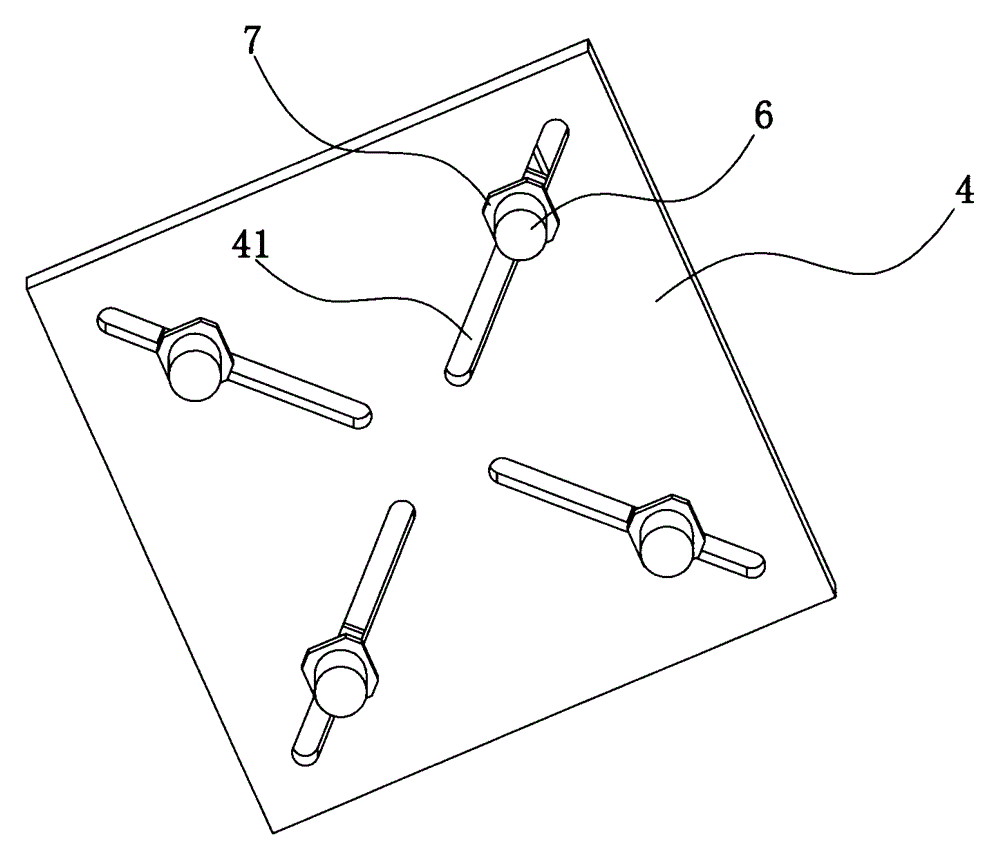

[0014] See figure 1 machine figure 2 , the present invention includes a punching drive device 1, an upper template 4 and a punching head 6 installed on a frame (not shown), the punching driving device 1 drives the upper template 4, and the lower surface of the upper template 4 is connected to the punching head 6. The punching driving device 1 drives the upper template 4 to drive the punching head 6 to reciprocate up and down. A fixed column 3 makes an operating space between the mounting plate 2 and the upper formwork 4, in order to improve the connection stability between the upper formwork 4 and the mounting plate 2, the fixed column 3 is arranged symmetrically with respect to the center of the upper formwork 4; A plurality of mounting grooves 41 are symmetrically arranged, and the mounting grooves 41 are arranged radially relative to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com