Scrap-free cutting device

A cutting device and cutting unit technology, applied in the direction of shearing device, pipe shearing device, shearing machine equipment, etc., can solve the problems of high cost and many devices, and achieve the effects of simple structure, reduced use cost and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

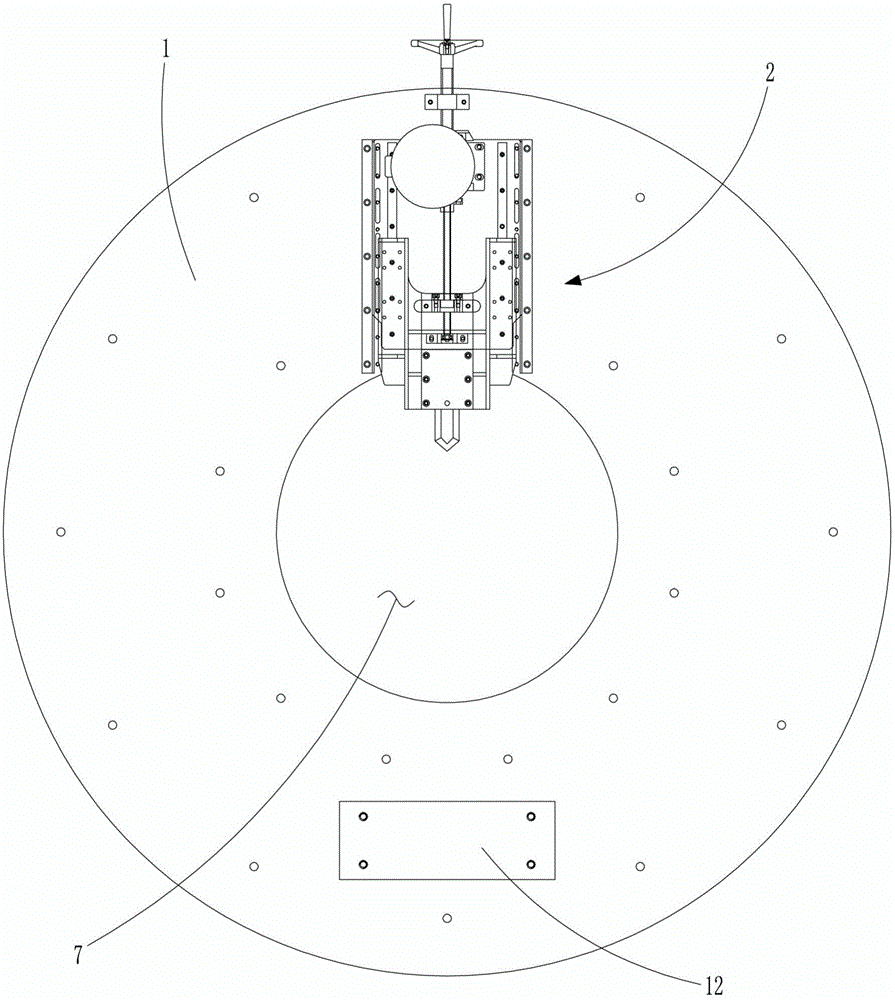

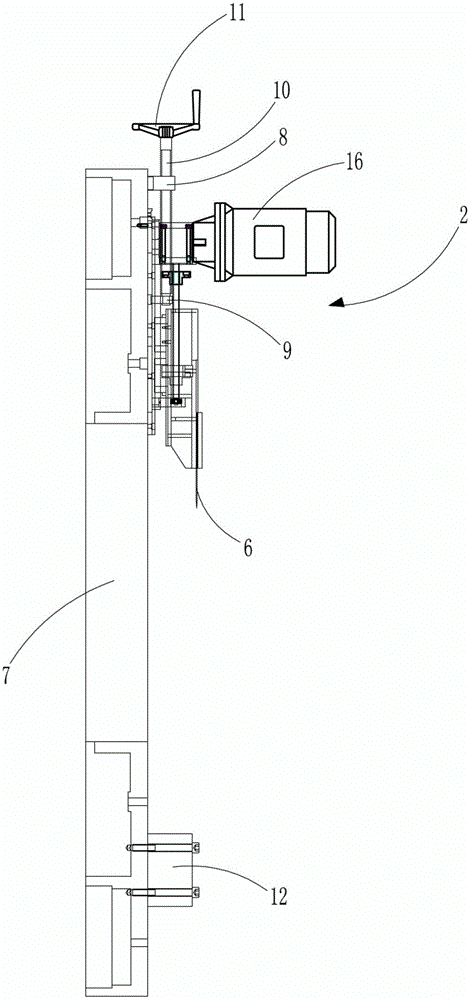

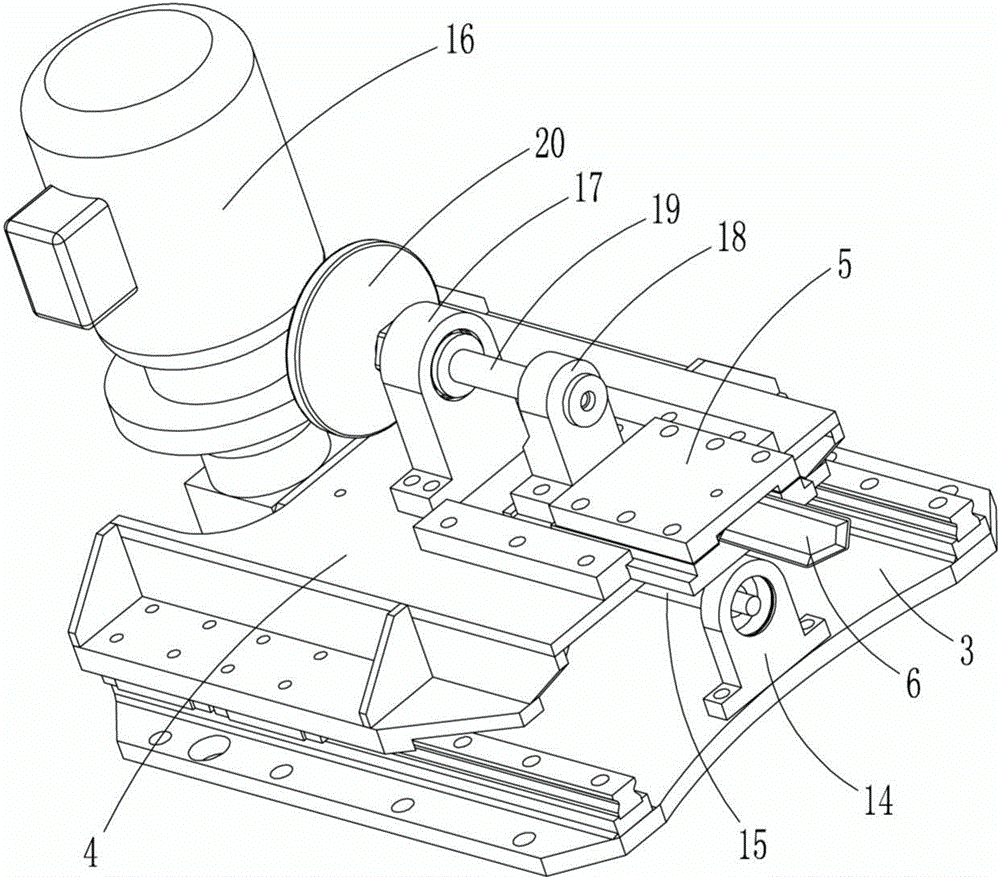

[0020] as attached figure 1 to attach Figure 4 As shown, a chipless cutting device is used for cutting tubular products, and its structure includes a rotating disk 1 that can be rotatably arranged on the frame, and a cutting unit 2 installed on the rotating disk 1. The cutting unit 2 includes a To the support plate 3 that is movably arranged on the rotating disk 1, the knife rest 4 that can be radially moved on the support plate 3, and the knife seat 5 that can be radially moved on the knife rest 4, that is, cutting Between the knife 6 and the rotating disk 1, there are three stages of telescopic mechanisms, the cutting knife 6 for cutting the tubular product is installed on the knife seat 5, and the center of the rotating disk 1 is provided with a through hole 7 for the tubular product to pass through. A first drive assembly for mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com