Device for heating inner holes of workpieces in interference fit

An interference fit, heating device technology, applied in metal processing, manufacturing tools, metal processing equipment and other directions, can solve the problems of inability to heat the inner hole of the workpiece, the practicability needs to be improved, and the heating efficiency is affected, so as to overcome the adaptability Weak, novel and reasonable structure, efficient heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

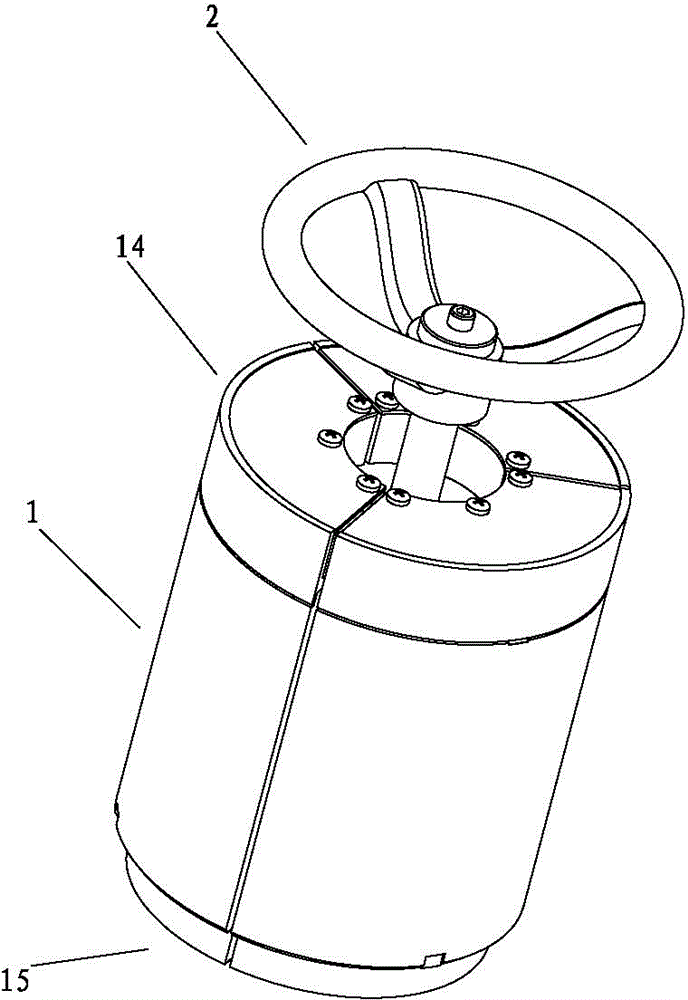

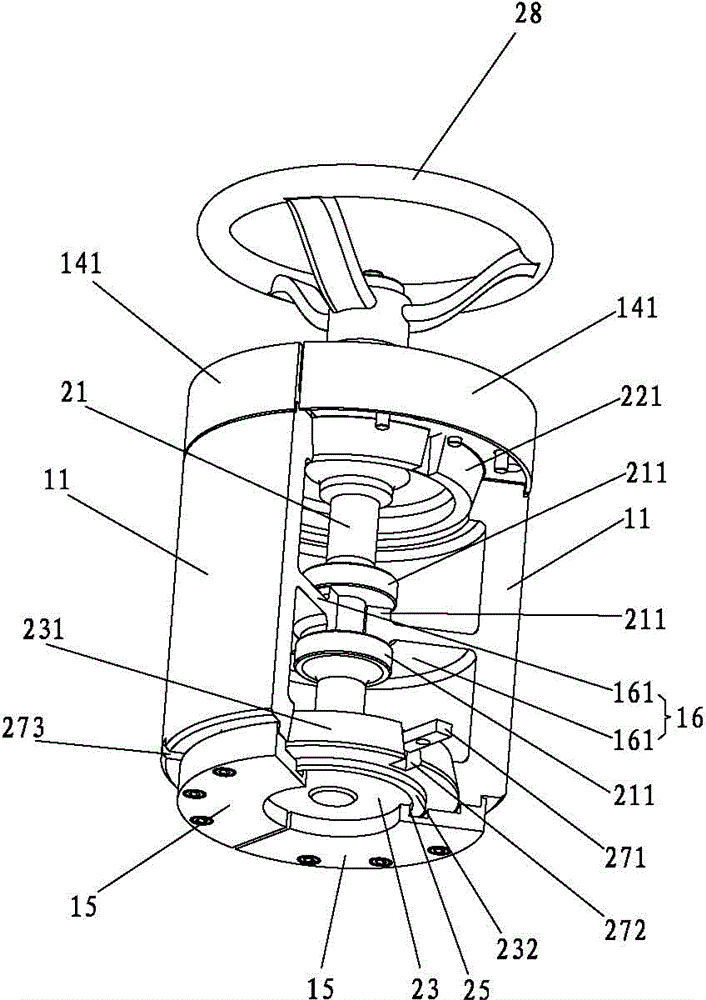

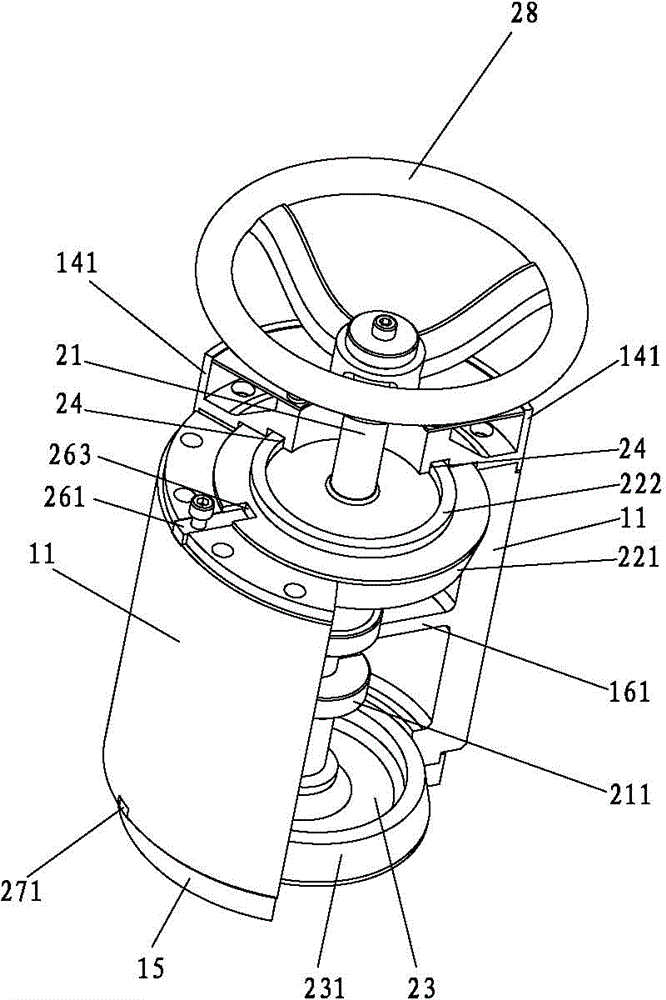

[0048] A heating device for an interference fit workpiece inner hole of the present invention, such as Figure 1-4 As shown, it includes a heating cartridge 1 and an expansion driving device 2 .

[0049] The heating cylinder 1 contacts and heats the inner hole wall of the outer interference fit workpiece to be heated, so that the workpiece is heated and expands, which is convenient for the inner interference fit workpiece to be put in to realize the interference fit after cooling. The heating cylinder 1 includes more than two petals The detachable heating cylinder petals 11, the expansion driving device 2 is equipped with the heating cylinder 1, which can drive the heating cylinder petals 11 to expand and move outward, so as to adapt to different inner diameters and workpiece inner holes with larger inner diameters after being heated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com