Automatic stamping machine

An automatic stamping machine and seal technology, which is applied in the improved invention field of the automatic stamping machine, can solve the problems of dirty paper, easy smearing, and difficult drying of the stamp, and achieve the effect of clear stamp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

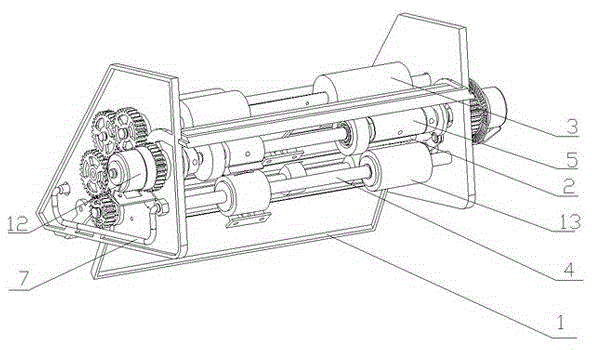

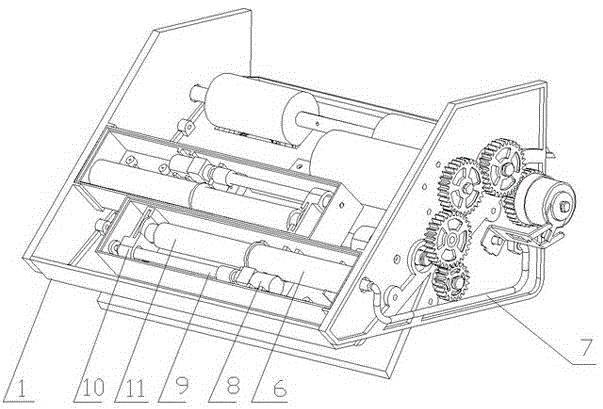

[0013] Accompanying drawing has shown structure of the present invention, further illustrates its relevant details below again in conjunction with accompanying drawing. The automatic stamping machine includes a frame 1, a stamping device and a motor, the frame 1 is provided with a paper inlet and a paper outlet, and the stamping device includes a stamp 2, a pressing roller 3 and an oil transfer roller 4 , the stamp 2 is arranged on a transmission roller 5, the transmission roller 5 is connected with the motor, the transmission roller 5 is arranged between the pressure roller 3 and the oil transfer roller 4, and the seal 2 and the oil transfer roller 4 and the pressure roller The rollers 3 are all matched, that is, the seal 2, the oil transfer roller 4 and the pressure roller 3 can be respectively attached to carry out oil transfer and stamping when they are working. The oil transfer roller 4 is connected to an oil inlet device, and the oil inlet device includes The syringe 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com