Supporting Structure and Supporting Method for Cut Eye in Coal Mining Face

A technology of coal mining face and support structure, which is applied in mining equipment, earthwork drilling, shaft equipment, etc., can solve the problems of high support cost, broken roof, and long construction period, so as to improve safety operability and avoid secondary The effect of simplification of secondary damage and support links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the examples, the purpose is only to understand the content of the present invention better.

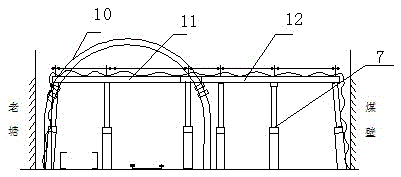

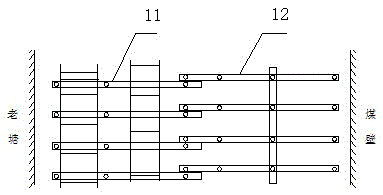

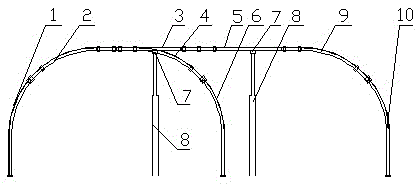

[0036] see image 3 , the coal mining face cut-eye supporting structure that the embodiment provides, comprises shed leg, shed beam, straight beam, pillar, shed leg is made up of straight section and curved arc section, comprises left shed leg 1, can withdraw shed leg 6. The right shed leg 10; the shed beam is composed of a straight section and a curved arc section, including the left shed beam 2, the removable shed beam 4, and the right shed beam 9; the straight beam includes the left straight beam 3 and the right straight beam 5; the left The shed leg 1 and the left shed beam 2, the right shed leg 10 and the right shed beam 9 are overlapped respectively through arc sections, the straight section of the left shed beam 2 is overlapped with one end of the left straight beam 3, and the other end of the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com