Electromagnetic gas valve

A solenoid valve, valve body technology, applied in valve details, valve device, valve shell structure, etc., can solve problems such as poor sealing effect, small air output, and slow response of pneumatic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

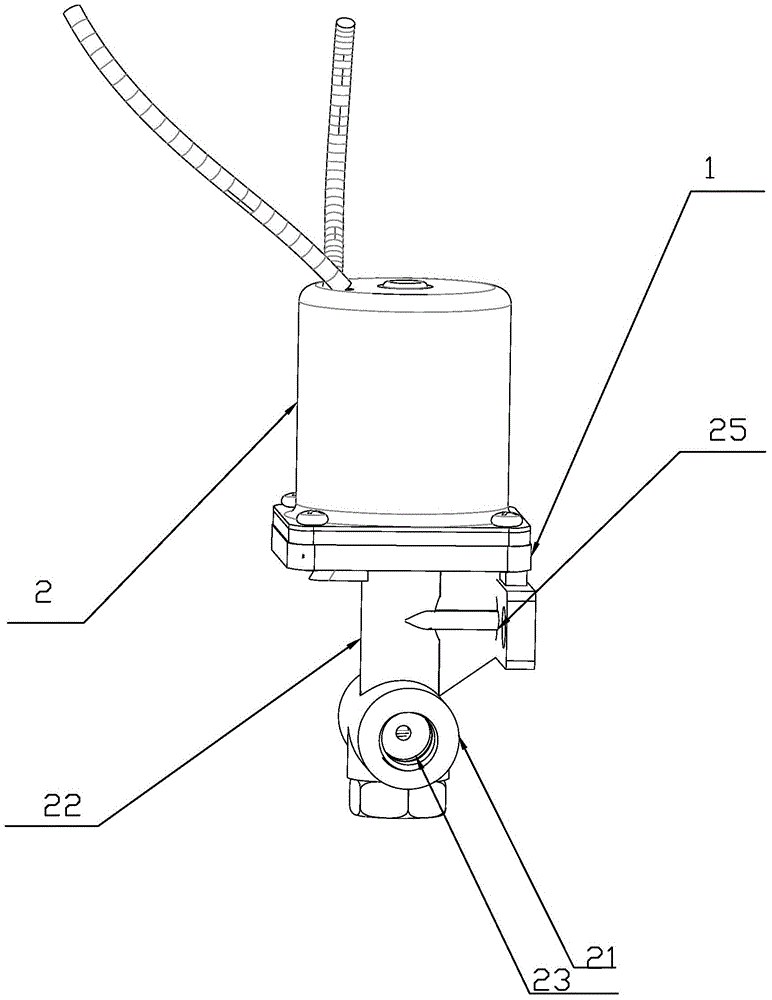

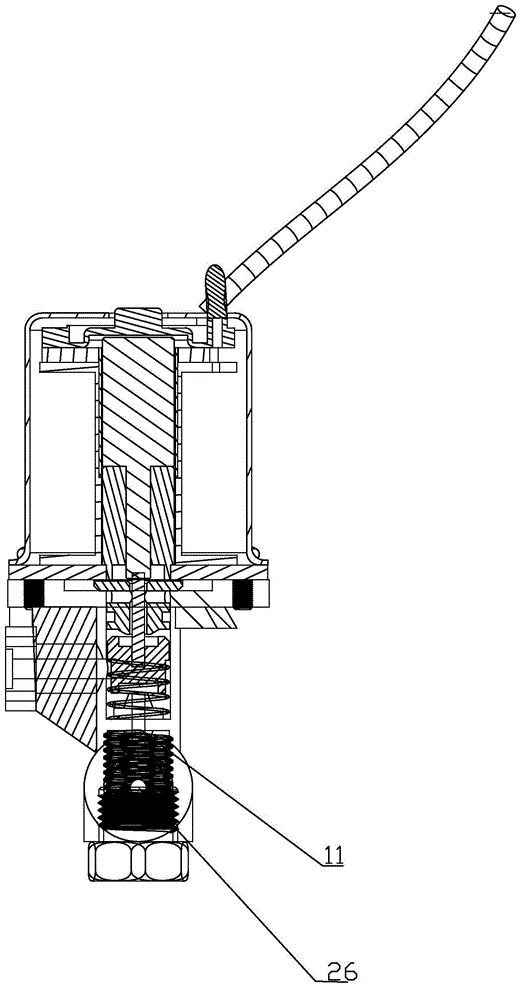

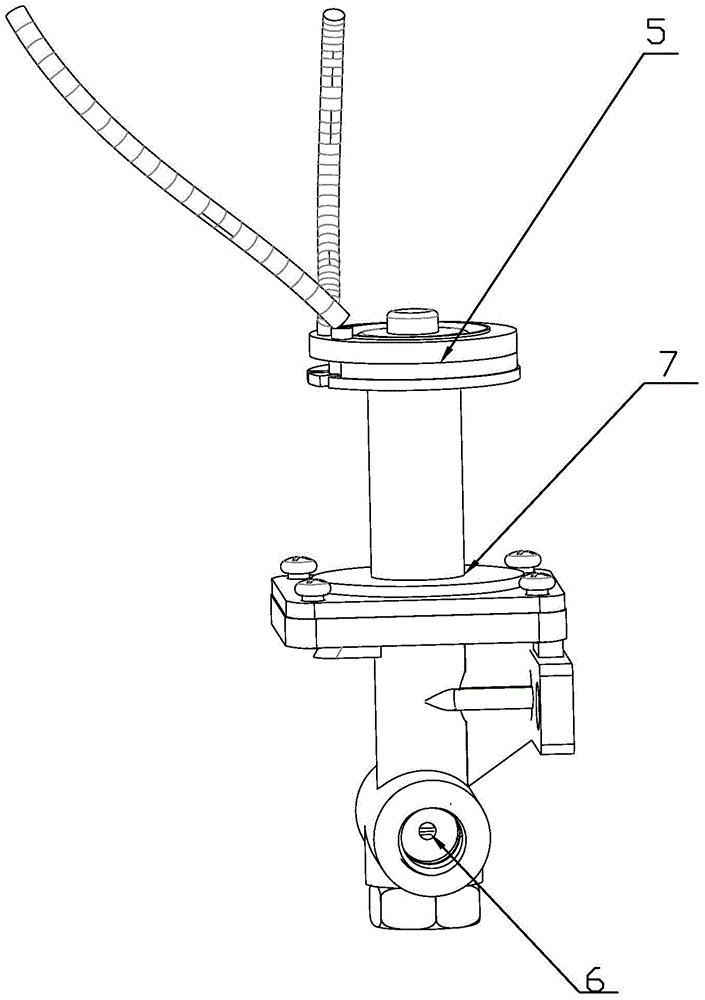

[0025] Such as figure 1 figure 2 Figure 4 Figure 6 As shown, the electromagnetic gas valve includes a valve body (1) and a casing (2) that is movably connected with the valve body (1) above the valve body (1). The inside of the casing (2) is hollowed out to form a first cavity. Electromagnetic components are arranged in the cavity, and the electromagnetic components include a moving iron core (3), a static iron core (4) and an electric drive unit (5). The electric drive unit (5) is a common electric power generating device similar to a motor. The body (1) is provided with a number of inlet holes (6) for the gas to enter the valve body (1), the valve body (1) and the shell (2) are connected with a socket (7), and the static iron core (4) Fixed in the second cavity, a moving iron core (3) is arranged at intervals above the static iron core (4) in the second cavity, and the static iron core (4) is provided with a through hole (8). One end of the iron core (3) is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com