Electromagnetic valve with fluid flow regulation function

A fluid flow and solenoid valve technology, applied in the field of solenoid valves, can solve problems such as the inability to adjust and control fluid flow in real time, and achieve the effects of high flow regulation stability and reasonable structure settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

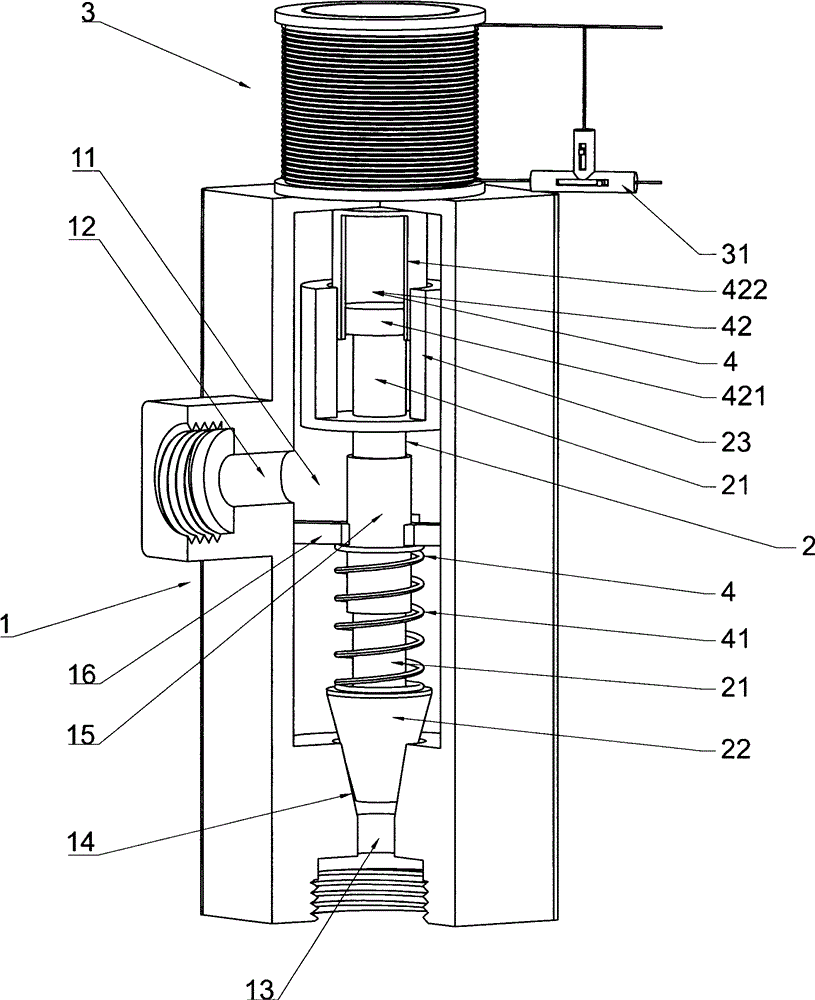

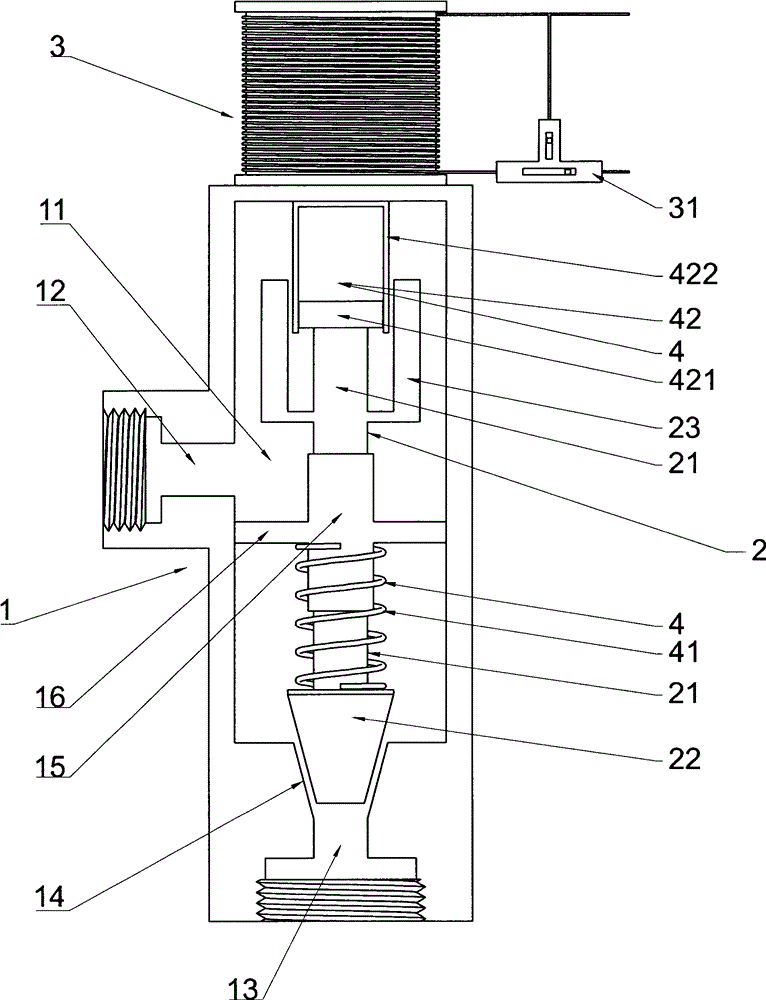

[0029] Such as figure 1 with figure 2 As shown, the solenoid valve with fluid flow regulating function according to the present invention includes a casing 1 and a core body 2. The casing 1 is provided with an inner cavity 11, and the core body 2 is arranged in the inner cavity so that it can move up and down. In the cavity 11, the above two components constitute the main structure of the present invention. It should be noted that, in order to facilitate the installation of the core body 2, the shell 1 can be formed by butting the left and right shells or the upper and lower shells, and of course a combination of multiple shells is not excluded.

[0030] The housing 1 is provided with a first port 12 , a second port 13 and a valve port 14 , the first port 12 communicates with the inner cavity 11 , and the second port 13 communicates with the inner cavity 11 through the valve port 14 . It should be noted that the first port 12 can be provided in multiples, forming a many-to-...

Embodiment 2

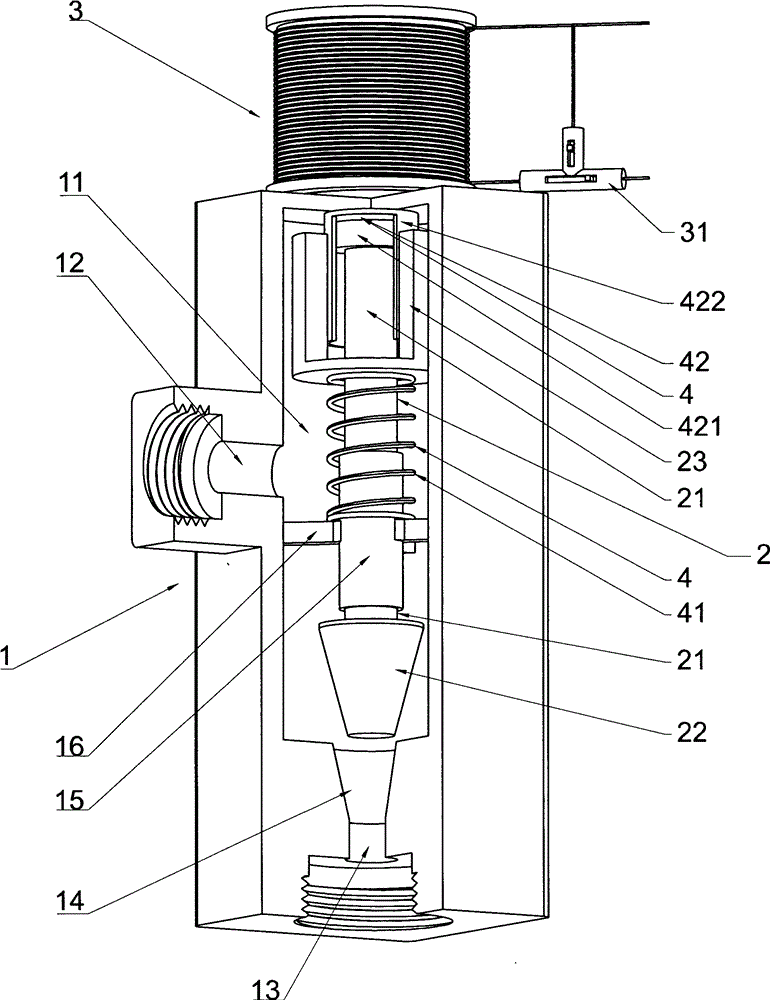

[0039] Such as image 3with Figure 4 As shown, the electromagnet 3 produces a repelling force on the magnetizer 23, and the direction is downward. The piston 421 is arranged at the bottom of the cylinder shell 422. The rebound force is due to the thin gas in the cylinder shell 422 after the piston 421 is pulled. The piston 421 is generated by the fluid outside the cylinder shell 422 or the atmospheric pressure. Of course, a fully sealed cylinder shell 422 can also be used. At this time, the rebound force is generated by the piston 421 reversely compressing the gas in the cylinder shell 422. The rebound force The direction is upward; the spring 41 is a compression spring, which is sleeved outside the pillar 21, and one end is supported by the support member 16, and the other end is supported by the magnetizer 23. The rebound force is generated by the compression of the spring 41, and the direction is upward.

[0040] The working principle of this embodiment is that after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com