Tight armature winding of starter

A compact, winding technology, applied in the direction of windings, electromechanical devices, electric components, etc., can solve the problems affecting the use of the starter, the loose copper wire windings, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

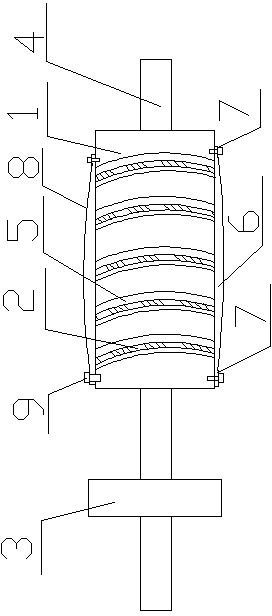

[0010] Such as figure 1 It is a structural schematic diagram of the present invention, a compact starter armature winding, including an iron core 1, a copper wire winding 2, a commutator 3 and an armature shaft 4, the iron core 1 is sleeved on the armature shaft 4, and the iron core 1 The front end is provided with a commutator 3 and the commutator 3 is sleeved on the iron core 1. The iron core 1 is provided with several slots 5 that can accommodate the copper wire winding 2. The slots 5 of the iron core 1 are provided with copper wires. The winding 2, the copper wire winding 2 is provided with a pressure plate 6. Preferably, the pressure plate 6 includes two base surfaces 7 and an arc surface 8 , and the two base surfaces 7 are connected to the iron core 1 through bolts 9 .

[0011] The copper wire winding 2 on the iron core 1 of the present invention is arranged in the slot 5 on the iron core 1, and a pressing plate 6 is also arranged on it, so as to prevent the copper wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com