Washing machine water level sensor element shear foot fixing device

A water level sensor and fixing device technology, which is applied in the field of mechanical equipment, can solve problems such as difficult welding, low welding efficiency, and difficult positioning, and achieve the effects of convenient positioning welding, novel structure, and improved welding quality and welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing by embodiment:

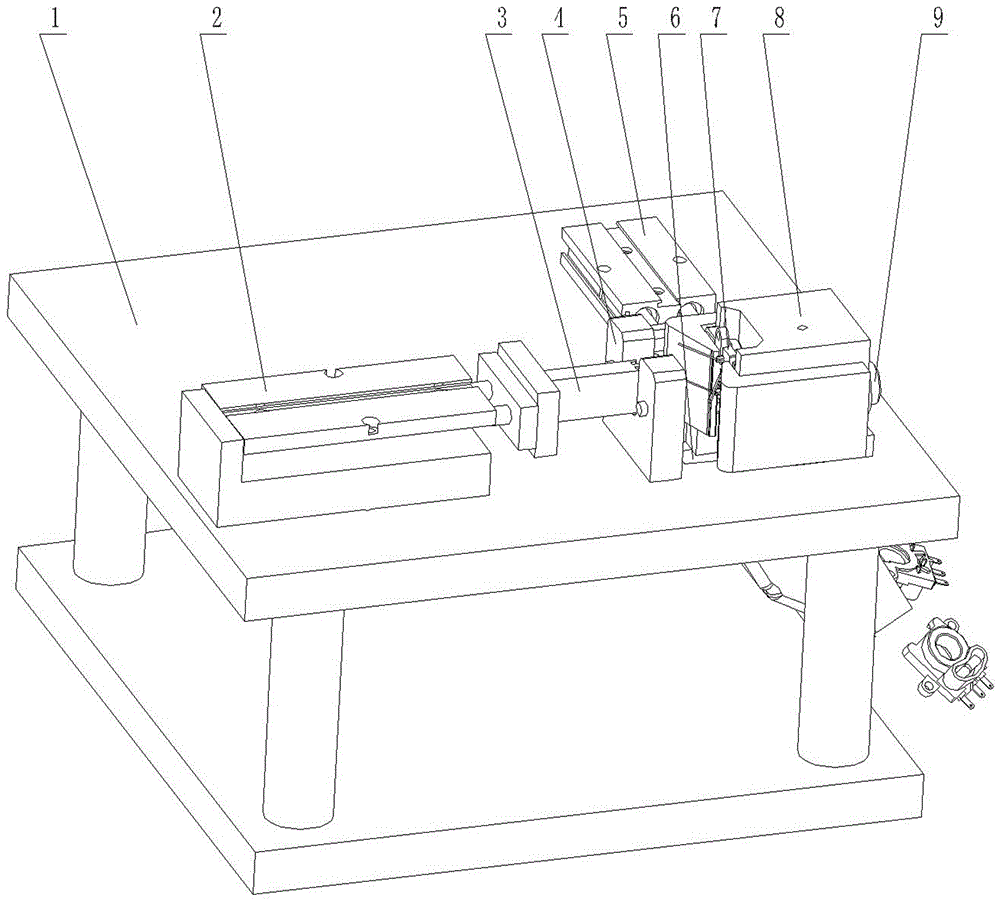

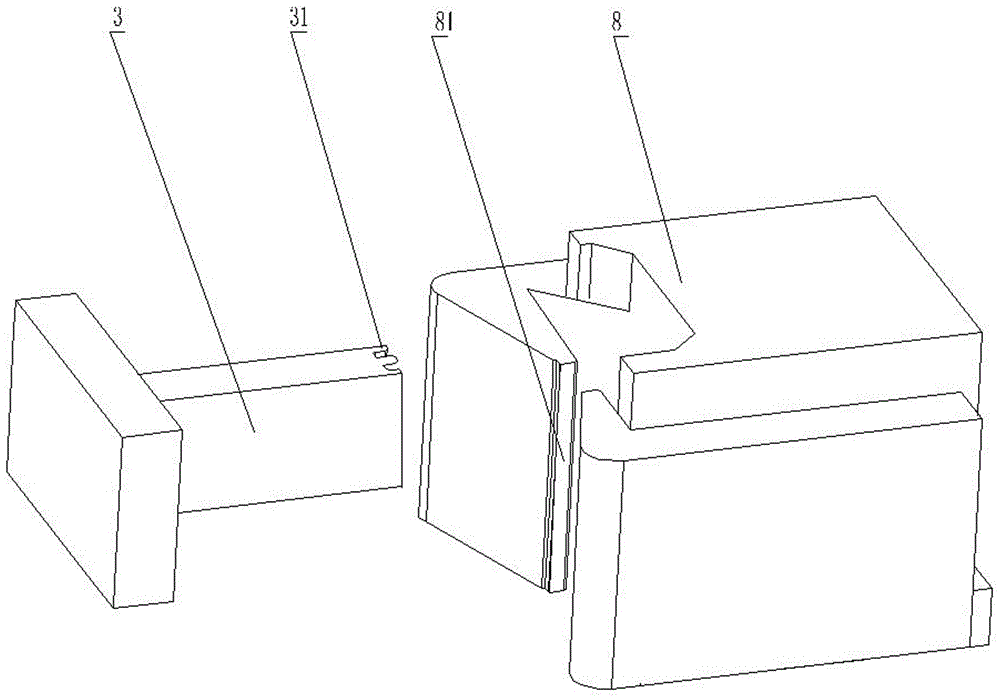

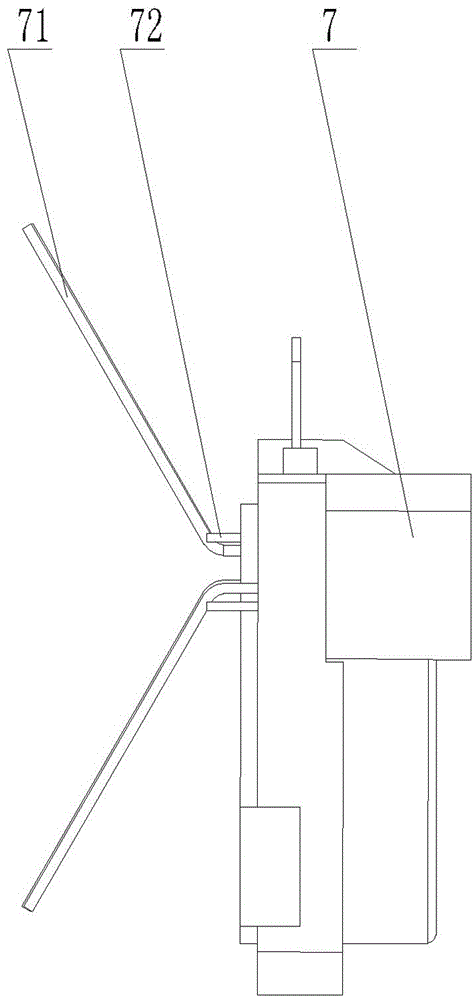

[0012] Such as figure 1 and figure 2 As shown, a kind of washing machine water level sensor element cutting foot fixing device of the present invention, it comprises worktable 1, is provided with punching seat 8 and punching rod 3 driven by punching rod cylinder 2 on working table 1, punching seat 8 has punching The knife edge 81 is characterized in that the above-mentioned punch seat 8 is C-shaped, a pair of punching knife edges 81 are wedge-shaped, the workpiece 7 is put in from the C-shaped hollow, the punching blade 31 at the top of the punch rod 3 is E-shaped, and its two sides are cut off. Blade, the center is a shaping head, and the punch rod 3 is also provided with a bracket 4, and the bottom of the C-shaped hollow of the above-mentioned punch seat 8 is also provided with a backing plate 6 driven by a discharge cylinder 5.

[0013] Such as figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com