Patents

Literature

50results about How to "Convenient welding positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

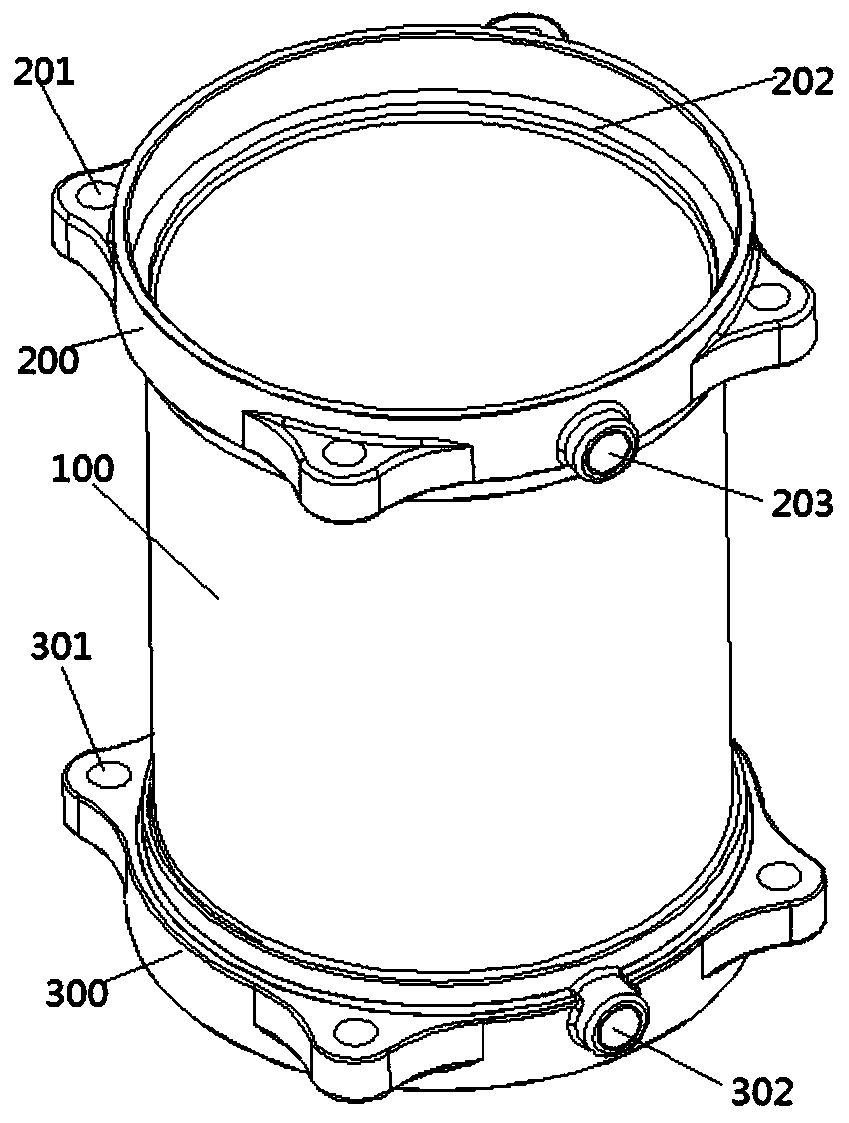

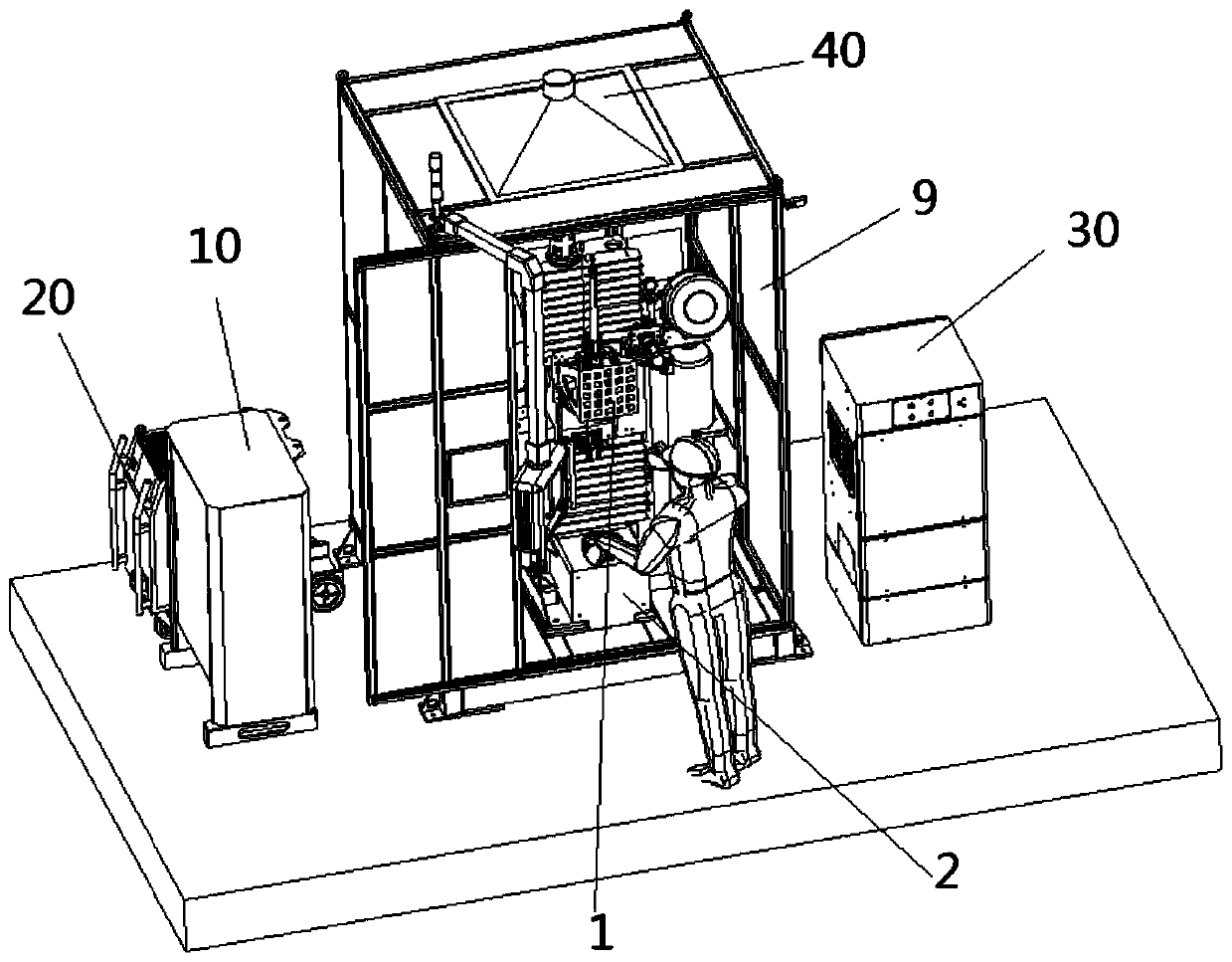

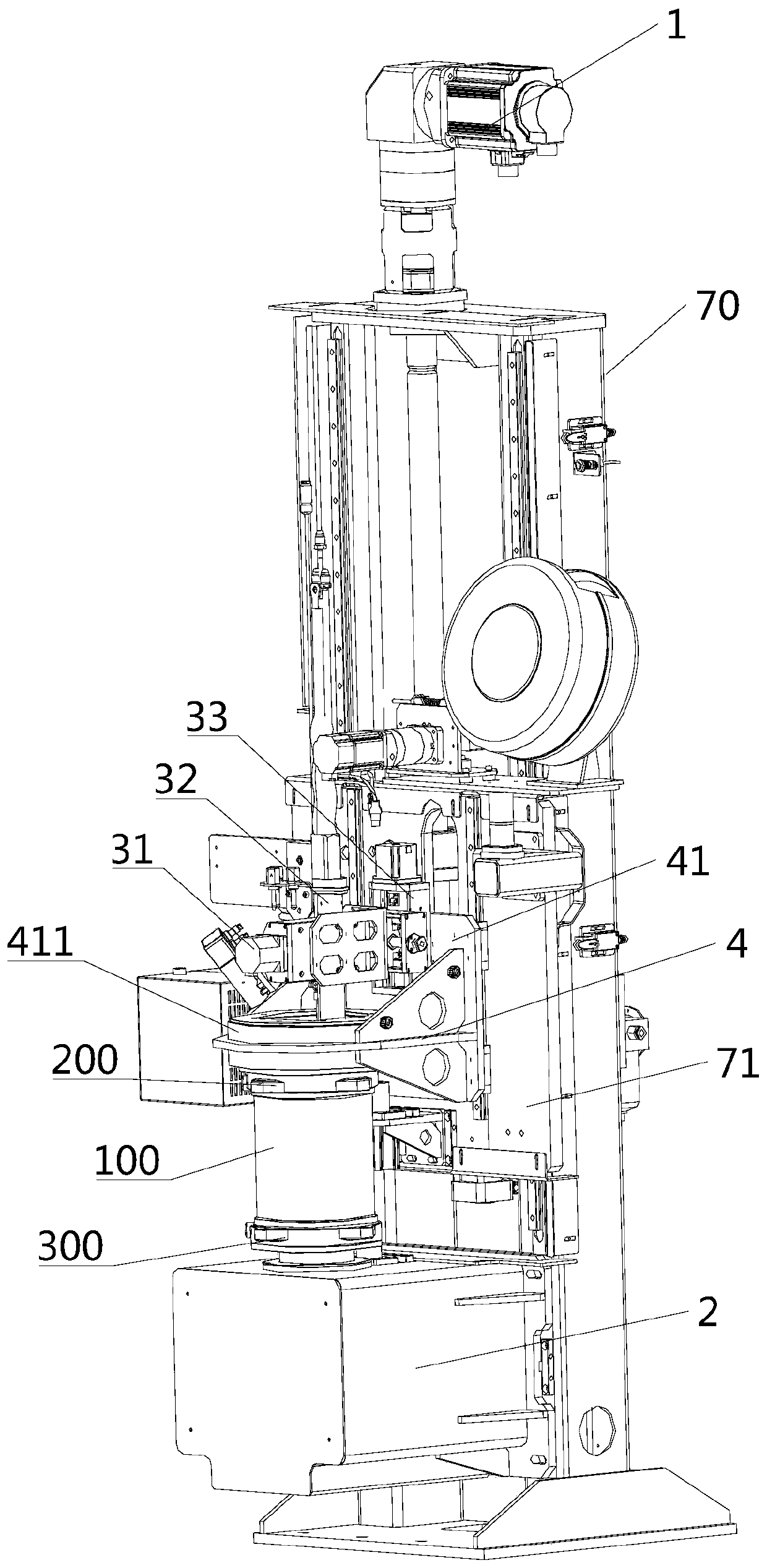

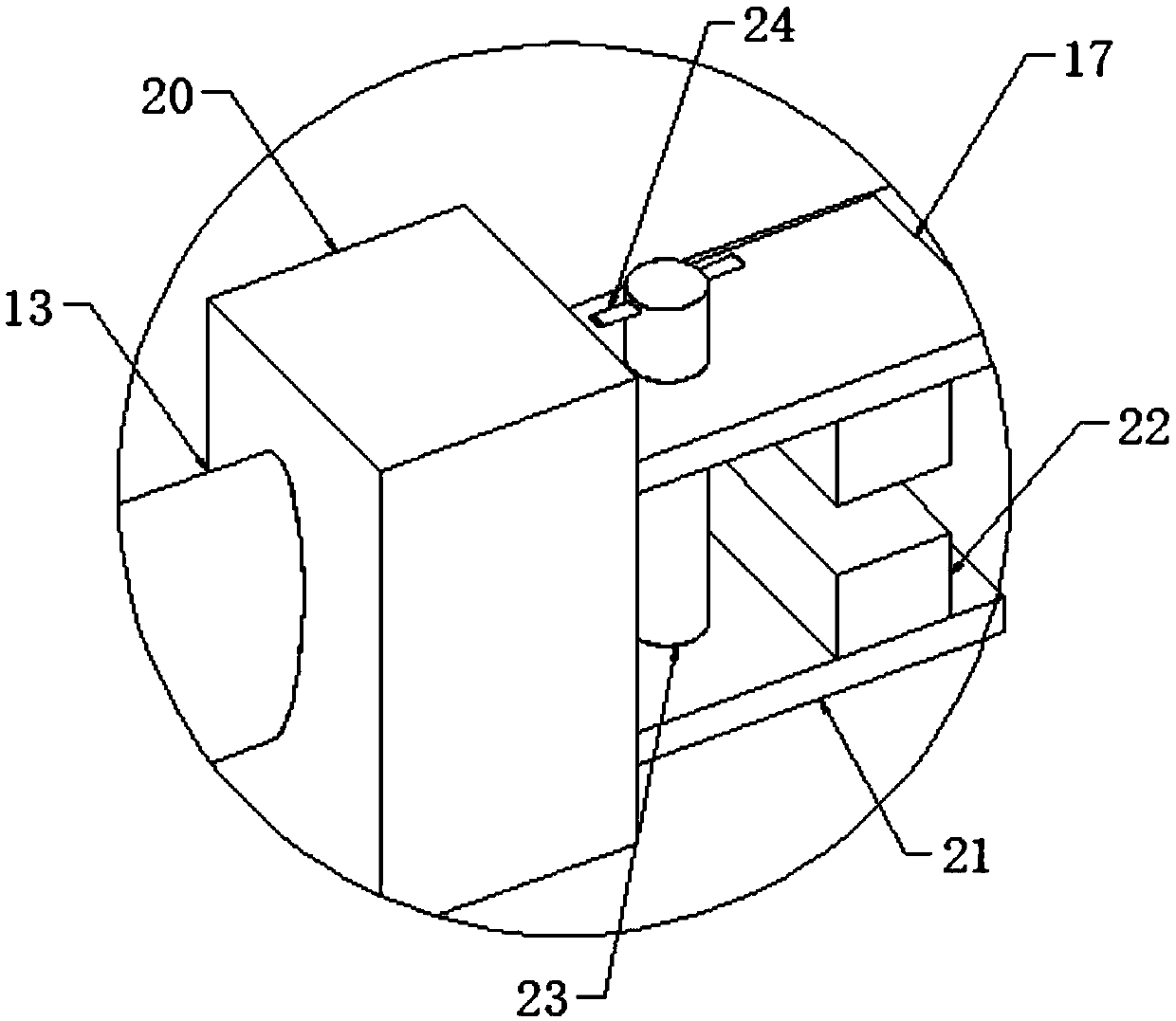

Positioning device, welding system and welding method

PendingCN111347208AConvenient welding positioningAvoid misalignmentWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWeld seam

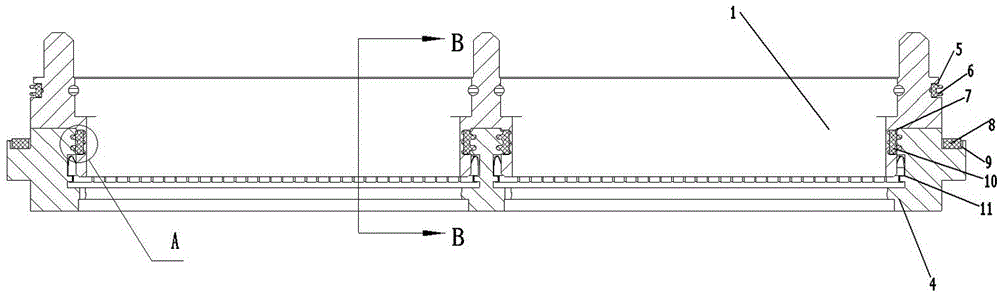

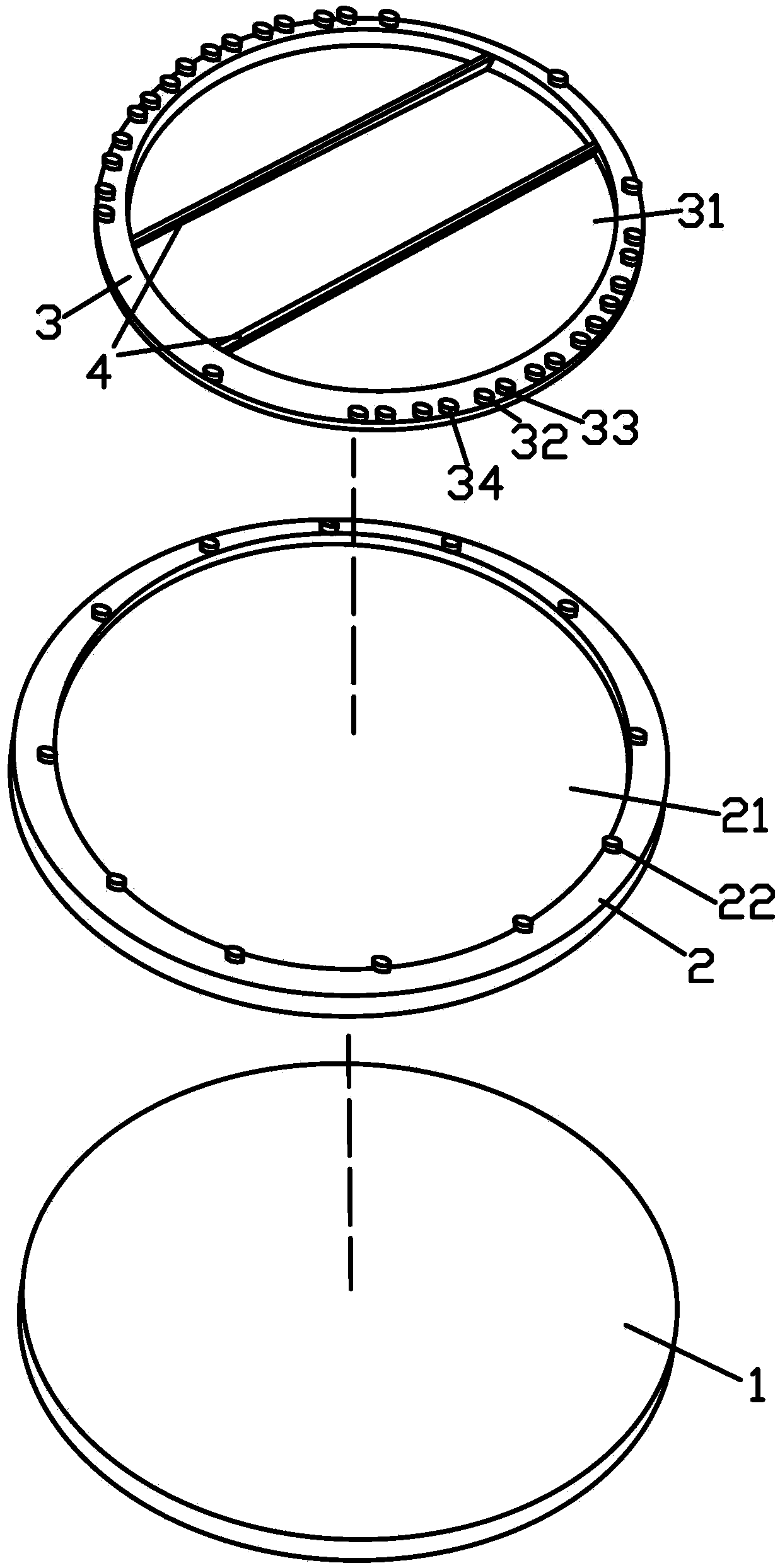

The invention discloses a positioning device, a welding system and a welding method. The positioning device comprises a supporting table used for supporting a workpiece to be welded, a pressing mechanism mounted above the supporting table and a driving mechanism used for driving the pressing mechanism to move close to or away from the supporting table, the positioning device further comprises a first flange positioning device and a second flange positioning device mounted between the pressing mechanism and the supporting table in a spaced manner in the up and down direction, compared with theprior art, through the first flange positioning device and the second flange positioning device, an upper flange and a lower flange are positioned, it is ensured that after the upper flange and the lower flange are welded, thread holes are opposite, finally, through the pressing mechanism, the positioned upper flange and the positioned lower flange are pressed and fixed to a shell pipe, it is ensured that in the welding process, the flanges and the shell pipe are axially pressed and positioned, the malposition in the welding process is avoided, and positioning welding of an annular welding seam is facilitated.

Owner:HUAHENG WELDING

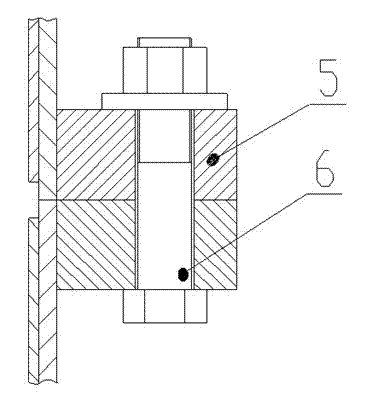

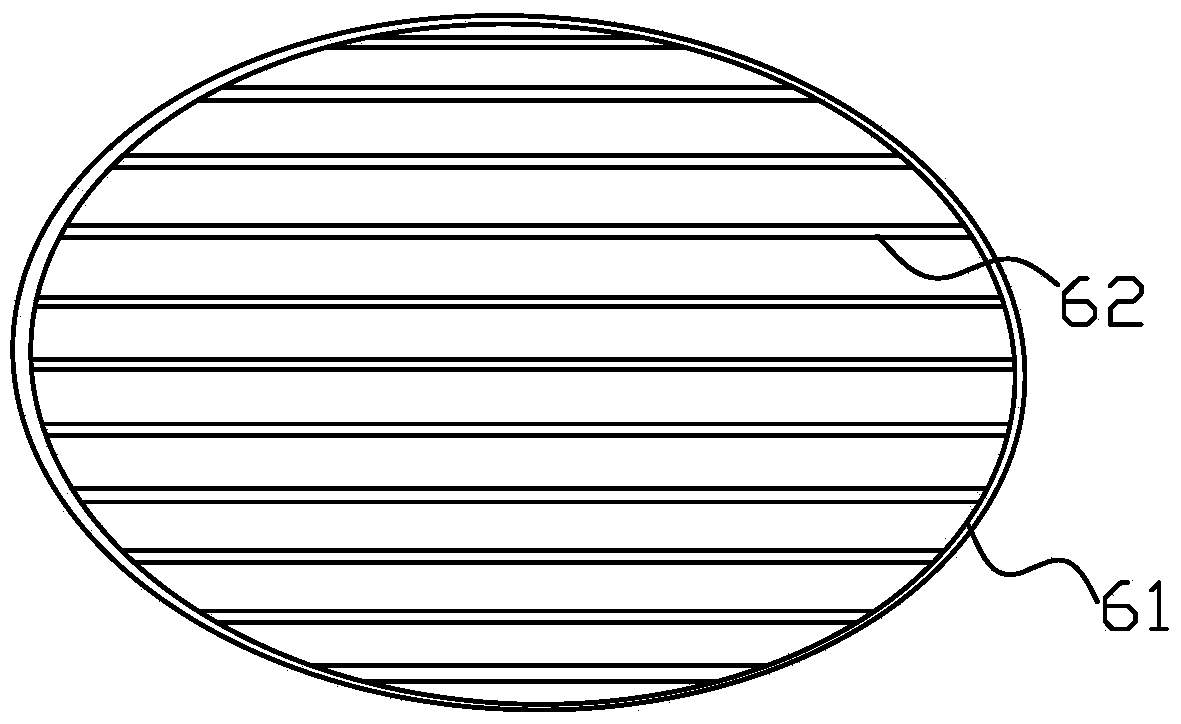

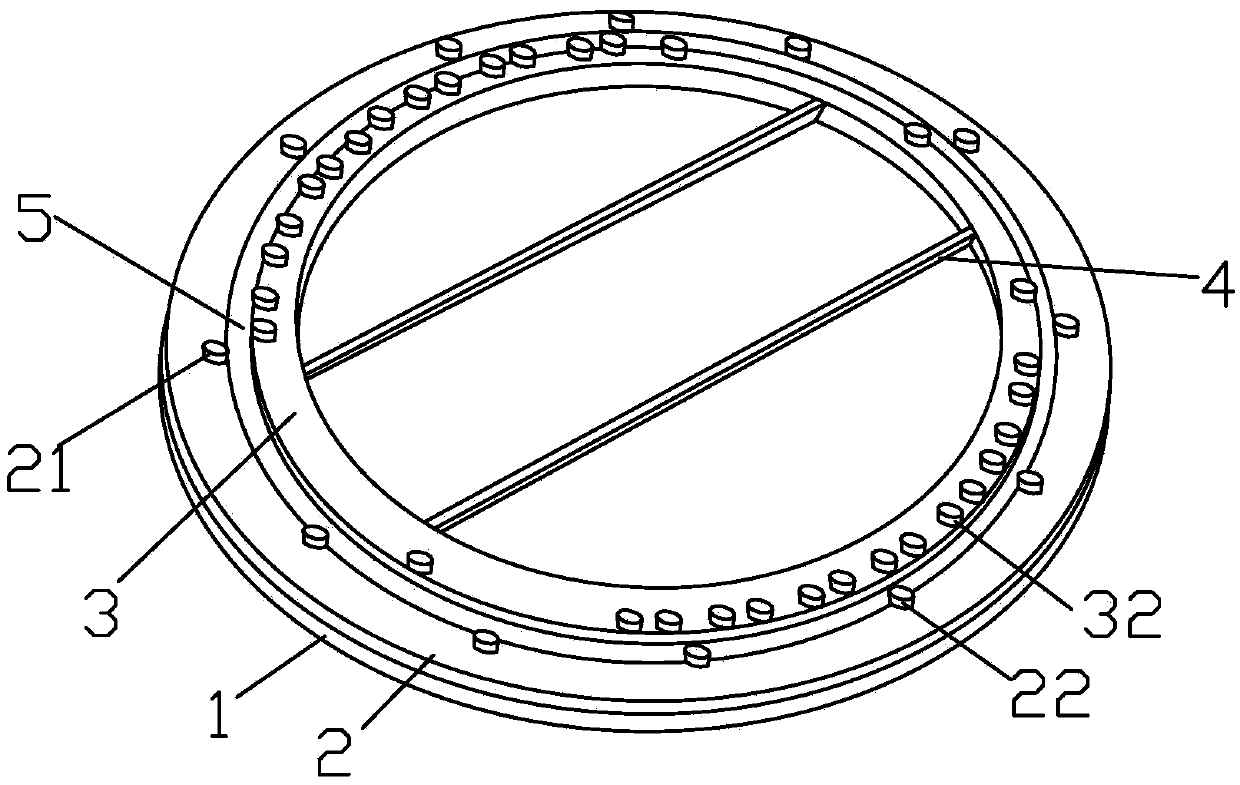

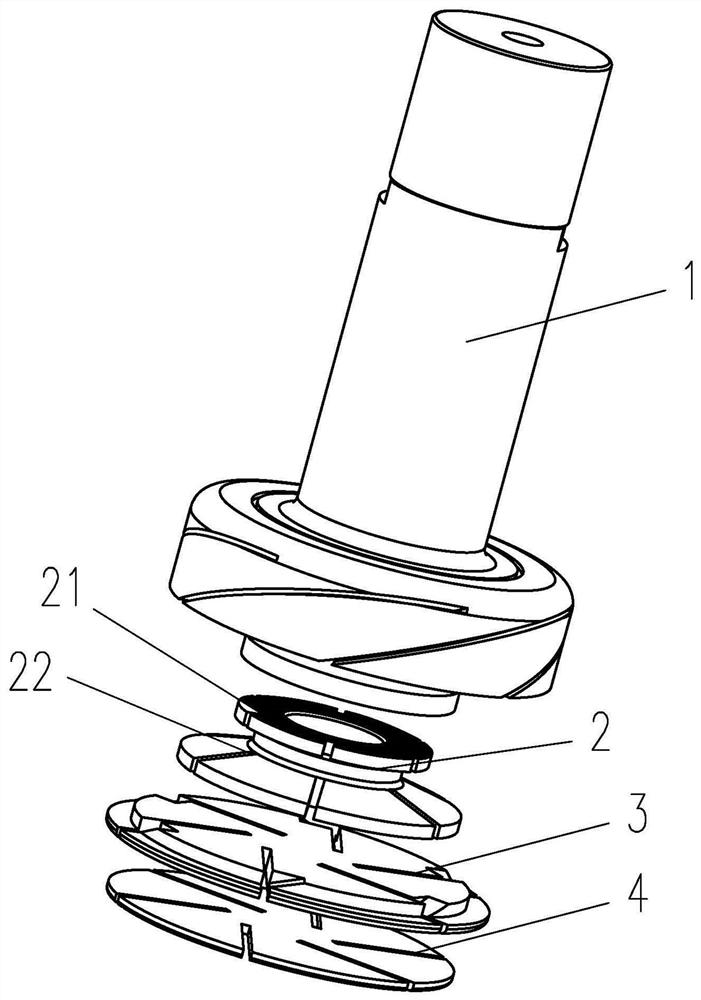

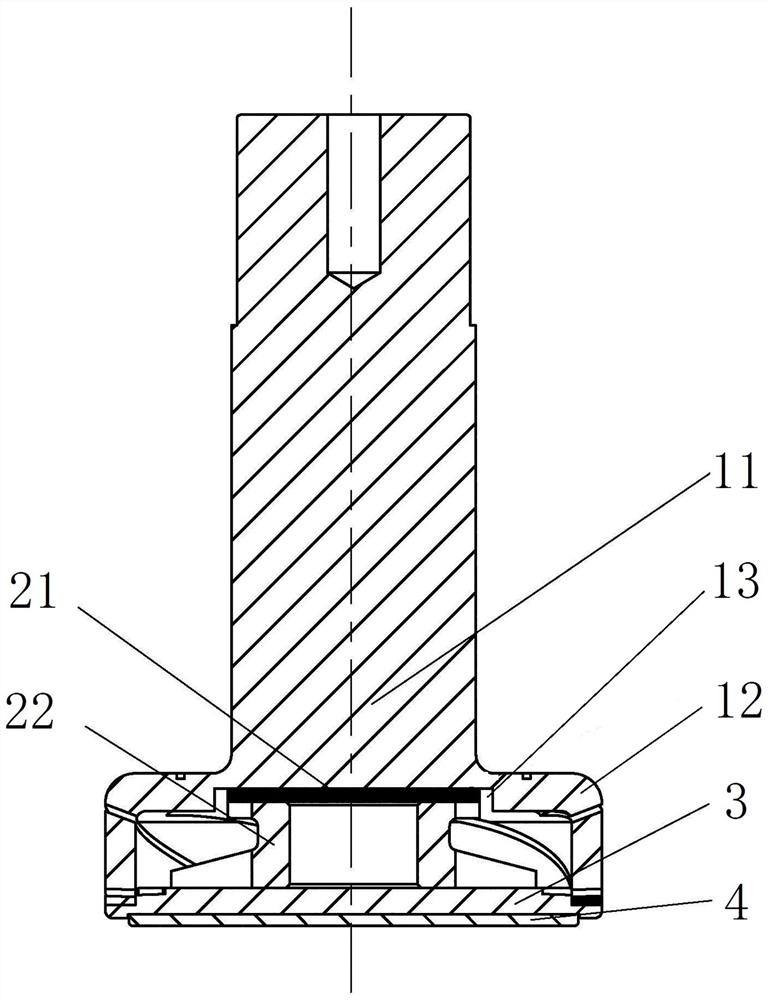

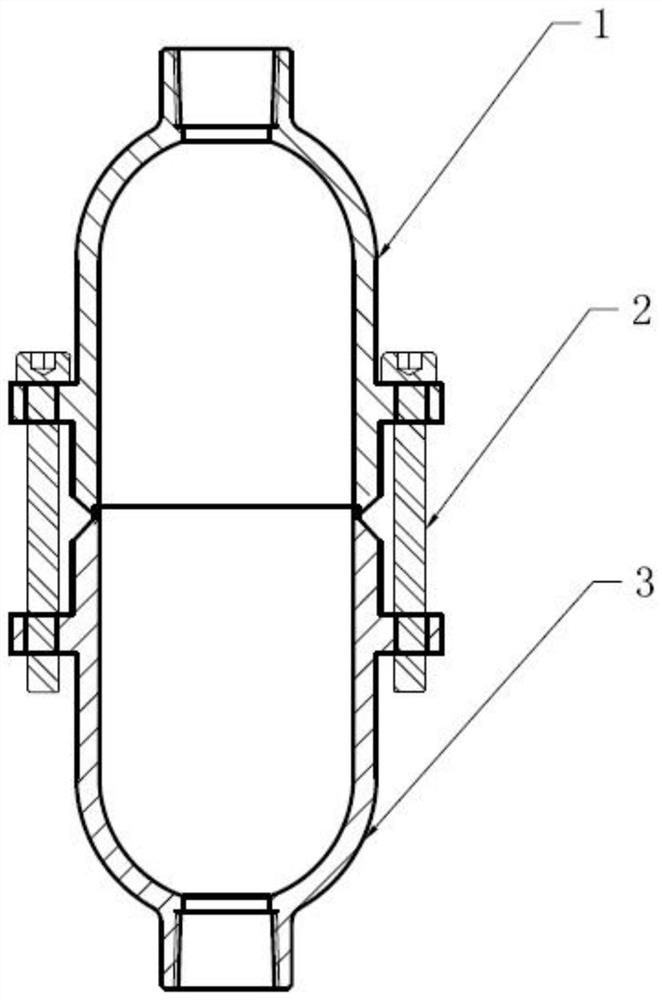

Shielding grounding spring, connector employing same, and connector assembly

ActiveCN104319554AEasy to fixReliable contactCoupling protective earth/shielding arrangementsMechanical engineeringPhysics

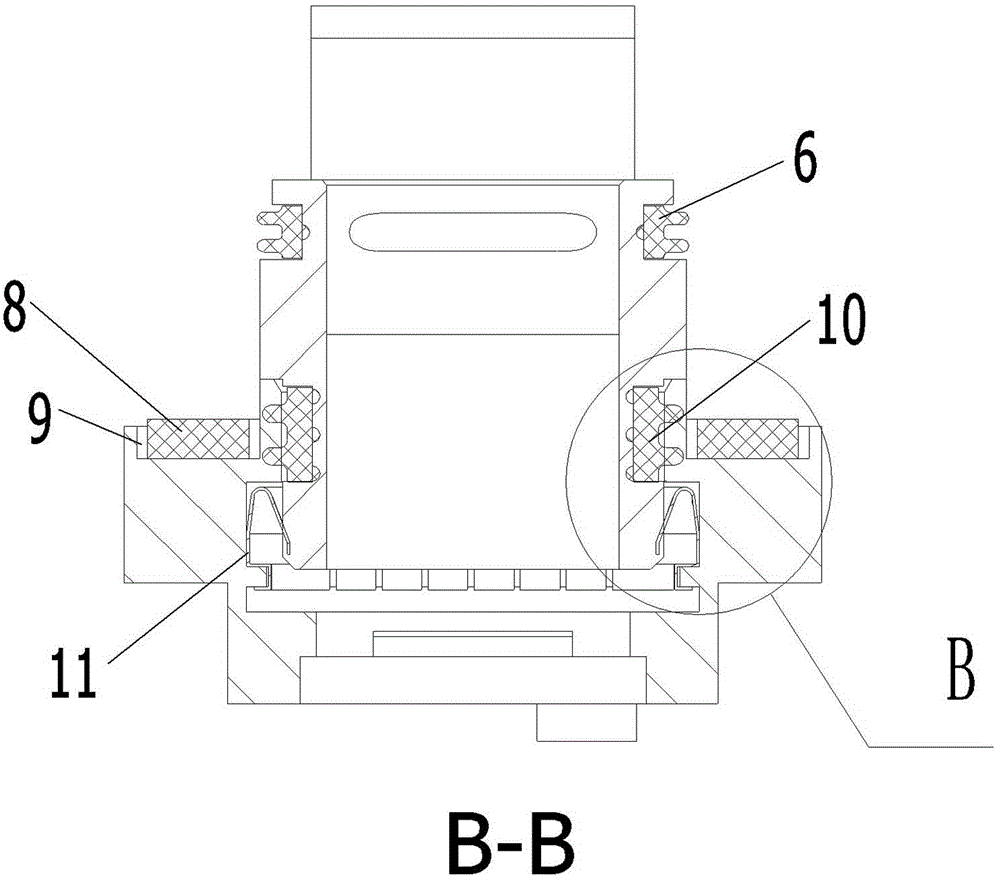

The invention relates to a shielding grounding spring, a connector employing the same, and a connector assembly. The shielding grounding spring comprises an annular body, and the annular body is provided with a grounding spring inner hole, wherein the grounding spring inner hole is used for the inserting of a housing of a corresponding adaptive connector from the front to the back. The annular body is provided with a plurality of spring pieces which are arranged along the peripheral direction at intervals, face the center of the grounding spring inner hole to extend in a suspension manner and are used for the sliding top-pressure cooperation with the housing of the adaptive connector. The annular body is provided with a plurality of U-shaped clamping pieces which are arranged at intervals along the peripheral direction. Each U-shaped clamping piece is provided with a clamping mouth which faces the direction departed from the center of the grounding spring inner hole. The invention also provides the shielding grounding spring which can be reliably fixed with the housing of the connector, the connector employing the shielding grounding spring, and the connector assembly.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

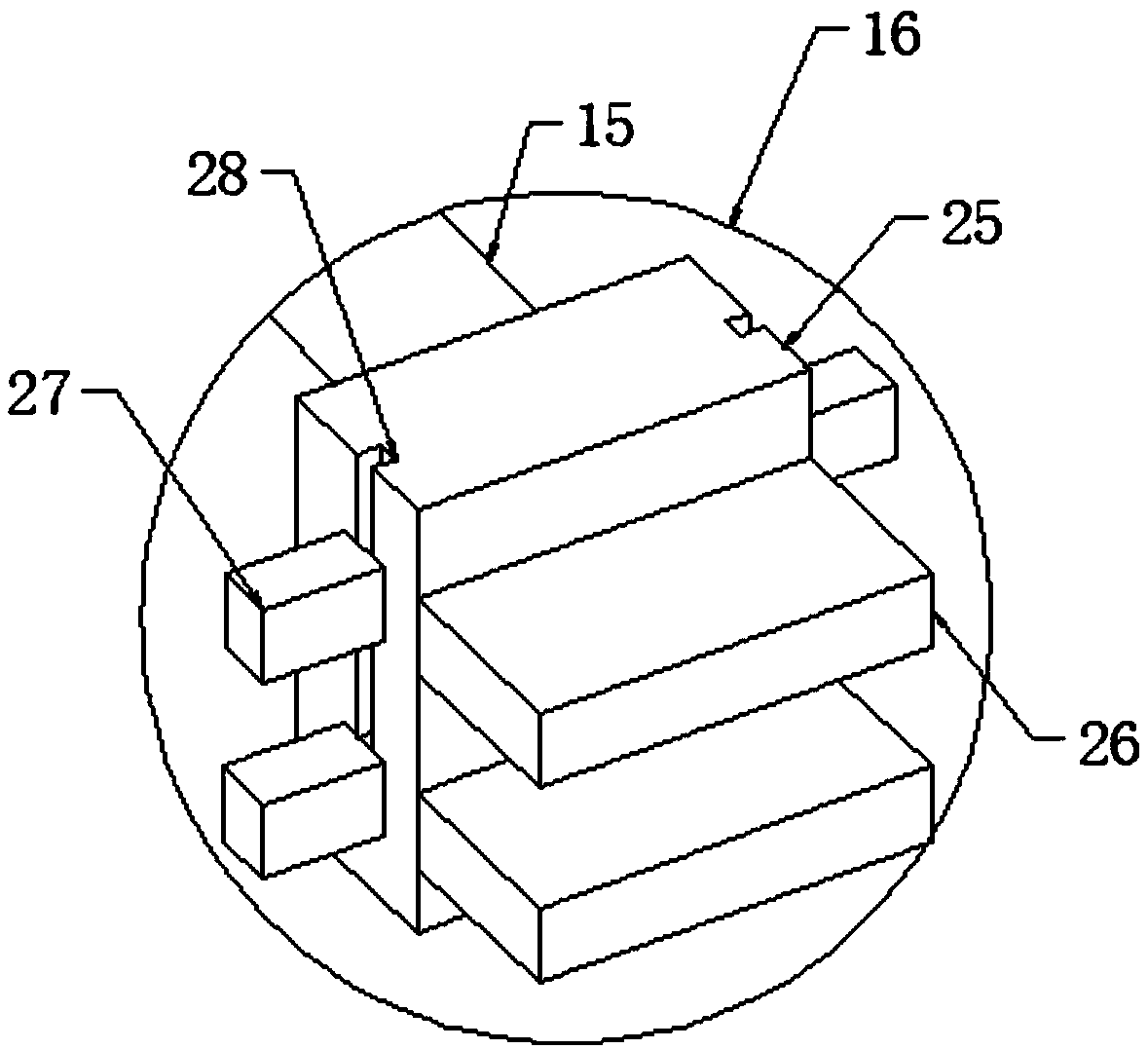

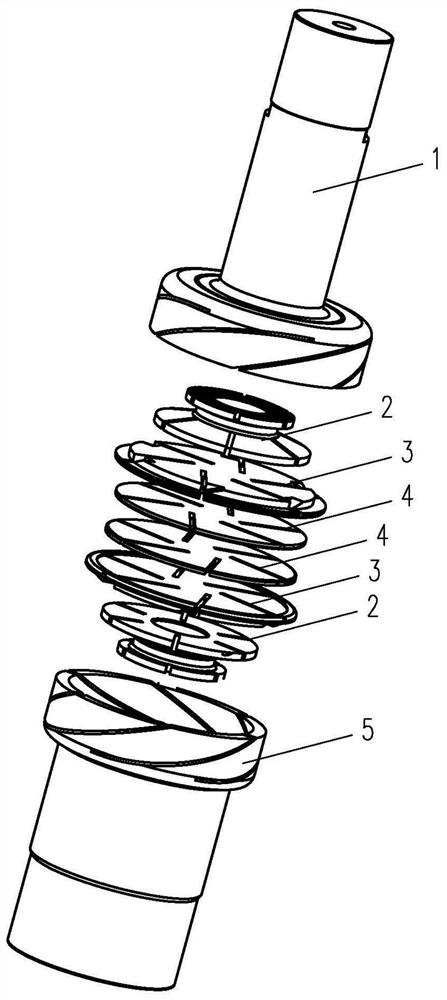

High-strength motor shaft

InactiveCN104154105AConvenient welding positioningGuaranteed accuracyShaftsStress concentrationHigh intensity

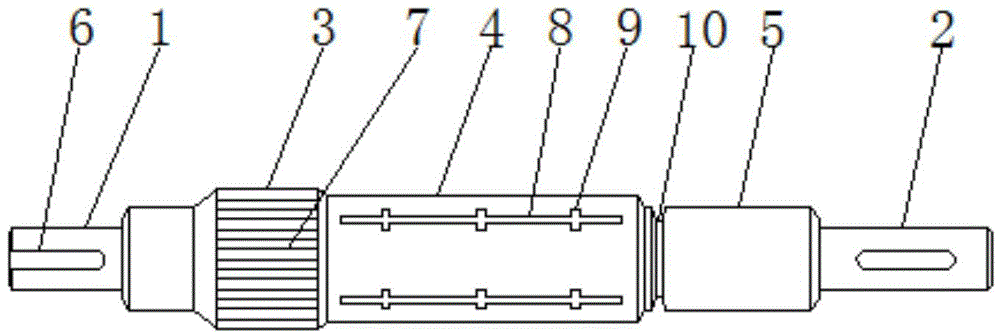

The invention discloses a high-strength motor shaft. The high-strength motor shaft comprises a front connection rod and a rear connection rod, wherein a knurled rod, a first polished rod and a second polished rod are sequentially connected between the front connection rod and the rear connection rod; splines are arranged on the outer circle surfaces of the front connection rod and the rear connection rod; the splines on the front connection rod extend to the end side of the front connection rod; straight-line knurls are rolled on the outer circle surface of the knurled rod; a plurality of axial bar grooves are distributed at equal intervals in the outer circle surface of the first polished rod; a plurality of cross-shaped reinforcing groove nodes are distributed on the bar grooves. The high-strength motor shaft is simple and reasonable in structure, convenient to mount and use, small in possibility of skidding in the radial direction in the operation process, relatively good in torsion resistance, capable of conveniently locating and welding rib plates, good in stability and not easy for stress concentration and deformation; the precision of the motor shaft is effectively guaranteed; the service life of the motor shaft is prolonged; the normal operation of the motor is guaranteed.

Owner:池州扬帆微电机有限责任公司

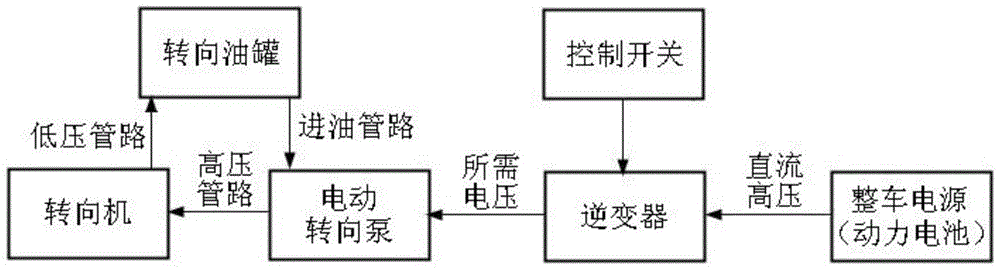

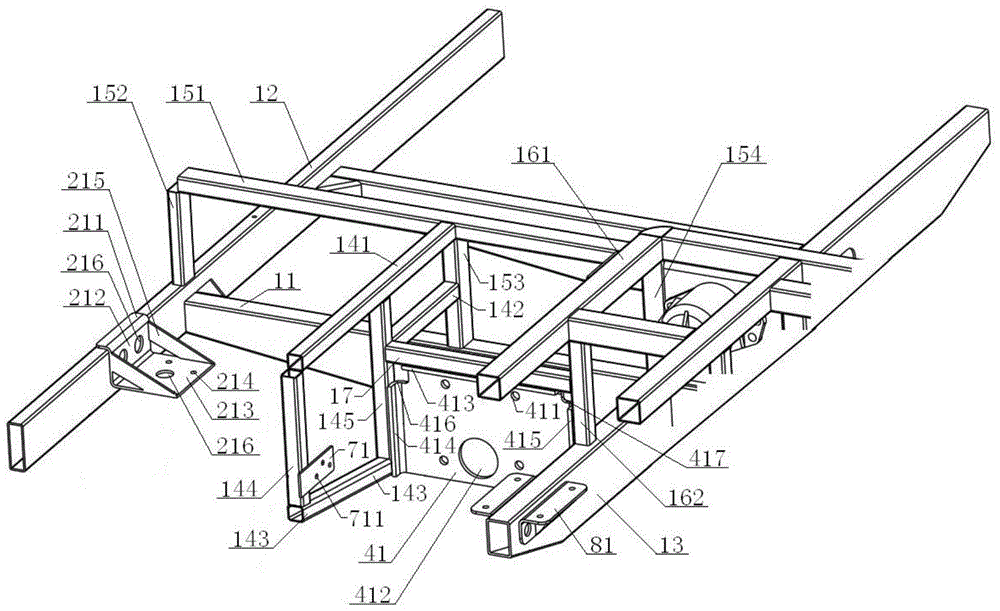

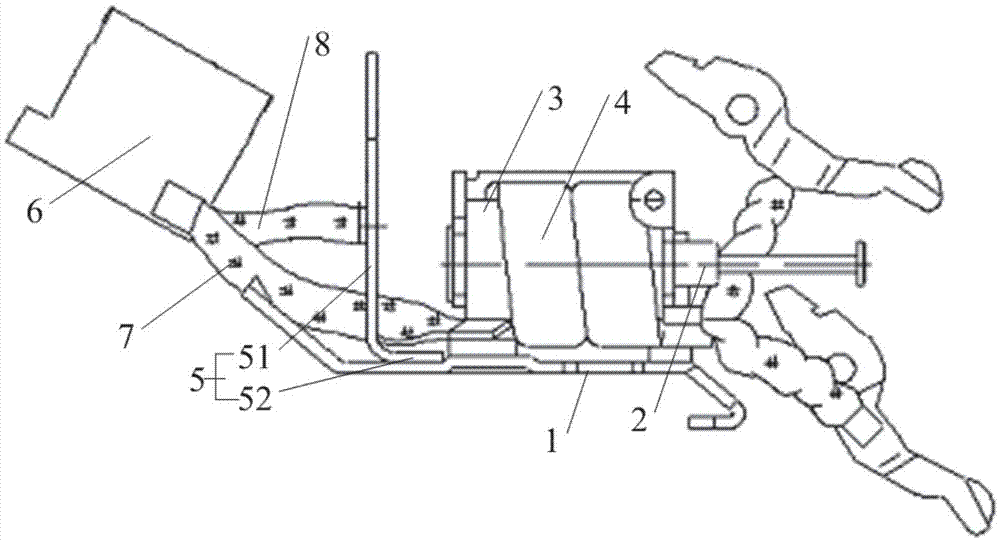

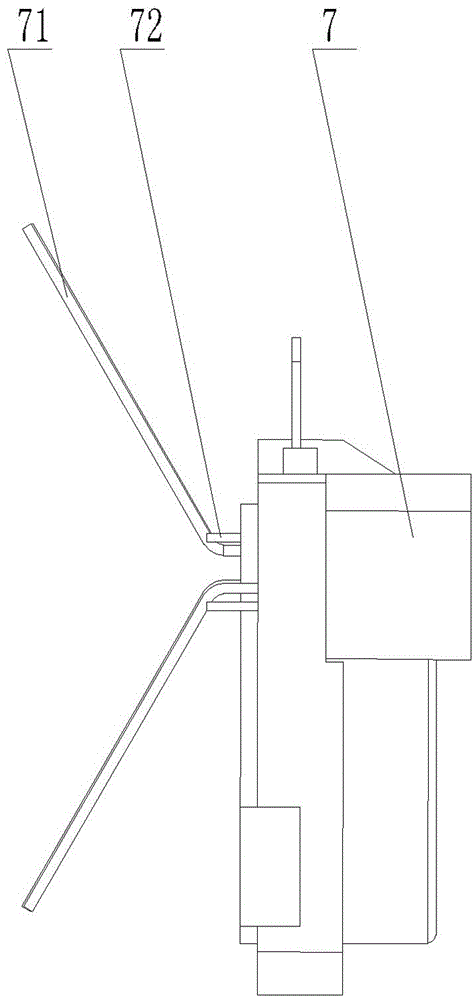

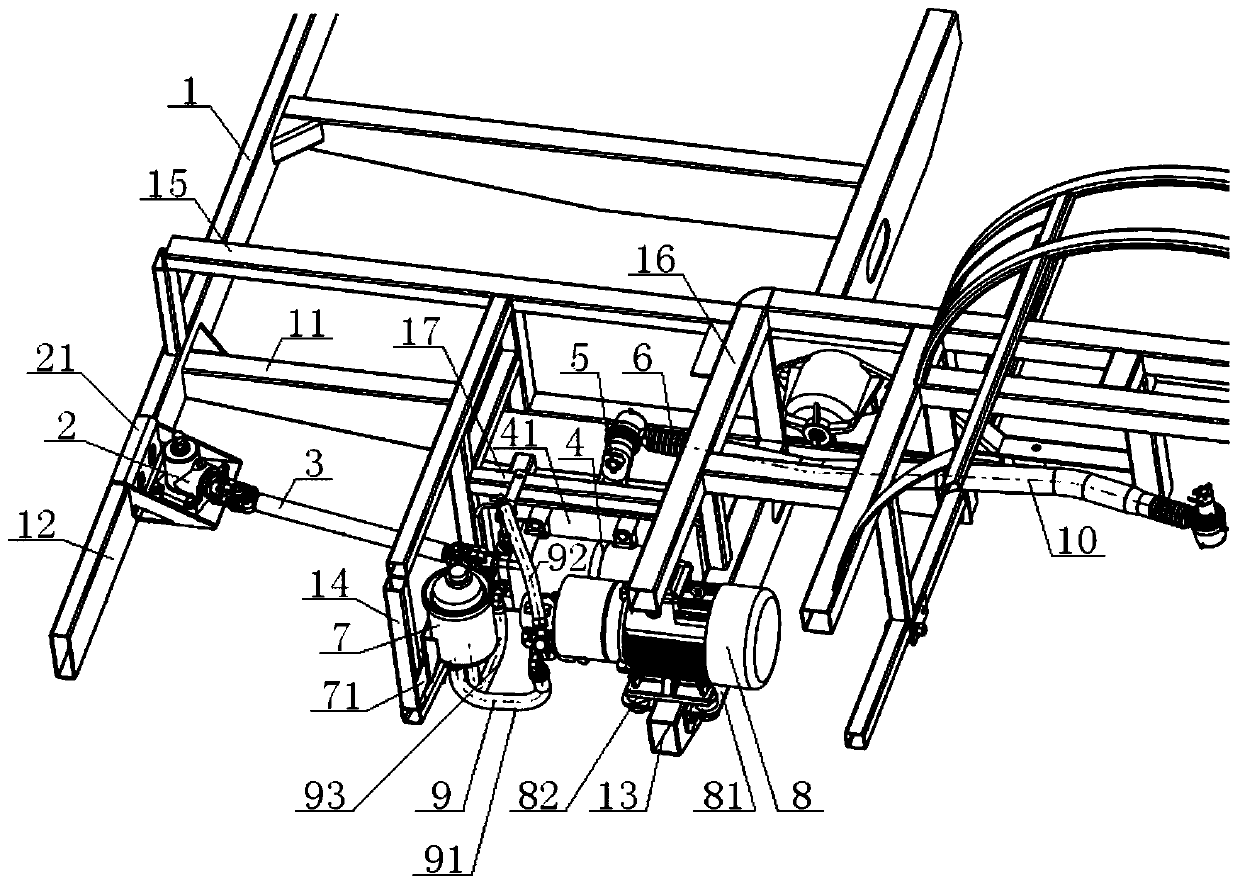

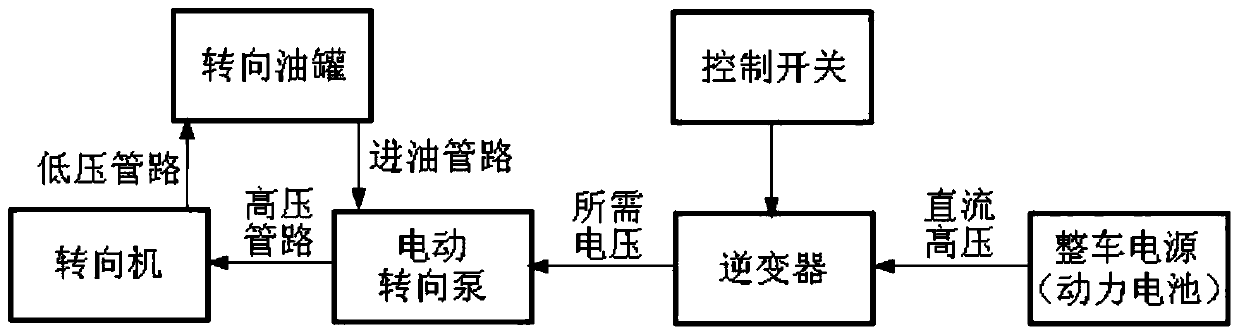

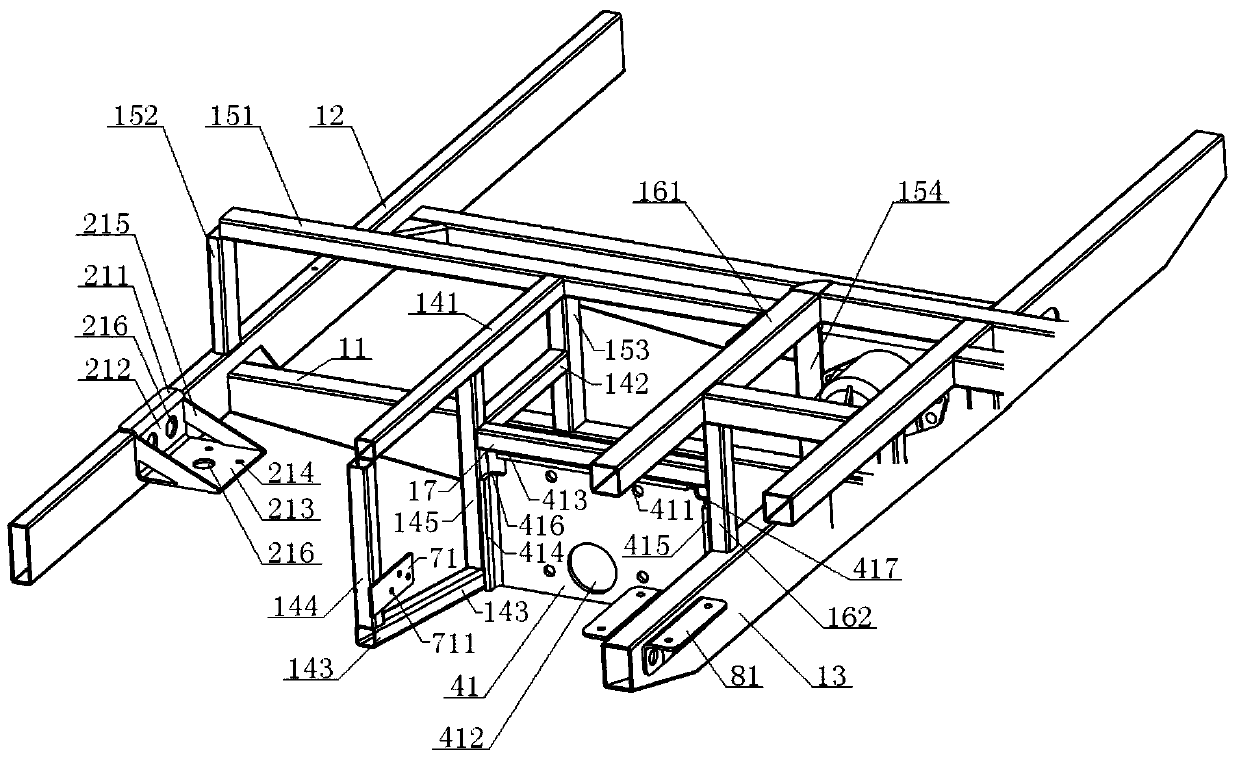

Centralized arrangement type electric hydraulic power steering system for large-scale full-bearing passenger car

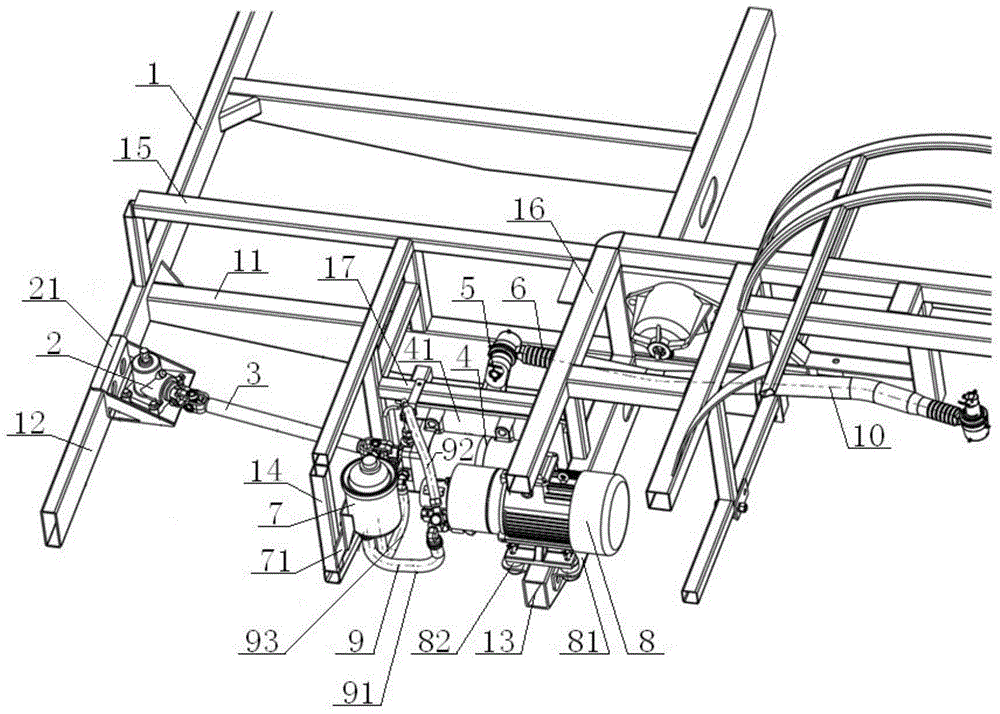

The invention relates to a centralized arrangement type electric hydraulic power steering system for a large-scale full-bearing passenger car. The centralized arrangement type electric hydraulic power steering system comprises a frame system, a steering pull rod system and a steering pipeline system, wherein the frame system comprises a left stringer for a frame, a first beam for the frame, a second beam for the frame, an edge beam framework for the frame, an upper stringer frame for the frame, a rear beam framework for the frame, and an edge stringer for the frame; the steering pull rod system comprises a steering diverter, a steering diverter bracket, a steering intermediate transmission shaft, a steering engine, a steering engine bracket, a steering drop arm and a steering drag rod; the steering pipeline system comprises a steering oil tank, an electric steering pump, the steering engine, an oil inlet pipeline, a high-pressure pipeline and a low-pressure pipeline. The centralized arrangement type electric hydraulic power steering system disclosed by the invention not only is easy to arrange and high in the height of a low drive zone, but also is convenient to assemble and disassemble.

Owner:DONGFENG COMML VEHICLE CO LTD

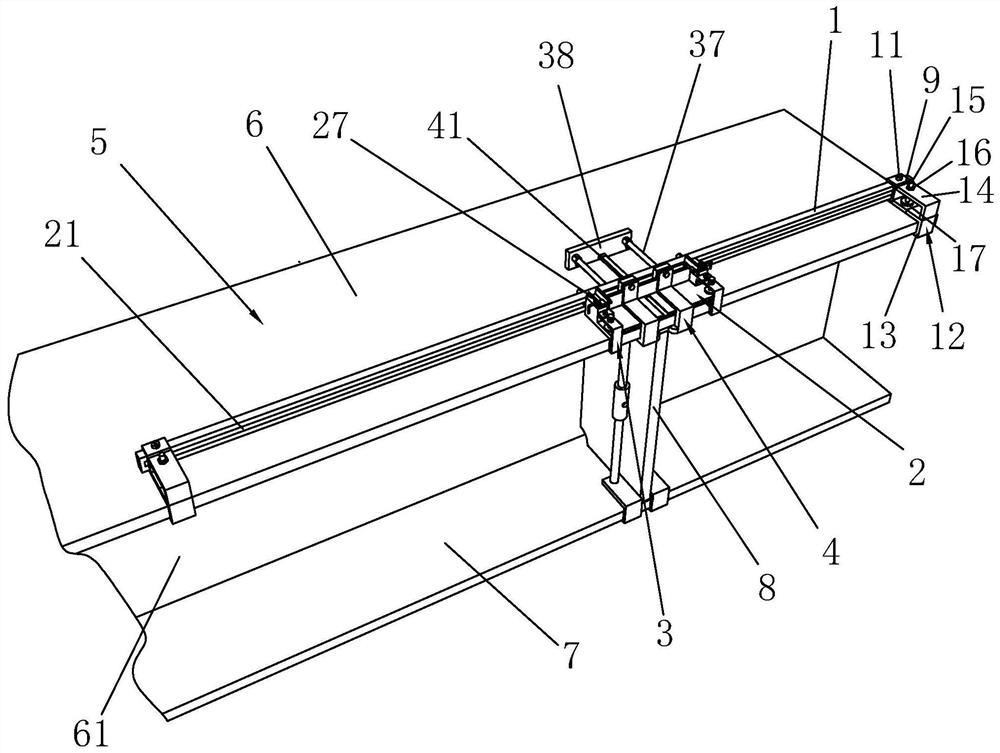

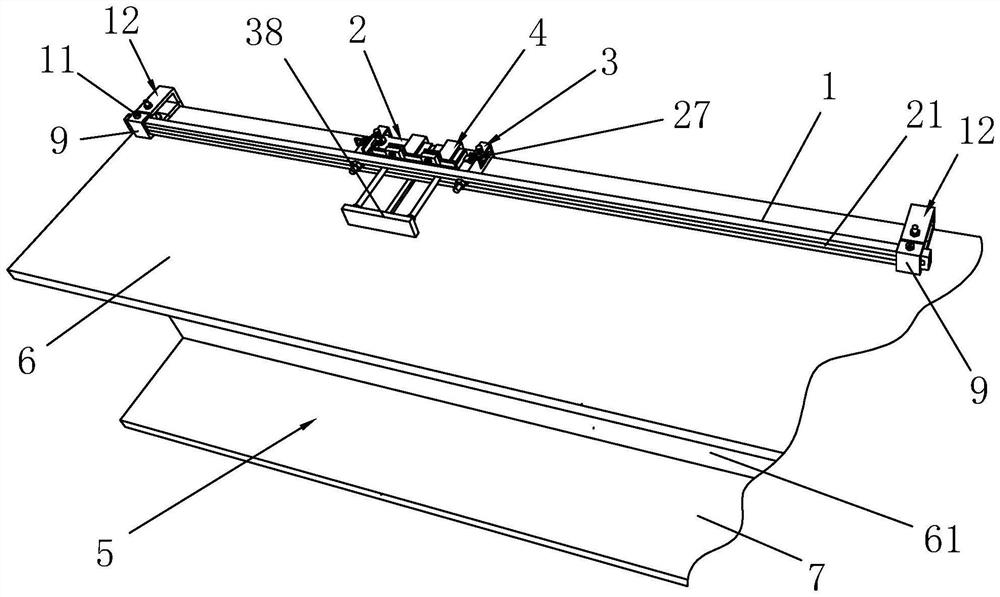

Accurate positioning method for stiffening plate of H-shaped steel component

PendingCN114227107AQuick fixEasy to adjustWelding/cutting auxillary devicesGirdersStructural engineeringIndustrial engineering

The invention discloses a precise positioning method for a stiffening plate of an H-shaped steel component. The precise positioning method comprises the following steps: 1) measuring, marking and carrying out region division; 2) installing a guide slide rail; (3) a movable limiting mechanism is installed, adjusted and positioned; 4) mounting an auxiliary fixing device; and (5) the connecting plates and the H-shaped steel beams are welded and fixed in sequence. The device is simple and reasonable in structural design, high in practicability, clear in principle and simple and convenient to adjust and operate, the H-shaped steel beam is segmented and divided in the length direction according to the length of the guide sliding rail and the actual length of the H-shaped steel beam, and step-by-step welding and positioning of the connecting plate are conducted with the divided segments as units; according to the auxiliary device for welding and fixing the connecting plates, the connecting plates at one division section are welded and installed firstly, after all the connecting plates in the division section are welded and installed, the whole auxiliary device is moved to the next division section, welding and positioning of the connecting plates at other division sections are conducted till welding and fixing of all the connecting plates are completed, the whole installation process is reasonable and scientific, and actual operation is convenient.

Owner:浙江中南绿建科技集团有限公司 +1

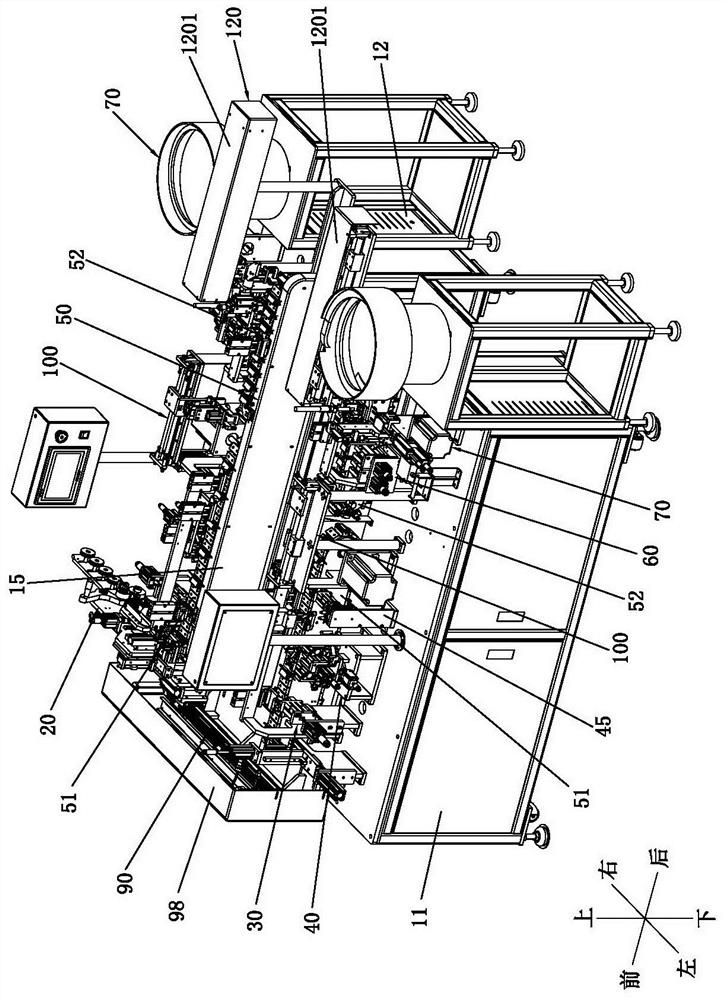

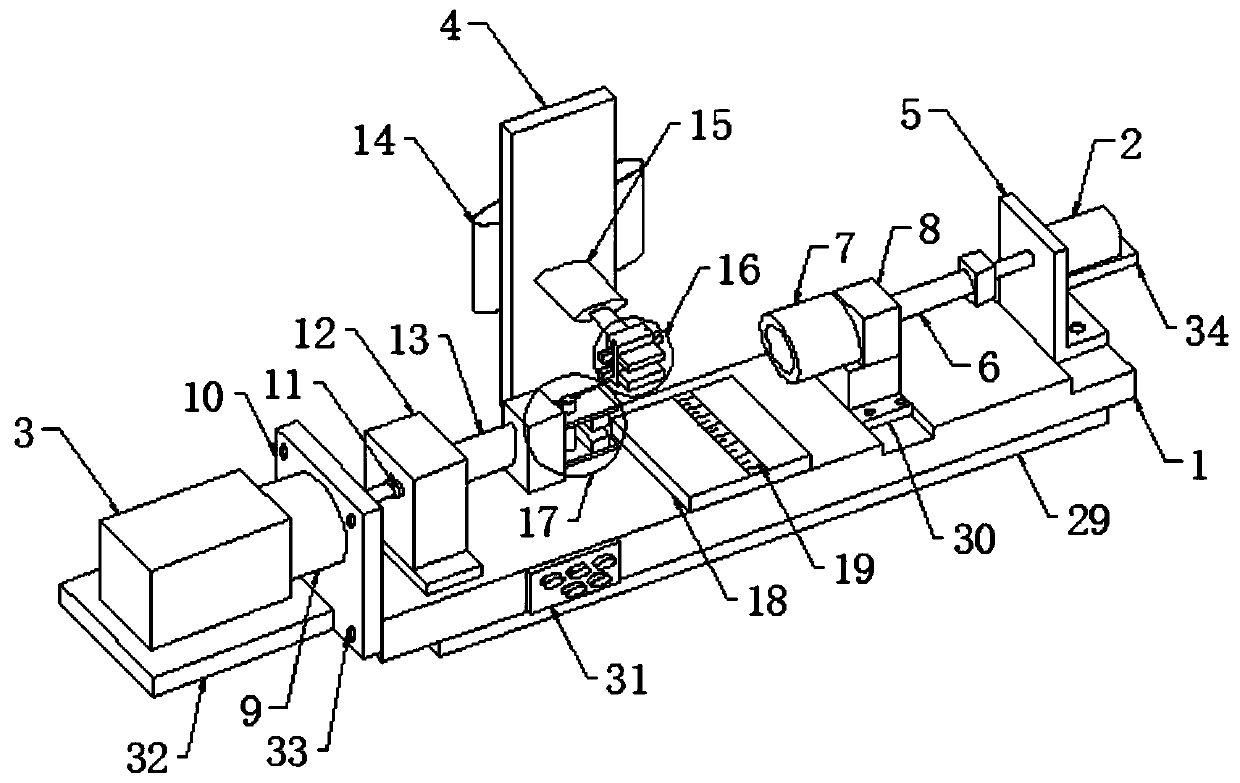

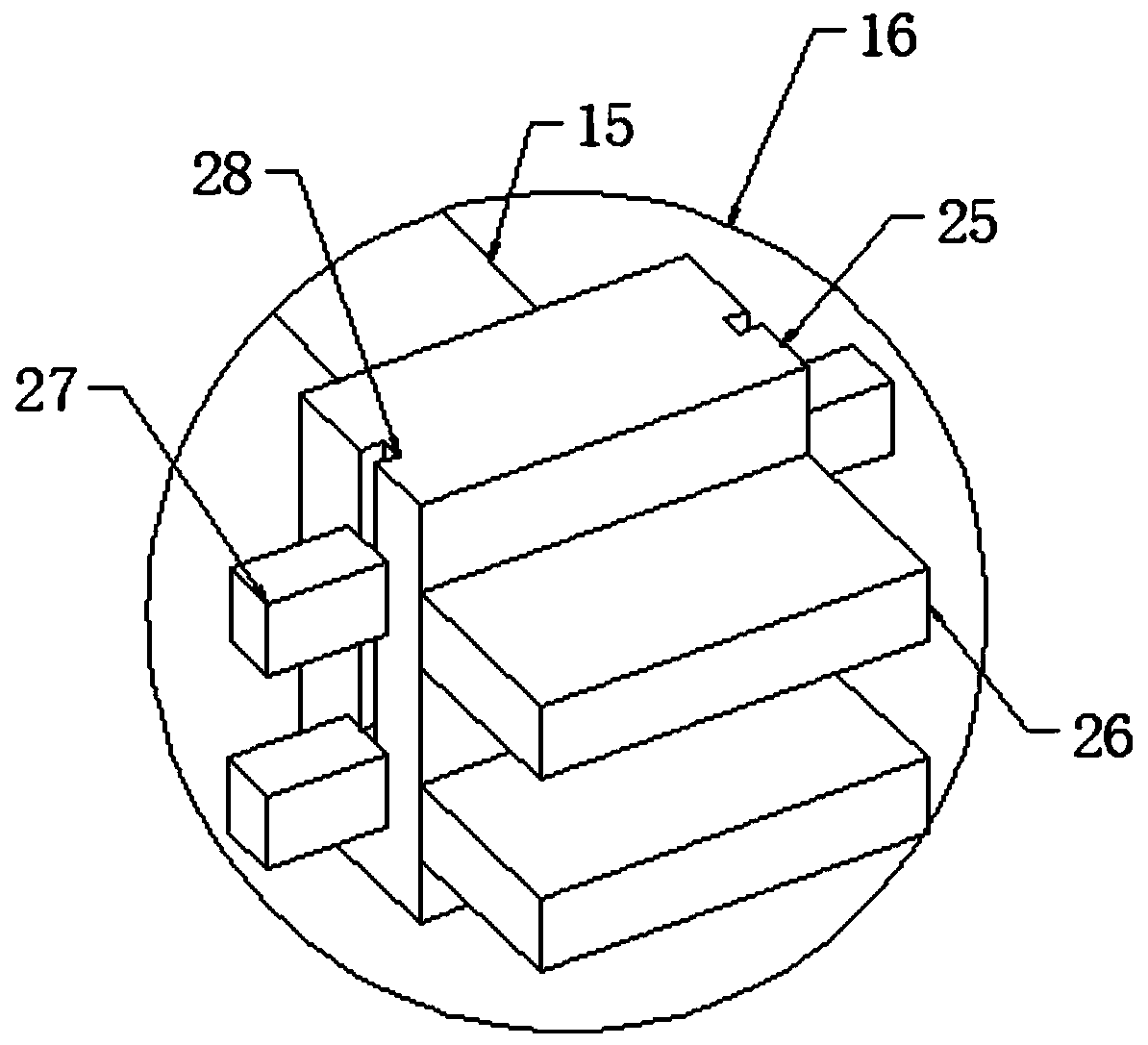

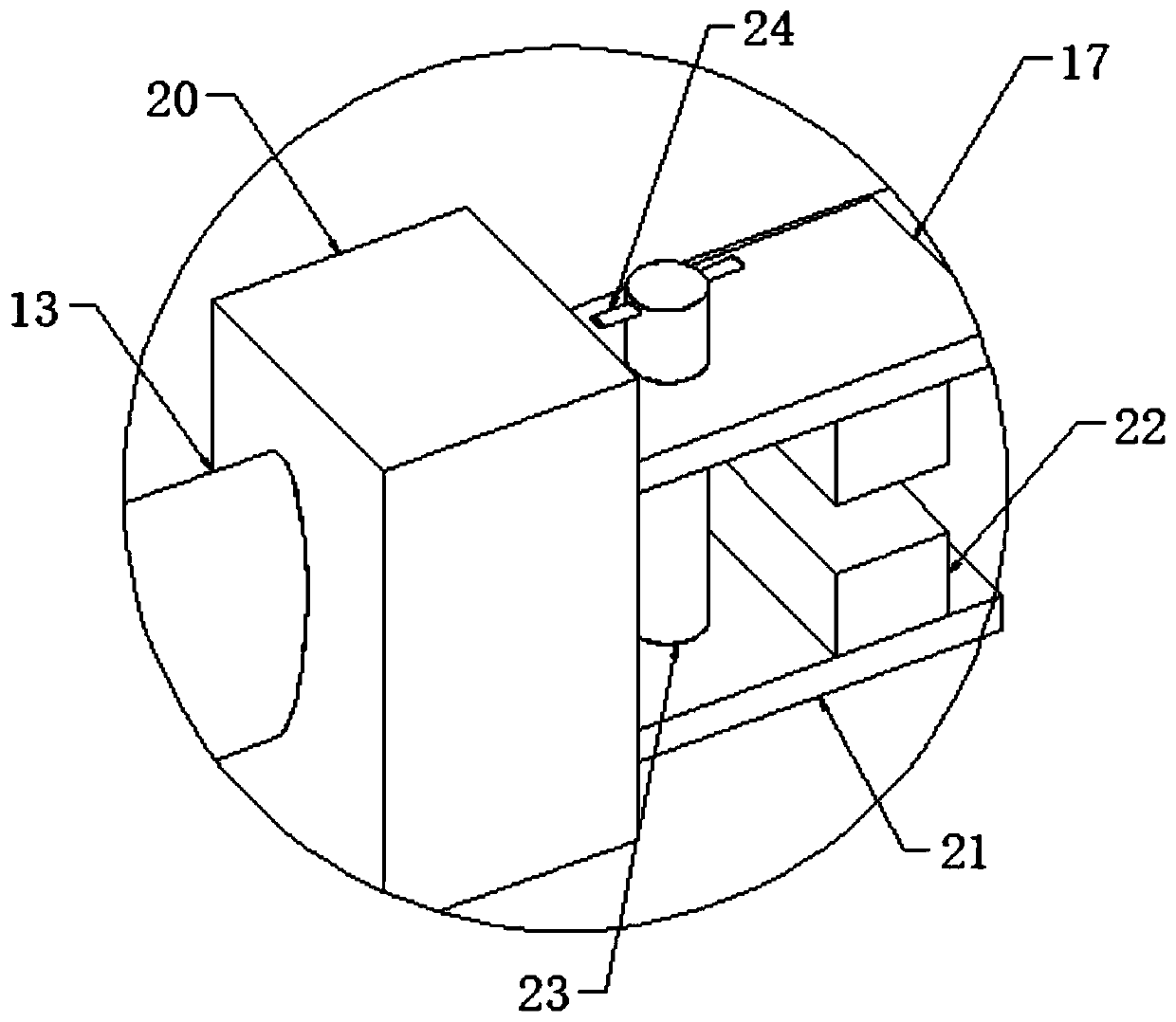

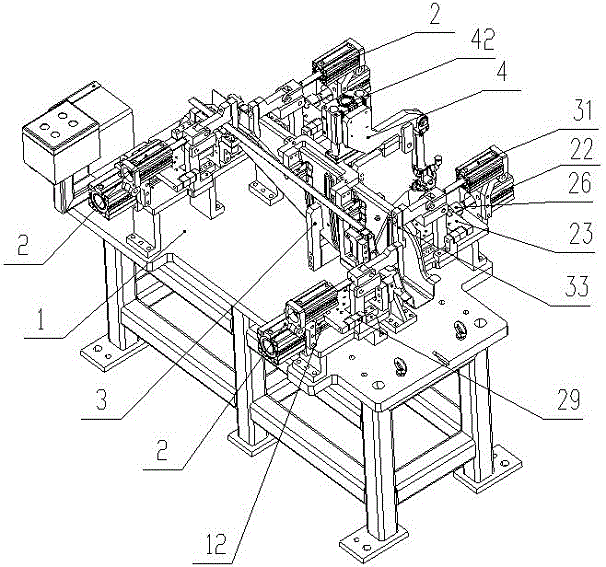

Full-automatic double-end peeling and welding machine for data line

PendingCN113783074AIncrease productivityImprove processing qualityLine/current collector detailsMachineIndustrial engineering

The invention discloses a full-automatic double-end peeling and welding machine for a data line. The full-automatic double-end peeling and welding machine comprises a left machine body, a right machine body, a first feeding mechanism used for conveying and cutting a data line, a first peeling mechanism used for peeling an outer sheath of the data line, a line arrangement mechanism used for flattening and adjusting the relative position of two core lines, a positioning clamp used for clamping and positioning the data line, a conveying mechanism used for conveying the positioning clamp for displacement, a second peeling mechanism used for peeling the outer sheath of the core lines, a second feeding mechanism used for conveying a joint, and a welding mechanism used for welding the joint and the core lines, wherein a first grabbing mechanism is arranged between the left machine body and the right machine body; and the conveying mechanism comprises a first conveying device and a second conveying device, and a second grabbing mechanism is arranged between the first conveying device and the second conveying device. Therefore, through the design of each mechanism, the automatic production of the data line and the joint is realized, the production efficiency of the data line is improved, the processing quality is stable and consistent, and the production cost of the data line is reduced.

Owner:深圳市帆与航电子科技有限公司

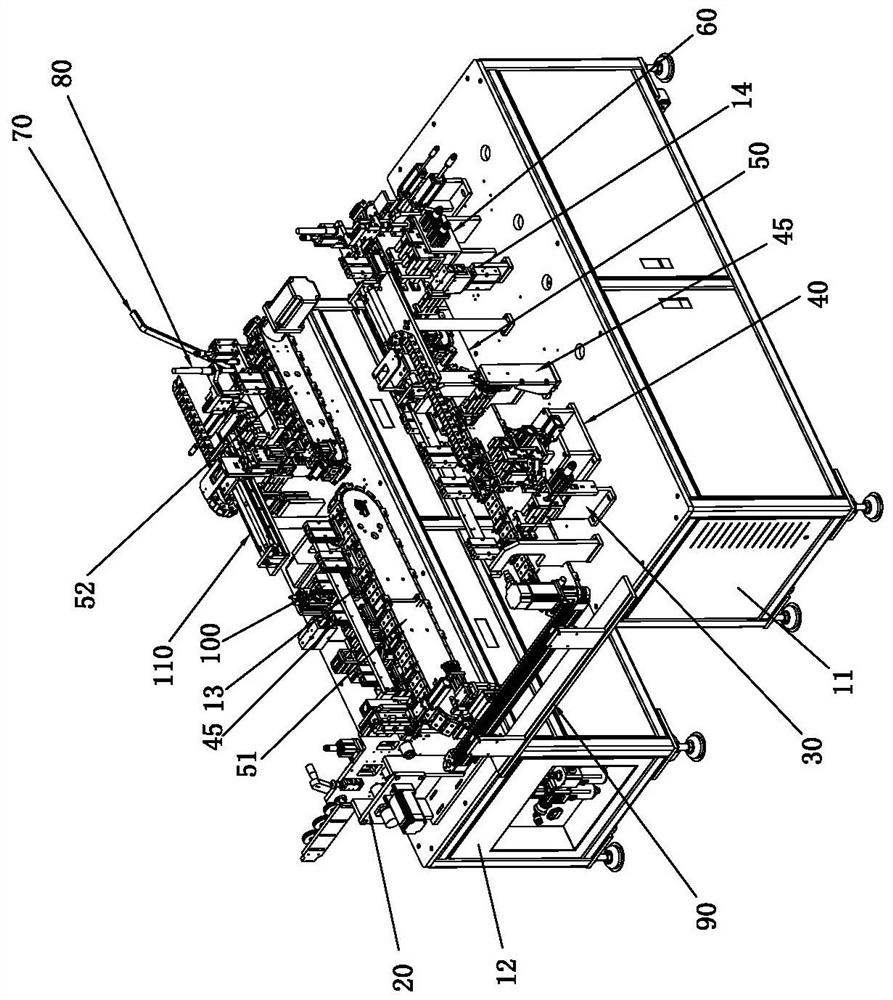

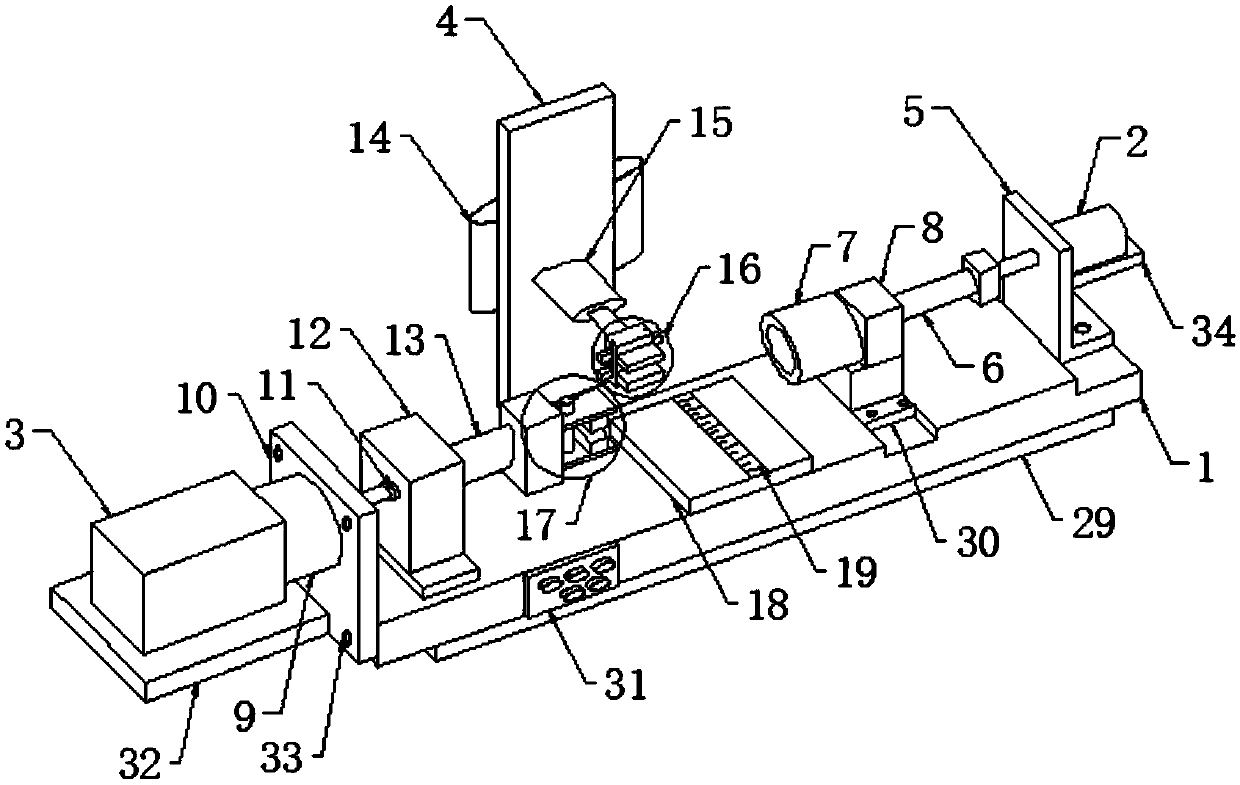

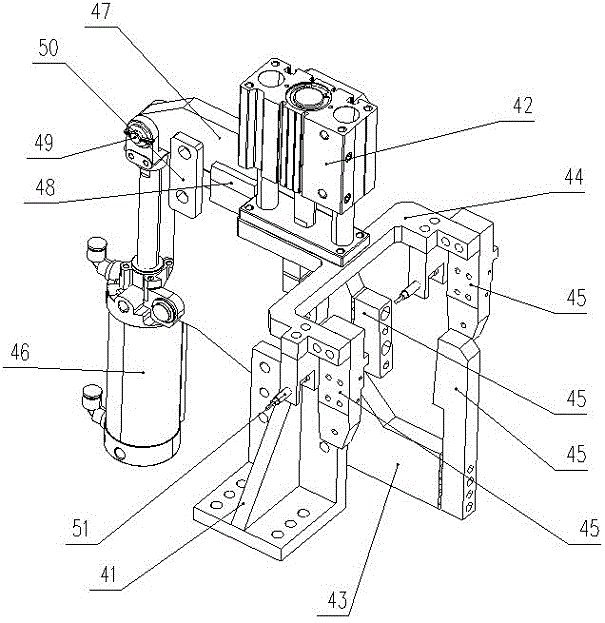

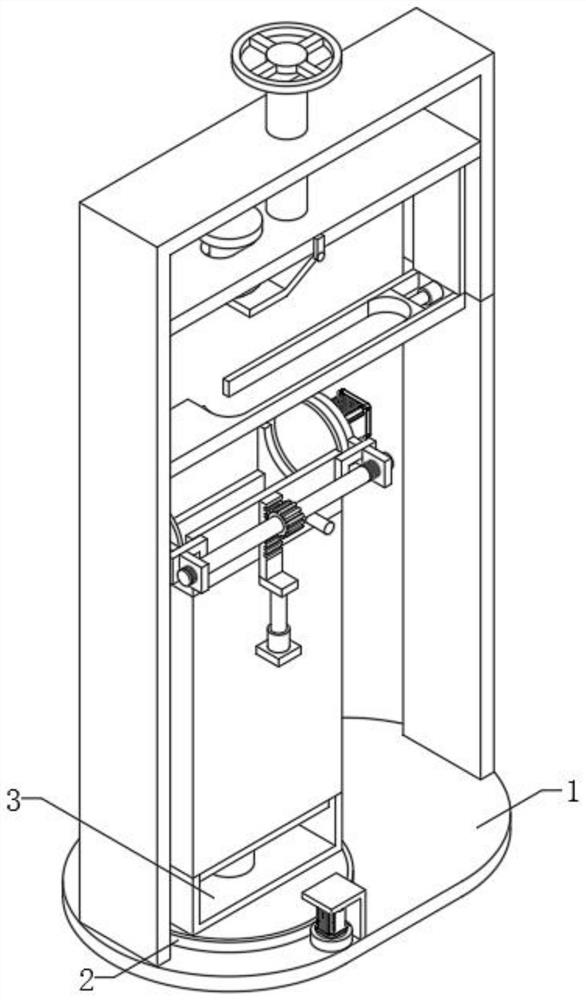

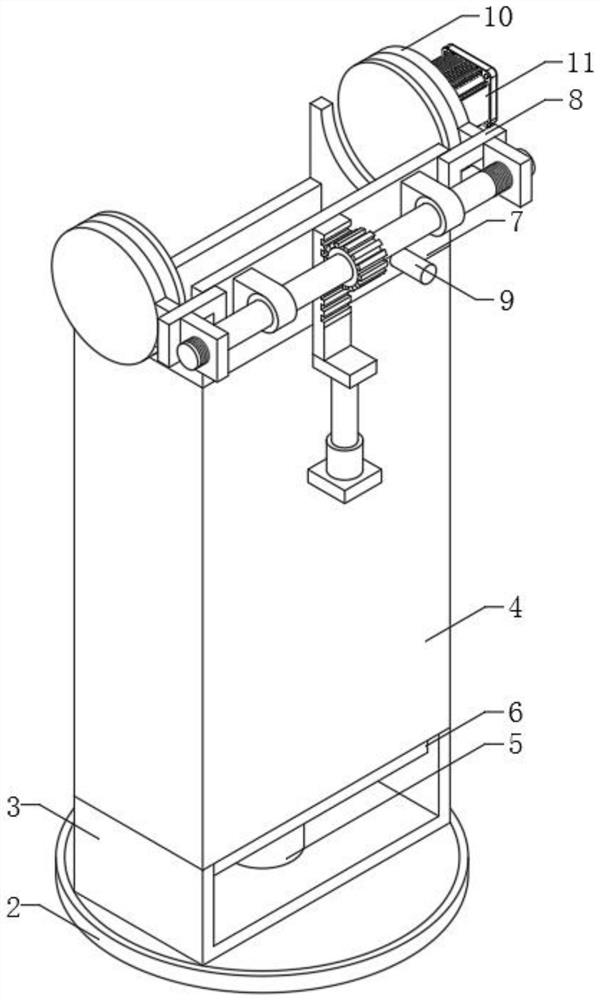

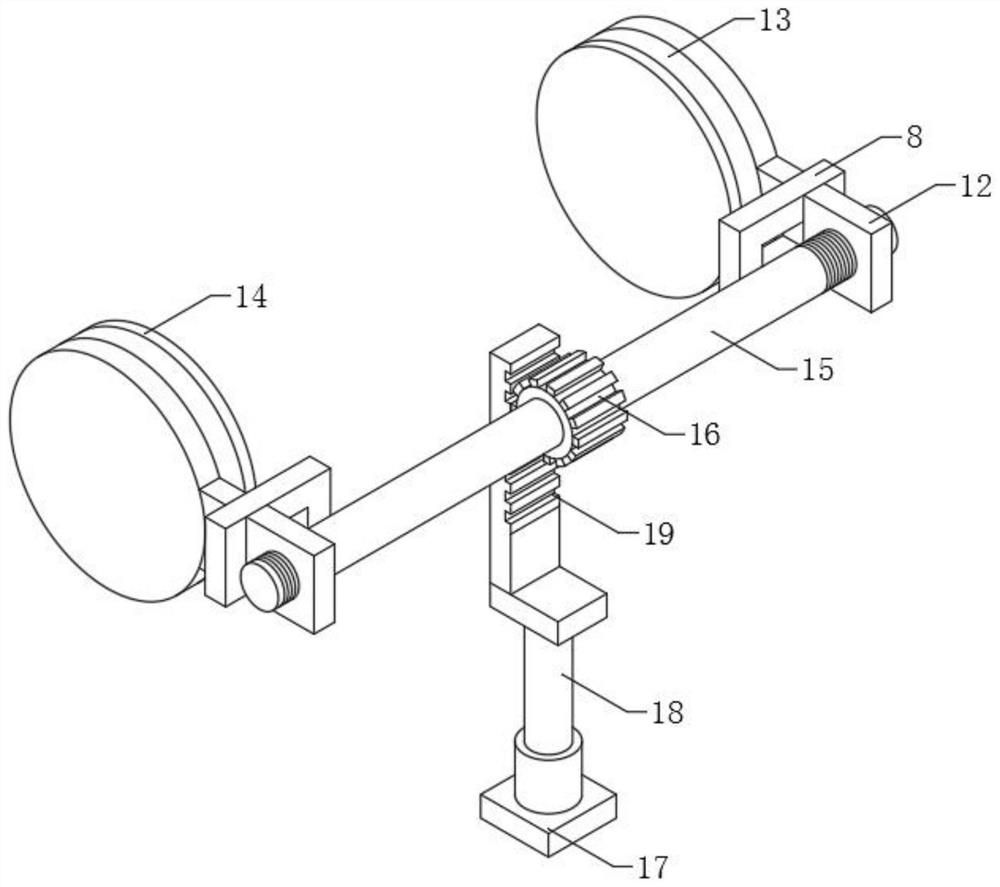

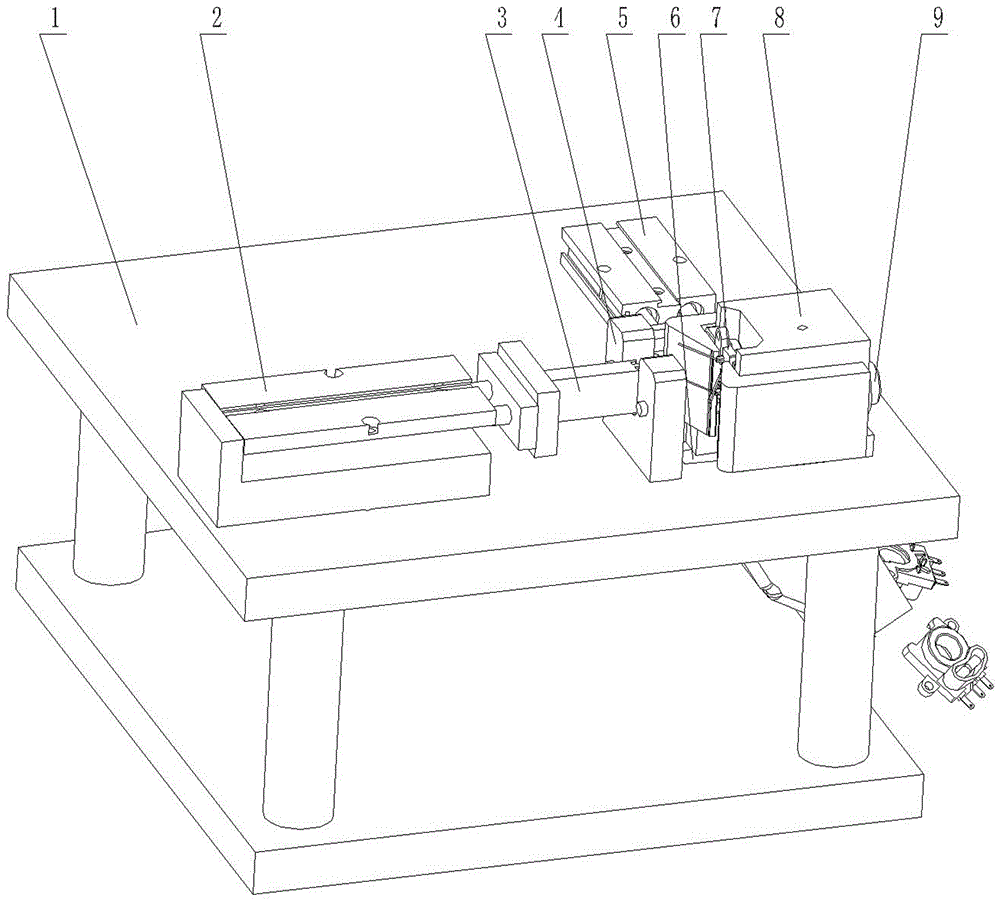

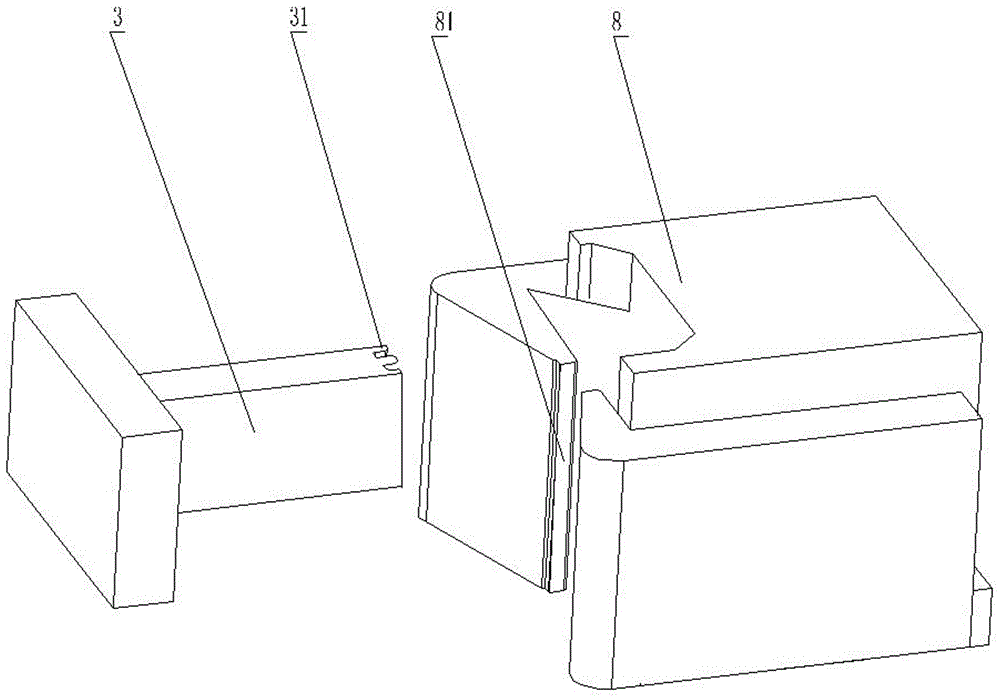

Multi-angle positioning fixture for welding

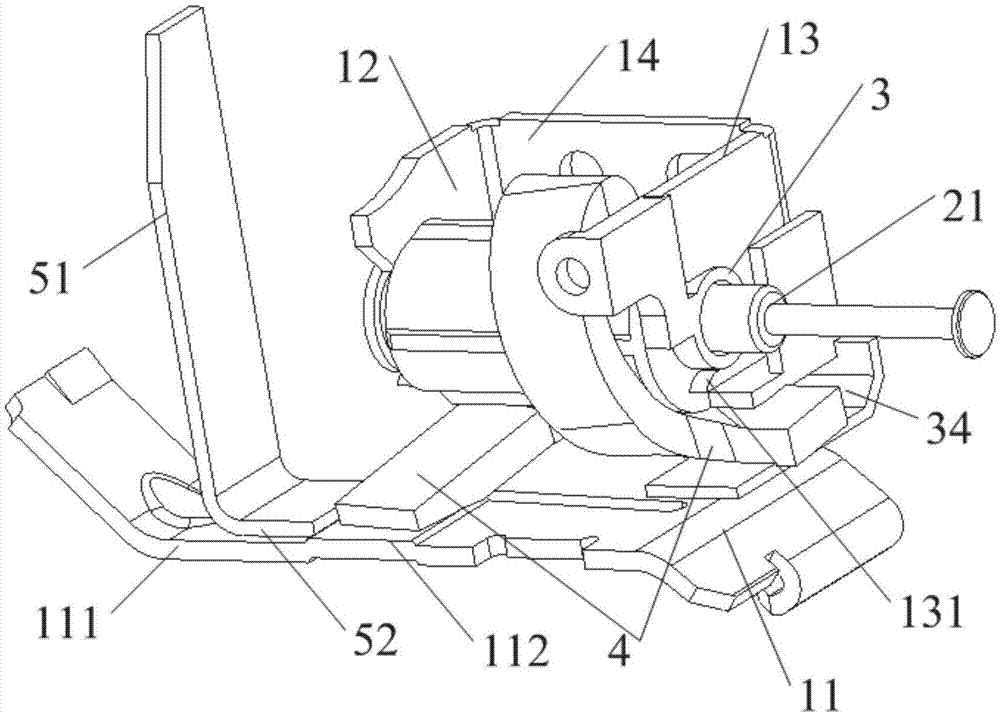

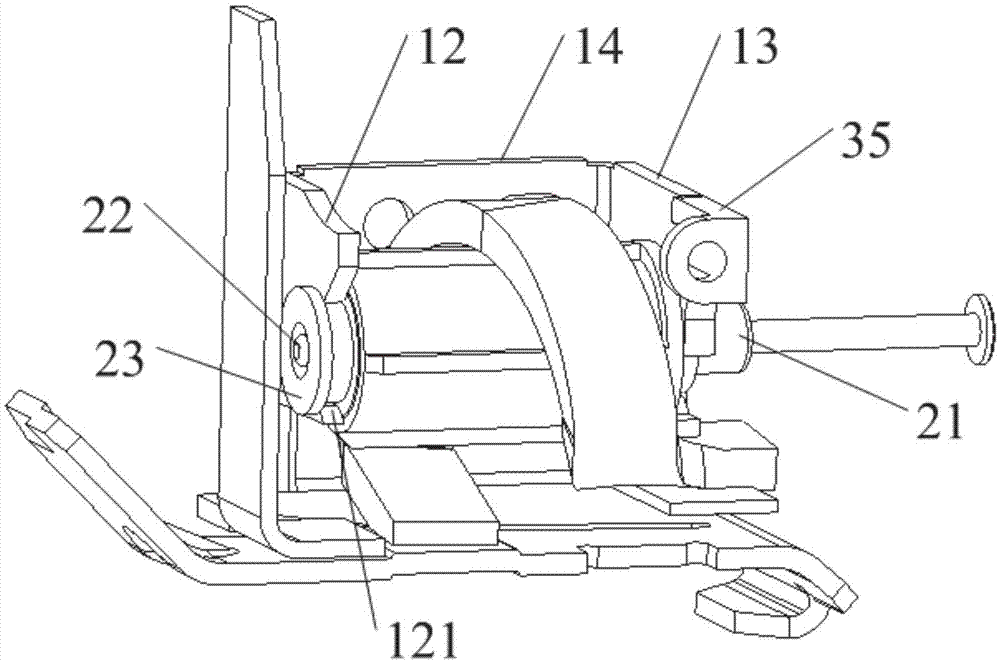

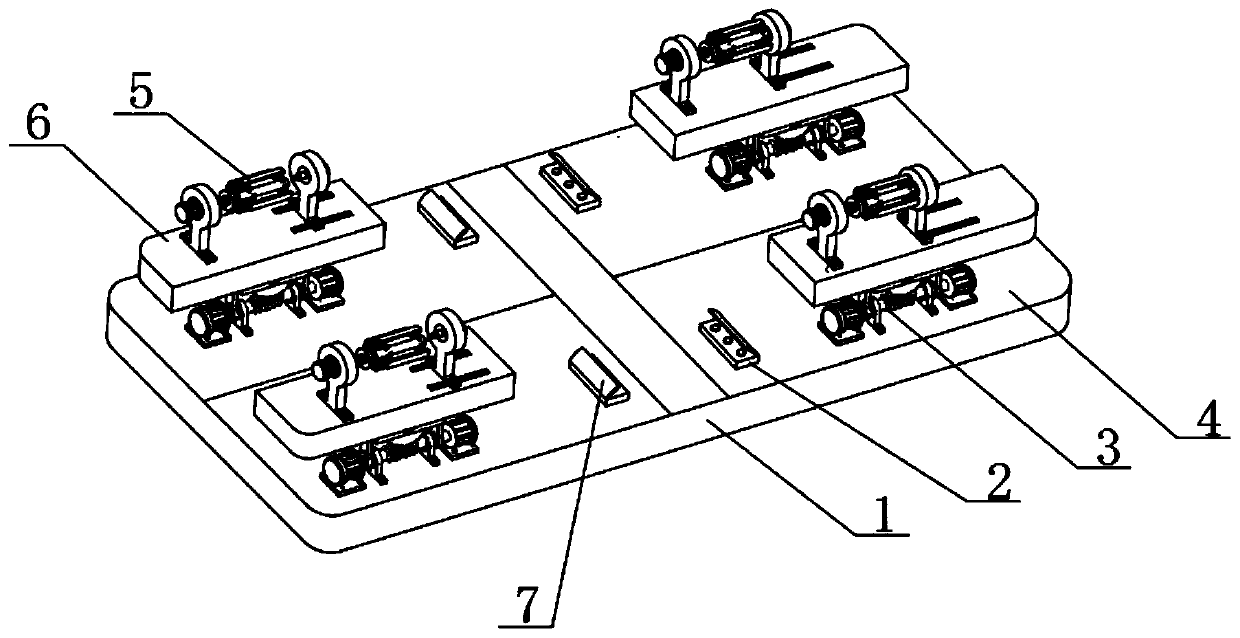

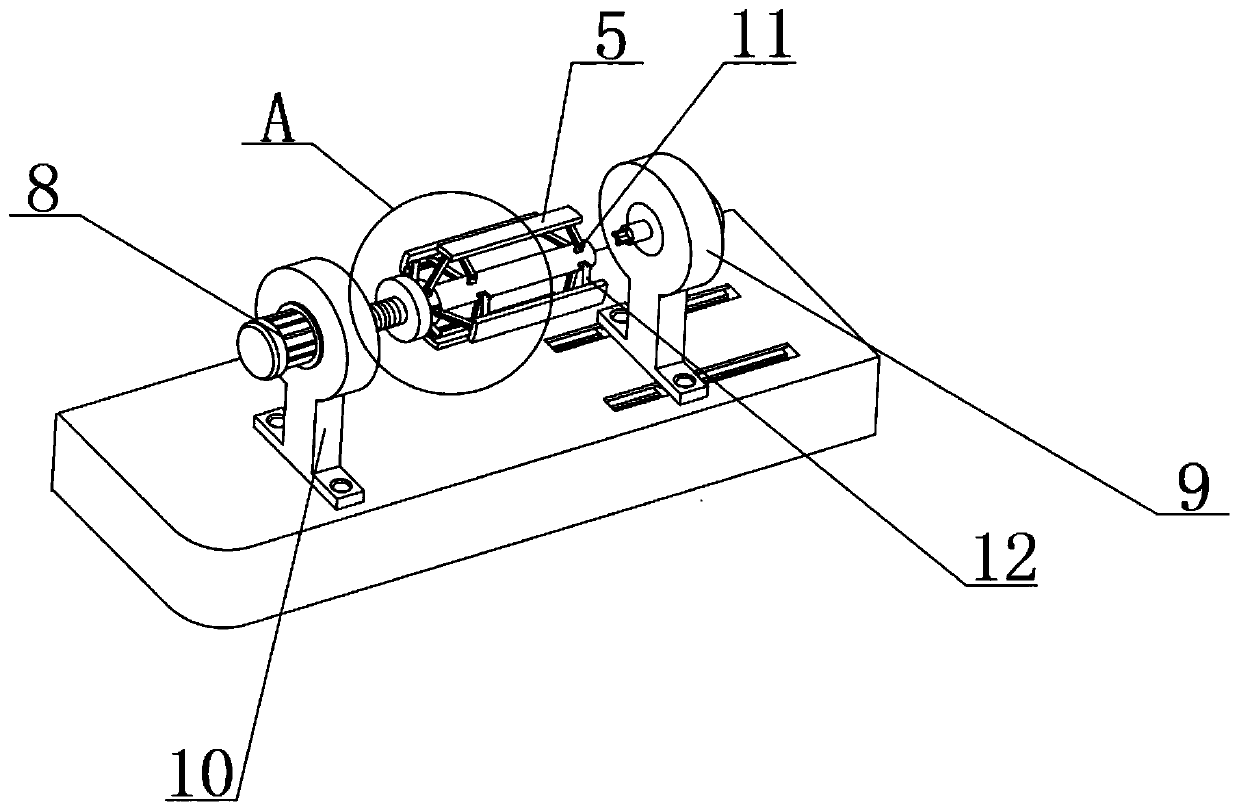

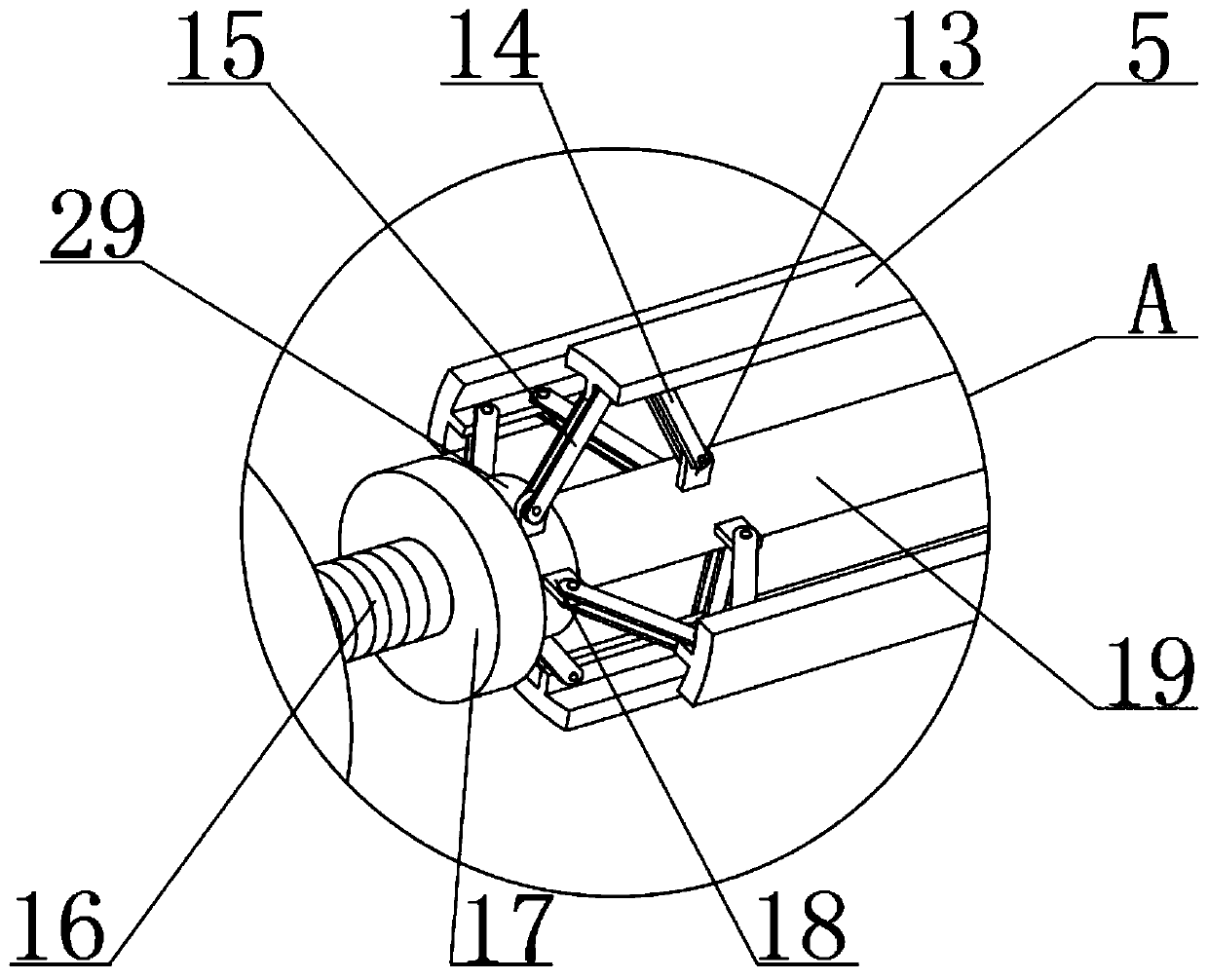

ActiveCN107617840AImprove fitPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesDrive shaftHydraulic pump

The invention discloses a multi-angle positioning fixture for welding. The multi-angle positioning fixture for welding comprises a workbench, a first hydraulic pump and a motor. A hydraulic pump mounting plate is installed at one end of the workbench, one side of the hydraulic pump mounting plate is connected with the first hydraulic pump, a motor mounting plate is installed at the other end of the workbench, and one side of the motor mounting plate is connected with the motor. The middle of one side of the workbench is connected with a vertical supporting plate, a first hydraulic rod is connected to one end of the first hydraulic pump and penetrates through the hydraulic pump mounting plate, the top end of the first hydraulic rod is connected with a sleeve, a positioning plate is connected to one side of the sleeve and located on the first hydraulic rod, one end of the motor is connected with a transmission shaft, one end of the transmission shaft is connected with a rotating shaft, one side of the rotating shaft is connected with a gearbox, and one side of the gearbox is connected with a connecting rod. A first chuck and a second chuck are arranged and used for clamping multipleweldments to facilitate positioning and welding of the weldments. Multiple hydraulic rod and hydraulic pump combinations are arranged and used for driving the chucks and the sleeve to move in the horizontal direction to facilitate attachment and positioning of the weldments during welding.

Owner:南京康达焊接设备有限公司

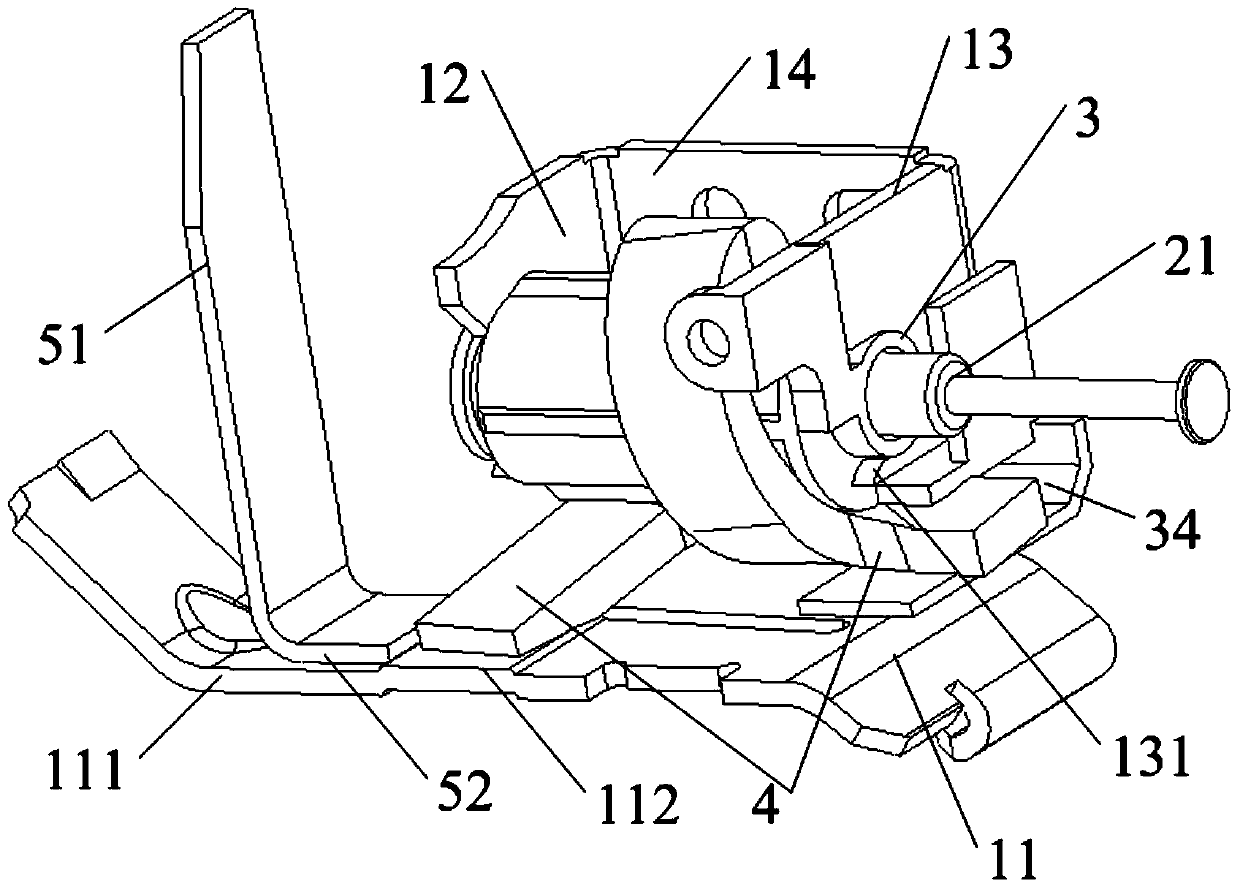

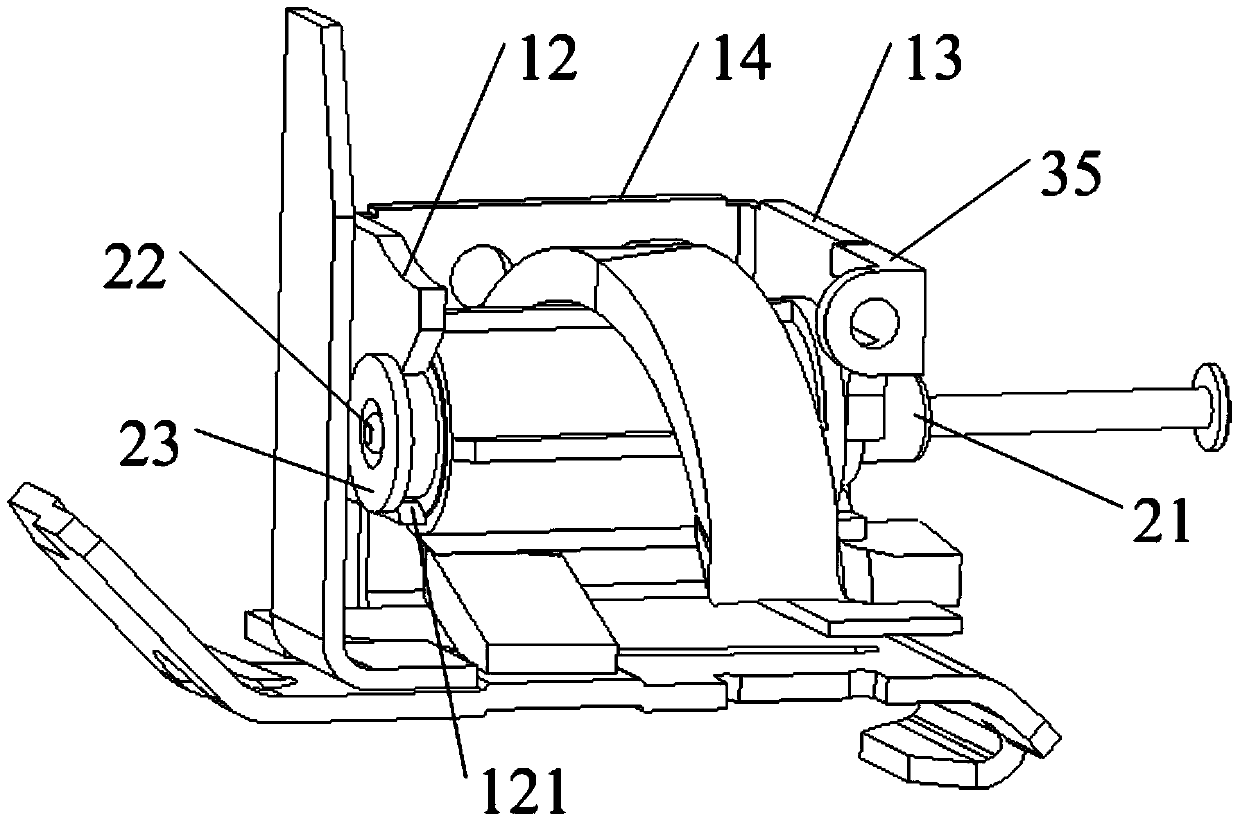

Thermo magnetic release for circuit breaker

ActiveCN106898528ASimple assembly structureSimple and reliable assembly structureProtective switch operating/release mechanismsRelease - actionCircuit breaker

A thermo magnetic release for a circuit breaker comprises a contact plate, a magnetic yoke bracket, and a bimetallic strip and a coil connected with the magnetic yoke bracket, wherein the contact plate is electrically connected with the bimetallic strip and the coil respectively, one part of current flowing through the contact plate flows to the bimetallic strip, and the other part flows to the coil; and the bimetallic strip and the coil are indirectly electrically connected through the magnetic yoke bracket, and thus, current flowing through the bimetallic strip enters the coil through the magnetic yoke bracket. According to the thermo magnetic release for the circuit breaker provided by the invention, through effectively dividing current flowing through the contact plate, overload protection can be realized, temperature rise of a product can also be reduced, the structure is simple and reliable, and the release action reliability and the stability of the circuit breaker can be improved.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

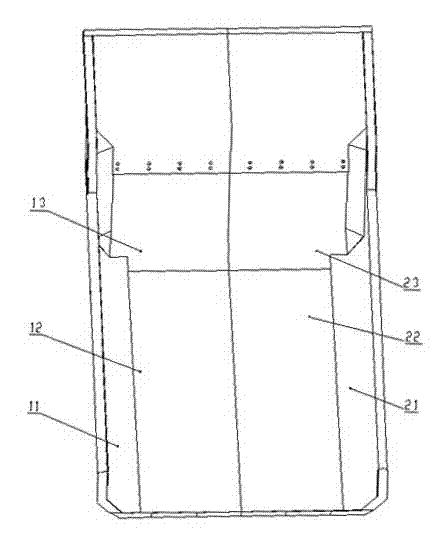

Two-section packing case structure of mining dump truck

InactiveCN102363416AConvenient on-site welding positioningConvenient welding positioningVehicle with tipping movementLoading-carrying vehicle superstructuresLeft halfEngineering

The invention discloses a two-section packing case structure of a mining dump truck, belonging to the technical field of packing case structures. The two-section packing case structure comprises a left half part packing case and a right half part packing case, wherein the left half part packing case comprises a left side main plate assembly, a left bottom main plate assembly and a left front part main plate assembly which are connected with one another; the right half part packing case comprises a right side main plate assembly, a right bottom main plate assembly and a right front main plate assembly which are connected with one another; and the left half part packing case is connected integrally with the right half part packing case. The two-section packing case structure has the advantages: the packing case transportation convenience is enhanced greatly, and the field installation efficiency of packing case is increased.

Owner:XUZHOU CONSTR MACHINERY INST XUZHOU CONSTR MACHINERY GRP

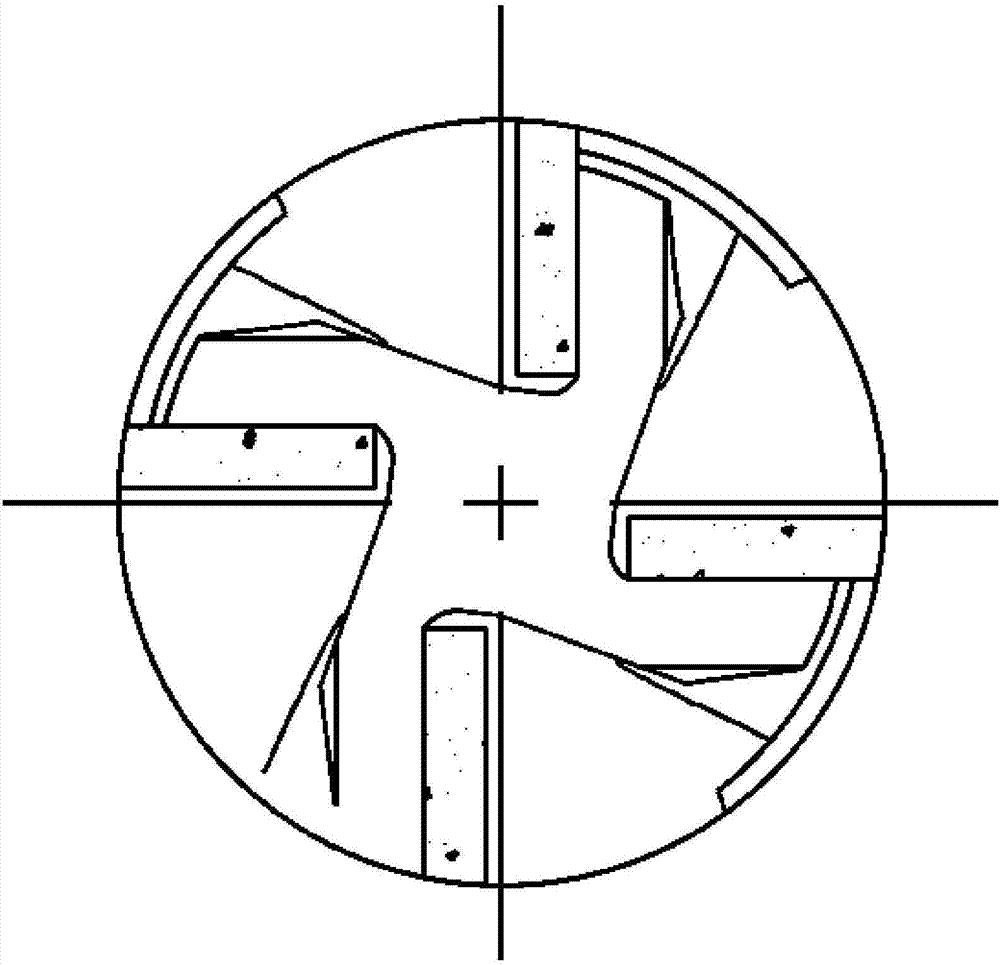

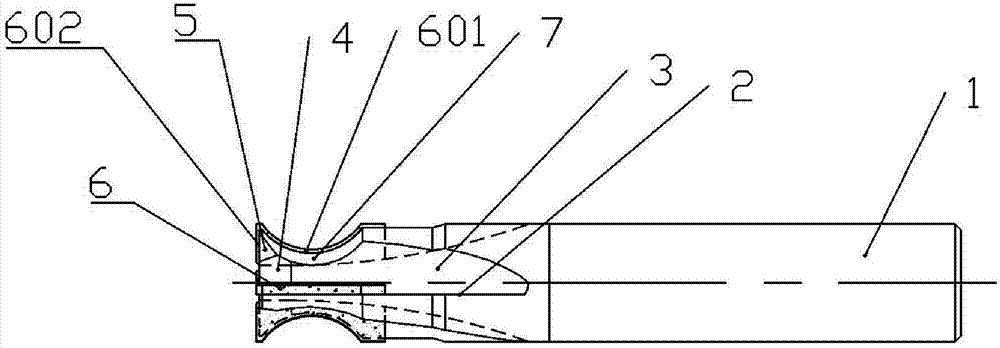

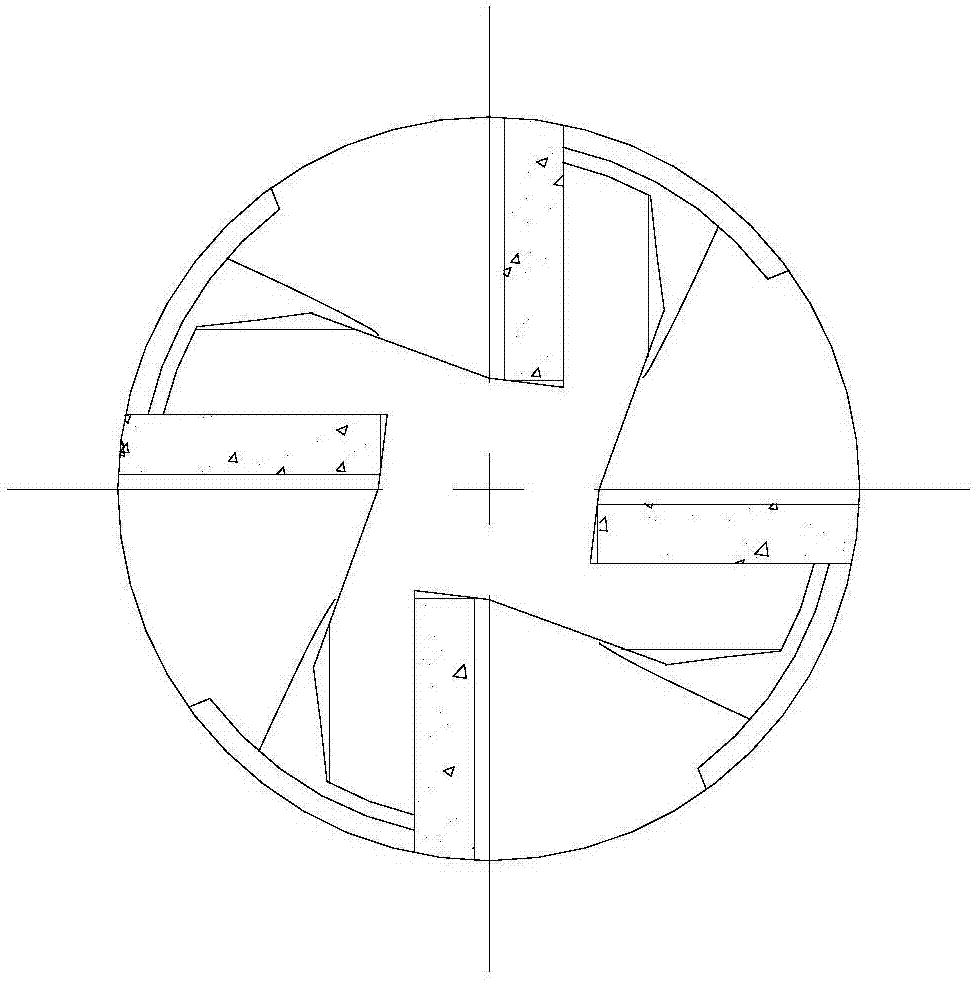

Highlight PCD appearance milling cutter

InactiveCN107414158ATool structure is simple and reliableEasy to installMilling cuttersAgricultural engineeringMilling cutter

The invention discloses a highlight PCD appearance milling cutter. The highlight PCD appearance milling cutter comprises a tool body (1) and PCD blades (6). The highlight PCD appearance milling cutter is characterized in that four cutter grooves are formed in the front end of the tool body (1); a cutter groove concave arc (7) is arranged on the outer side face of each of the cutter grooves; each of the cutter grooves is composed of a groove bottom face (2), a first groove side face (3), a second groove side face (4) and a third groove side face (5); the PCD blades (6) are welded between the groove bottom faces and the first groove side faces; a blade concave arc (601) is arranged on the outer side of each of the PCD blades; and the blade concave arc (601) is matched with the cutter groove concave arc in structure.

Owner:WUXI GUOHONG MEASURING & CUTTING TOOLS

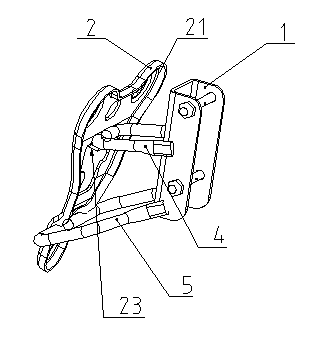

Positioning and welding device of anti-jumping rail support of escalator

ActiveCN103831570AGuaranteed installation qualityConvenient welding positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineering

The invention discloses a positioning and welding device of an anti-jumping rail support of an escalator. The linear segment of the escalator is provided with connecting channel steel, a left main auxiliary rail and a right main auxiliary rail, wherein the left main auxiliary rail is provided with a first horizontal supporting face and a first side face, and the right main auxiliary rail is provided with a second horizontal supporting face and a second side face. The anti-jumping rail positioning and welding device comprises a transverse rod body, and the left end and the right end of the transverse rod body can be supported on the first horizontal supporting face and the second horizontal supporting face respectively; the transverse rod body is provided with a fixing block tightly abutting against the first side face correspondingly and a locking connecting structure tightly abutting against and locking the second side face correspondingly; the transverse rod body is further provided with a two-way positioning block used for limiting the horizontal distance and the welding height between the anti-jumping rail support and the first side face. By adopting the positioning and welding device of the anti-jumping rail support of the escalator, the anti-jumping rail support can be positioned and welded quite conveniently, fast and accurately, and it is guaranteed that the mounting quality of subsequent anti-jumping rails can meet mounting requirement.

Owner:SJEC CORP

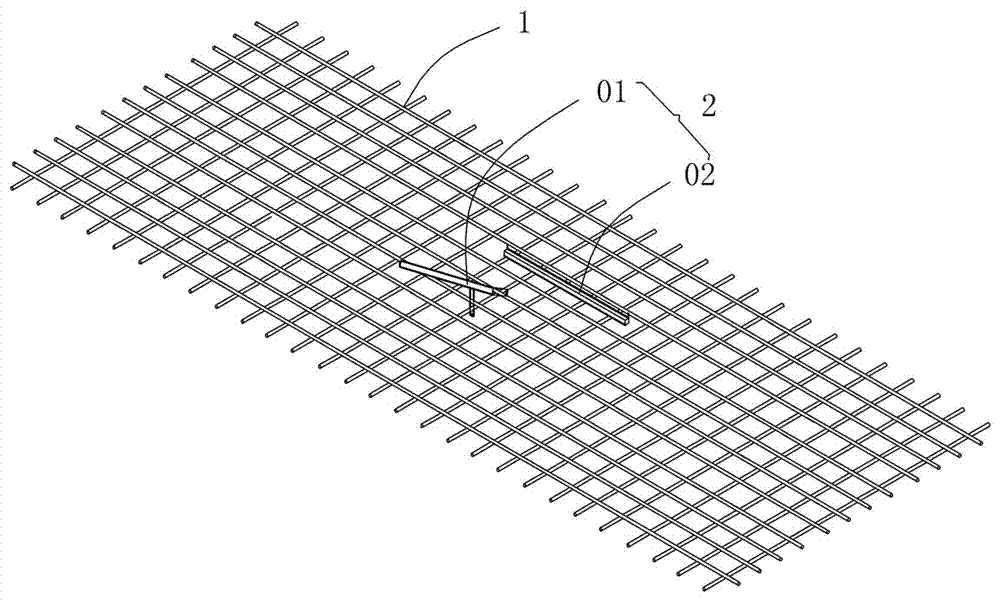

Leveling tool and leveling method for bridge deck pavement reinforcing mesh

PendingCN107386124ASimple designReasonable designBridge erection/assemblyArchitectural engineeringBridge deck

The invention discloses a leveling tool and leveling method for a bridge deck pavement reinforcing mesh. The leveling tool comprises a crow bar with a rotatable fulcrum and a leveling tool body, the leveling tool body comprises a leveling rod and a leveling rope, and two ends of the leveling rod are directly placed on a set scale height control point; the leveling rope is arranged at two ends of the top surface of the leveling rod, two ends of the leveling rope are connected with the leveling rod through a fixing part respectively, and the leveling rope is in a straight line state. By adoption of the leveling tool for the bridge deck pavement reinforcing mesh, the bridge deck pavement reinforcing mesh is leveled, a worker only needs to press the crow bar downwards through a holding portion of the crow bar, so that the crow bar upwards pries the reinforcing mesh, the leveling rope of the leveling tool located on the reinforcing mesh is completely in contact with the top surface of the leveling rod, when supporting steel bars are welded to the designed position of the reinforcing mesh, the worker holds the supporting steel bars conveniently to conduct positioning welding, welding is convenient, and the construction efficiency is improved. The leveling tool for the bridge deck pavement reinforcing mesh is reasonable in design, simple in structure, convenient to use and manufacture, and low in manufacturing cost.

Owner:HENAN HIGHWAY ENG GROUP +1

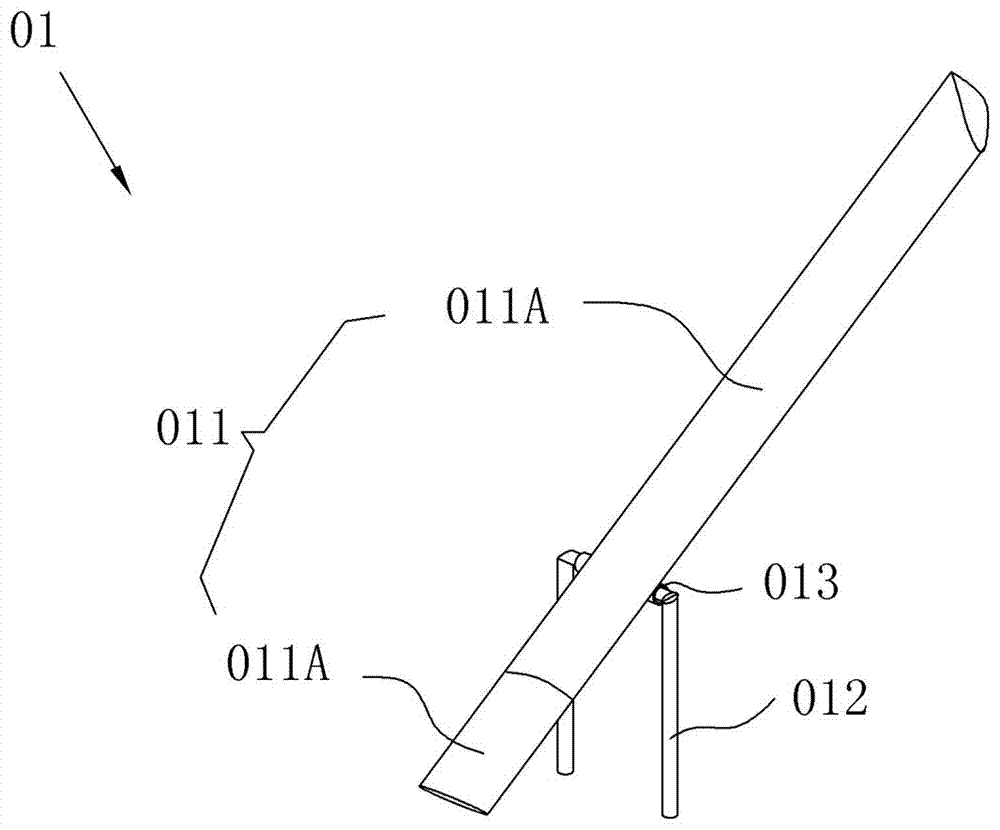

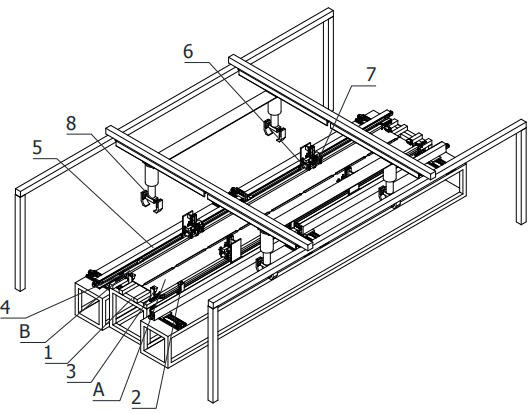

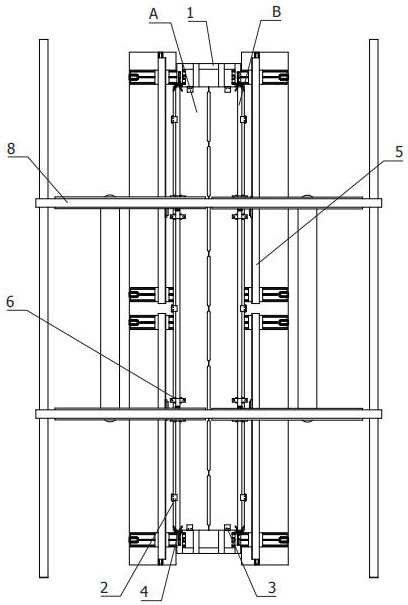

Bias-rail type girder automatic welding equipment

InactiveCN111660029AEasy to weldFit tightlyWelding/cutting auxillary devicesAuxillary welding devicesPortal frameOrbital welding

The invention relates to the technical field of automatic welding, in particular to bias-rail type girder automatic welding equipment which is applied to horizontally welding rails to the two sides ofthe top end of a girder prefabricated panel. The welding equipment comprises a placing frame, at least three side surface elastic positioners, at least two end surface elastic positioners, rail end surface clamping positioners, dual-station two-way moving sliders, elastic dual-wheel resisters, a dual-station welding frame and a dual-station suspension portal frame, wherein the side surface elastic positioners are arranged at the two sides of the placing frame in a spaced mode; the rail end surface clamping positioners are arranged on four corners of the top end of the placing frame; the dual-station two-way moving sliders are horizontally arranged at the two sides of the placing frame; the working ends of the elastic dual-wheel resisters are vertically downwards arranged on dual working ends; dual working ends of the dual-station welding frame are arranged between the dual working ends of the elastic dual-wheel resisters in an inclined mode towards the two side surface of a rail welding surface; and the dual-station suspension portal frame is placed at the top end of the placing frame. The equipment can automatically position a prefabricated panel, can automatically weld the rail,and is high in work efficiency.

Owner:张雨

A multi-angle positioning fixture for welding

ActiveCN107617840BImprove fitPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesDrive shaftHydraulic pump

The invention discloses a multi-angle positioning fixture for welding. The multi-angle positioning fixture for welding comprises a workbench, a first hydraulic pump and a motor. A hydraulic pump mounting plate is installed at one end of the workbench, one side of the hydraulic pump mounting plate is connected with the first hydraulic pump, a motor mounting plate is installed at the other end of the workbench, and one side of the motor mounting plate is connected with the motor. The middle of one side of the workbench is connected with a vertical supporting plate, a first hydraulic rod is connected to one end of the first hydraulic pump and penetrates through the hydraulic pump mounting plate, the top end of the first hydraulic rod is connected with a sleeve, a positioning plate is connected to one side of the sleeve and located on the first hydraulic rod, one end of the motor is connected with a transmission shaft, one end of the transmission shaft is connected with a rotating shaft, one side of the rotating shaft is connected with a gearbox, and one side of the gearbox is connected with a connecting rod. A first chuck and a second chuck are arranged and used for clamping multipleweldments to facilitate positioning and welding of the weldments. Multiple hydraulic rod and hydraulic pump combinations are arranged and used for driving the chucks and the sleeve to move in the horizontal direction to facilitate attachment and positioning of the weldments during welding.

Owner:南京康达焊接设备有限公司

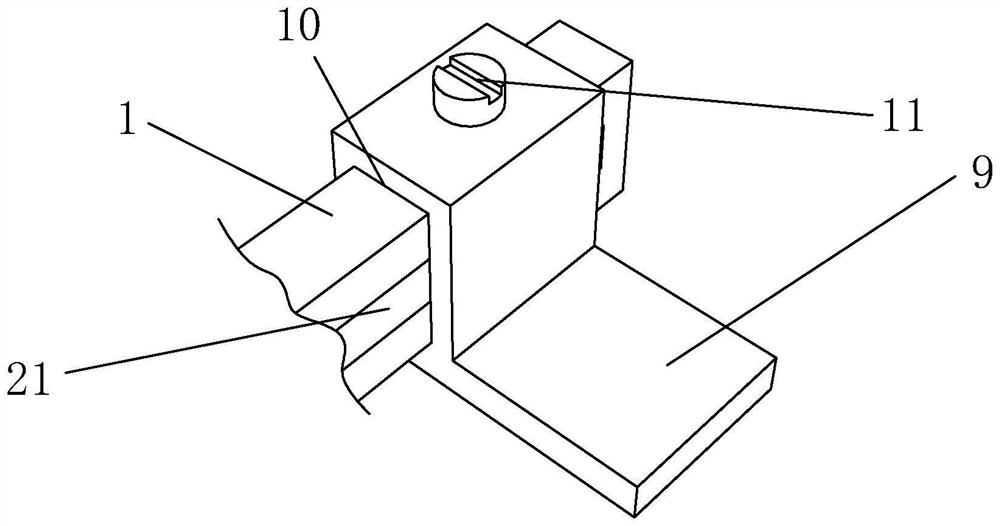

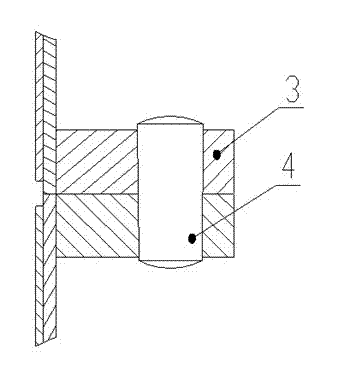

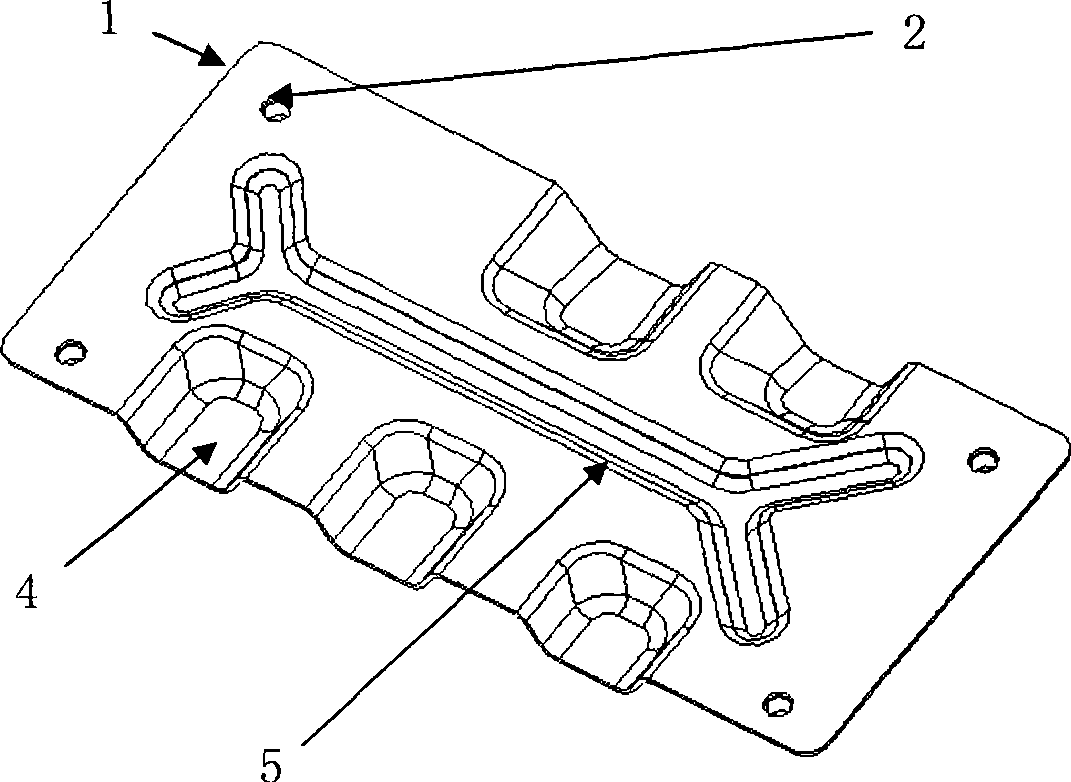

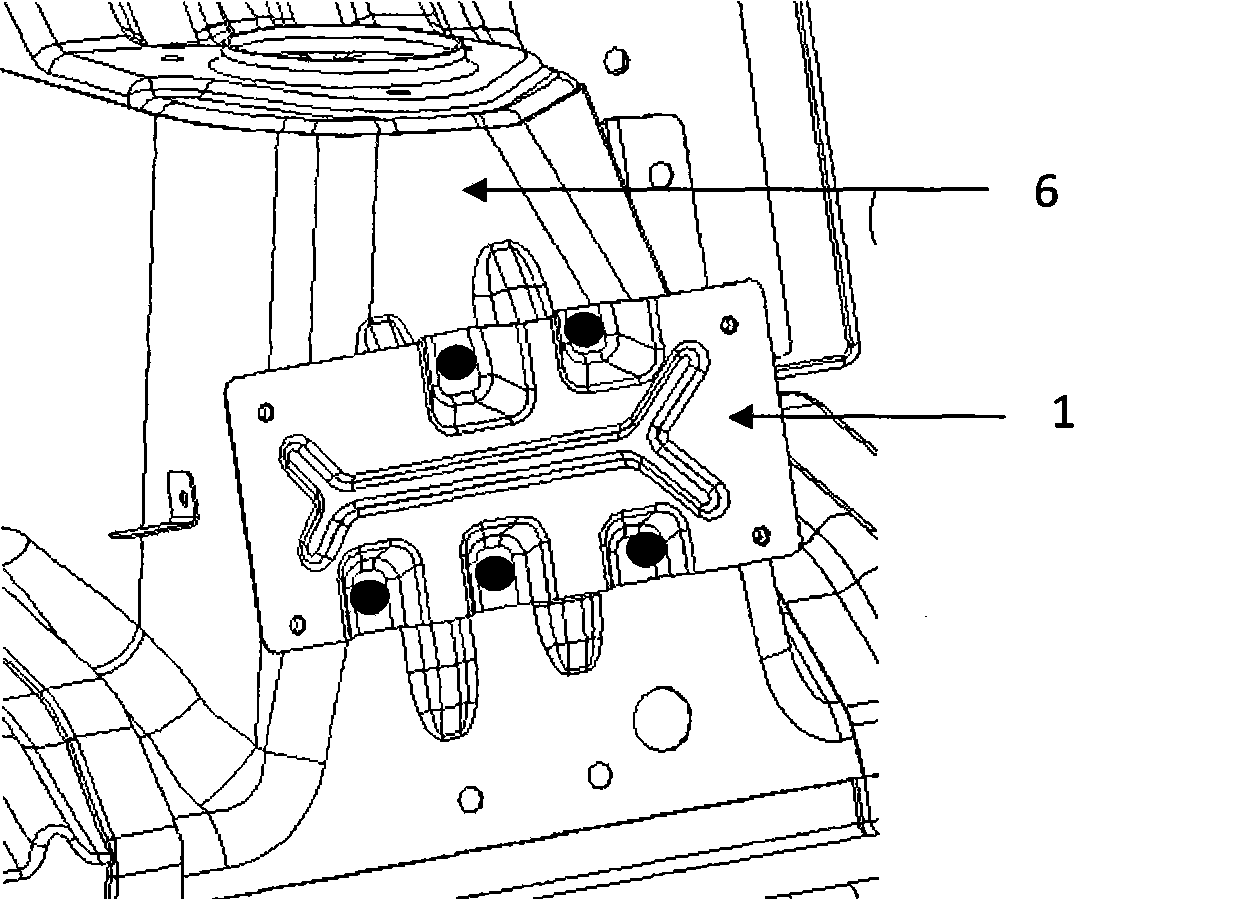

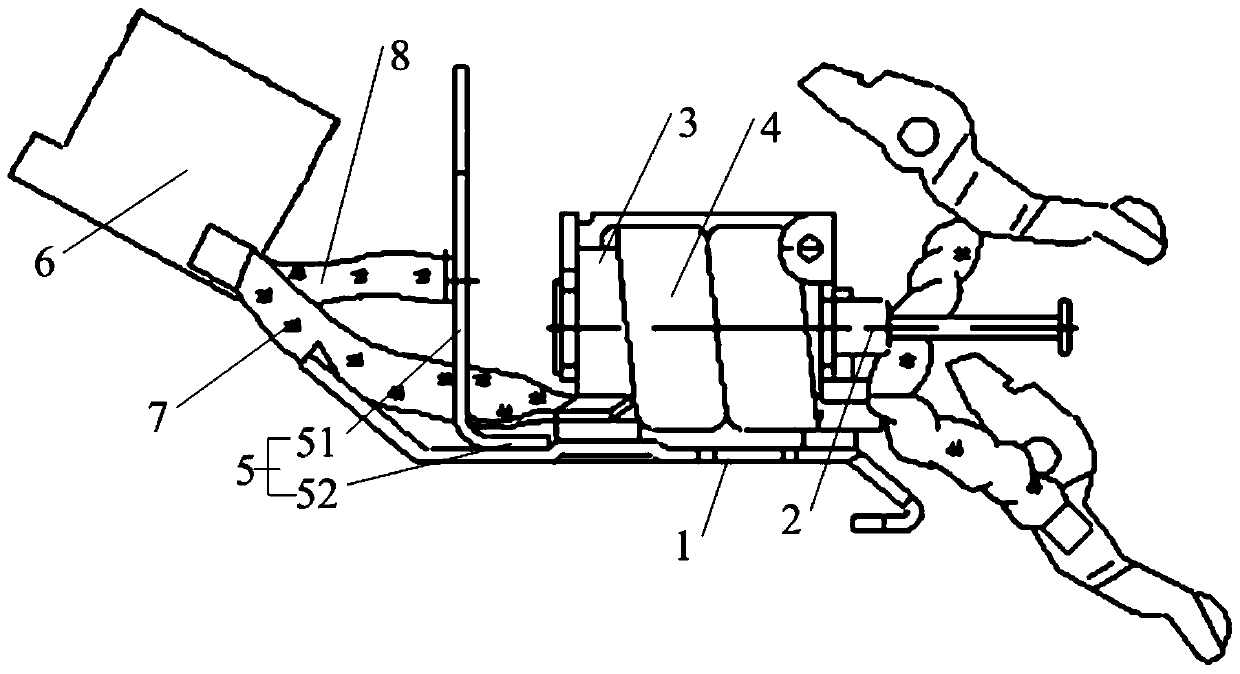

Mounting means of electronic control unit

InactiveCN101445084AHigh strengthIncrease profitInstrument housingElectric/fluid circuitManufacturing technologyUltimate tensile strength

The invention relates to vehicle manufacturing technology, in particular a mounting structure of electronic control unit (ECU). The mounting structure of electronic control unit (ECU) of the invention comprises a bracket plate (1), a nut hole (2), the bracket plate (1) being provided with a welding concave bar (4) and connected with the vehicle by the welding concave bar (4). The invention uses the technical solution which has great forming technique, regular shape and high material utilization rate; which has crossed reinforced concave bar and greater parts intensity; it is convenient to position the welding concave bar and enhance intensity of the parts; depth of the welding concave bar can be set according to the vehicle part welded with it, which is suitable for plane, male and female face and arc shape connection to enhance universality, stability and application scale of the mounting structure of electronic control unit (ECU).

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

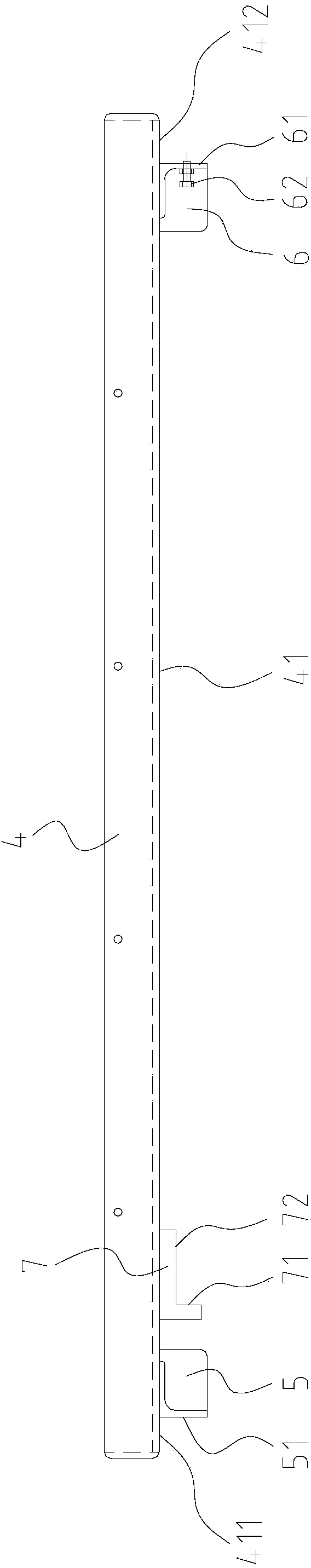

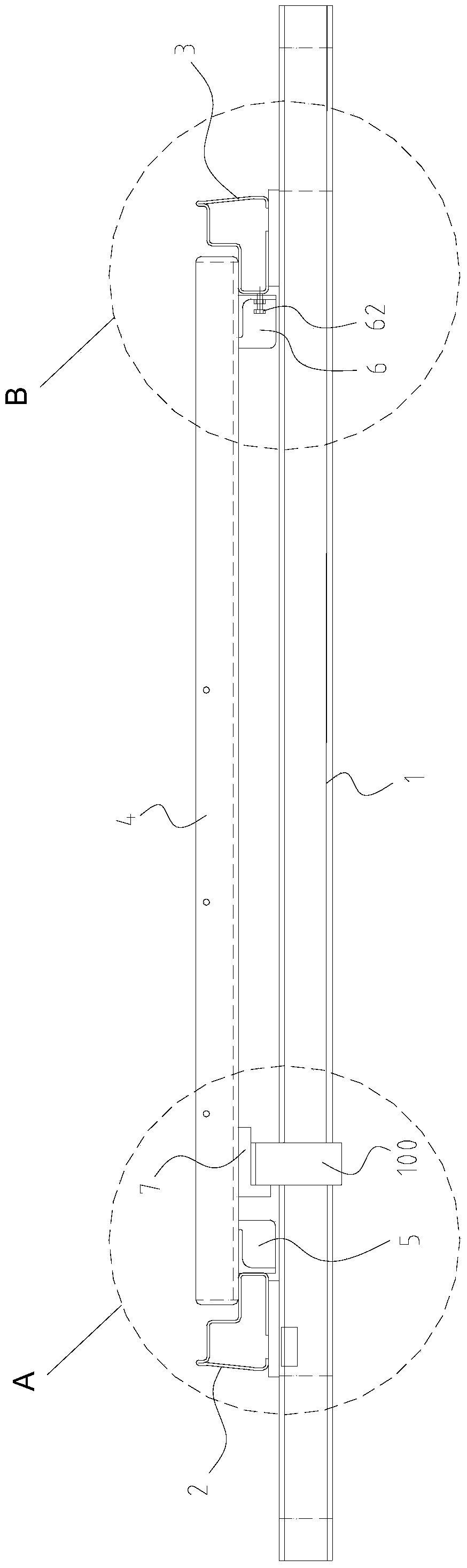

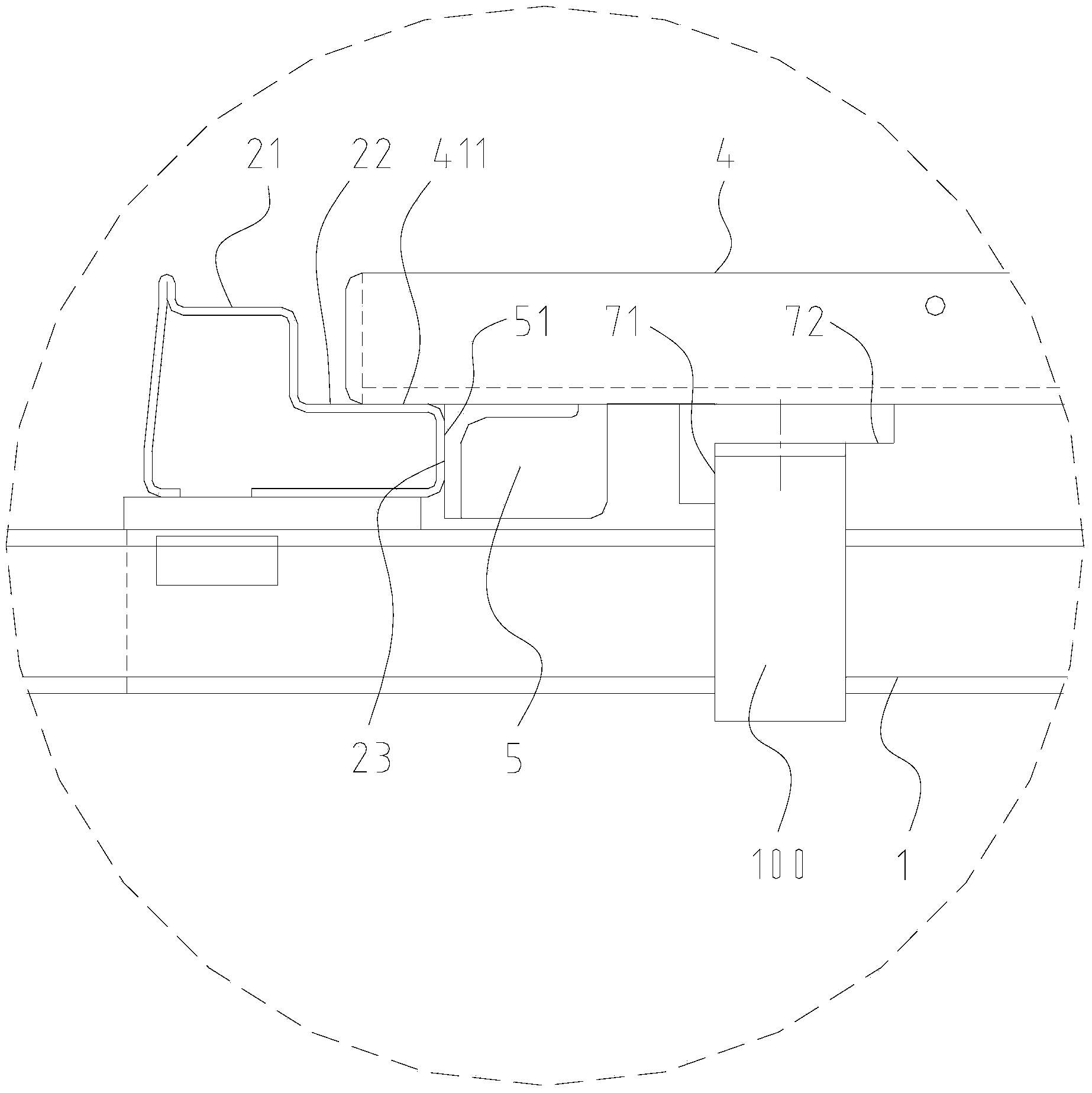

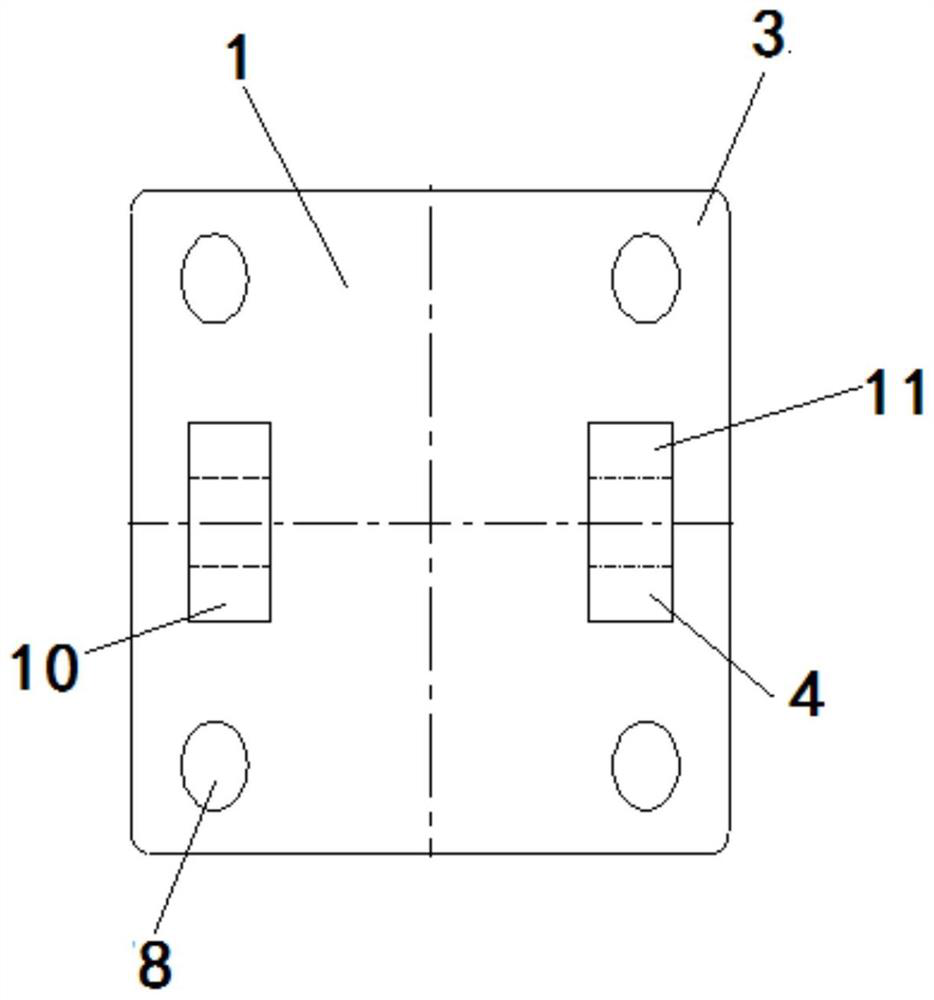

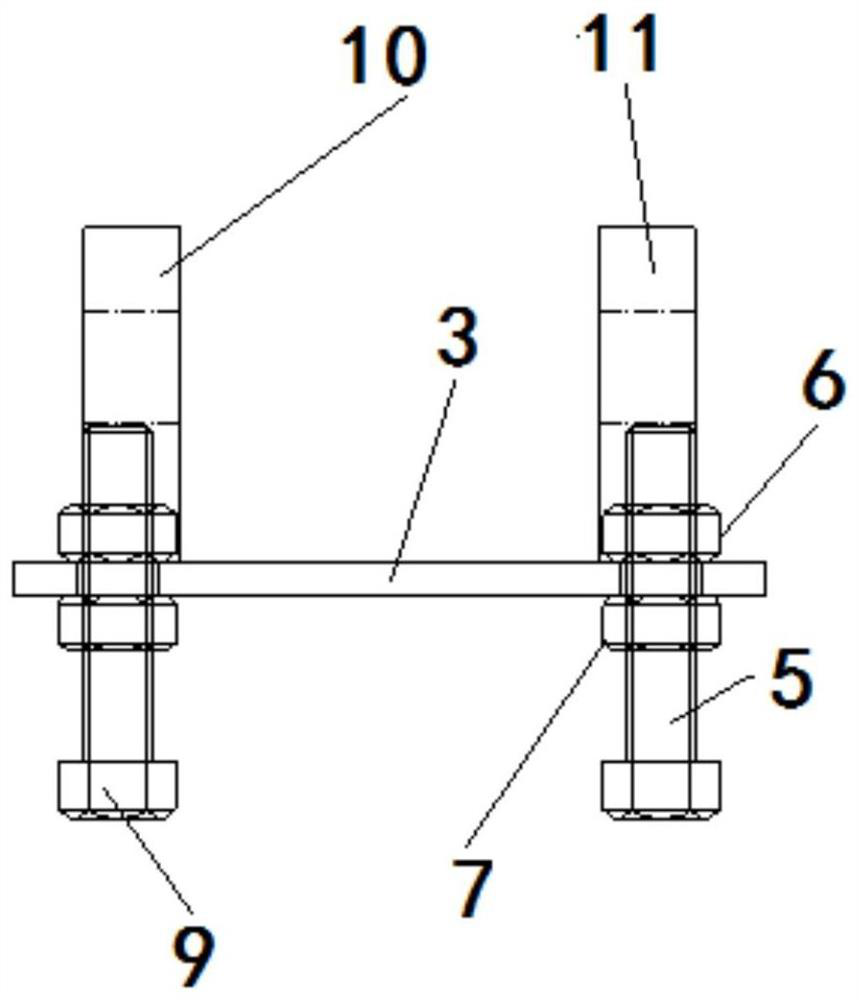

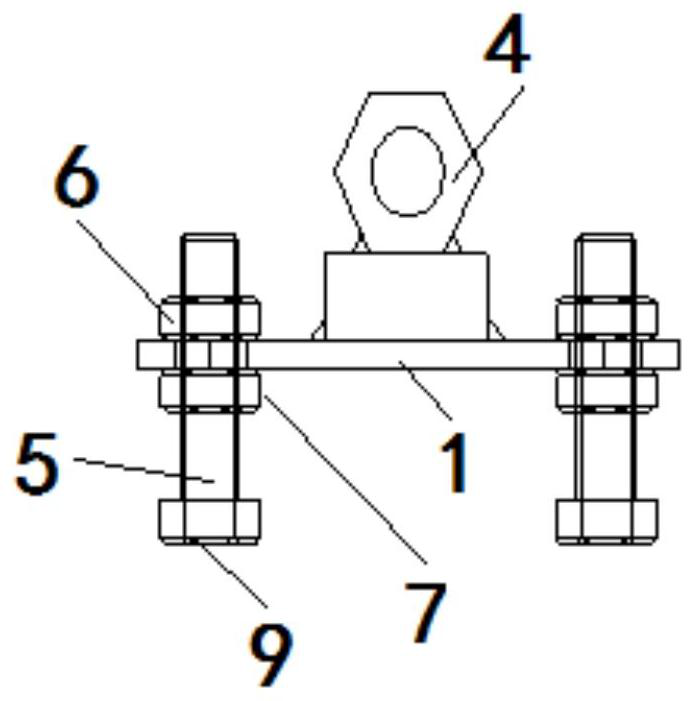

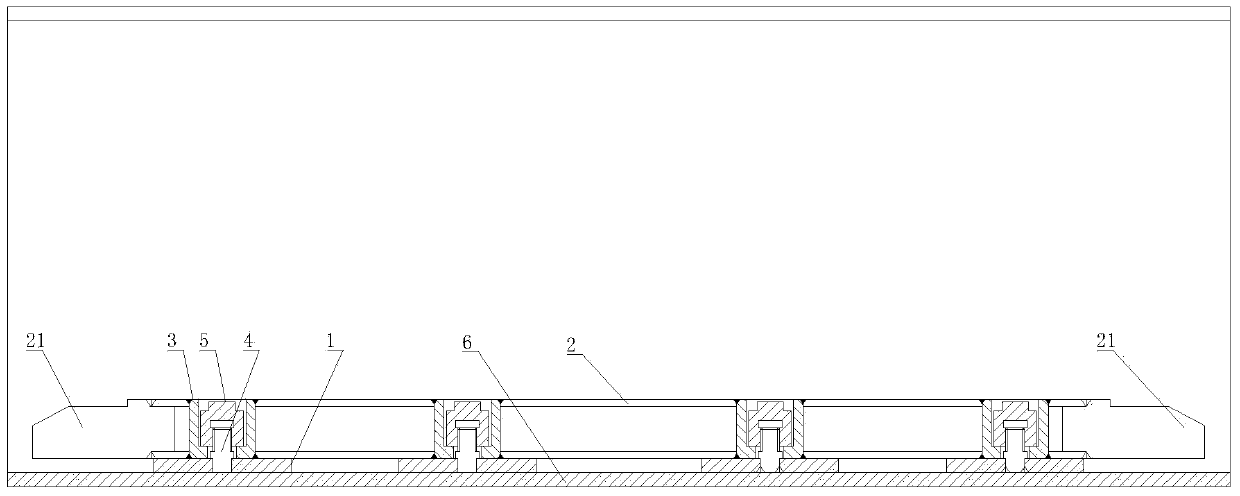

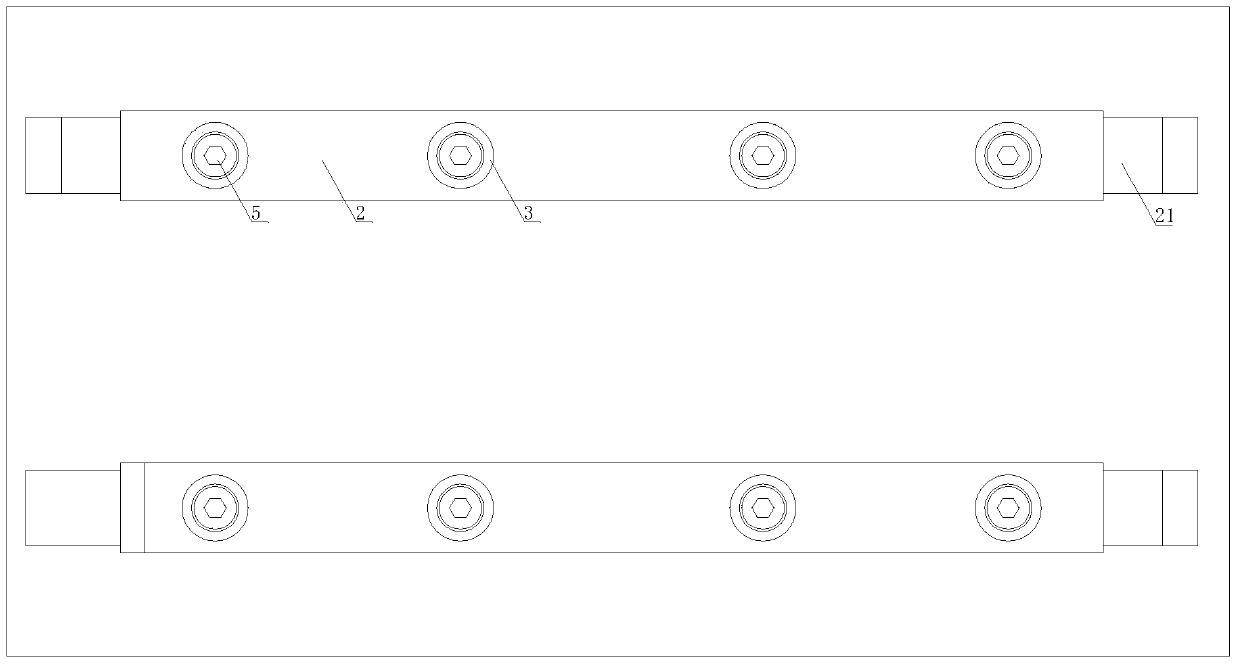

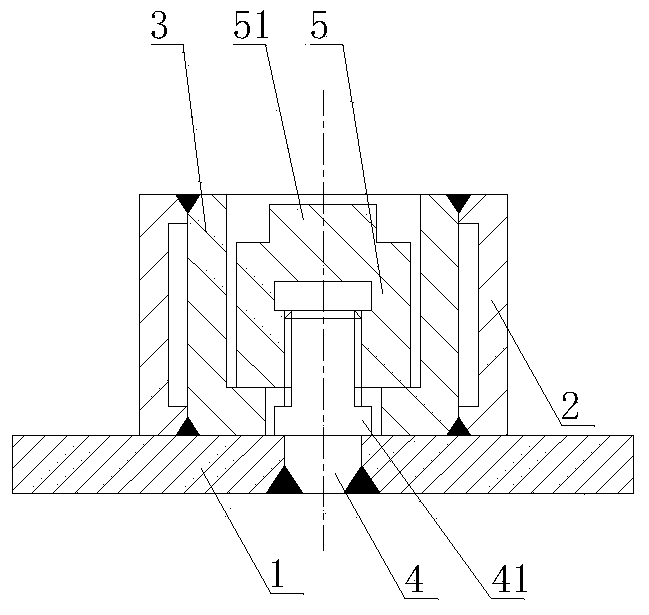

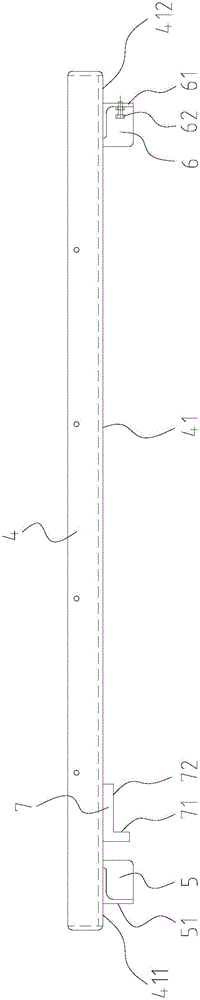

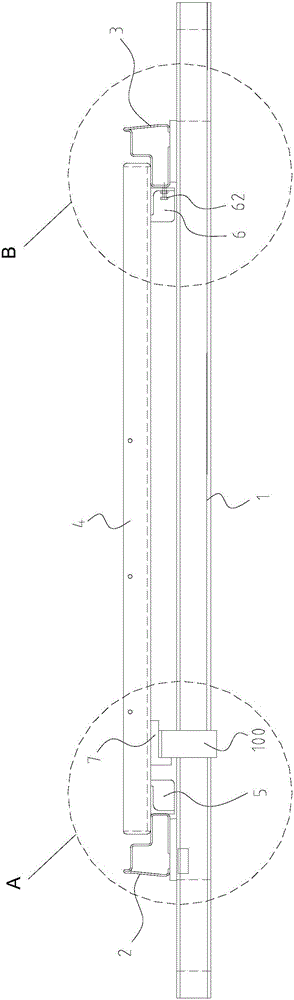

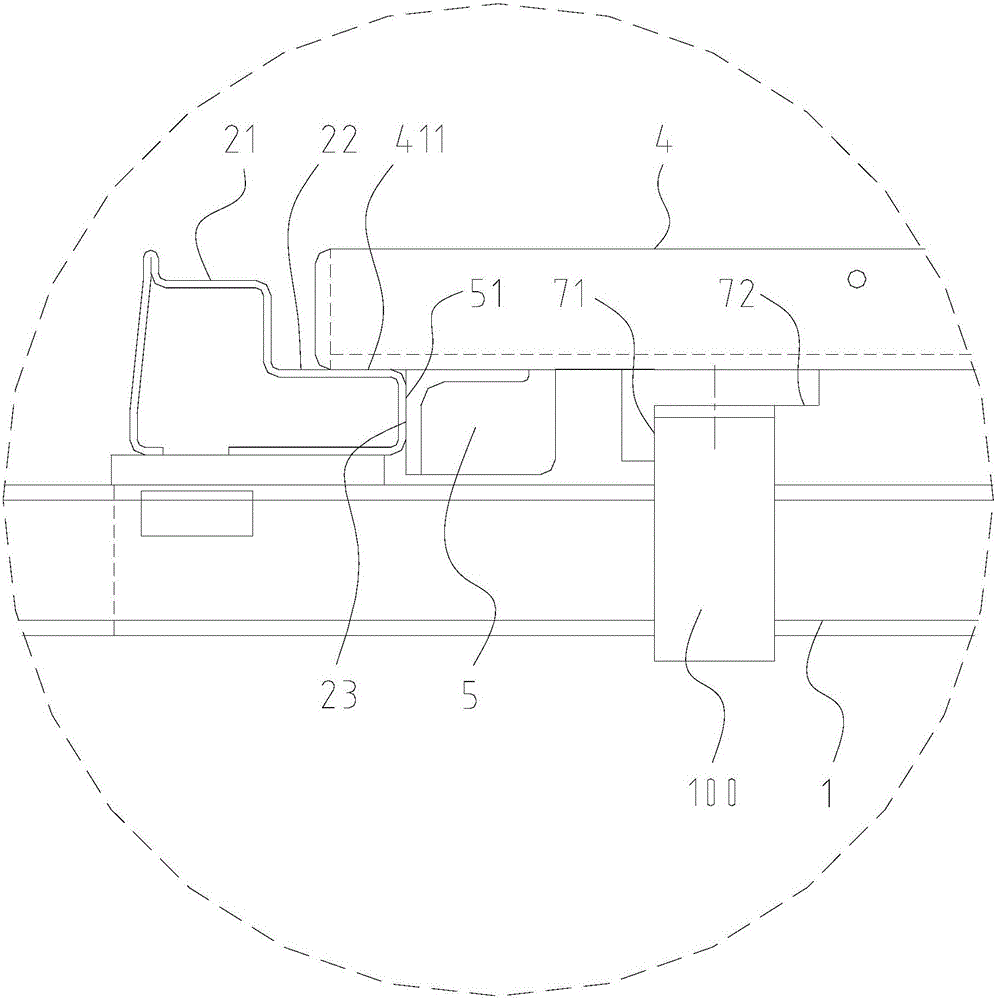

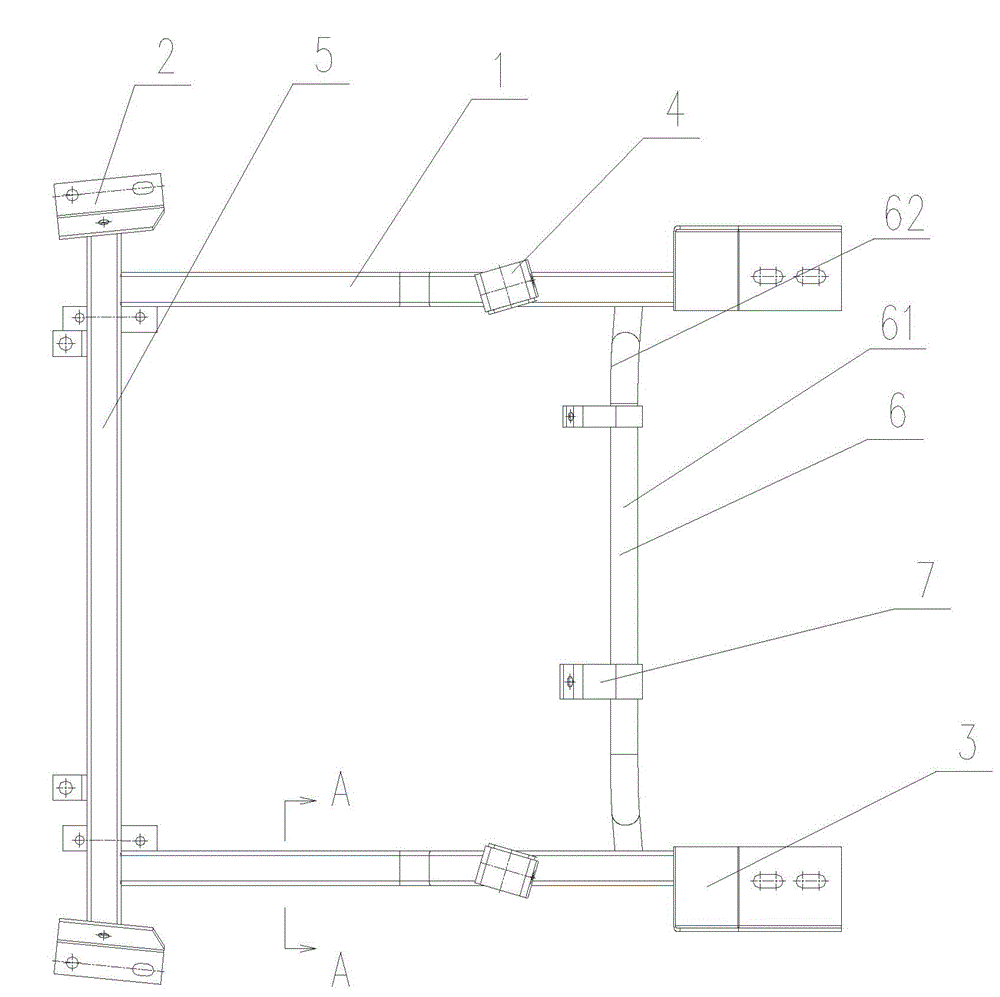

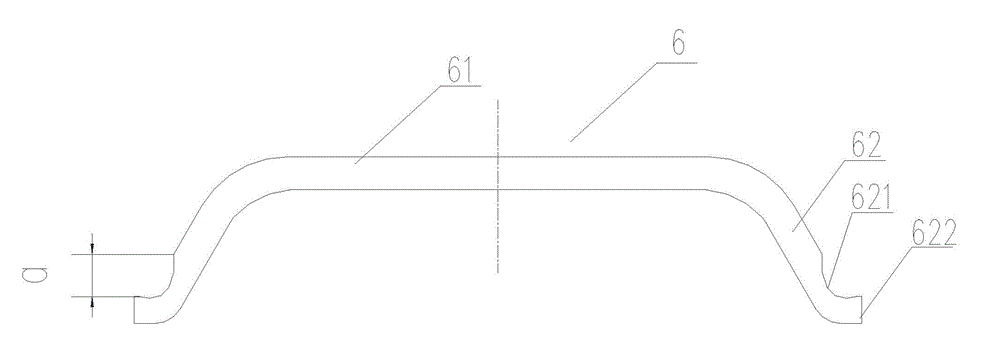

Positioning welding tool and positioning welding method for long-distance hinge bases

ActiveCN112372205ASimple structureEasy to manufactureWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWelding

The invention provides a positioning welding tool for long-distance hinge bases applied to the technical field of workpiece / box hinge bases, and further relates to a positioning welding method for thelong-distance hinge bases. Each positioning assembly (1) of the positioning welding tool for the long-distance hinge bases comprises a base (3), lug plates (4), adjusting bolts (5), adjusting nuts I(6) and adjusting nuts II (7), wherein a plurality of adjusting holes (8) are formed in the base (3), each adjusting bolt (5) passes through each corresponding adjusting hole (8), the adjusting nuts I(6) are screwed at the positions, above the base (3), of the adjusting bolts (5), and the adjusting nuts II (7) are screwed at the positions, below the base (3), of the adjusting bolts (5). By meansof the tool and method, positioning welding of the plurality of hinge bases can be conveniently and rapidly realized, and meanwhile, during positioning welding, the positioning size and the requirement for the coaxiality of all hinges are effectively guaranteed, so that the situation that hinge arms deform or clamping stagnation occurs when a product is overturned by using the hinges later is avoided.

Owner:WUHU SHIPYARD CO LTD

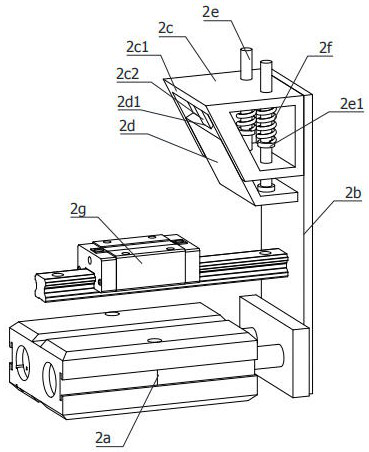

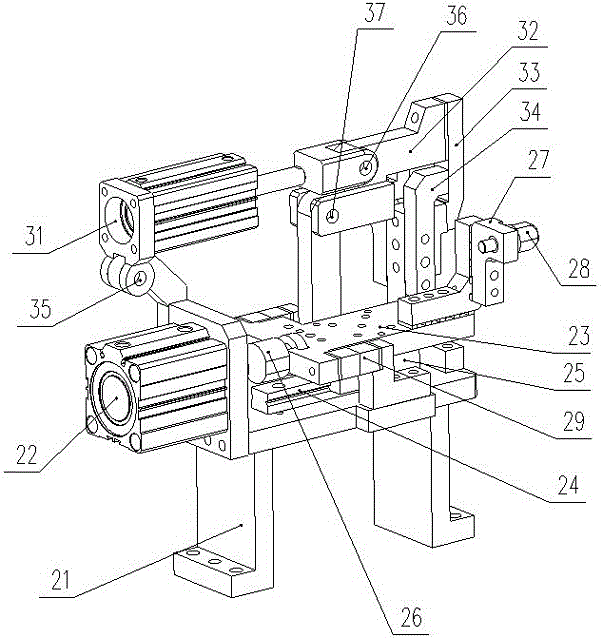

Overturning clamping device

ActiveCN105563000AReasonable structural designScientific and reasonable structure designWelding/cutting auxillary devicesAuxillary welding devicesFoot supportsEngineering

The invention provides an overturning clamping device. The overturning clamping device comprises a workbench, front side and rear side clamping mechanisms, a lateral clamping mechanism, first foot support bases and a second foot support base. The front side and rear side clamping mechanisms are installed on the workbench through the first foot support bases. The lateral clamping mechanism is installed on the workbench through the second foot support base. Two sets of the front side and rear side clamping mechanisms are arranged and correspond to the two ends of a part correspondingly. Each set of the front side and rear side clamping mechanisms is composed of two first clamping working sections and two first overturning working sections. The two first clamping working sections of each set of the front side and rear side clamping mechanisms are arranged on the front side and on the rear side of the part correspondingly. The lateral clamping mechanism is arranged by corresponding to the middle of the part and comprises a second clamping working section and a second overturning working section. The overturning clamping device is reasonable in structural design, low in cost, capable of accurately positioning and clamping the part and good in effect through combination of the front side and rear side clamping mechanisms with the lateral clamping mechanism.

Owner:柳州市楷都汽车零部件有限公司

Detachable sterilization vehicle track for sterilization cabinet

ActiveCN104208732AIncrease drynessEasy dischargeLavatory sanitoryDisinfectionAgricultural engineeringCushion

The invention discloses a detachable sterilization vehicle track for a sterilization cabinet, which is convenient to clean and is high in sanitation degree. The detachable sterilization vehicle track comprises a plurality of cushion blocks arranged on a bottom plate of the sterilization cabinet, wherein each cushion block is provided with two parallel closed trolley tracks with the cross section in a rectangular shape, each track is provided with a plurality of mounting holes, a lining sleeve is arranged in each mounting hole in a sealing mode, the bottom of each lining sleeve is provided with a locating plate, the center of each locating plate is provided with a connecting through hole, each cushion block is fixedly connected with a mounting bolt, the upper part of each mounting bolt penetrates out of the corresponding connecting through hole, each lining sleeve is internally provided with a compression part, the top surface of each compression part is not higher than that of the corresponding lining sleeve, and each compression part is provided with a threaded hole which is connected with the corresponding mounting bolt.

Owner:张家港欧思瑞医疗科技有限公司

Thermal-magnetic release for circuit breakers

ActiveCN106898528BSimple assembly structureSimple and reliable assembly structureProtective switch operating/release mechanismsEngineeringRelease - action

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

Mold for soldering copper mesh

ActiveCN104551501BSimple structureFunctionalWelding/cutting auxillary devicesAuxillary welding devicesCopperMaterials science

Owner:日照大正焊接材料有限公司

Multi-station working platform for machining

ActiveCN111390847AEasy to operateInnovative designGrinding carriagesWelding/cutting auxillary devicesControl switchMachining

The invention relates to the technical field of machining, in particular to a multi-station working platform for machining. The upper surface of a platform surface is divided into four station areas,each station area is provided with an independent control switch, and a station table is arranged above each station area, each station area is connected with the corresponding station table through an adjusting part, a limiting tool for fixing a workpiece is fixedly arranged above each station table, and a protective cover is arranged above each control switch. The multi-station working platformfor machining is novel in design and simple in structure, annular pipes can be fixed from the interiors of the annular pipes through the limiting tools, welding and grinding between the two annular pipes are facilitated, the labor intensity and the rework rate are reduced, the overall operation efficiency is improved, the station tables can be located at any angle through bidirectional adjustmentof the adjusting parts, convenience is provided for welding of an operator, the operator can conveniently adjust the station tables according to the welding habit of the operator, and the normal welding level is guaranteed.

Owner:JIANGSU OCEAN UNIV

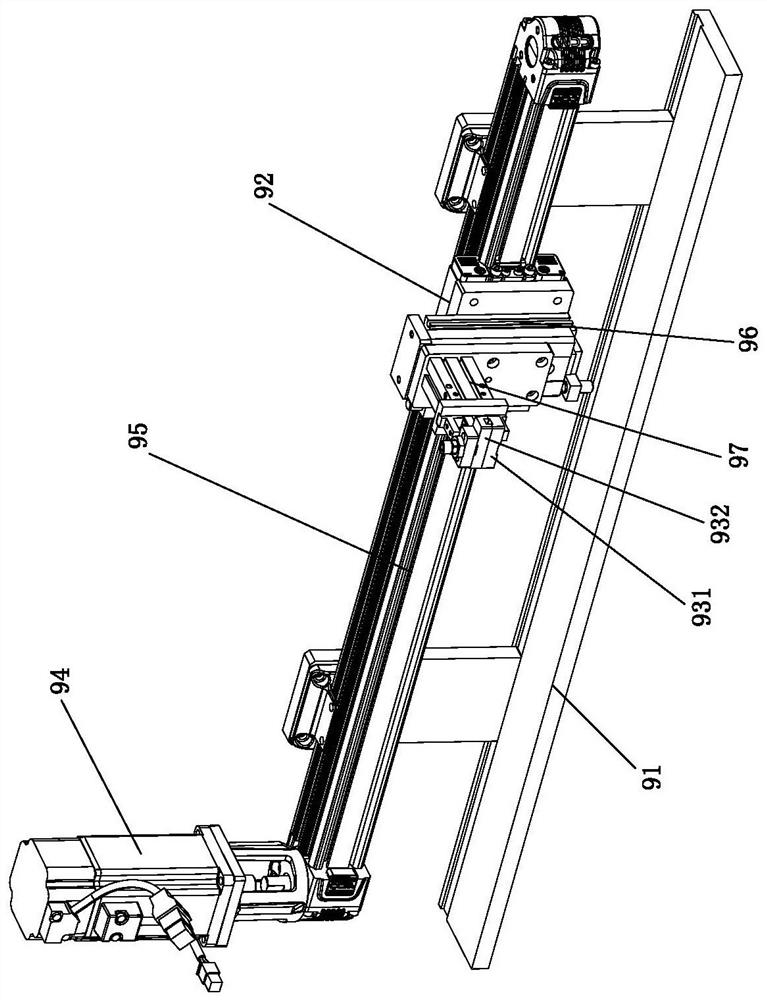

Valve welding equipment with lifting, rotating and adjusting integrated function

ActiveCN113828952AEasy to turn and adjustImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringVALVE PORT

The invention discloses valve welding equipment with a lifting, rotating and adjusting integrated function. The valve welding equipment with the lifting, rotating and adjusting integrated function comprises a positioning seat; a positioning disc is rotationally arranged at one end of the top of the positioning seat; a positioning frame is fixedly arranged in the middle of the top of the positioning disc; a first feeding frame is fixedly arranged at the top end of the positioning frame; a first electric telescopic rod is fixedly arranged in the middle of the top of the positioning frame; and a feeding plate is fixedly arranged at the telescopic end of the first electric telescopic rod. According to the invention, to-be-welded valve parts are placed on the first feeding frame and the second feeding frame, the two fixing discs drive the rotating disc and the protective pad on one side to be clamped at the two ends of a first workpiece, the to-be-welded outer ring of a second workpiece is uniformly and stably welded through the welding equipment, so that feeding, rotating and adjusting of the valve welding equipment are more convenient, the working efficiency of valve welding is improved, the welding precision is higher, and the practicability of the valve welding equipment with the lifting, rotating and adjusting integrated function is improved.

Owner:浙江高中压阀门有限公司

Positioning welding device for anti-jump rail bracket of escalator

ActiveCN103831570BGuaranteed installation qualityConvenient welding positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineering

The invention discloses a positioning and welding device of an anti-jumping rail support of an escalator. The linear segment of the escalator is provided with connecting channel steel, a left main auxiliary rail and a right main auxiliary rail, wherein the left main auxiliary rail is provided with a first horizontal supporting face and a first side face, and the right main auxiliary rail is provided with a second horizontal supporting face and a second side face. The anti-jumping rail positioning and welding device comprises a transverse rod body, and the left end and the right end of the transverse rod body can be supported on the first horizontal supporting face and the second horizontal supporting face respectively; the transverse rod body is provided with a fixing block tightly abutting against the first side face correspondingly and a locking connecting structure tightly abutting against and locking the second side face correspondingly; the transverse rod body is further provided with a two-way positioning block used for limiting the horizontal distance and the welding height between the anti-jumping rail support and the first side face. By adopting the positioning and welding device of the anti-jumping rail support of the escalator, the anti-jumping rail support can be positioned and welded quite conveniently, fast and accurately, and it is guaranteed that the mounting quality of subsequent anti-jumping rails can meet mounting requirement.

Owner:SJEC CORP

Washing machine water level sensor element shear foot fixing device

Owner:SELONG ELECTRIC

Centralized layout electro-hydraulic power steering system for large full load passenger car

Owner:DONGFENG COMML VEHICLE CO LTD

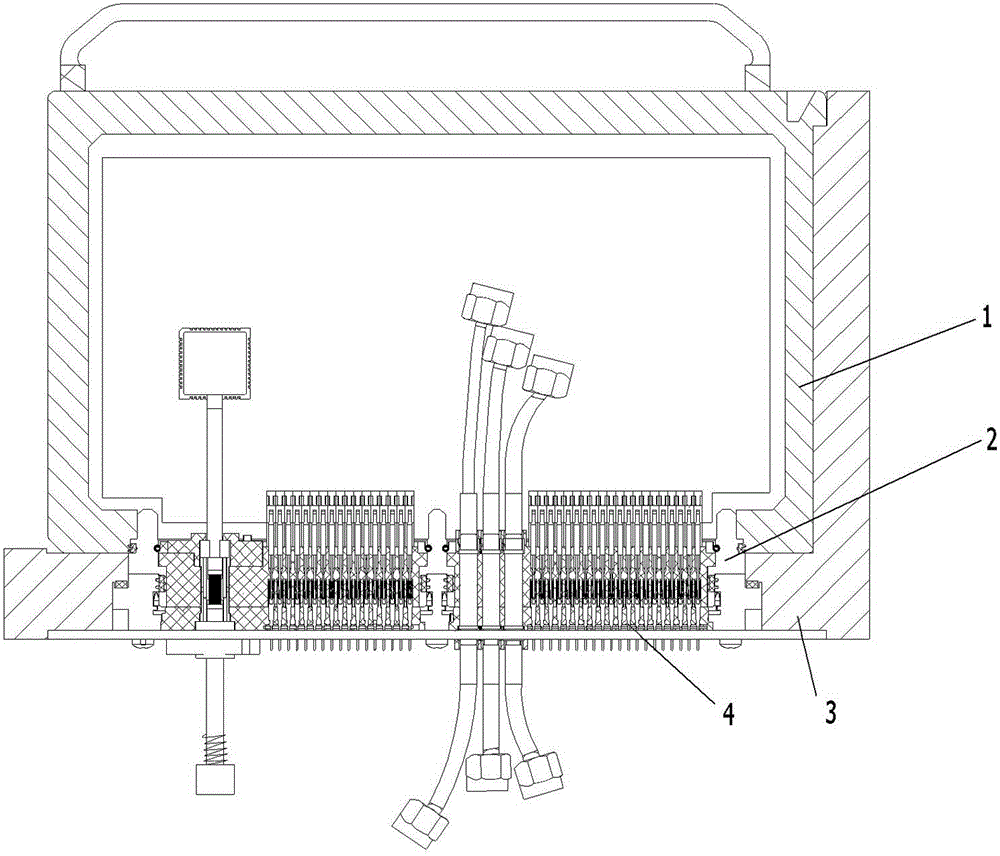

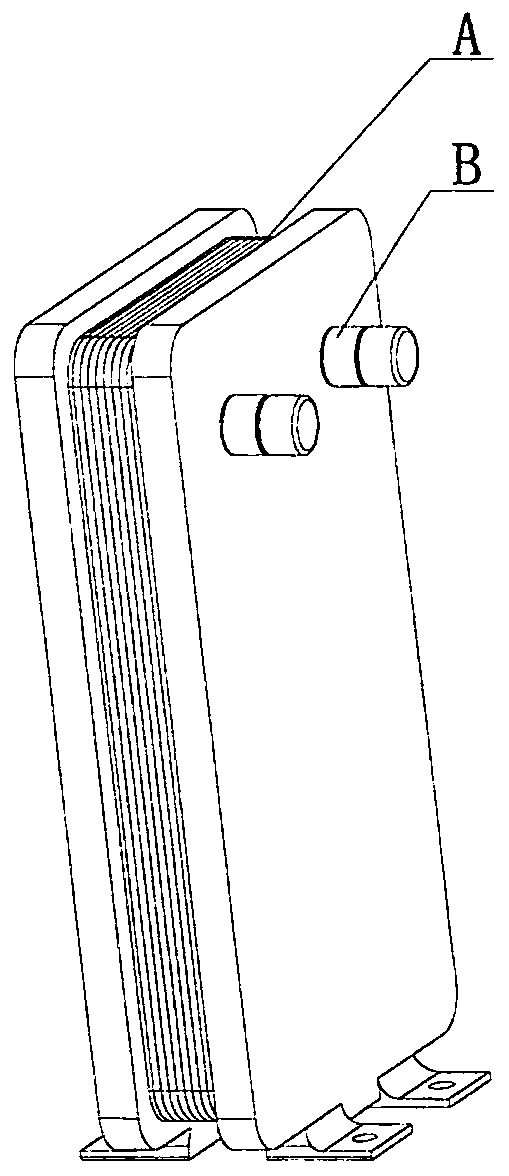

Contact of vacuum interrupter, vacuum interrupter and vacuum circuit breaker

ActiveCN110729151BStable supportAvoid dent deformationHigh-tension/heavy-dress switchesAir-break switchesEngineeringElectric current flow

The invention relates to a vacuum interrupter contact, a vacuum interrupter and a vacuum circuit breaker. The vacuum interrupter contact includes: a conductive rod on which a contact seat with a hollow cavity is arranged; a contact piece fixed on The end surface of the contact seat; the support body is arranged between the bottom of the contact seat and the contact sheet, and is used to support the contact sheet; the support body includes a support body body, and in the extending direction of the conductive rod, the support body At least one of the two ends of the main body is provided with an insulating layer, which can prevent the current flowing through the conductive rod from flowing through the support body, and compared with the current part of the current flowing through the support body in the prior art, it increases the contact strength. The circular current on the head improves the magnetic field generated by the circular current on the contacts, thereby enhancing the arc extinguishing capability of the vacuum interrupter and solving the problem that the contacts of the vacuum interrupter are easily ablated in the prior art.

Owner:PINGGAO GRP +2

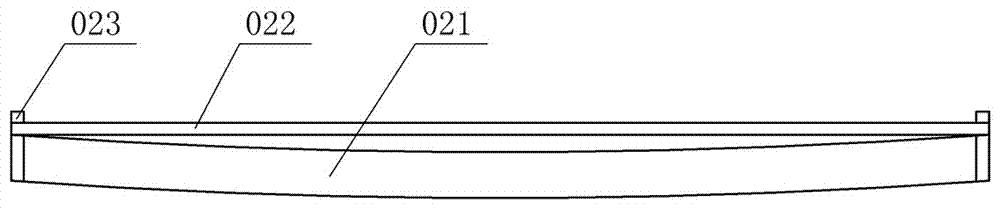

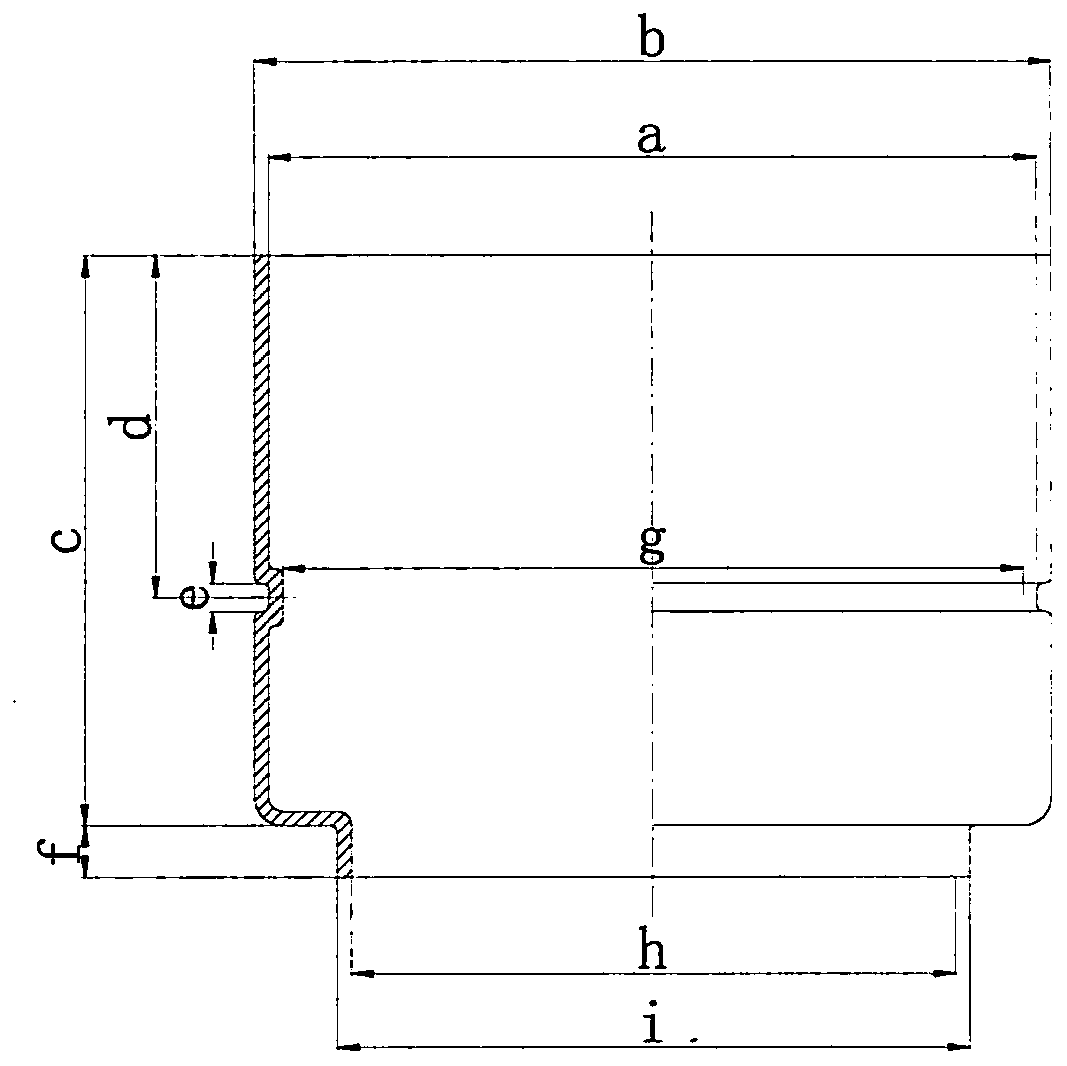

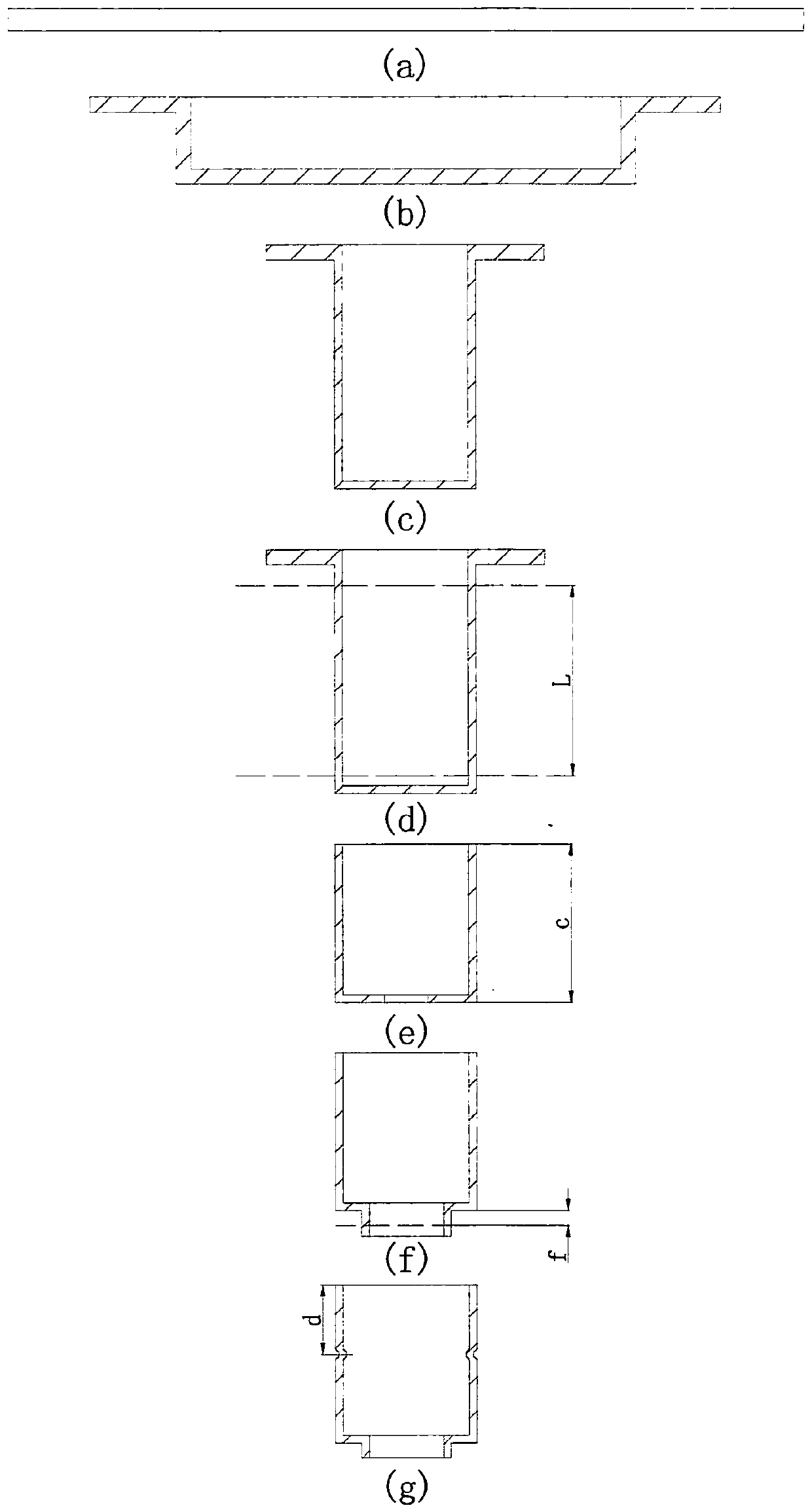

Expansion-type welded tensile joint and its realization process

ActiveCN108515323BLow costSimple structureHeat exchanger casingsHeat exchanger fasteningManufactured materialSS - Stainless steel

The invention discloses an expanded-connection-type welding stretching connecting pipe and two stretching forming processes thereof. The stretching forming process adopting a stainless steel plate comprises the working procedures that preparation is conducted; the plate is continuously stretched through a stretching die; the two ends of the connecting pipe are milled; forming is conducted througha spinning die; the bottom end of the connecting pipe is flanged through a flanging die; the bottom end of the connecting pipe is milled; a limiting groove is extruded through an extruding die; the expanded connection position is cleaned; expanded connection is conducted; and quality inspection is conducted. The stretching forming process adopting a stainless steel pipe comprises the working procedures that preparation is conducted; the bottom end of the pipe is milled; forming is conducted through the spinning die; the bottom end of the connecting pipe is flanged through the flanging die; thebottom end of the connecting pipe is milled; the limiting groove is extruded through the extruding die; the expanded connection position is cleaned; expanded connection is conducted; and quality inspection is conducted. The expanded-connection-type welding stretching connecting pipe and the two stretching forming processes thereof have the advantages that the processing processes of the connecting pipe are simplified, and the raw material cost and the machining cost are greatly reduced.

Owner:JIANGSU BAODE HEAT EXCHANGER EQUIP

Front sub-frame of minicar

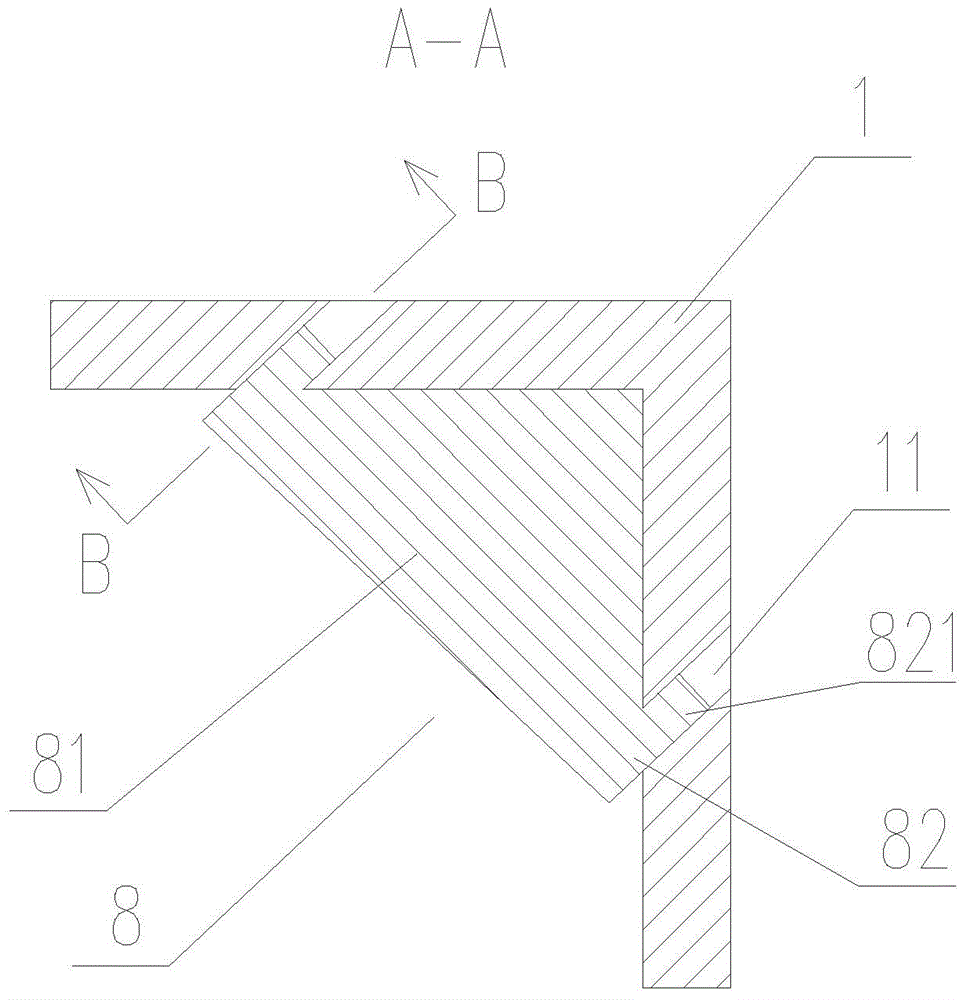

InactiveCN105644623AConvenient welding positioningReduce FixturesUnderstructuresVehicle frameEngineering

The invention relates to a front sub-frame of a minicar, and provides a front sub-frame for the minicar, which is simple in structure and high in strength, and through the adoption of the front sub-frame, the number of tooling fixtures can be effectively reduced, the capital investment can be reduced, and the labor intensity can be reduced. The front sub-frame takes the shape of a framework, and comprises a pair of front stringers, a pair of front brackets, a pair of rear brackets, a pair of front swing arm brackets, a beam and a steering gear bracket, wherein the steering gear bracket comprises a fixing rod and a pair of connecting rods; the connecting rods are separately arranged at two ends of the fixing rod, and are separately arranged on the front stringers; abdicating grooves are separately formed in each of the connecting rods, and each of the connecting rods is provided with a supporting segment; a plurality of reinforcing blocks are also arranged on the front stringers; each of the reinforcing blocks comprises a reinforcing medium plate and a pair of reinforcing side plates, wherein the reinforcing medium plate is triangular; each of the reinforcing side plates comprises a reference column and a supporting extension plate which are integrally connected; a plurality of positioning holes are formed in each of the front stringers. According to the front sub-frame disclosed by the invention, the tooling fixtures are reduced, the investment cost is reduced, the labor intensity is reduced, and the structure strength is improved.

Owner:JIANGSU DAOJUE GRAND NEW ENERGY VEHICLE

Motorcycle front panel installing plate structure

The invention discloses a motorcycle front panel installing plate structure. The motorcycle front panel installing plate structure comprises a front panel installing plate, wherein the profile of the outer periphery of the front panel installing plate is turned up, the middle portion of the front panel installing plate is provided with a T-shaped hollow cavity, the upper end of the T-shaped hollow cavity is bent, the lower portion of a flanging is provided with two symmetrical arc notches, the front panel installing plate and a motorcycle frame installing block are connected through a U-shaped upper supporting rod and a convex lower supporting rod, the opening end of the upper supporting rod and the opening end of the lower supporting rod are connected with the motorcycle frame installing block, and the other end of the upper supporting rod and the other end of the lower supporting rod are respectively arranged at the bending position and the positions of the arc notches. The periphery of the front panel installing plate is turned up so that the stiffness is enhanced, materials in the middle part is removed, due to the fact that the reserved part is bent, not only is stiffness increased, but also welding position is determined for the upper supporting rod, and welding is convenient. A reserved arc is cut so that weld location is convenient. The positions where the upper supporting rod and the lower supporting rod are located are in lap joint with the motorcycle, contacting is convenient, and welding is benefited, and besides, during an installing process, location is benefited, welding is convenient, machining time is saved, working efficiency is improved, and safety of a motorcycle is further increased.

Owner:万李

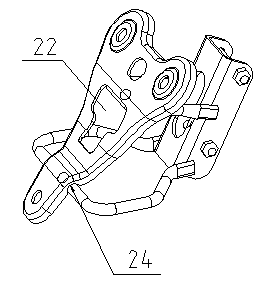

Small high-pressure storage tank

PendingCN112722514AImprove pressure resistanceConvenient welding positioningWithdrawing sample devicesRigid containersEngineeringPressure resistance

The invention discloses a small high-pressure storage tank. The small high-pressure storage tank comprises a lower half tank body with the upper portion opened and an upper half tank body with the lower portion opened, wherein a spigot structure is arranged between the upper half tank body and the lower half tank body; and the upper half tank body and the lower half tank body are welded. According to the small high-pressure storage tank, through the spigot structure, the upper half tank body and the lower half tank body can be nested, welding and positioning are convenient, and welding is matched; and a bolt fixing structure is arranged, and the high pressure resistance of the tank bodies is achieved.

Owner:SHANGHAI AUTOMATION INSTRAION CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com