Full-automatic double-end peeling and welding machine for data line

A data line, fully automatic technology, applied in the direction of connection, circuit/collector parts, electrical components, etc., can solve the problems of complex structural design, reduce processing efficiency, increase production cost, etc., achieve ingenious and reasonable structural design, and processing quality. Stable and consistent effect to improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

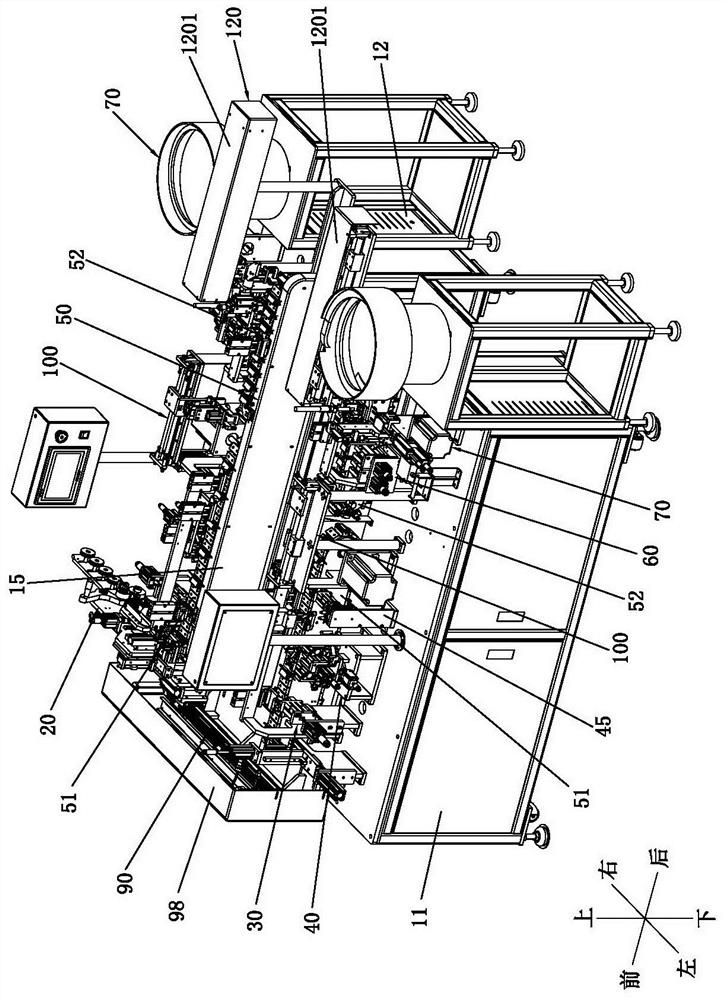

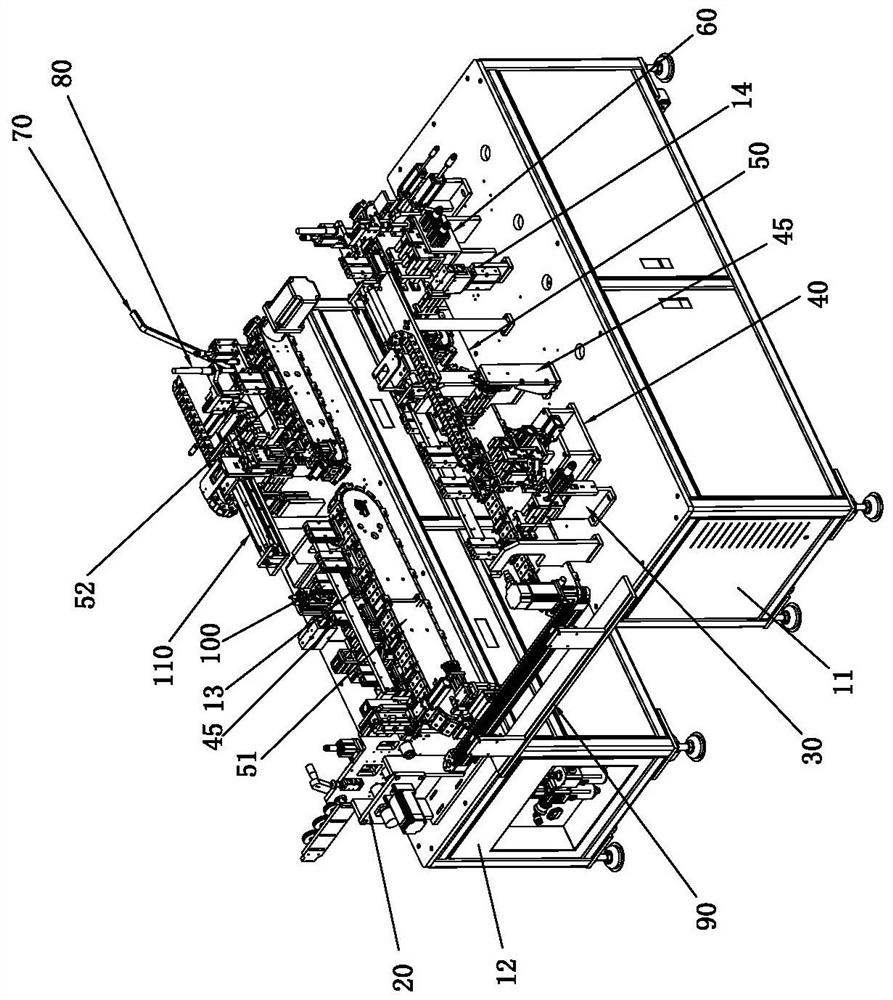

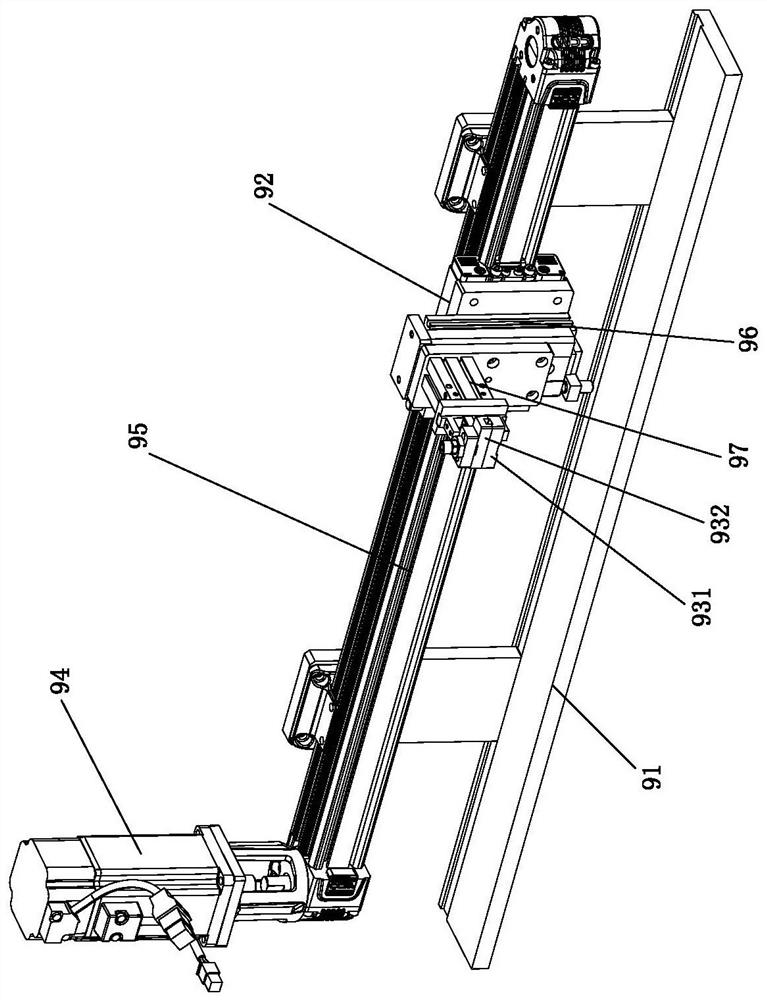

[0066] Please refer to Figure 1 to Figure 8 As shown, it shows the specific structure of the embodiment of the present invention.

[0067] A fully automatic double-head peeling and welding machine for data lines, including a left body 11, a right body 12, a first feeding mechanism 20 for conveying and cutting data lines, and a first peeling mechanism for stripping the data lines Mechanism 30, a whole line mechanism 40 for flattening and adjusting the relative position of two core wires, a positioning jig 13 for clamping and positioning data lines, a conveying mechanism 50 for conveying the displacement of the positioning jig, and a positioning jig for positioning the core wires. The second peeling mechanism 60 for stripping the outer covering, the second feeding mechanism 70 for conveying the joint and the welding mechanism 80 for welding the joint and the core wire; wherein: the first stripping mechanism 30, the whole line mechanism 40, the positioning The clamp 13, the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com