Two-section packing case structure of mining dump truck

A mining dump truck, two-stage technology, applied to the upper structure of the truck, upper structure, vehicle parts, etc., can solve the problems of reducing the service life of the container, increasing customer costs, and laborious labor, etc., to achieve convenient transportation , Convenient welding positioning, improving efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

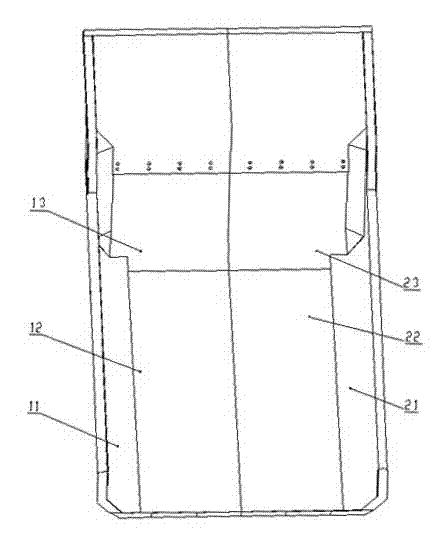

[0020] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the present invention comprises a left half container 1 and a right half container 2; the left half container 1 comprises a left main board assembly 11, a left bottom main board assembly 12, a left front main board assembly 13, and mutually Connection; the right half of the cargo box 2 includes the right mainboard assembly 21, the right bottom mainboard assembly 22, and the right front mainboard assembly 23, and is connected to each other; the left half of the cargo box 1 and the right half of the cargo box 2 are connected as one .

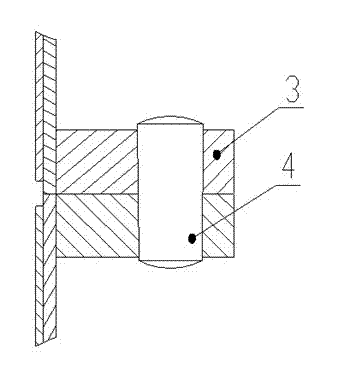

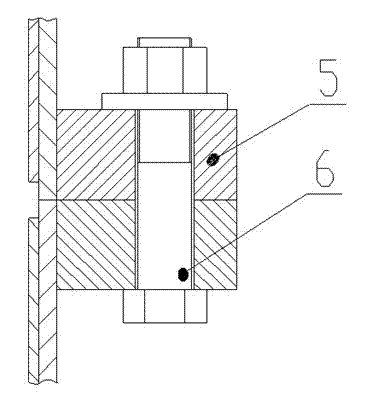

[0021] The present invention also includes a locating pin connecting block 3 and a conical locating pin 4, the locating pin connecting block 3 is paired and installed at the junction of the left half container 1 and the right half container 2, and the conical locating p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com