Contact of vacuum interrupter, vacuum interrupter and vacuum circuit breaker

A vacuum interrupter and contact technology, which is applied to high-voltage air circuit breakers, circuits, high-voltage/high-current switches, etc. The vacuum interrupter is not conducive to breaking large currents and other problems, so as to improve the magnetic field, avoid dent deformation, and improve the breaking capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

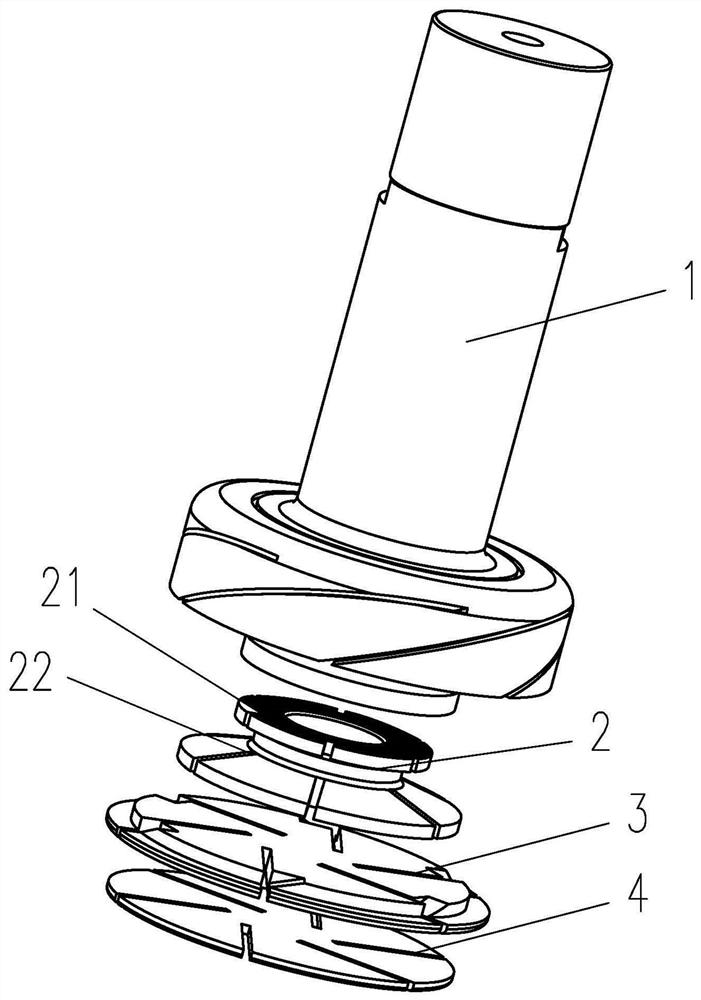

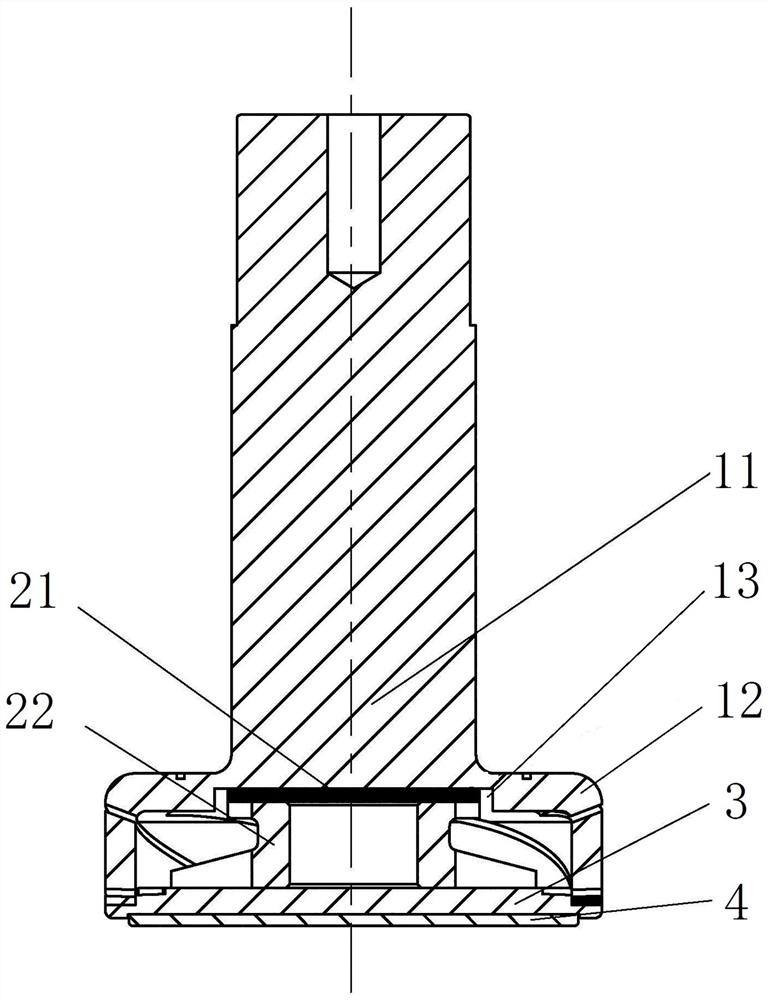

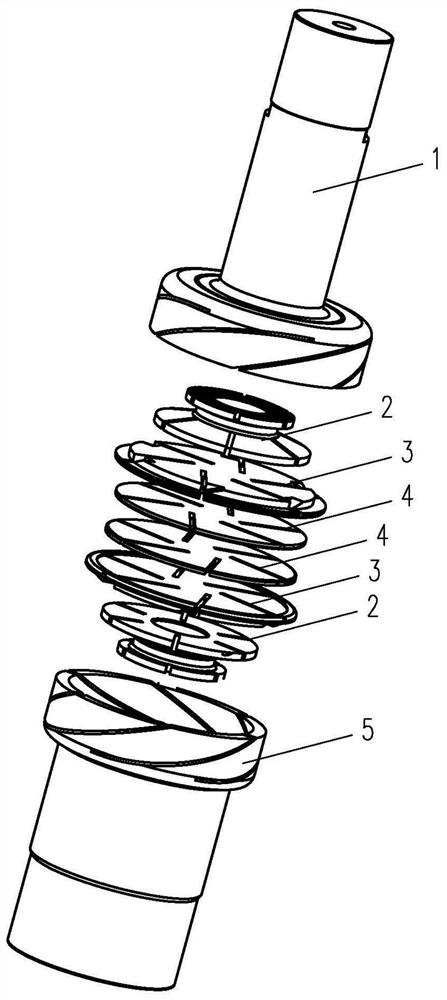

[0054] A specific embodiment of the vacuum interrupter contact of the present invention, such as figure 1 and figure 2 As shown, the vacuum interrupter contact includes a conductive rod 1, and the conductive rod 1 includes a rod body 11 and a contact seat 12 with a hollow cavity. The contact seat in this embodiment is a cup-shaped structure. The vacuum interrupter contact also includes a conductive sheet 3 and a contact sheet 4 fixed on the end surface of the contact seat 12, and the conductive sheet 3 is dish-shaped. The end faces are connected by soldering, the dish bottom part of the conductive sheet 3 is sunken toward the hollow cavity of the contact base 12 , and the other side of the conductive sheet 3 is connected to the contact sheet 4 by soldering. The conductive sheet 3 is made of copper and other conductive materials to ensure its good cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com