Patents

Literature

70results about How to "Avoid flowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

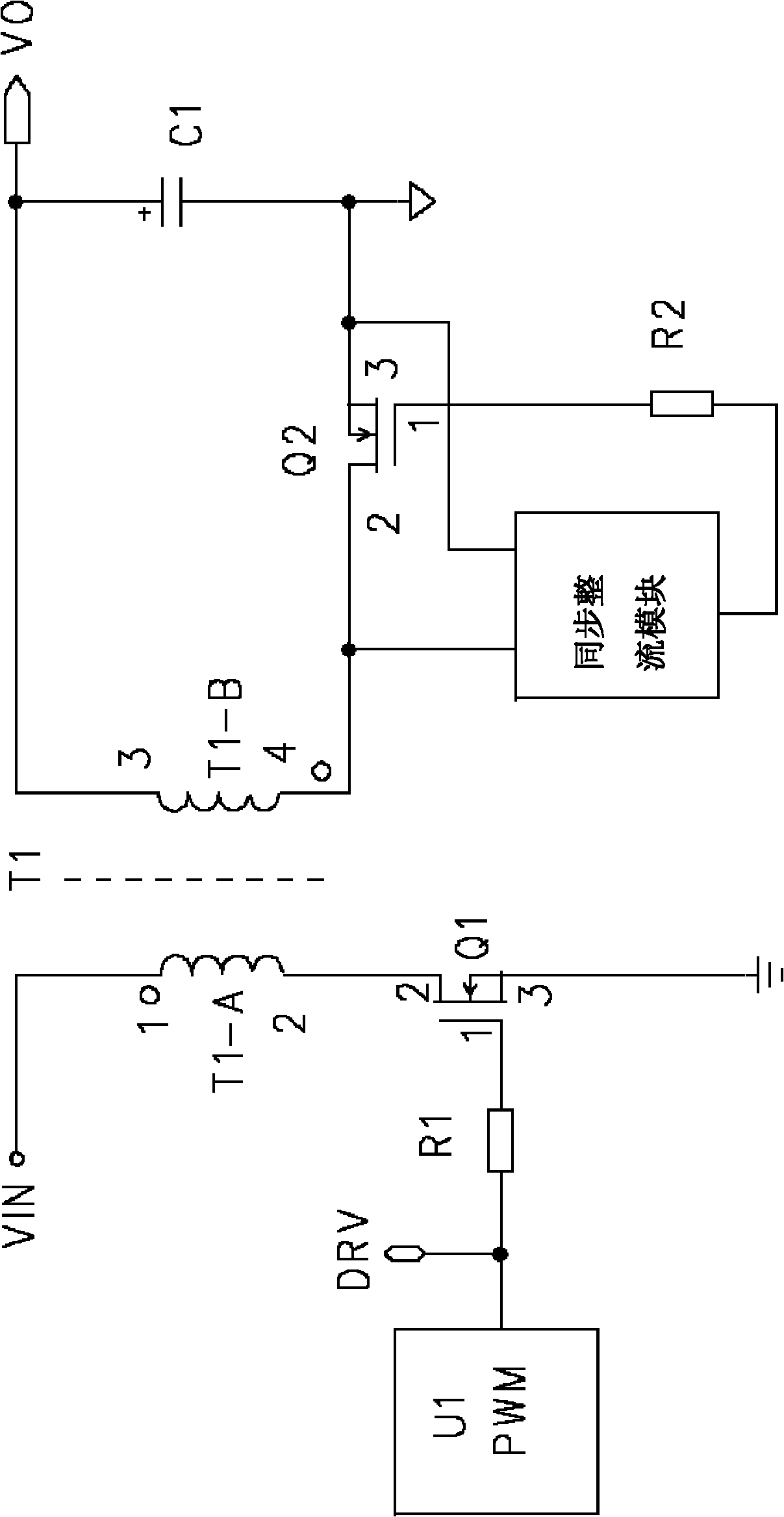

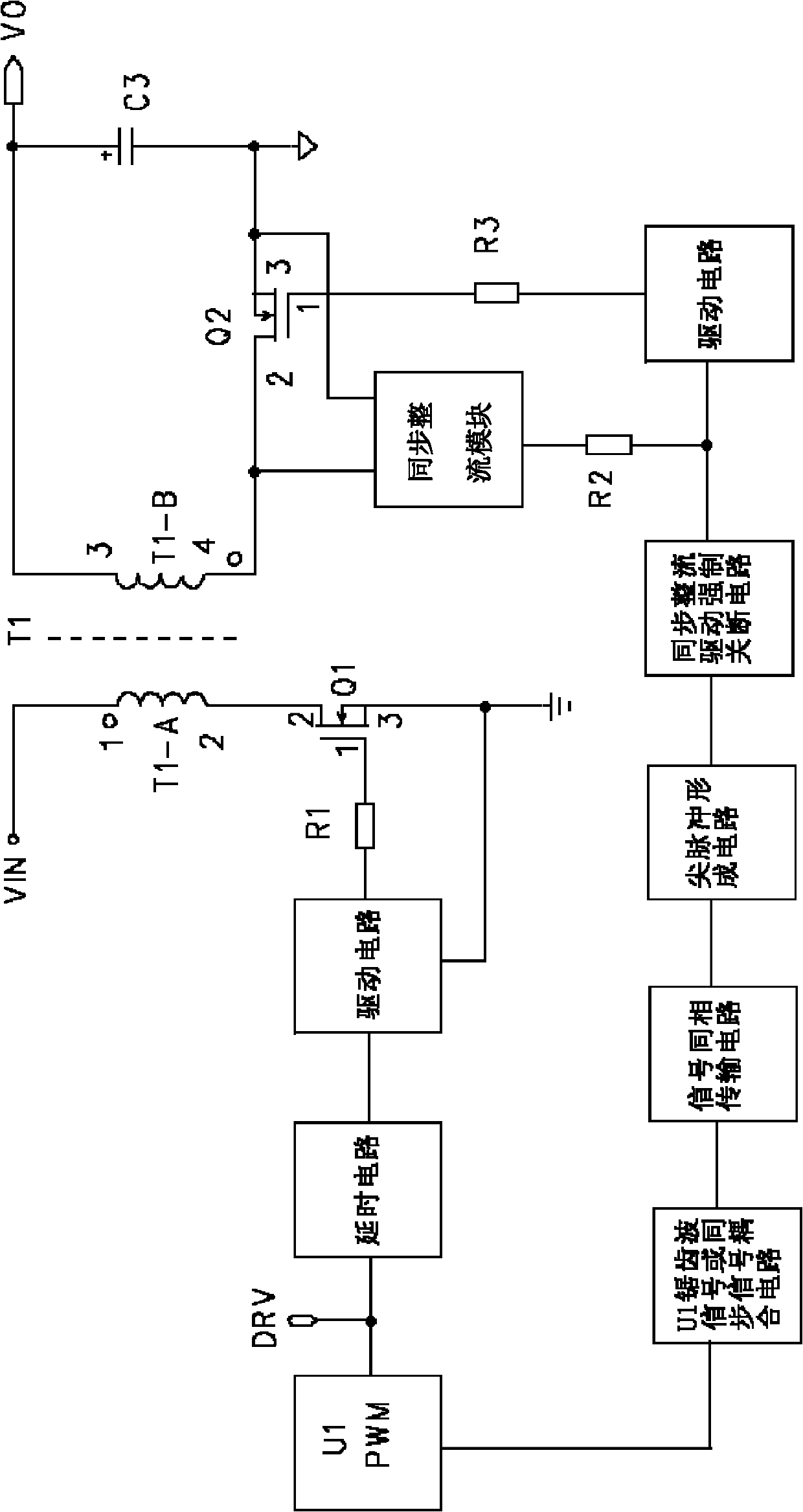

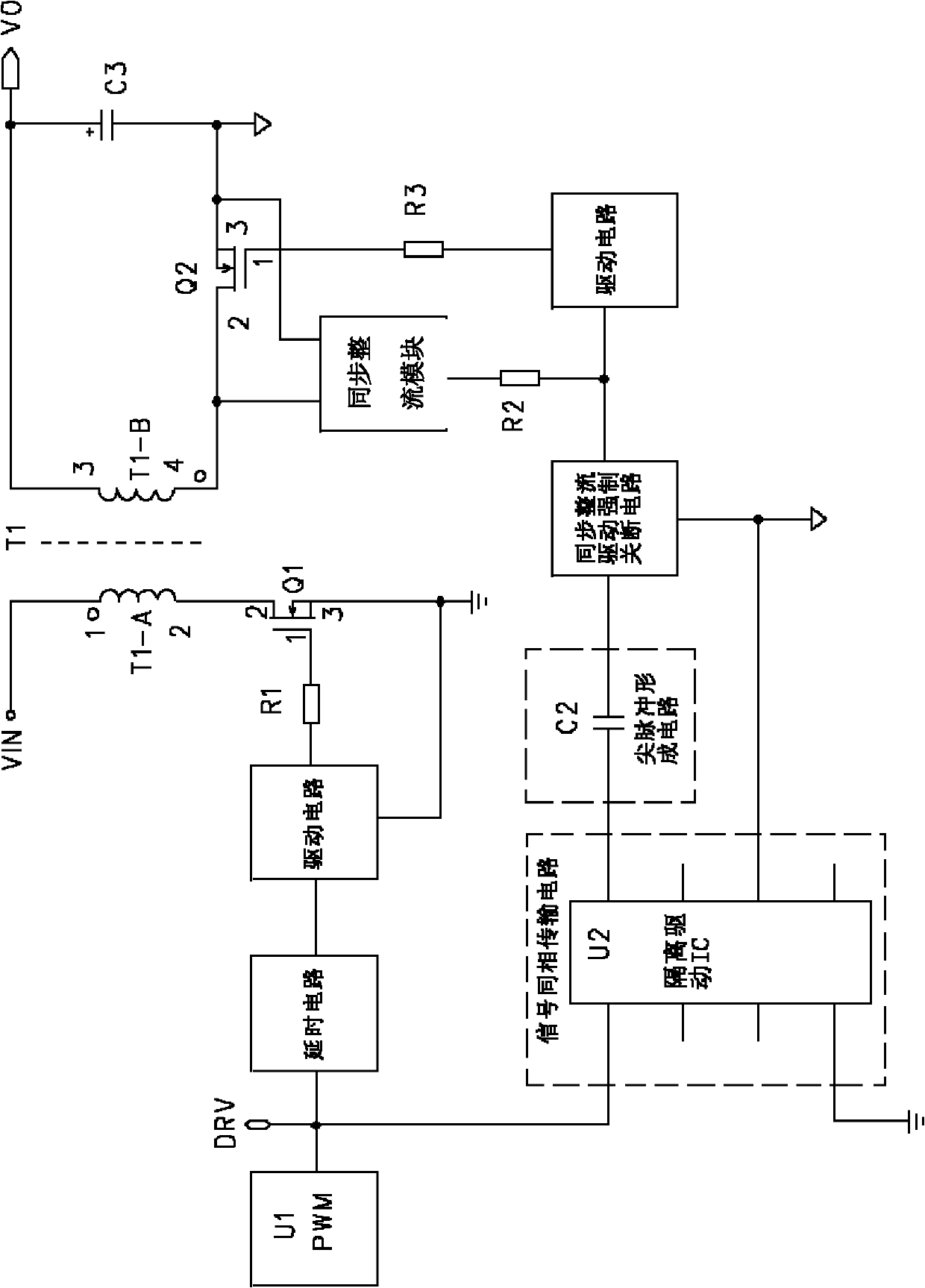

Flyback synchronous rectification control circuit

InactiveCN101951175AAvoid reverse current flowReduce losses and voltage stressAc-dc conversionReverse currentContinuous mode

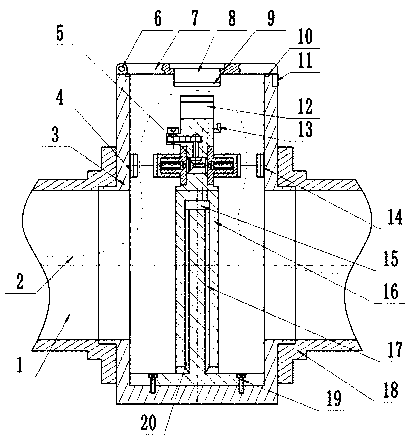

The invention relates to a flyback synchronous rectification control circuit, comprising a primary switching tube (Q1), a synchronous rectifier tube (Q2), a primary side of a main transformer (T1), a subsidiary side of the main transformer (T2), a synchronous rectifier module, a control circuit composed of a drive circuit (1), a delay circuit (2), a signal same-phase transmission circuit (3), a sharp pulse forming circuit (4) and a synchronous rectification forcibly turned-off circuit (5). When a power source operates in a continuous mode, the synchronous rectifier tube (Q2) can be forcibly turned off in advance through the control circuit, thus reverse current can not pass through the synchronous rectifier tube (Q2), thereby reducing the loss and the voltage stress of the synchronous rectifier tube (Q2), and improving the efficiency of the power source; and when the power source operates in a discontinuous mode or in a critical continuous mode, the control circuit is inoperative, and can not influence the normal operation of the circuit.

Owner:SHENZHEN VAPEL POWER SUPPLY TECH

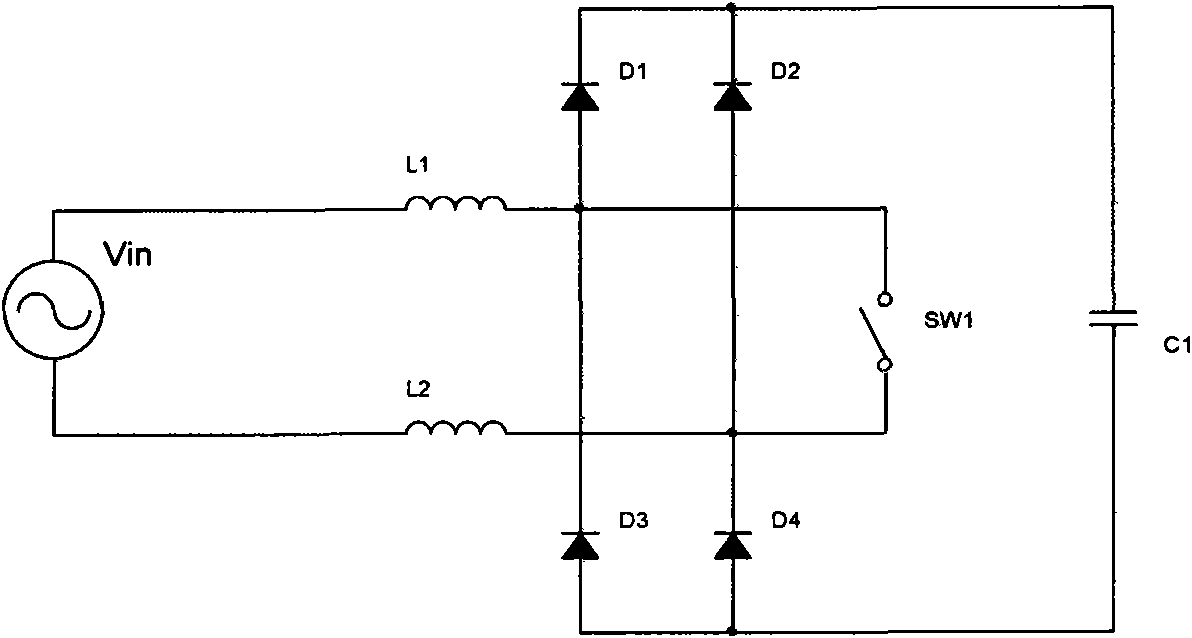

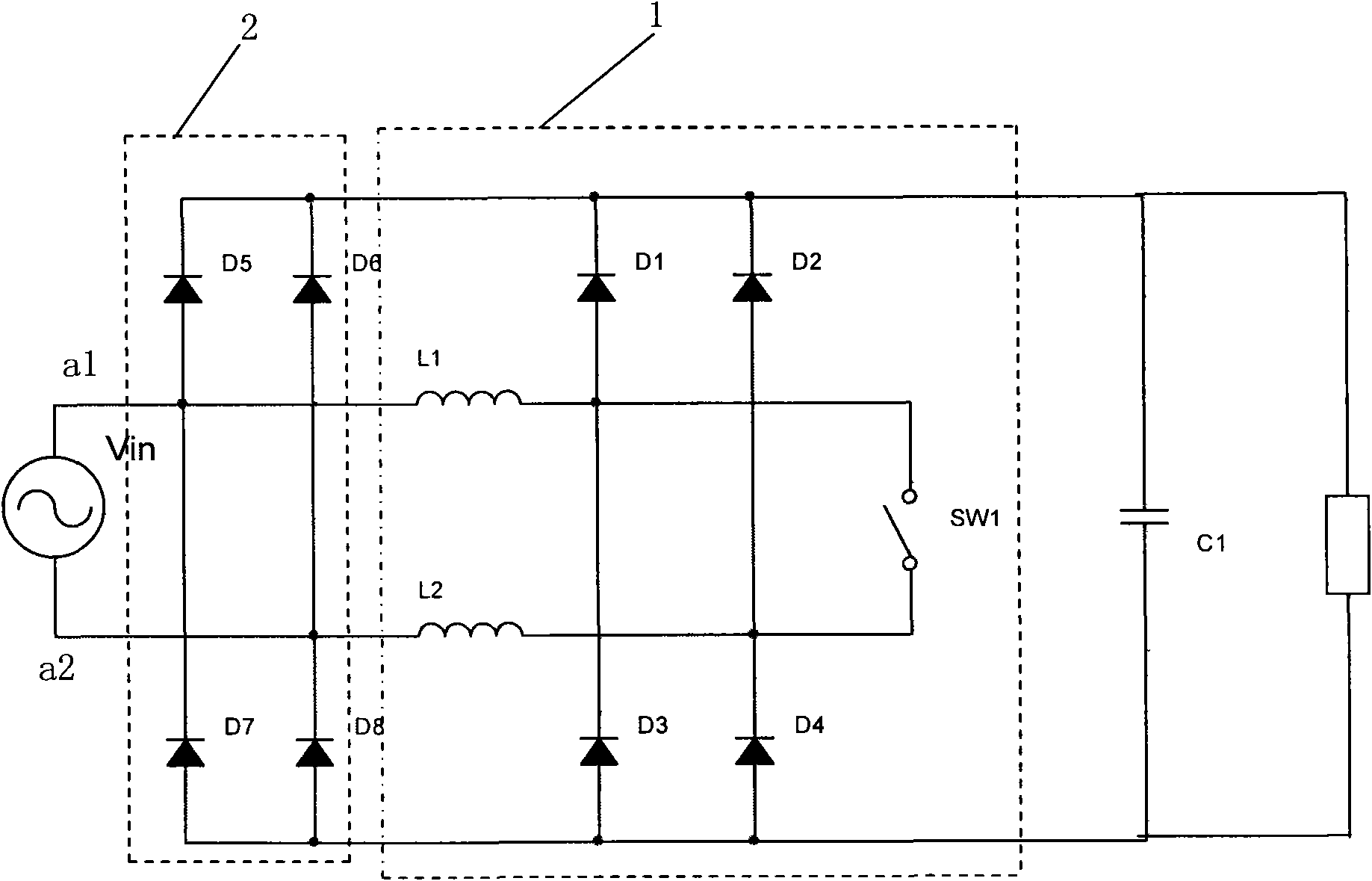

Anti-surge PFC circuit

ActiveCN101645649AAvoid flowingAvoid damageEfficient power electronics conversionEnergy industryCapacitanceEngineering

The invention relates to an anti-surge PFC circuit, which comprises a bridgeless PFC circuit and a filter capacitor sequentially connected between an alternating current power supply and a load, wherein a diode protective circuit is also connected between the alternating current power supply and the bridgeless PFC circuit and is used for directly guiding surge circuit to the filter capacitor C1. The anti-surge PFC circuit guides the surge current to directly flow to a PFC capacitor by increasing the diode protective circuit which is in bridge connection with an inductor and a diode in the bridgeless PFC circuit so as to prevent the surge current from flowing through the PFC capacitor and prevent the damages to a switching element.

Owner:VERTIV CORP

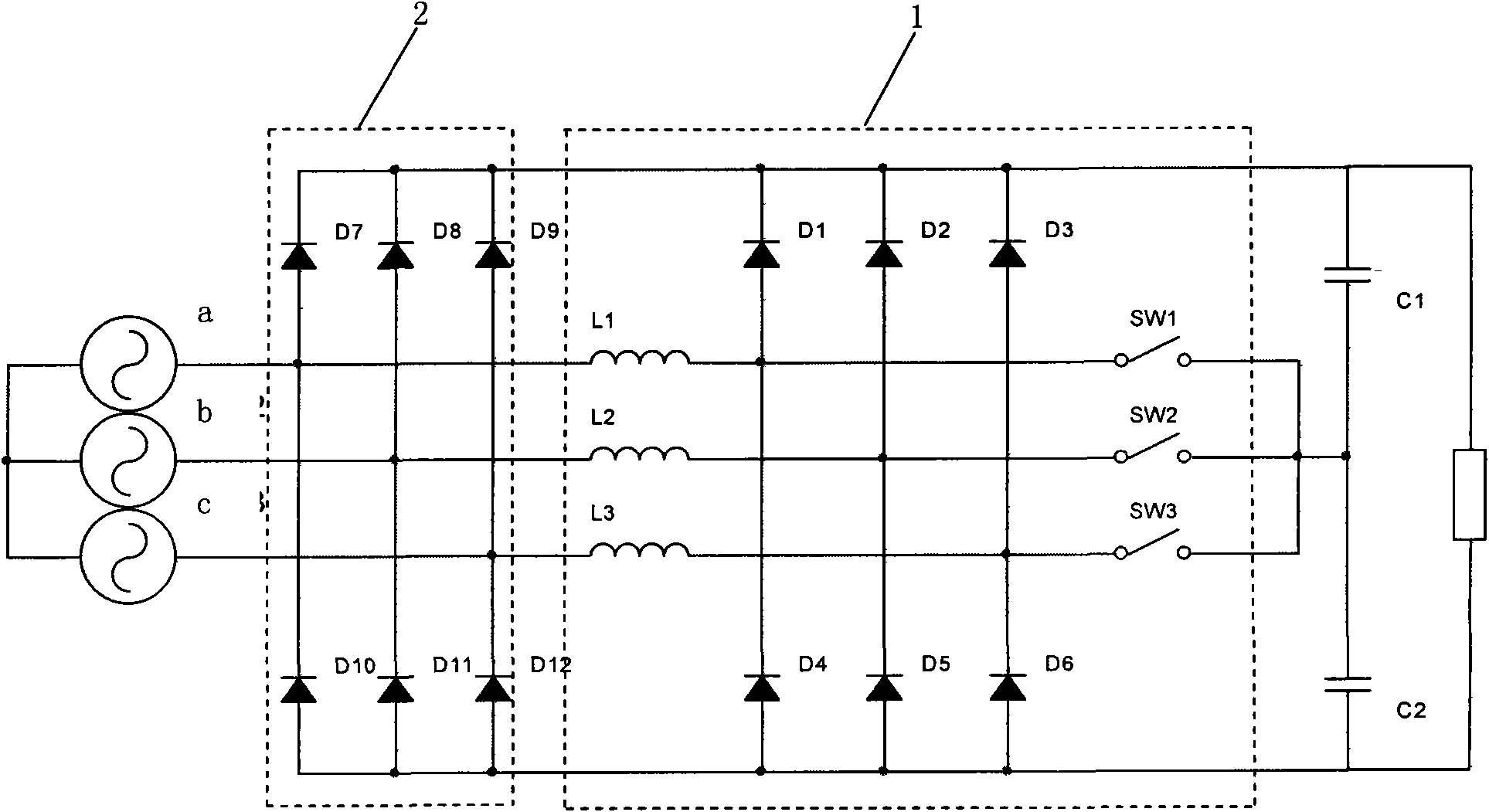

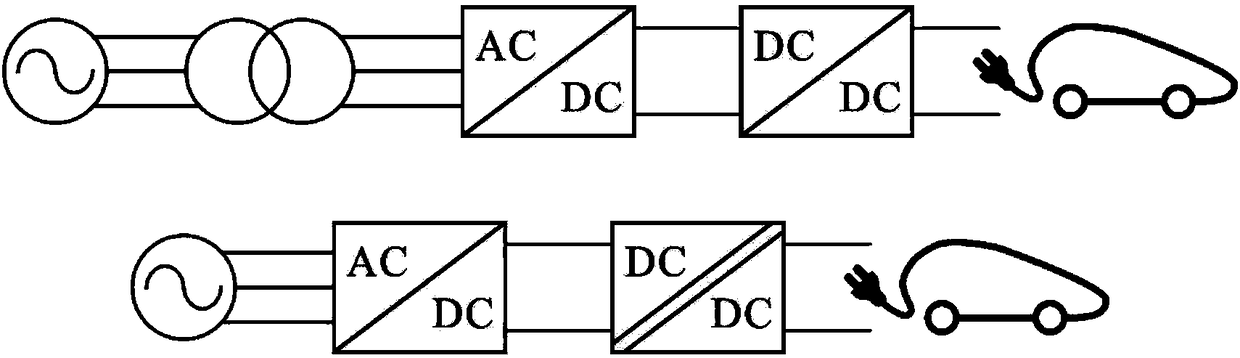

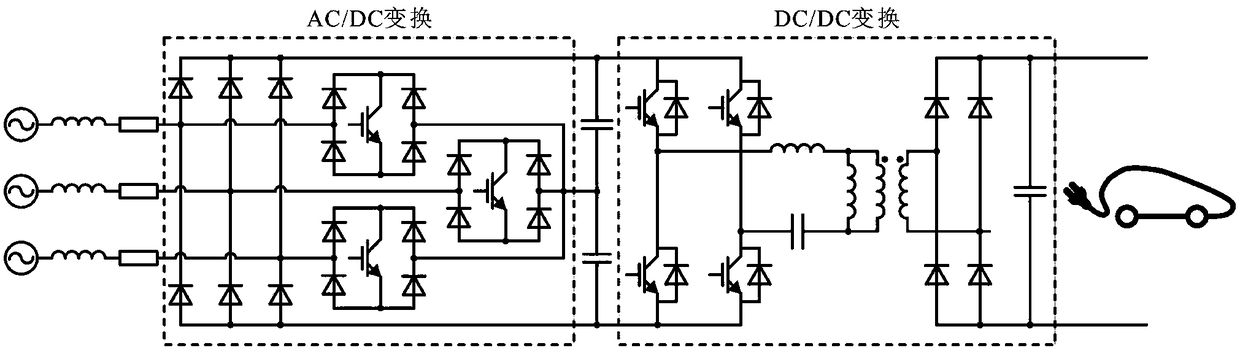

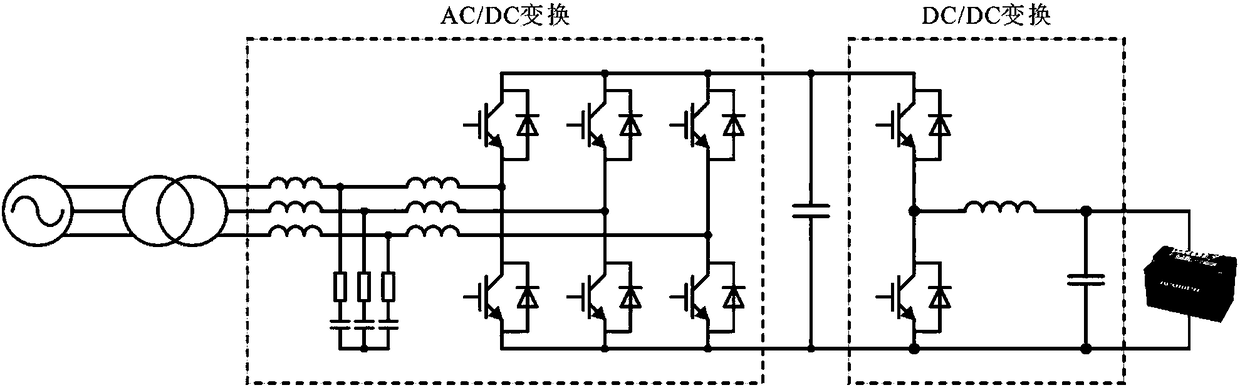

Efficient electric vehicle direct-current fast charge system

PendingCN108528263AImprove power conversion efficiencyAvoid flowingBatteries circuit arrangementsCharging stationsCapacitanceNew energy

The invention relates to an efficient electric vehicle direct-current fast charge system, and belongs to the field of new energy vehicles. The efficient electric vehicle direct-current fast charge system comprises a pile of a direct-current fast charge pile, output direct-current bus, an AC / DC converter, a DC / DC converter, a capacitor, a power distribution transformer and a power grid. One end ofthe power distribution transformer is connected to the power grid, the other end of the power distribution transformer is connected to an AC end of the AC / DC converter, and a DC end of the AC / DC converter is connected with the output direct-current bus of the electric vehicle direct-current fast charge pile; one end of the DC / DC converter is connected with the capacitor, the other end of the DC / DCconverter is connected with the output direct-current bus of the direct-current fast charge pile, and low-order harmonic waves in AC / DC direct-current output currents can be absorbed by the other endof the DC / DC converter under the control. The efficient electric vehicle direct-current fast charge system has the advantages that secondary-side winding transformation ratios of the power distribution transformer are designs, accordingly, three-phase alternating-current-side voltages can be reduced, and requirements of minimum values of voltage ranges of battery packs of mainstream electric vehicles can be met by AC / DC direct-current output; only single-stage AC / DC power conversion is required, only harmonic currents are absorbed by the low-power DC / DC converter, the problem that all chargepower is transmitted through extra DC / DC converters can be solved, accordingly, the cost can be saved, and the efficiency of the efficient electric vehicle direct-current fast charge system can be improved.

Owner:重庆聚陆新能源有限公司

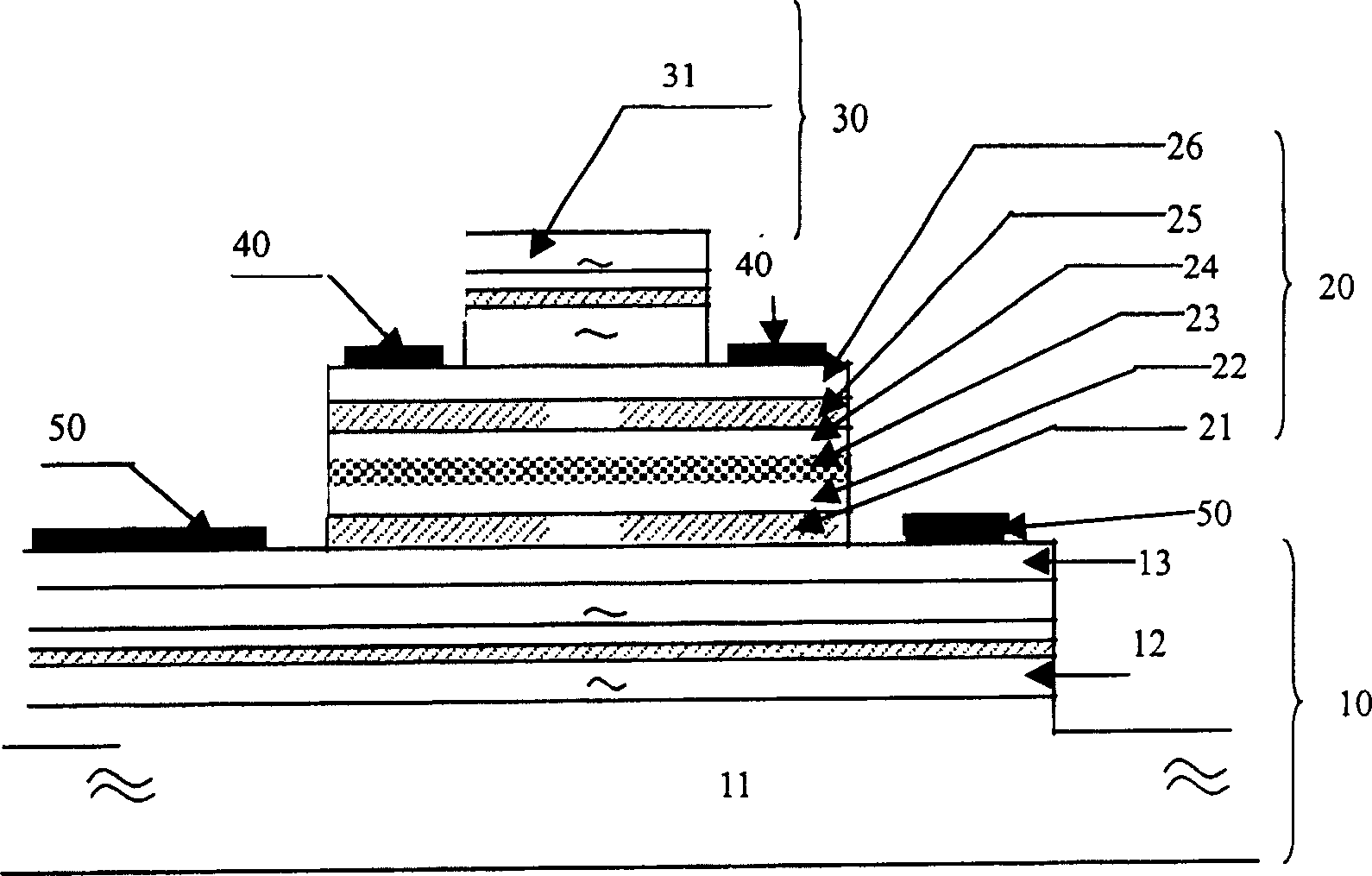

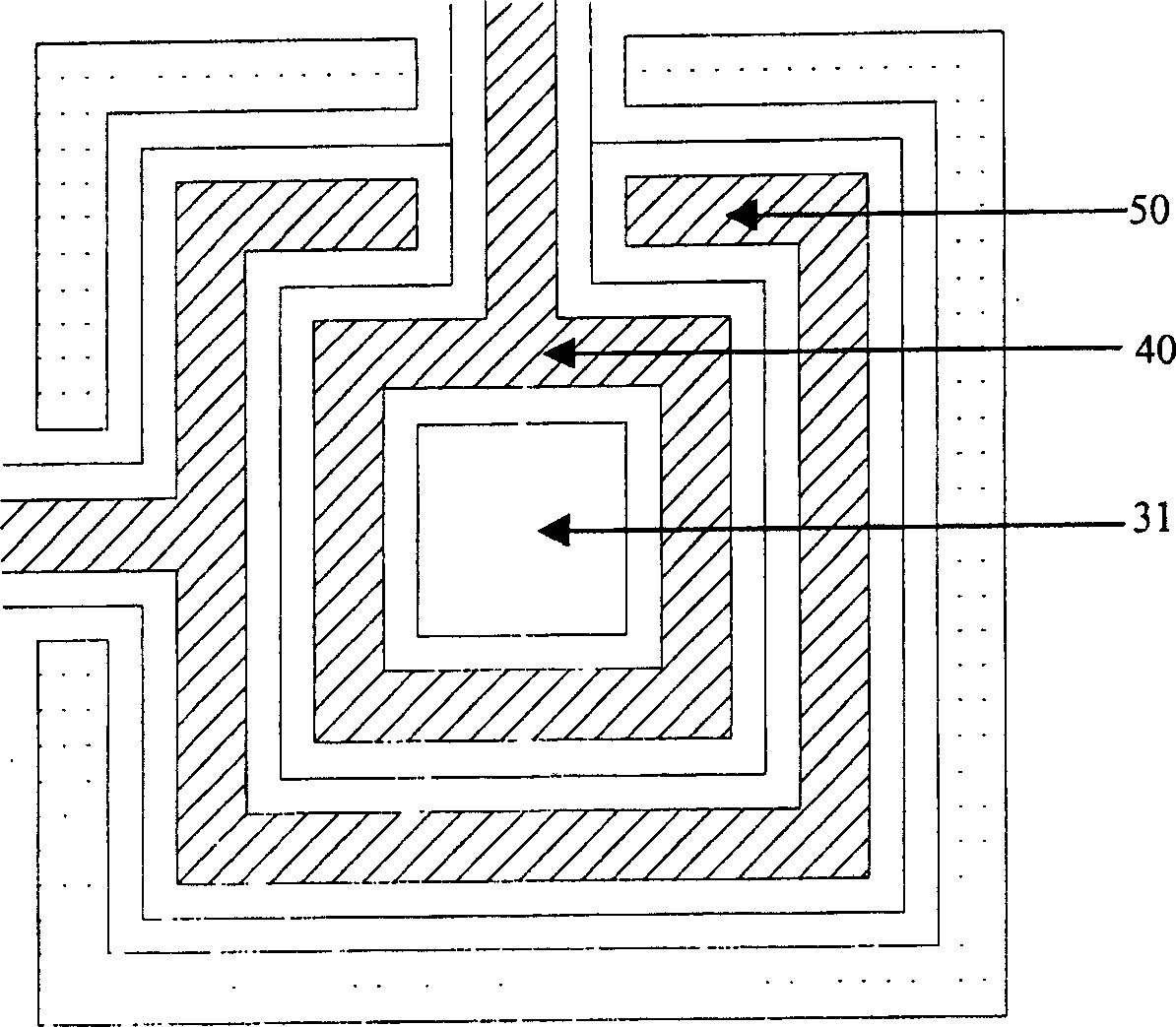

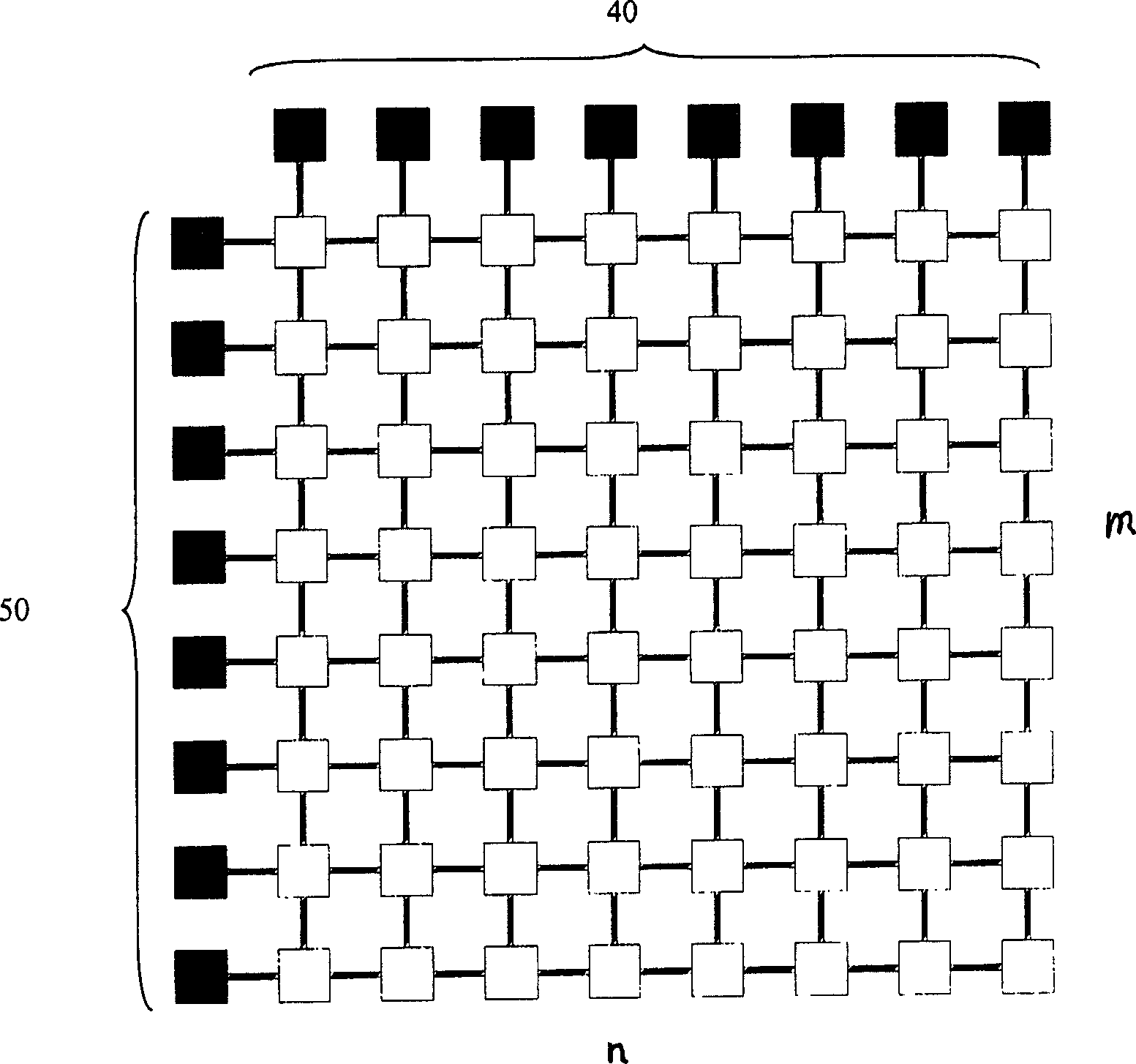

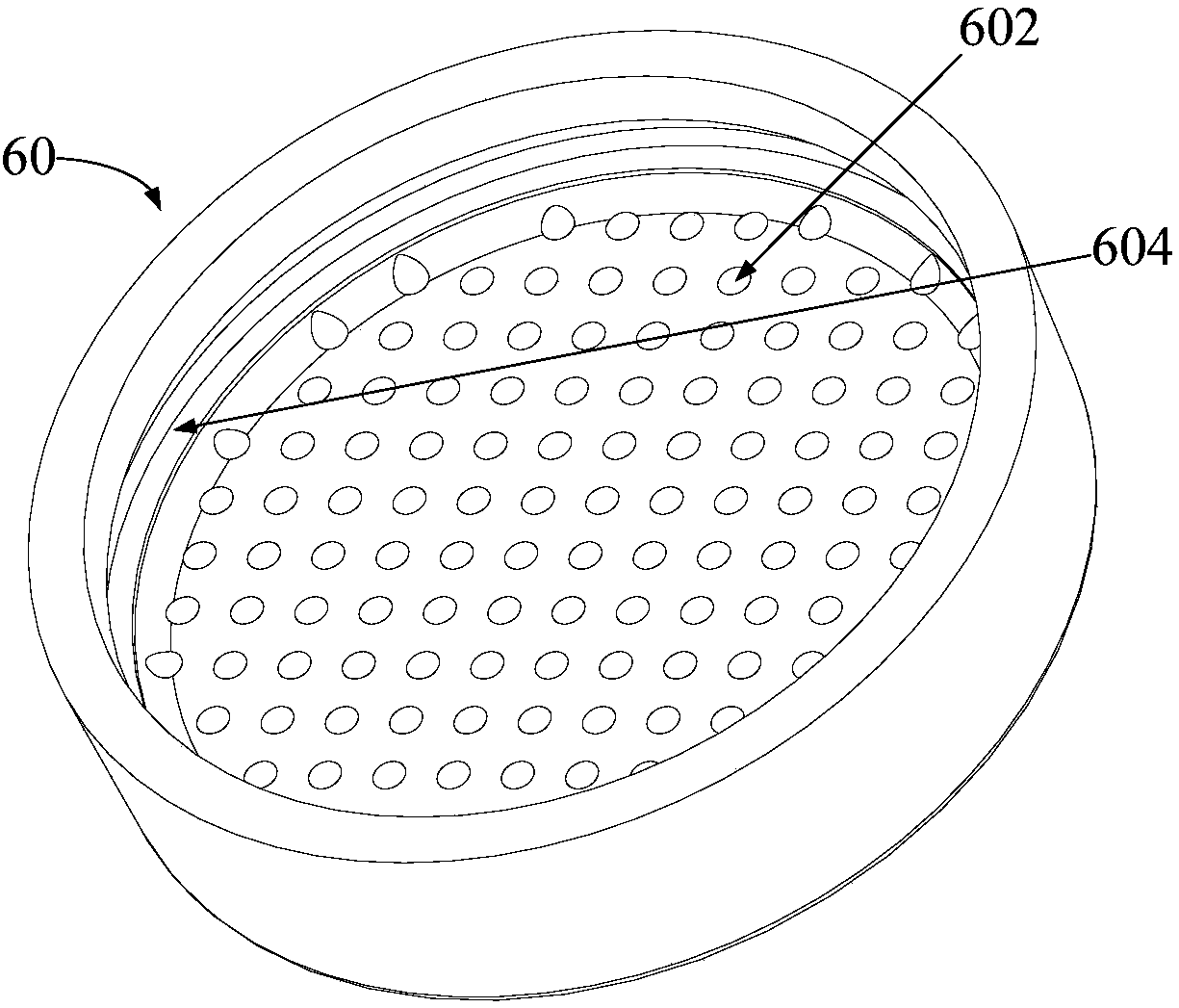

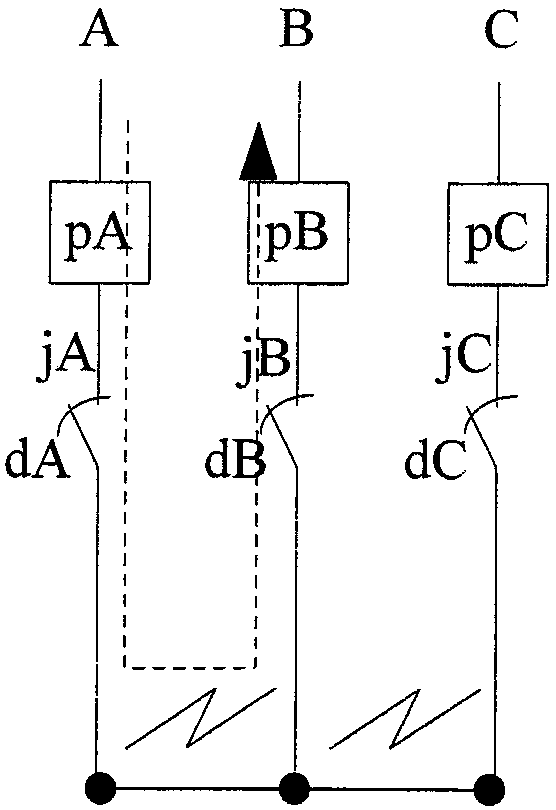

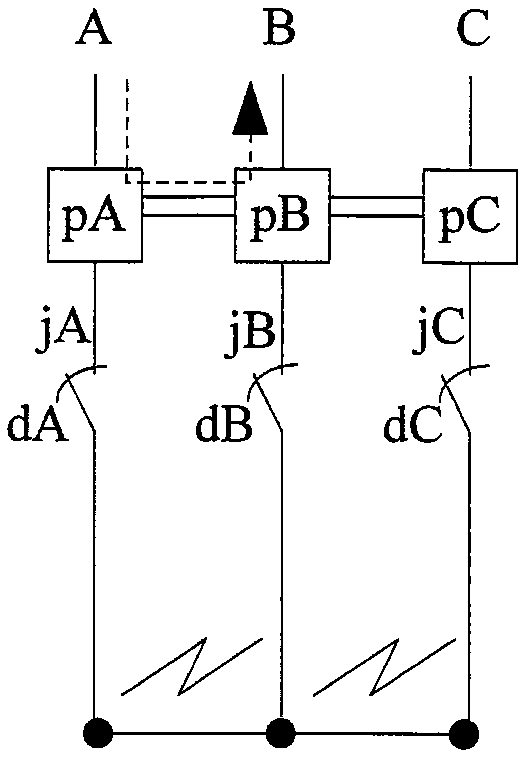

Matrix addressing vertical cavity surface emitting laser array device

InactiveCN1622410AAvoid drift in reflection peak wavelengthImprove reflectivityLaser detailsSemiconductor lasersVertical-cavity surface-emitting laserOptoelectronics

The matrix addressed vertical cavity emitting laser array device includes mXn vertical cavity emitting laser units. Each of the vertical cavity emitting laser units includes three mesas, including bottom reflector mesa, laser cavity mesan and top reflector mesa, of successively decrementing sizes as well as p electrode and n electrode. The laser cavity mesan is made on the bottom reflector mesa, and the top reflector mesan is made on the laser cavity mesa. The p electrode is made on the p-type re-doped conducting layer and around the top reflector mesa, and the p electrodes of each row of the vertical cavity emitting laser units are connected together. The n electrode is made on the n-type re-doped conducting layer and around the laser cavity mesa, and the n electrodes of each line of the vertical cavity emitting laser units are connected together.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

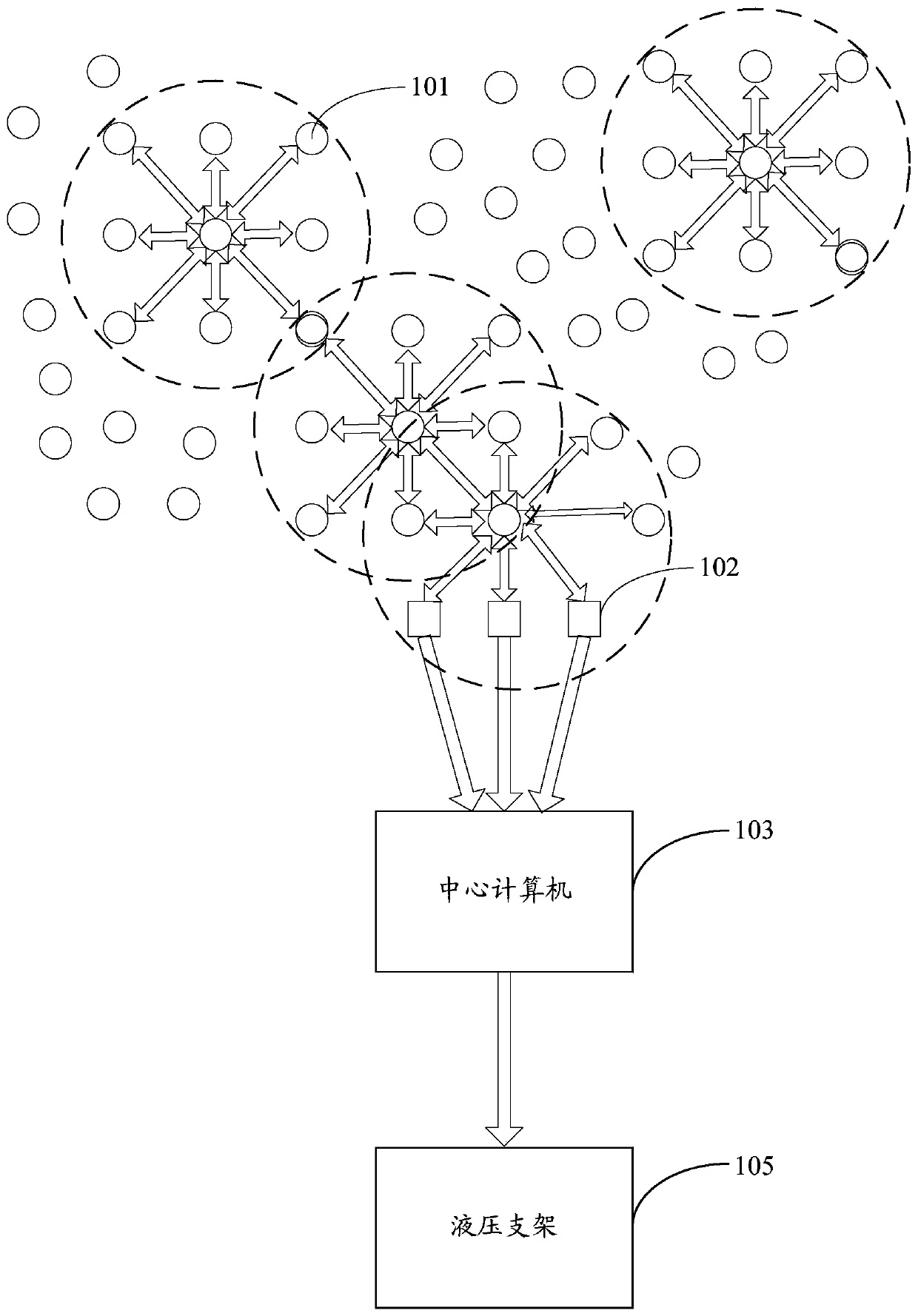

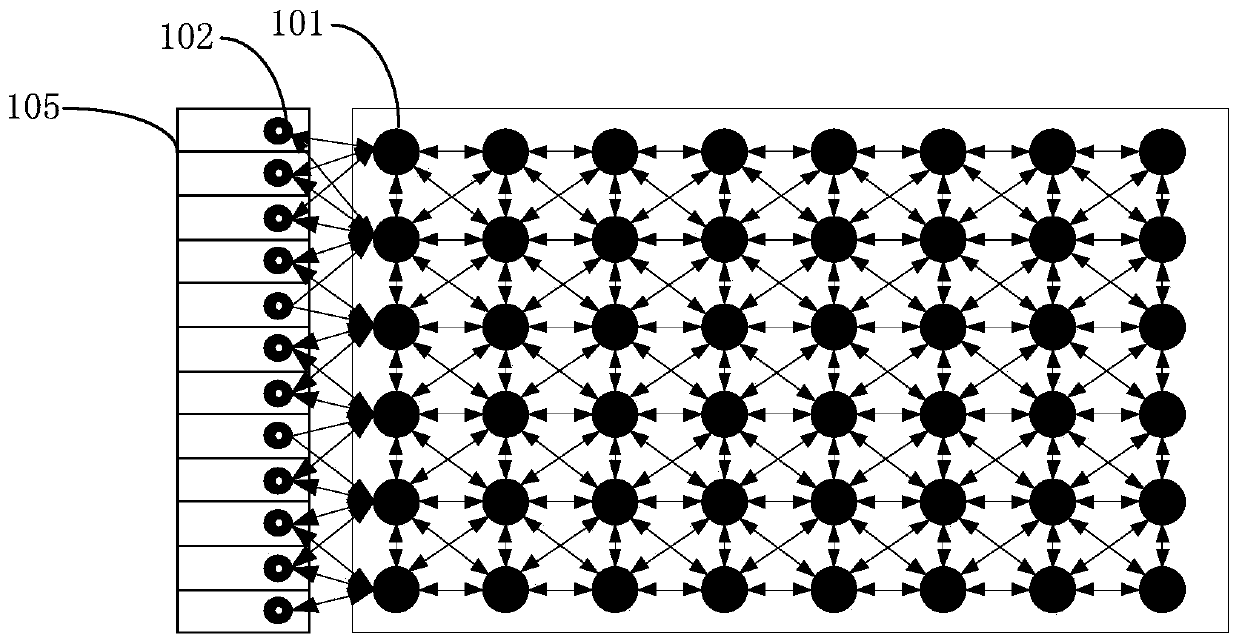

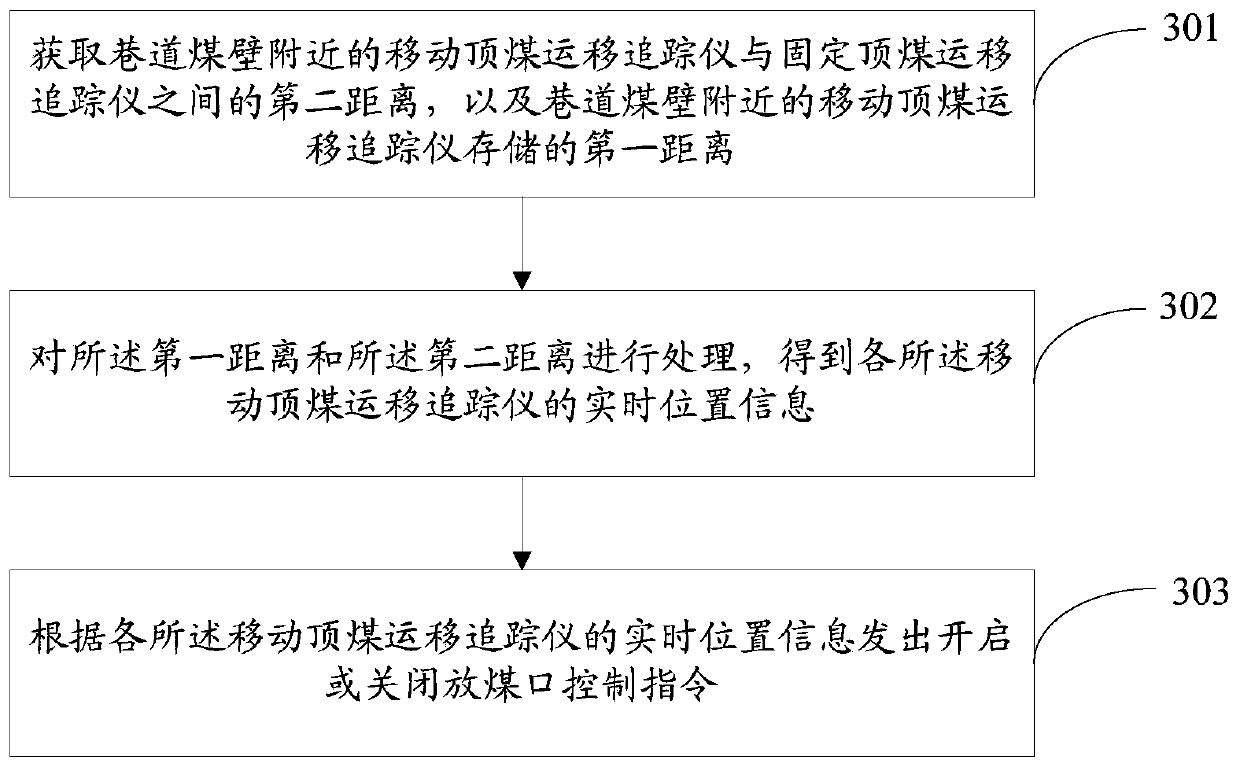

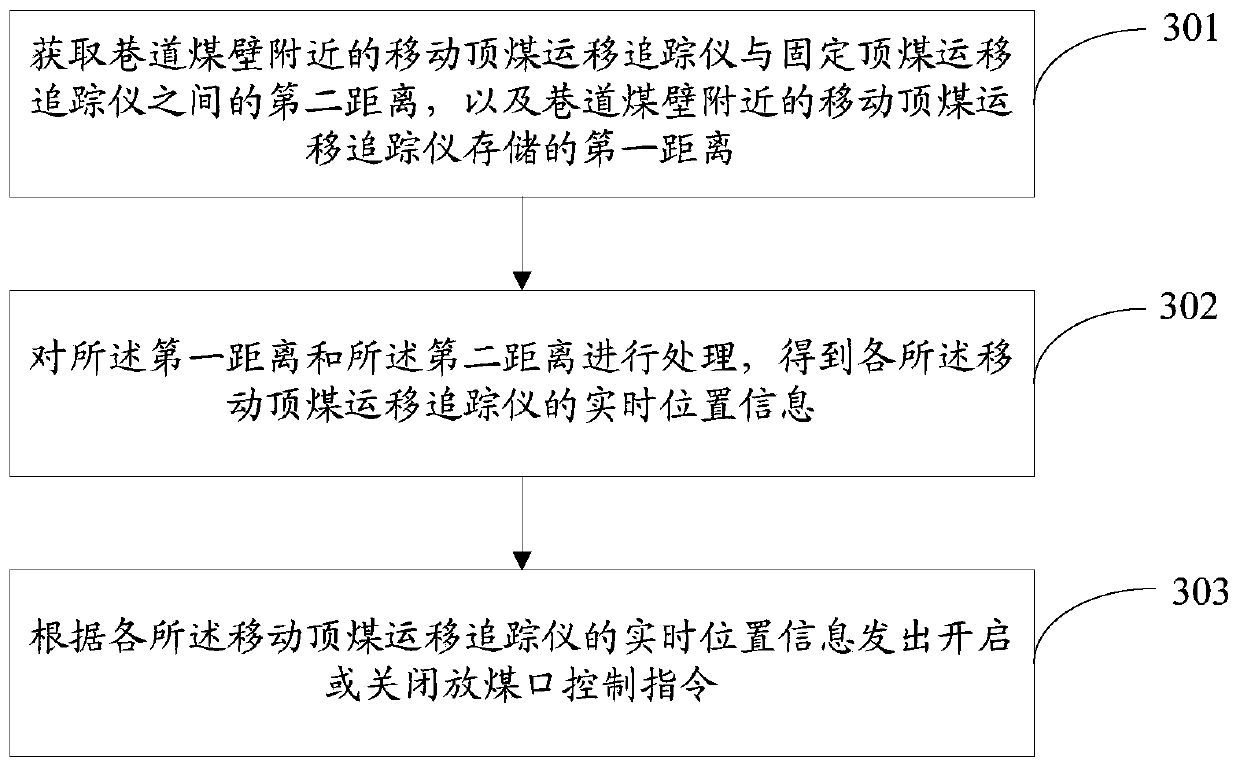

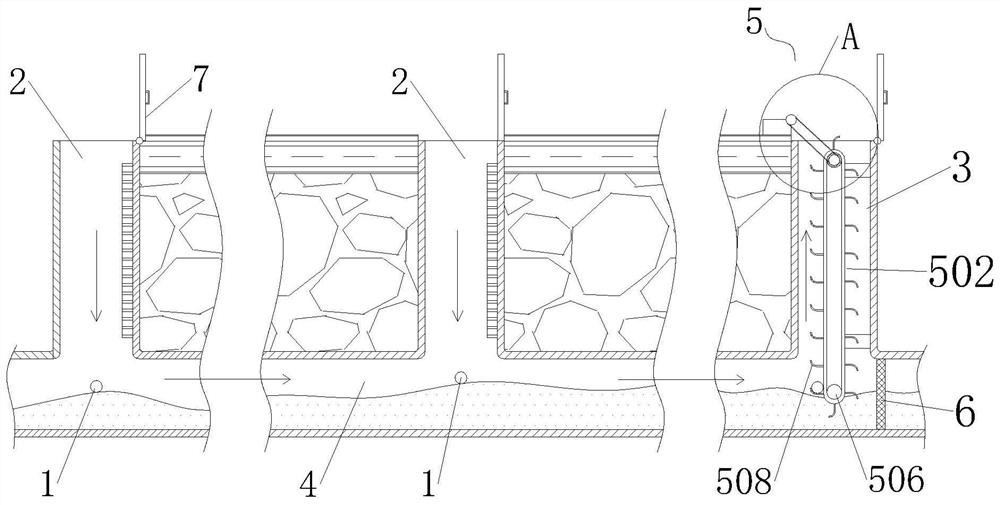

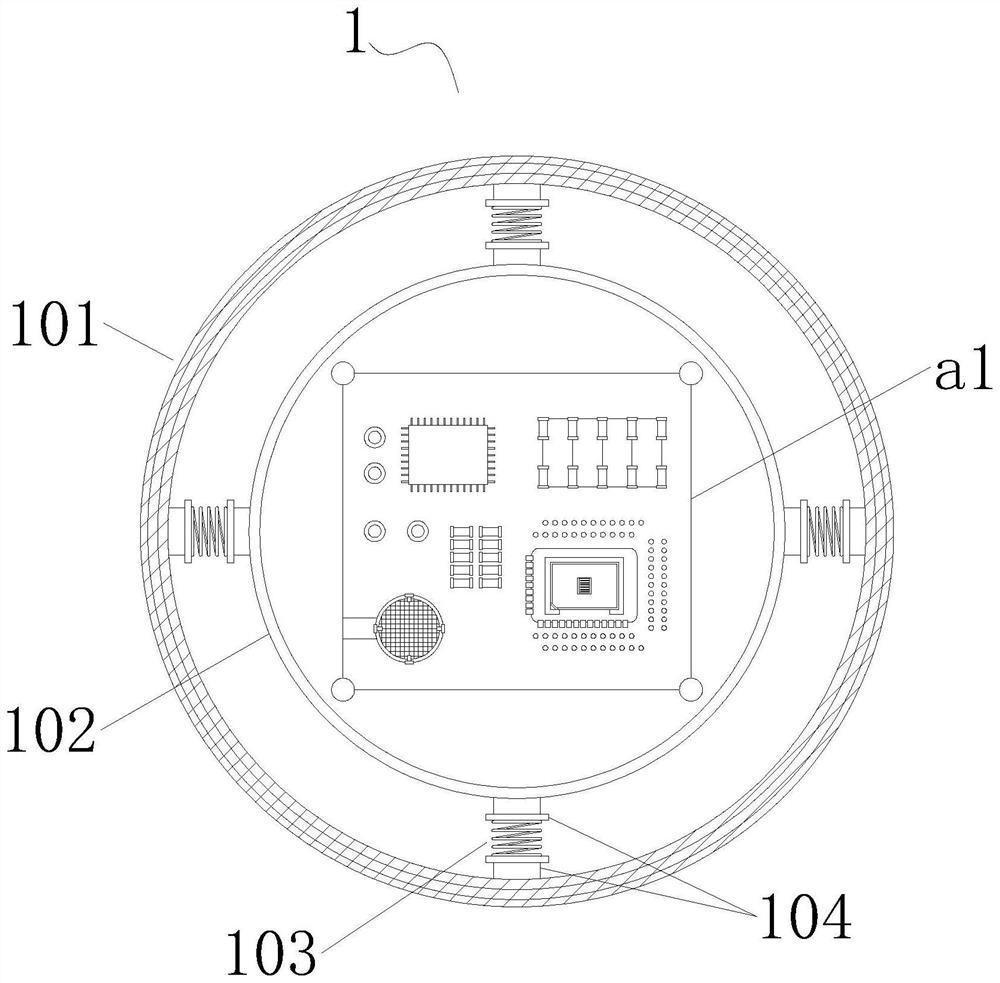

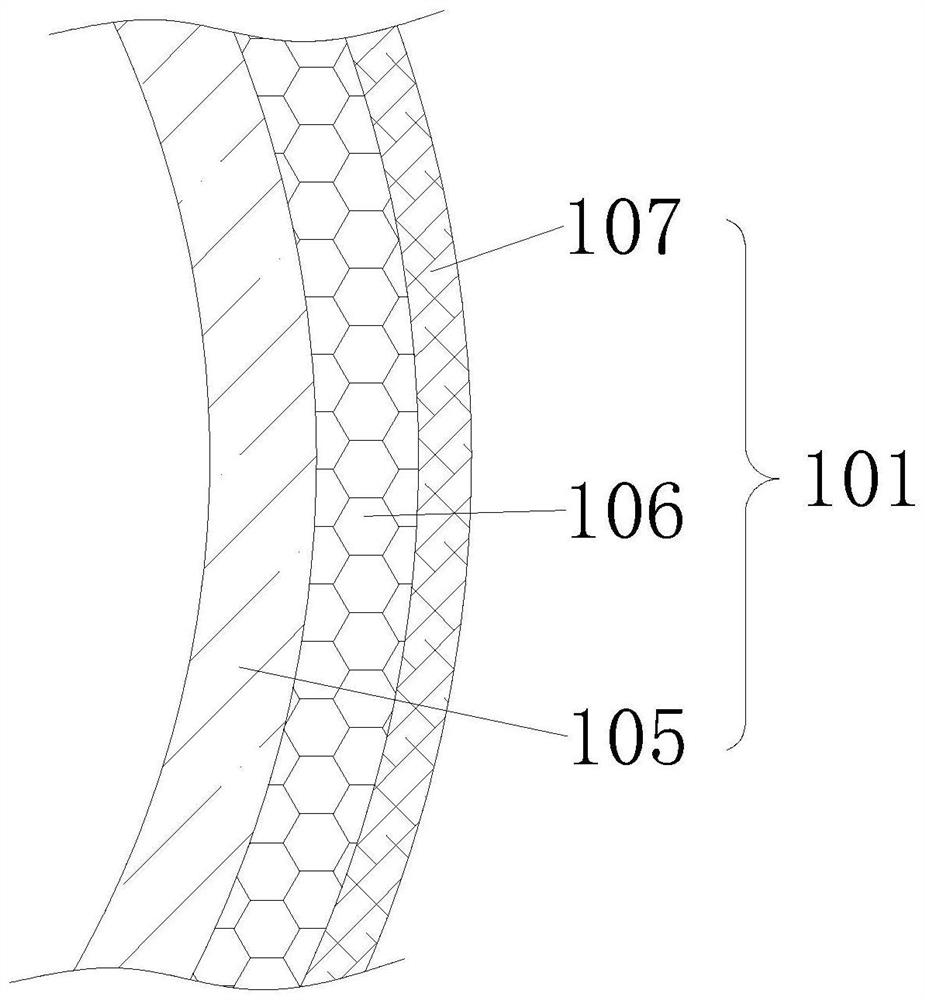

Automatic coal discharging control system and method

ActiveCN109763823AMonitor real-time location informationAchieve sharingUnderground miningClimate change adaptationControl systemEngineering

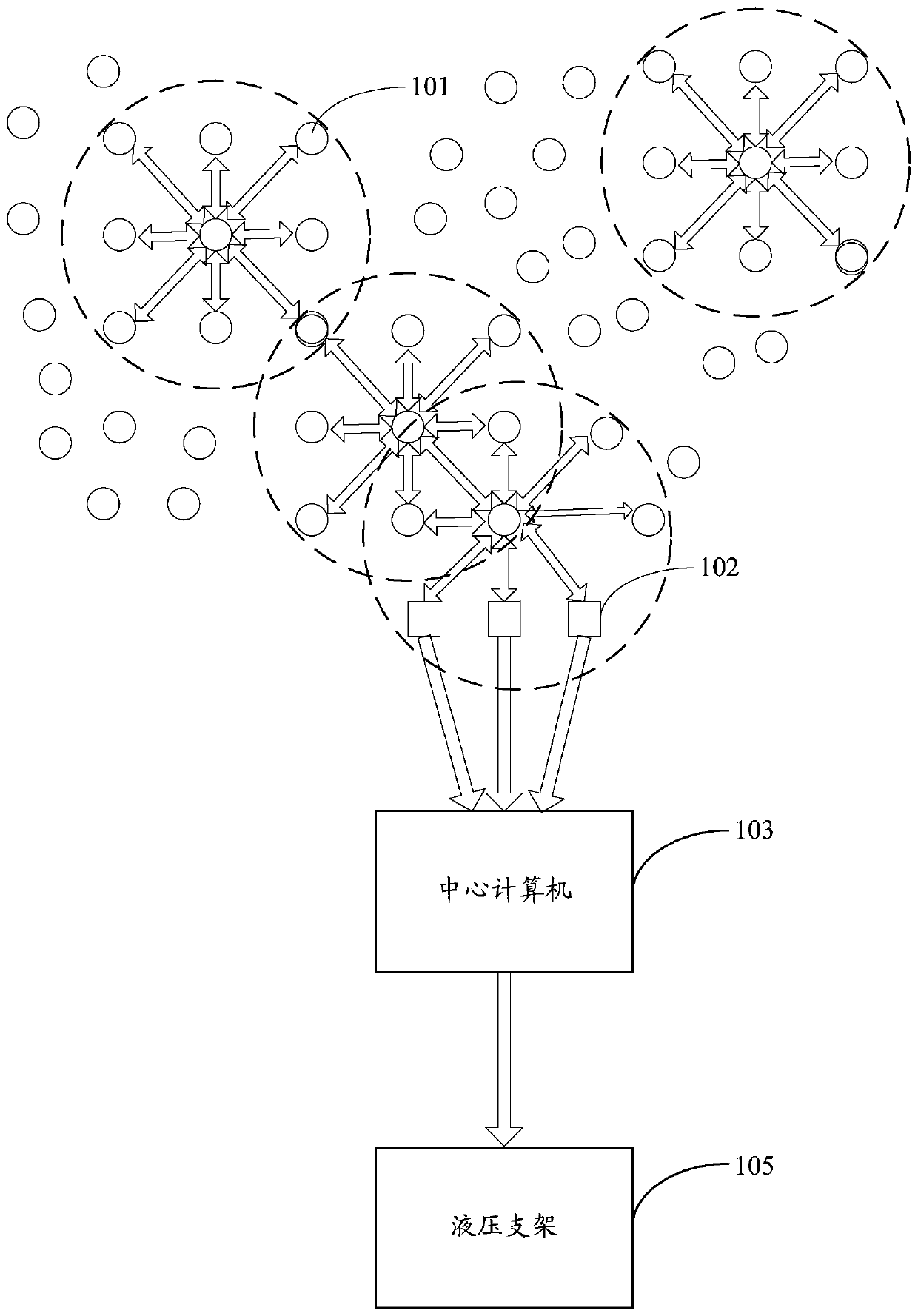

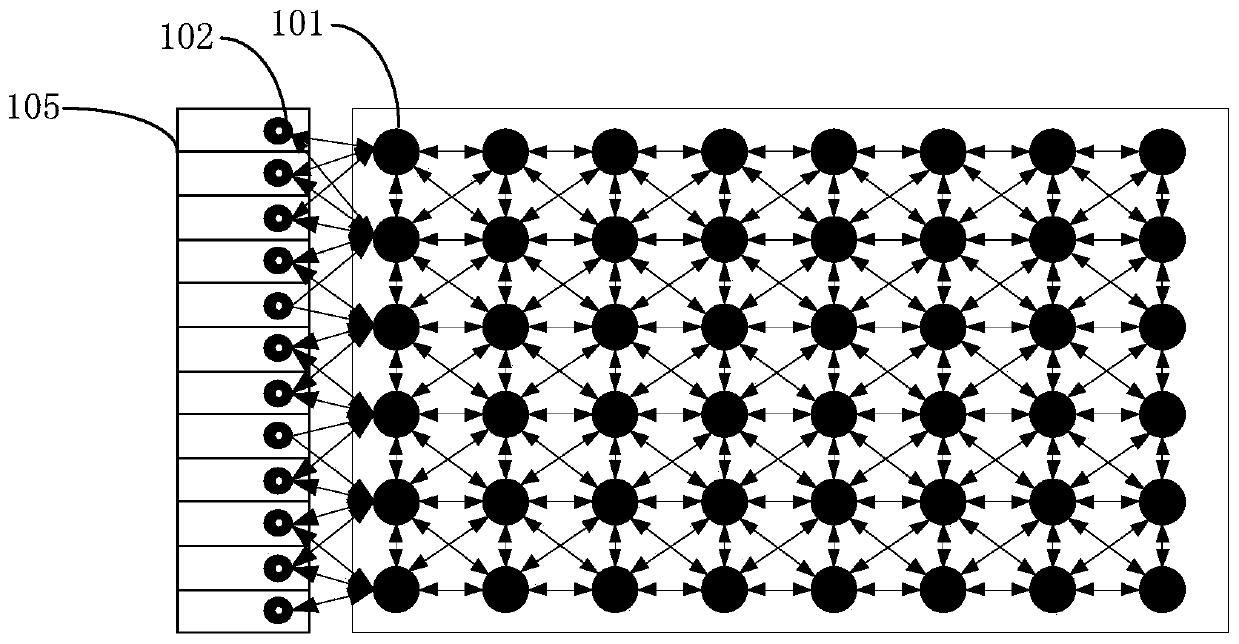

The invention discloses an automatic coal discharging control system and method. The system comprises a plurality of movable top coal conveying and transferring tracking instruments which are uniformly arranged in drilling holes in the coal gangue interface and move along with the coal gangues, a plurality of fixed top coal conveying and transferring tracking instruments which are uniformly fixedto a hydraulic support and are used for acquiring and storing first distance from the movable top coal conveying and transferring instrument close to the hydraulic support to the fixed top coal conveying and transferring tracking instrument and the first distance stored by the movable top coal conveying and transferring instrument close to the hydraulic support, and a central computer for handlingthe first distance and the second distance, acquiring the real-time position information of each movable top coal conveying and transferring tracking instrument, and sending an instruction to controlthe hydraulic support to open or close a coal discharging port based on the real-time position information of each movable top coal conveying and transferring tracking instrument. According to the system and the method, the time that a large number of coal gangues move to the coal discharging port can be determined, so that the time for opening and closing the coal discharging port can be accurately determined, and thus the top coal discharging rate is high, and the gangue containing rate is low.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

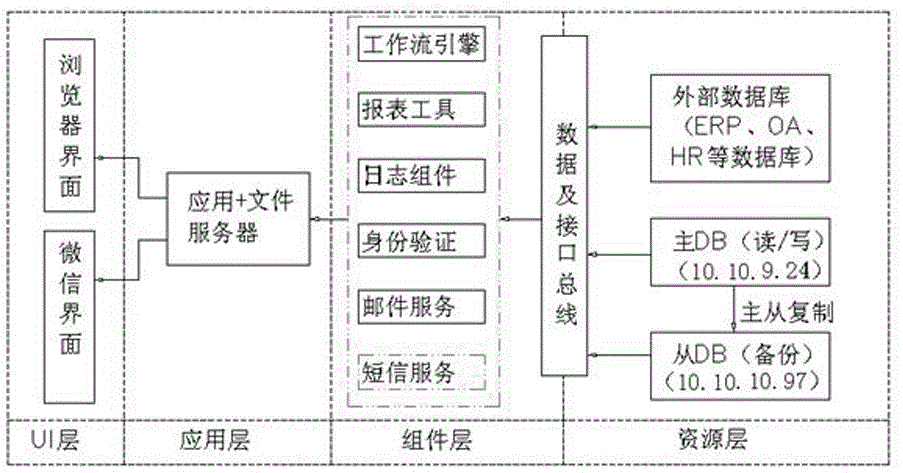

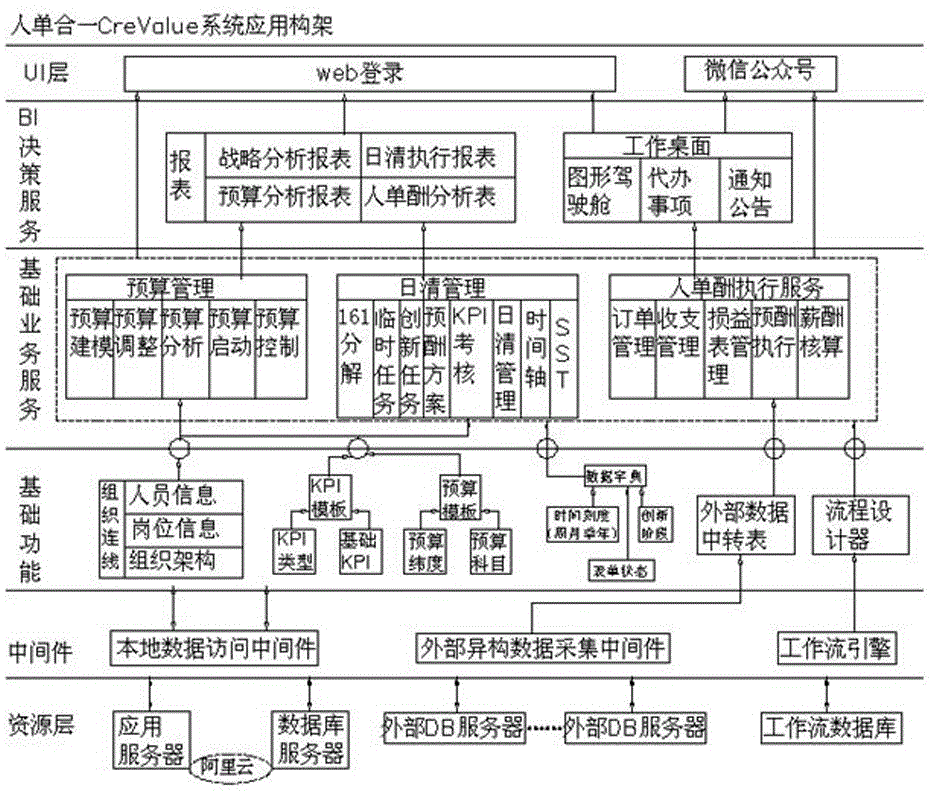

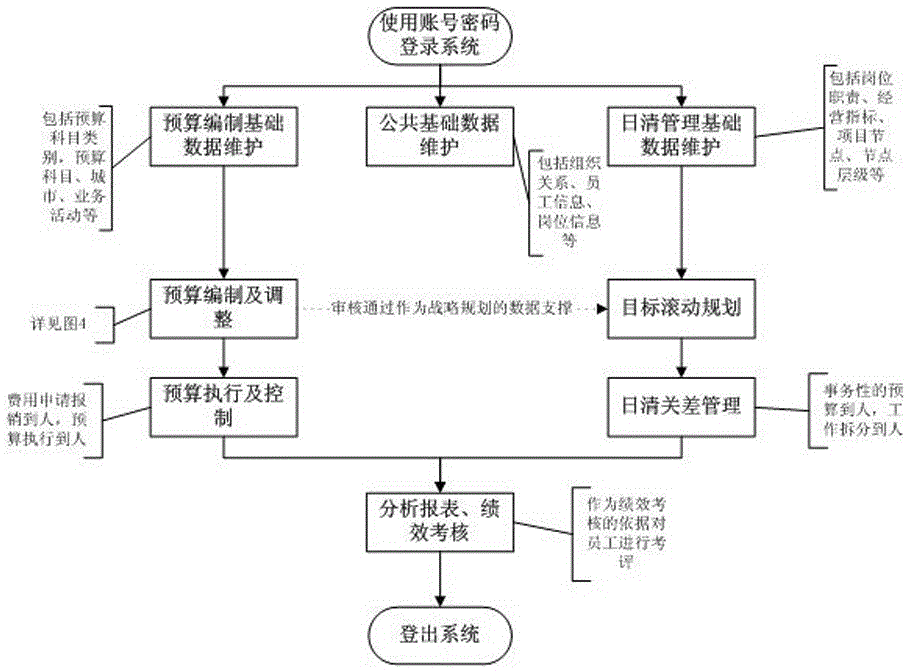

Enterprise management application system for budgeting for people and software

InactiveCN106157130AIncrease motivationAvoid flowingFinanceOffice automationNetwork management applicationBusiness process

The invention discloses an enterprise management application system for budgeting for people. The system comprises a resource layer, a component layer, an application layer and a user interface, the resource layer is connected with input ends of a plurality of software modules in the component layer through data and interface buses, an output end of the component layer is connected with the application layer, and the application layer is connected with the user interface. The invention further provides four business processes including financial budget, budget execution, strategic planning and employee day work finishing. The enterprise management application system has the advantages that budget compilation based on business natures is provided, the blank of most enterprises with only financial budget in budget compilation but without comprehensive budget is filled in, the concept of a budget template is introduced by the system, multi-organization and multi-privilege splitting compilation is performed for information to be compiled, compilation units are not mutually interfered and compile contents belonging to functional areas of the compilation units according to duties, and the enthusiasm of all staff participation is improved.

Owner:QINGDAO PENGHAI SOFT CO LTD

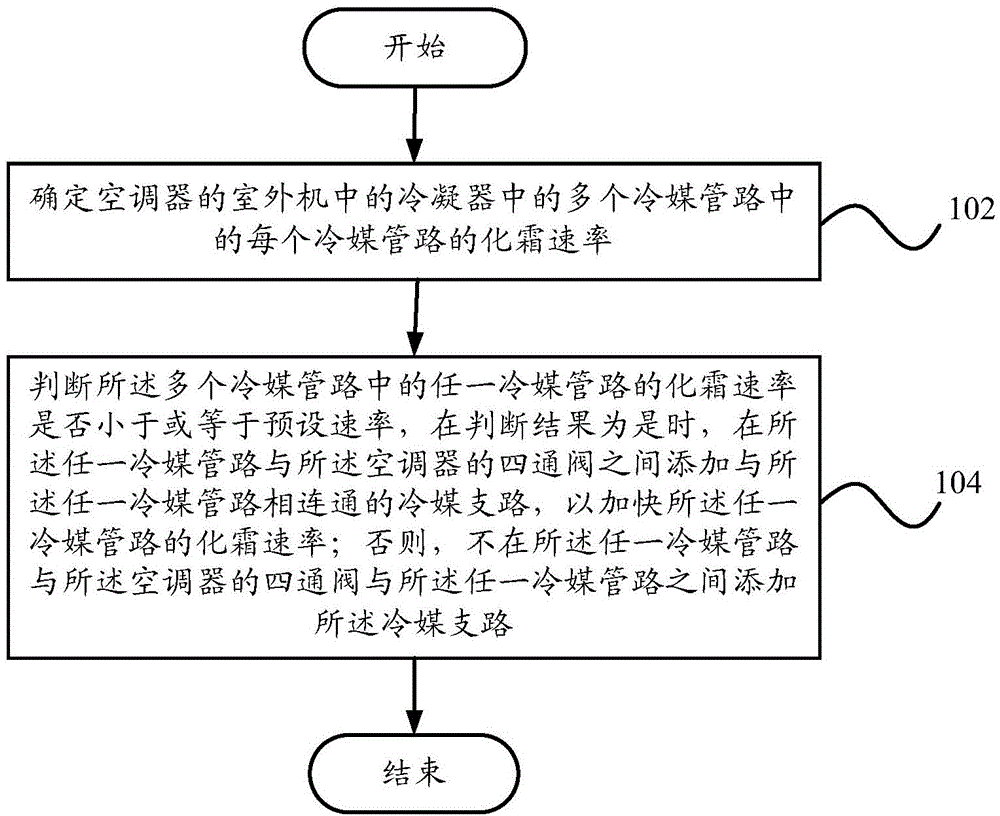

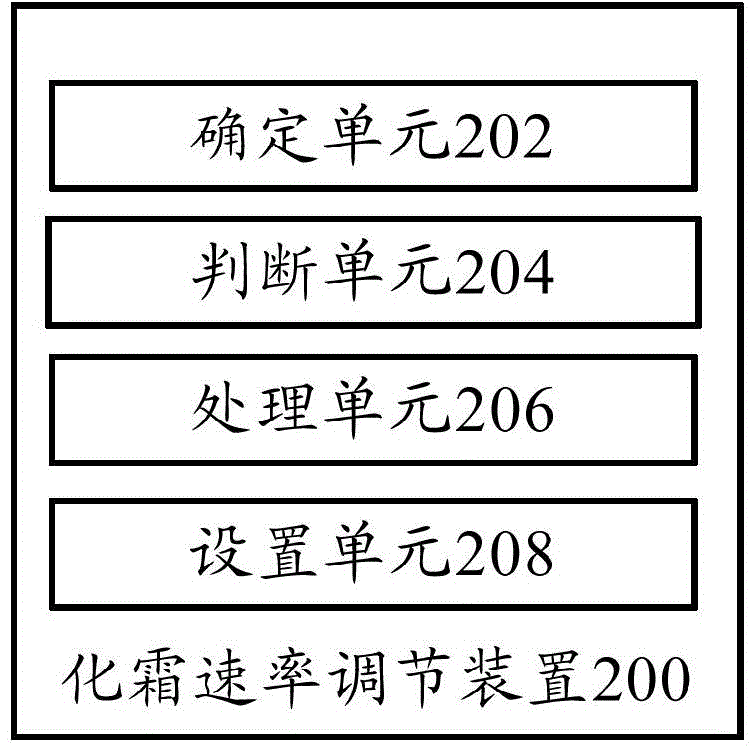

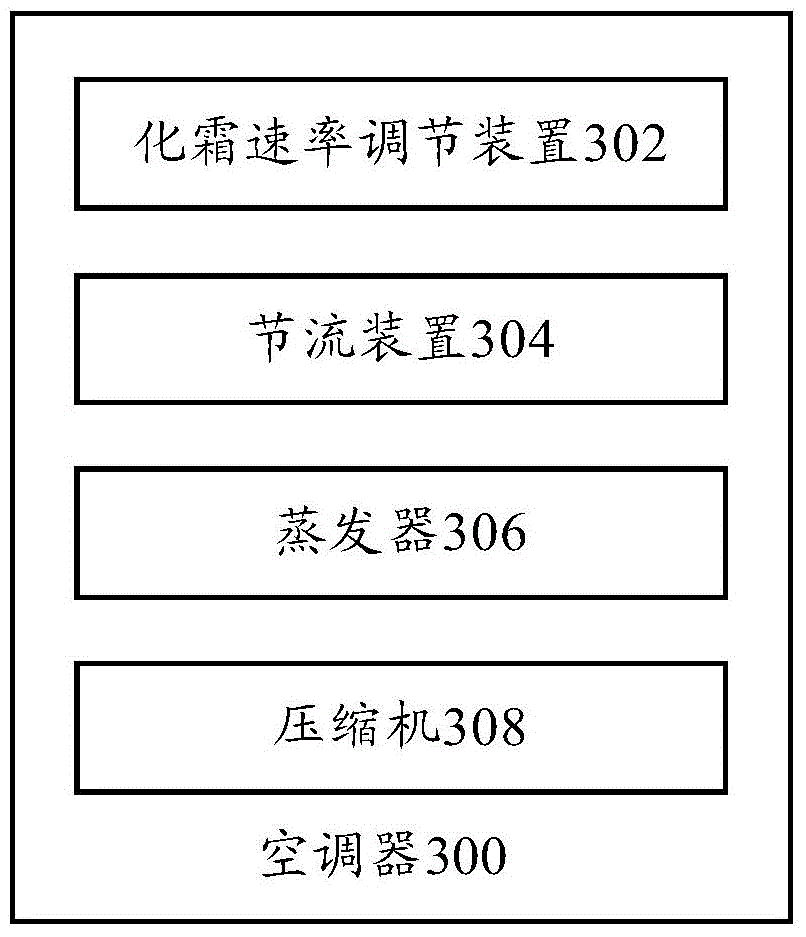

Defrosting speed adjusting method, defrosting speed adjusting device and air conditioner

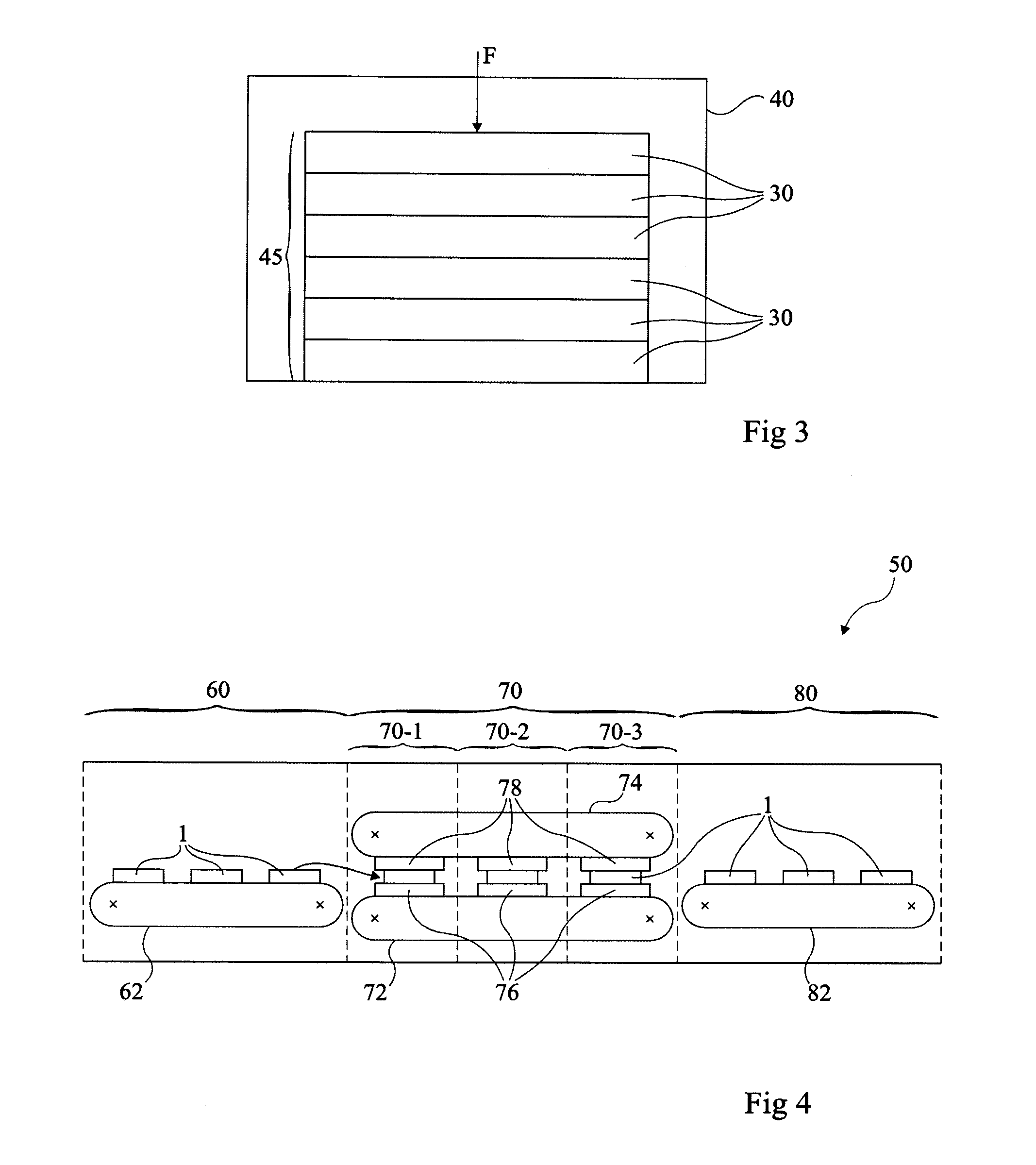

ActiveCN104634032AImprove heating effectGuaranteed recyclingCorrosion preventionCompression machines with reversible cycleFour-way valveHeat losses

The invention provides a defrosting speed adjusting method, a defrosting speed adjusting device and an air conditioner. The defrosting speed adjusting method comprises the steps of determining the defrosting speed of each refrigerant pipe of multiple refrigerant pipes in a condenser of an outdoor unit of the air conditioner, judging whether the defrosting speed of any refrigerant pipe of the multiple refrigerant pipes is smaller than or equal to preset speed, and adding a refrigerant branch communicated with any refrigerant pipe between any refrigerant pipe and a four-way valve of the air conditioner so as to improve the defrosting speed of any refrigerant pipe when a judgment result is yes. By means of the technical scheme, the defrosting speeds of the multiple refrigerant pipes can be more uniform, the multiple refrigerant pipes can simultaneously complete defrosting basically, accordingly the defrosting time required by the multiple refrigerant pipes is shortened, a refrigerant can be further prevented from continuously flowing through the refrigerant pipes completing defrosting earlier, accordingly heat loss of the refrigerant is reduced, and the heating effect of the air conditioner is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

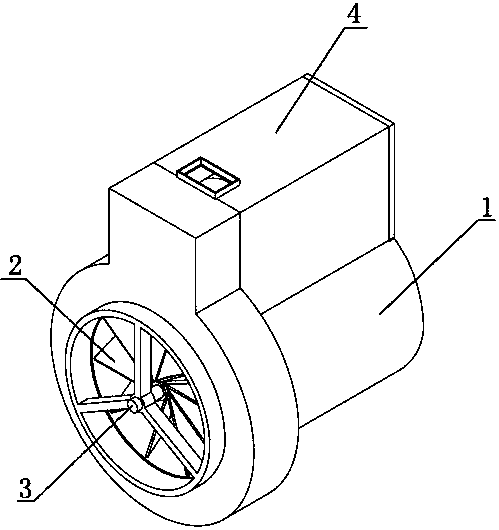

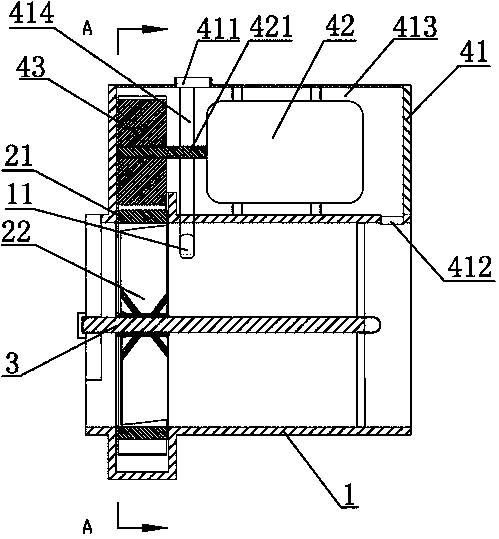

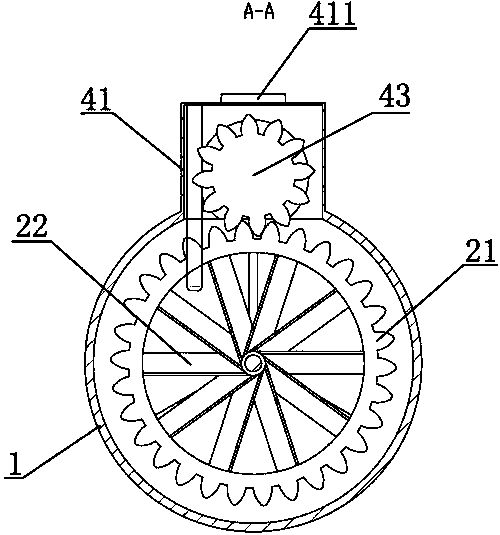

Firefighting smoke exhausting fan

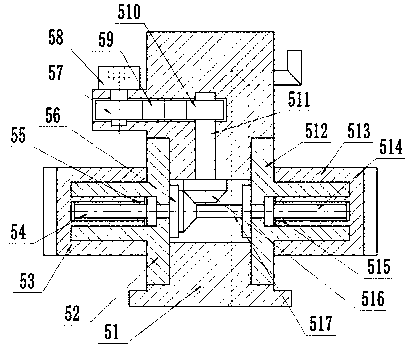

InactiveCN107906027AAvoid flowingLow costPump componentsMechanical energy handlingInterior spaceImpeller

The invention relates to the field of fire-fighting equipment, in particular to a fire-fighting smoke exhaust fan, which is characterized in that it includes a smoke exhaust pipe, an impeller, an impeller shaft and a driving device arranged outside the smoke exhaust pipe, and the impeller includes a ring gear and is arranged on a gear The blades in the ring and the impeller are rotatably arranged on the impeller shaft in the center of the smoke exhaust pipe. The driving device includes a motor casing arranged on the outer wall of the smoke exhaust pipe, a motor arranged in the motor casing, and a motor connected to the motor shaft. A driving gear, the driving gear meshes with the ring gear, and the impeller shell is provided with an air inlet and an air outlet. In the fire-fighting smoke exhaust fan provided by the present invention, the motor is arranged outside the smoke exhaust pipe to drive the impeller to rotate to exhaust smoke, so as to avoid high-temperature smoke directly flowing through the outer wall of the motor, and to introduce external air for cooling, which can achieve a good heat dissipation effect; since the motor does not occupy The internal space of the smoke exhaust duct has a large effective area for smoke exhaust and good ventilation effect.

Owner:盛立兴

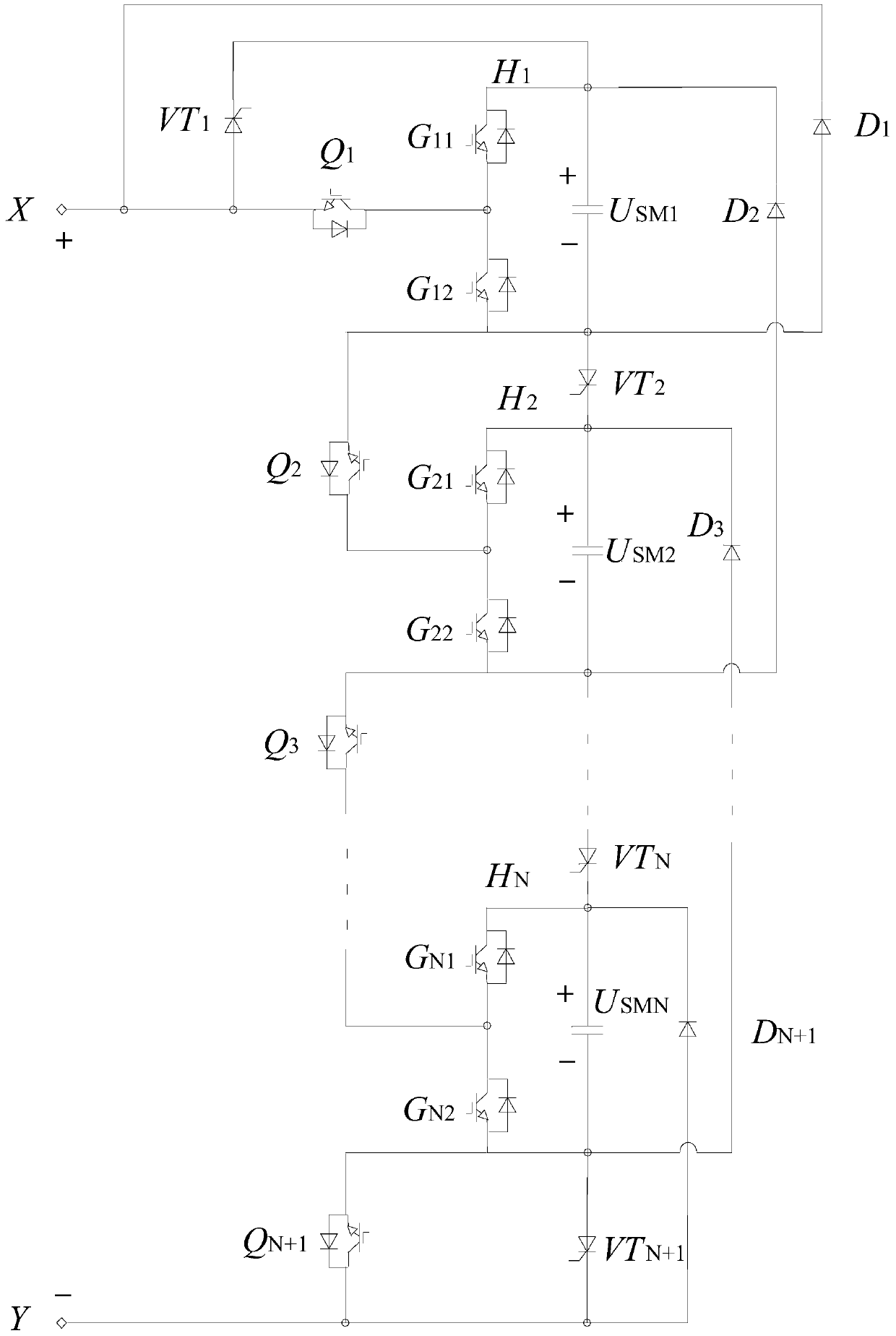

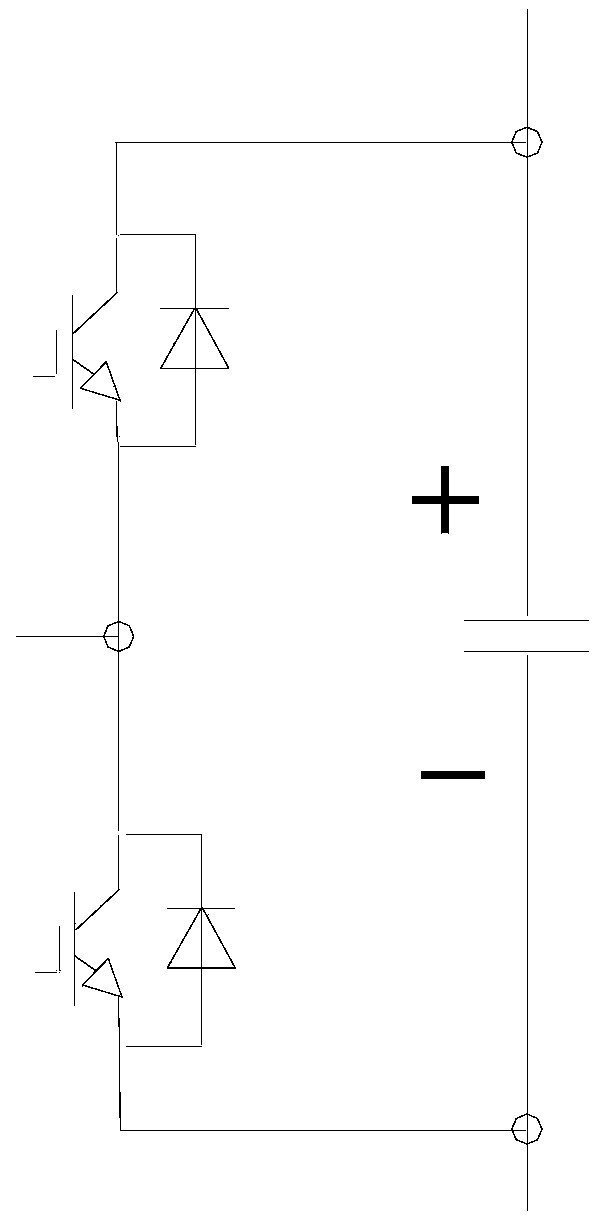

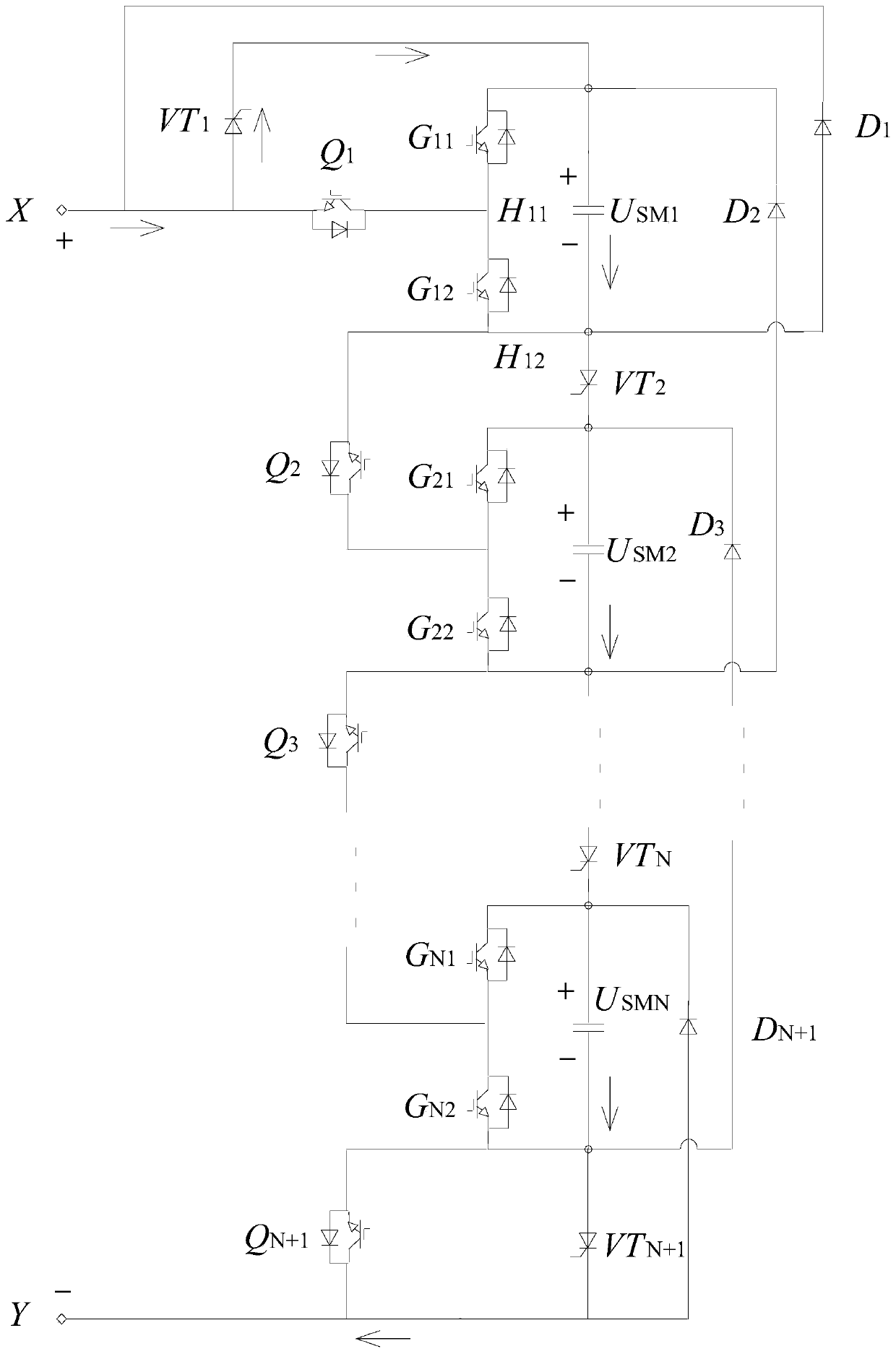

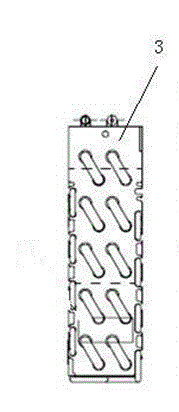

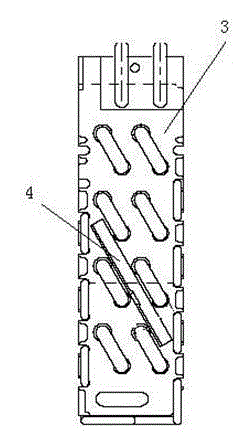

Novel modular multilevel converter submodule topology circuit and control method thereof

ActiveCN110417290AAvoid flowingSuppress fault currentThyristorAc-dc conversionMOSFETElectric power system

The invention discloses a novel modular multilevel converter submodule topology circuit and a control method thereof. The invention relates to the field of power system DC power transmission and distribution protection control, in particular to an MMC sub-module topology circuit with DC side fault ride-through capability and a control method thereof. The invention provides the novel modular multilevel converter sub-module topology circuit is high in modular degree, higher in reliability, higher in forward and reverse fault current suppression capacity and more balanced and the control method thereof. The circuit comprises a wire inlet port X and a wire outlet port Y, wherein at least two half-bridge sub-modules are connected in series between the wire inlet port X and the wire outlet portY, each half-bridge sub-module is provided with an input port, a first output port and a second output port, and the power switch device can be an IGBT or an MOSFET. The circuit has very strong faultcurrent suppression capability.

Owner:JIANGSU ELECTRIC POWER CO +2

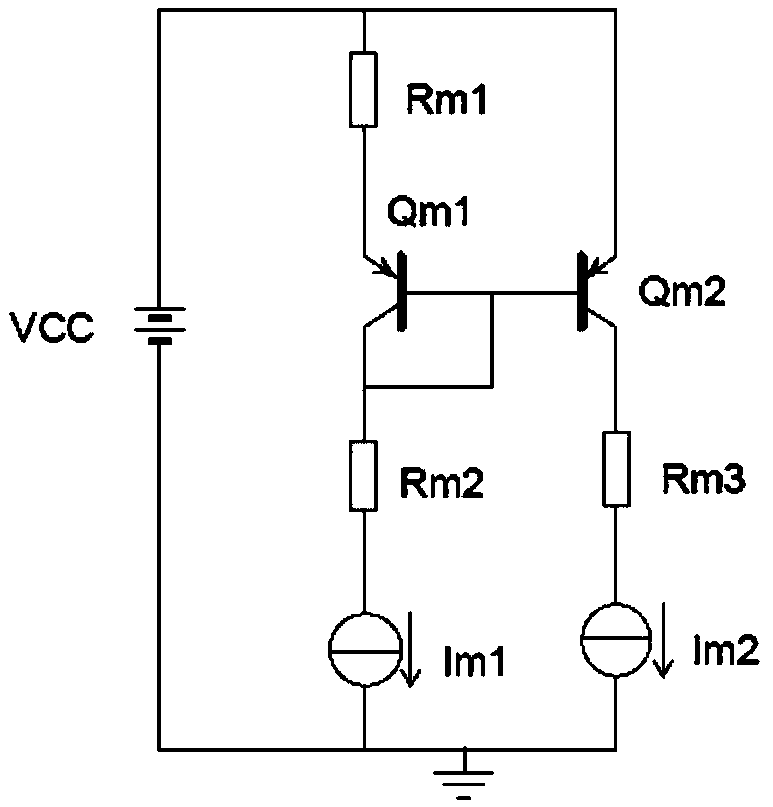

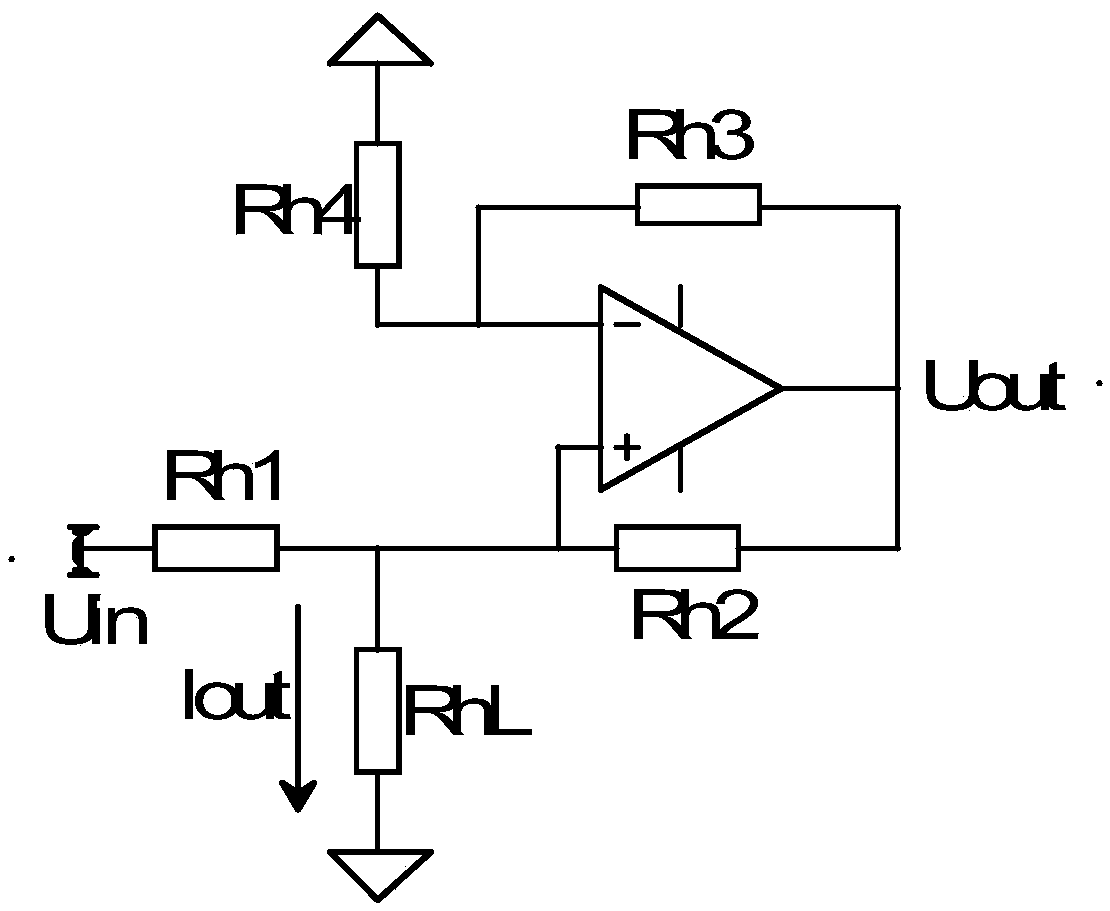

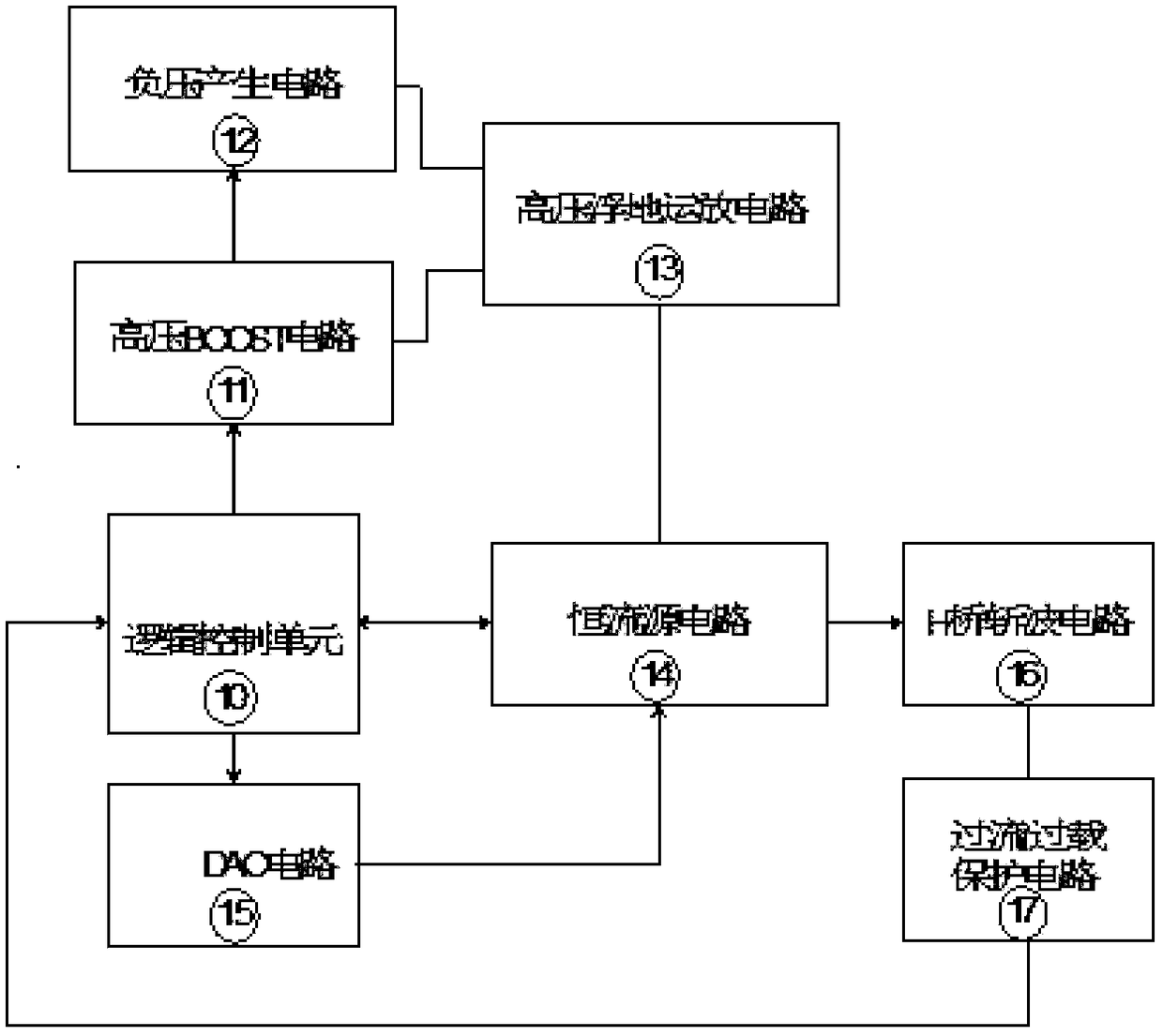

High-precision high-voltage current source circuit

ActiveCN109445501AEasy to controlEnsure output reliabilityElectric variable regulationPressure generationEngineering

The invention discloses a high-precision high-voltage current source circuit. The high-precision high-voltage current source circuit comprises a logic control unit, a high-voltage Boost circuit, a negative pressure generation circuit, a DAC circuit, a high-voltage floating operation and amplification circuit, a constant-current source circuit, a bridge-H chopper circuit, and an overcurrent overload protection circuit. By adopting the high-precision high-voltage current source circuit, the problems of the traditional Howland current source that the stability is poor, the circuit is easy in saturation state, the output current is relatively low, the efficiency is relatively low, the influence of the operation and amplification Ibias is great, the four peripheral matching resistors are difficult in consistency and the like can be solved. The high-precision high-voltage current source circuit is capable of realizing the fine stepper adjustment for the current, large in current output range, high in load capacity, flexible and variable in circuit parameters and relatively low in requirement for the consistence of peripheral parameters.

Owner:HANGZHOU CHENGNUO MEDICAL SCI & TECH CO LTD

Method for precisely counting putting quantity of auxiliary cleaning agent

PendingCN109402968AImprove accuracyImprove delivery efficiencyOther washing machinesTextiles and paperSolenoid valveRinse water

Provided is a method for precisely counting the putting quantity of an auxiliary cleaning agent. The method includes the steps of switching on a water feeding valve and switching off a backflushing solenoid valve and an auxiliary cleaning agent control valve to let water flow out from the water feeding valve and enter a pre-storage device through a Venturi tube until the pre-storage device is fullof the water; switching on the backflushing solenoid valve and the auxiliary cleaning agent control valve to let the water enter a cleaning drum through the Venturi tube and the backflushing solenoidvalve; when the auxiliary cleaning agent enters the pre-storage device, sucking the water in the pre-storage device into the Venturi tube through a metering device and conveying the water into the cleaning drum through the backflushing solenoid valve; when the flow rate of the water passing through the metering device reaches an assigned value and a washing machine controller measures a target flow signal, controlling the auxiliary cleaning agent control valve and the backflushing solenoid valve to be switched off through the washing machine controller to let the water flush the auxiliary cleaning agent into the cleaning drum from the water feeding valve through the Venturi tube. By means of the method, the putting quantity of the auxiliary cleaning agent can be precisely controlled, andwaste of the auxiliary cleaning agent and rinsing water is reduced.

Owner:NINGGUO JULONG IND

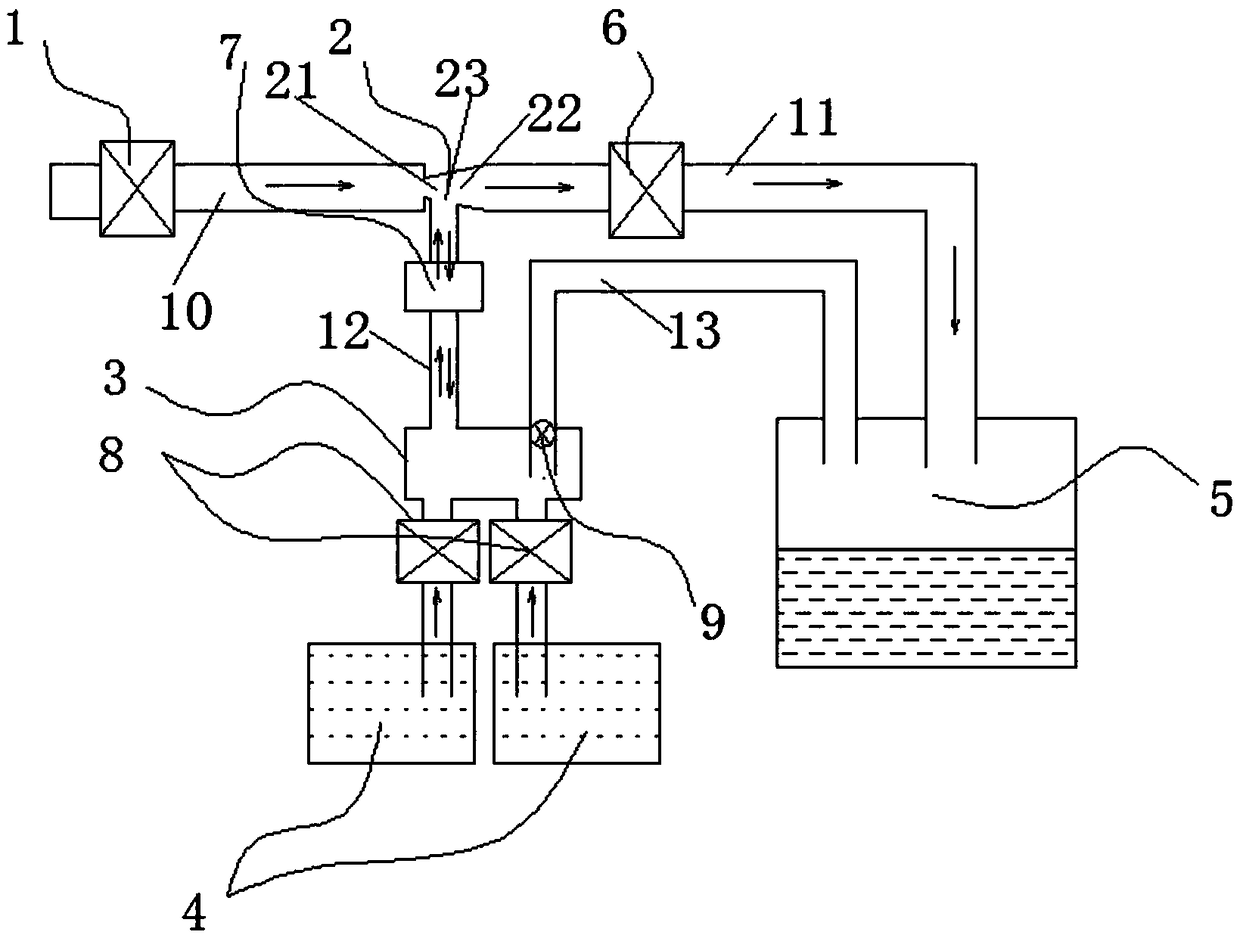

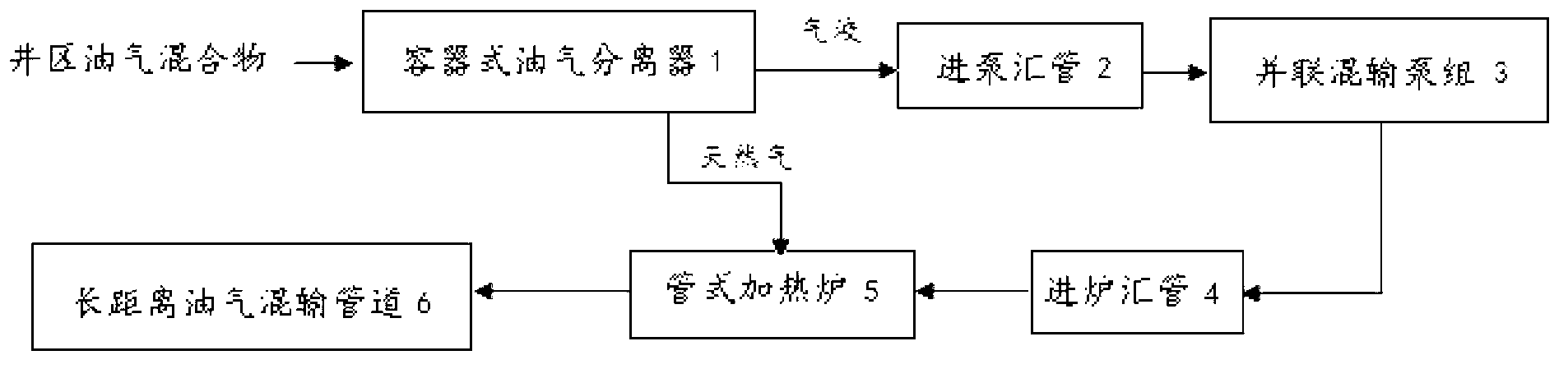

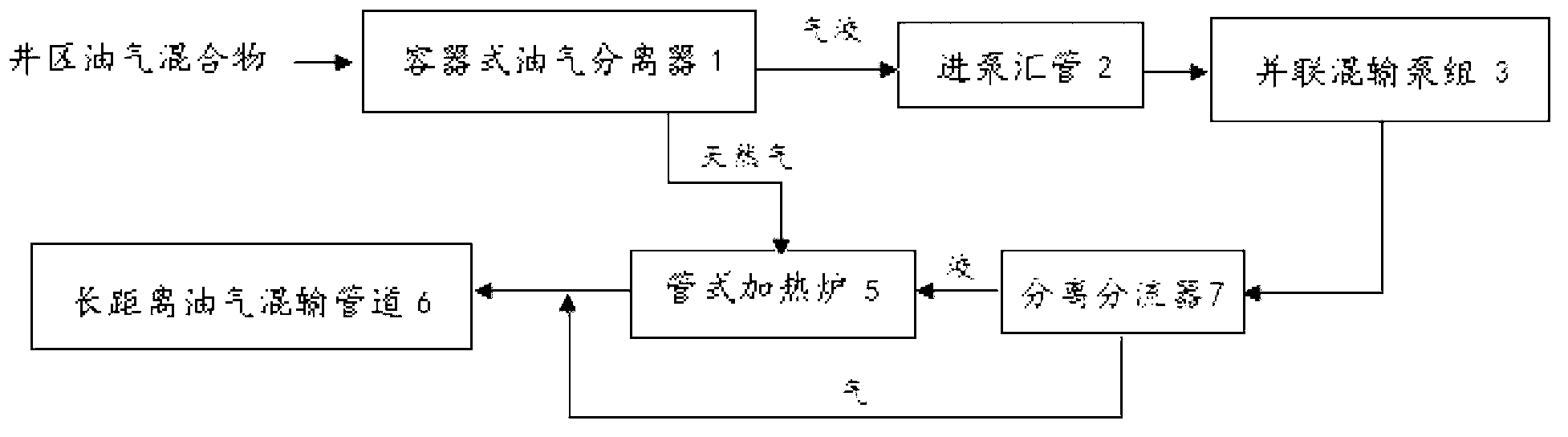

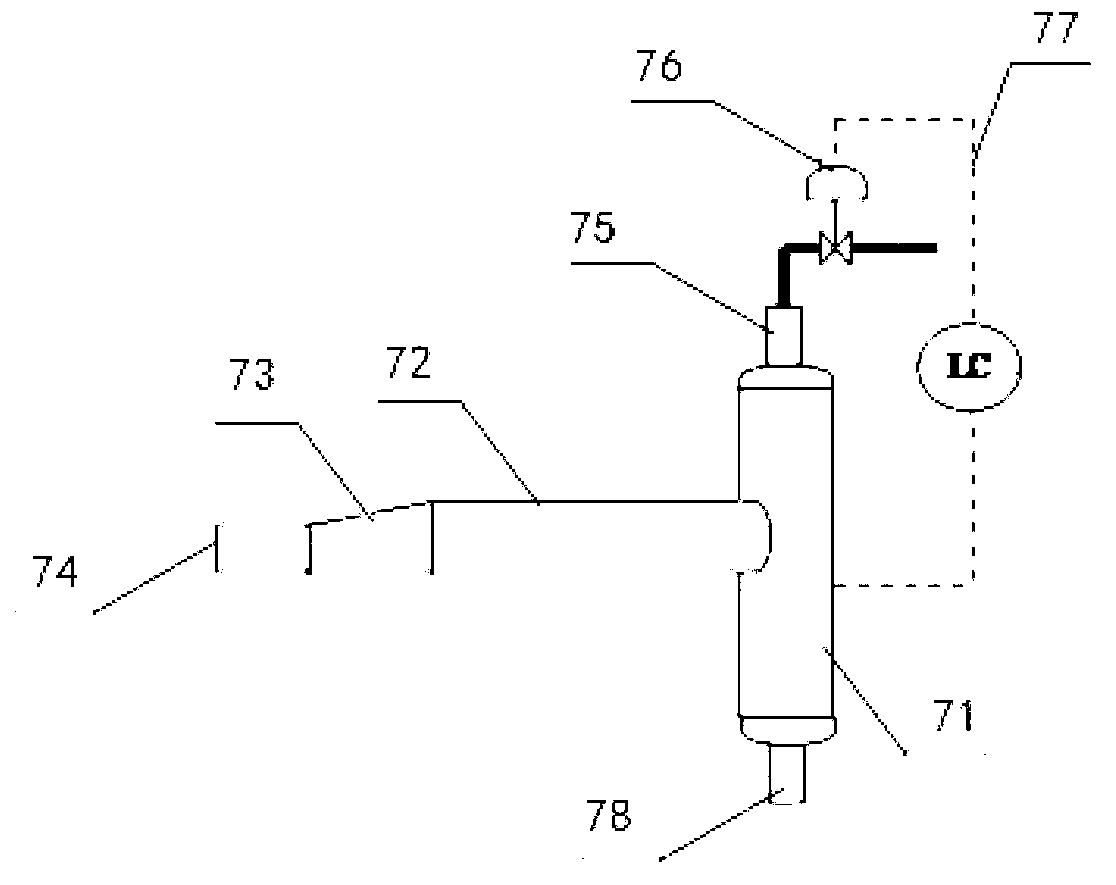

Oil-gas mixed transportation separating flow divider and oil-gas separating flow-dividing method

ActiveCN103239894AAvoid turbulenceAvoid flowingLiquid degasificationDispersed particle separationProduct gasProcess engineering

The invention discloses an oil-gas mixed transportation separating flow divider and an oil-gas separating flow-dividing method. The oil-gas mixed transportation separating flow divider is applied to oil field oil-gas mixed transportation engineering and connected between inlet and outlet pipelines of a tubular heating furnace; the oil-gas mixed transportation separating flow divider comprises a vertical separating tank and a liquid control loop, wherein a gas-liquid inlet is formed in the middle part of the separating tank and is communicated with a rectifying tube; a gas outlet is formed in the top of the separating tank and communicated with a gas and liquid mixing joint at the outlet of the heating furnace; a liquid outlet is formed in the bottom of the separating tank and communicated with a heating coiler pipe inlet of the heating furnace; and the liquid level control loop is arranged between a gas outlet pipeline and the separating tank. According to the oil-gas mixed transportation separating flow divider and the oil-gas separating flow-dividing method, the gas-liquid inlet and the rectifying tube are communicated with the middle part of the vertical separating tank in the horizontal direction, so that a gas-liquid laying flow pattern is quickly established, and the volume of the separating tank is greatly lowered. Liquid separated out by the separating flow divider is input to the heating furnace, and the separated-out gas is mixed with the heated liquid at the outlet of the heating furnace, so that furnace tube damages due to gas-liquid impact flow formed by enabling gas and liquid to simultaneously enter the heating furnace are avoided, and therefore, furnace tube pressure drop, investment of separating equipment and maintenance cost of the heating furnace are effectively lowered.

Owner:PETROCHINA CO LTD +2

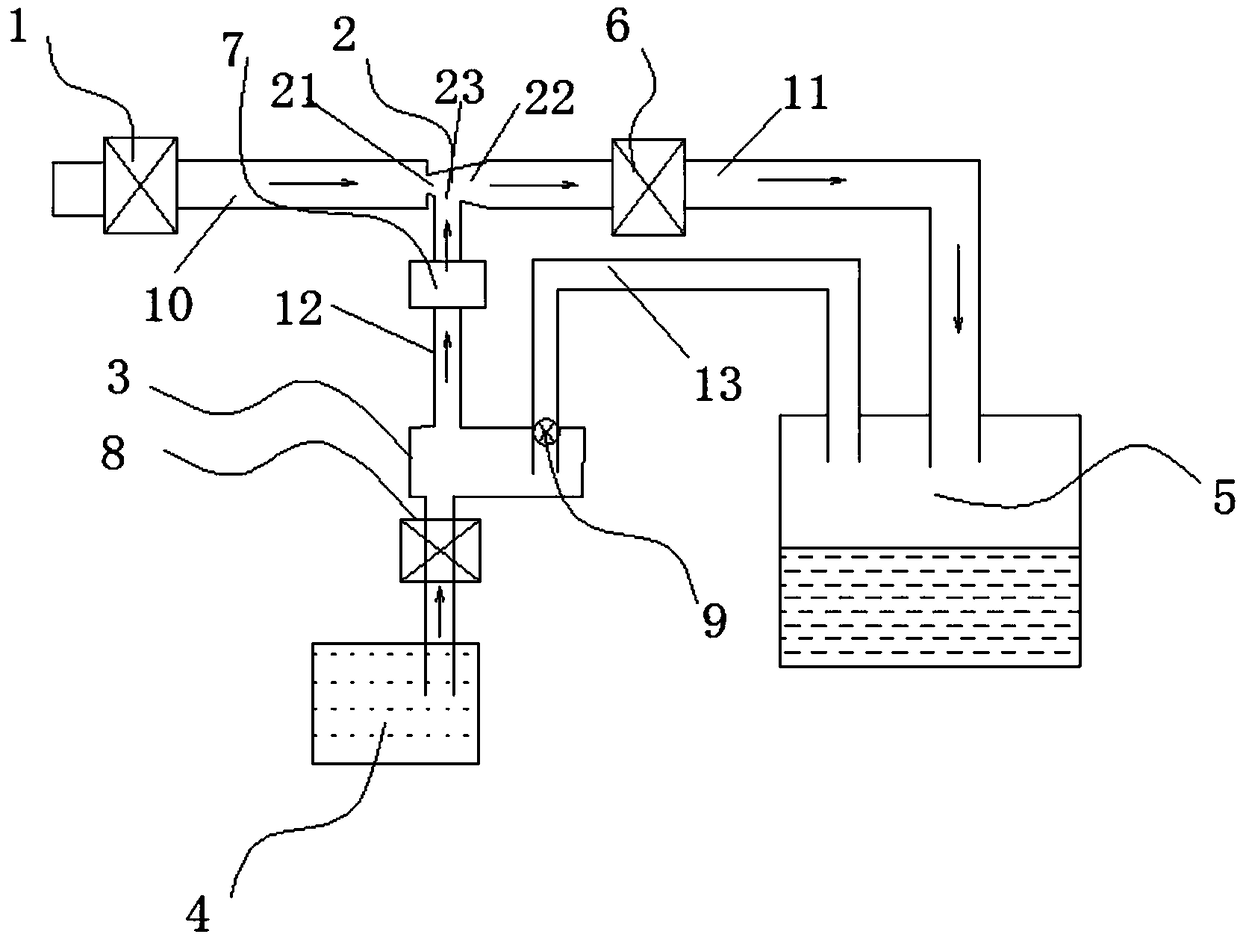

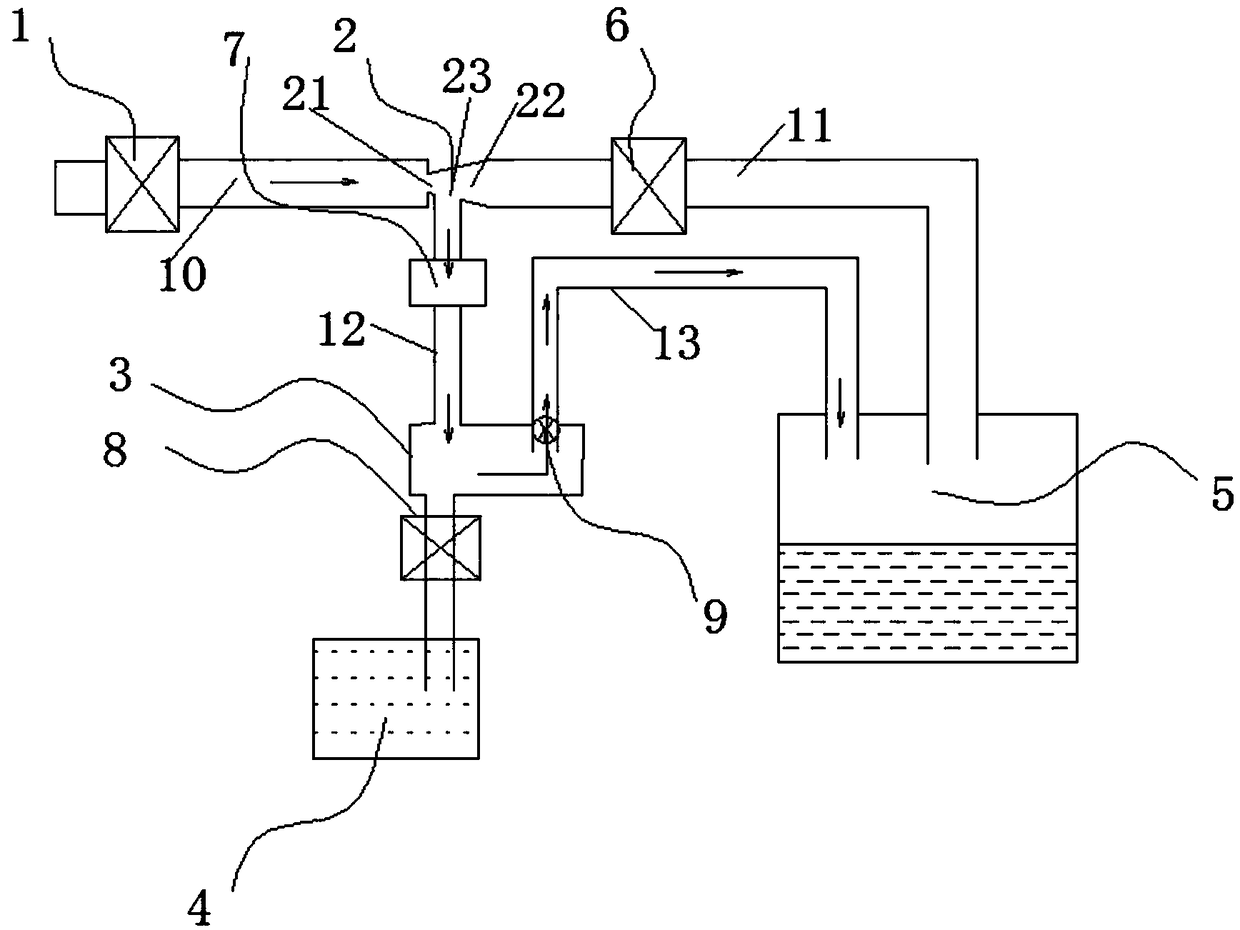

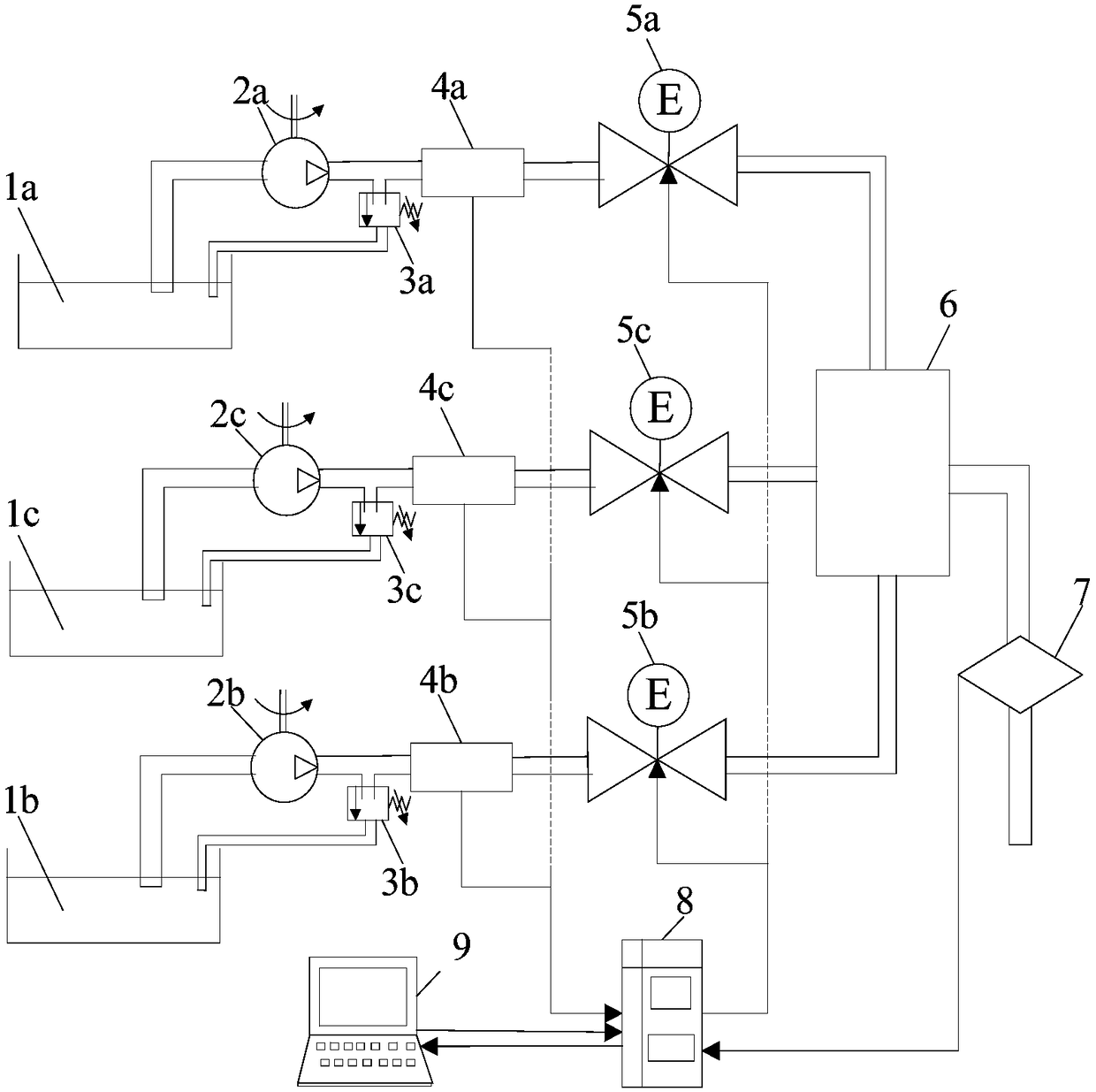

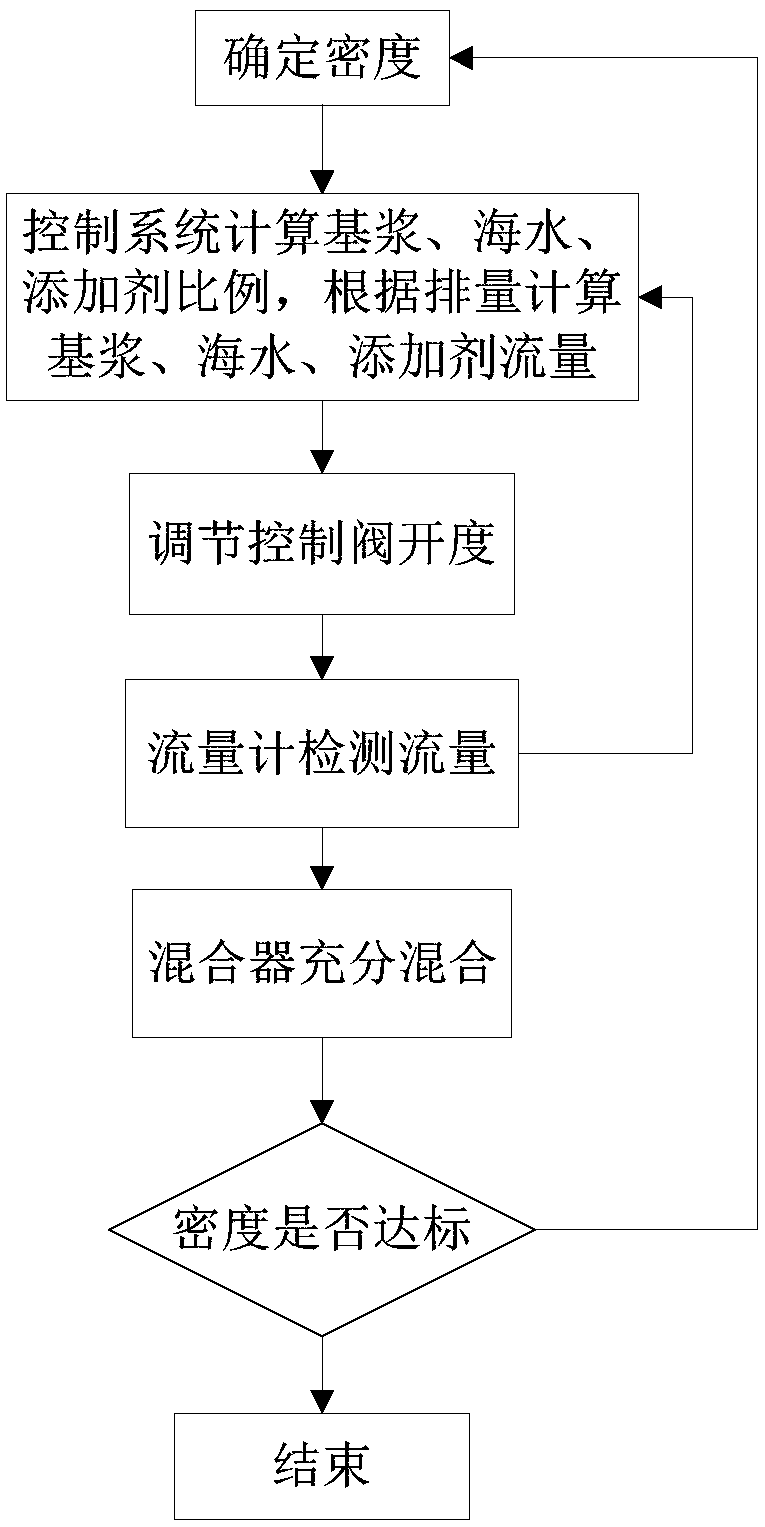

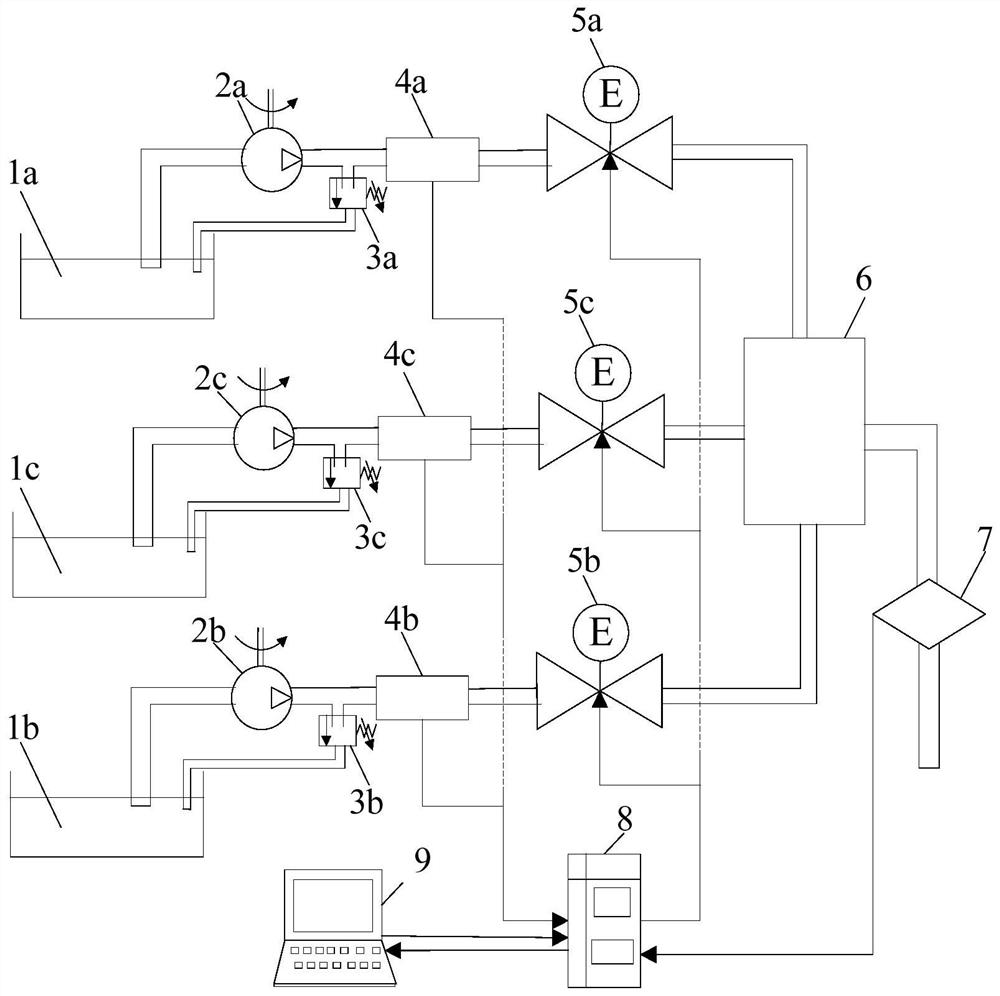

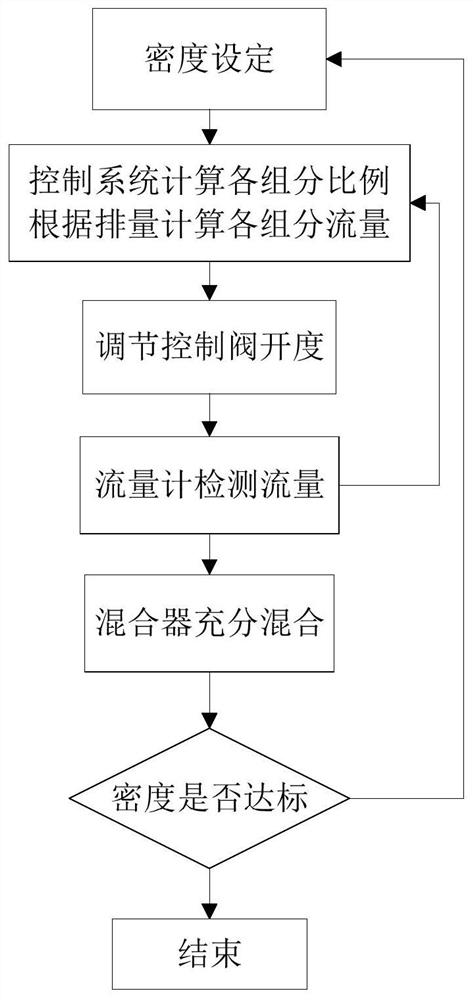

Self-feedback three-phase-system well drilling liquid mixing system and method for mixing well drilling liquid

The invention relates to a self-feedback three-phase-system well drilling liquid mixing system which comprises a mixing device, a seawater pool, a basic mud pool and an additive pool. The seawater pool is connected with the mixing device through a first pipeline, the basic mud pool is connected with the mixing device through a second pipeline, and the additive pool is connected with the mixing device through a third pipeline. The seawater pool contains seawater and is used for supplying seawater raw materials to the first pipeline, the basic mud pool contains basic mud and is used for supplying basic mud raw materials to the second pipeline, and the additive pool contains additives and is used for supplying additive raw materials to the third pipeline. The seawater, the basic mud and the additives enter the mixing device to be mixed and then enter a mud pool or a mud pump manifold through a density self-feedback module. By additionally arranging the density self-feedback module of theself-feedback well drilling liquid mixing system, the density of well drilling liquid can be more accurate, a flowmeter can further be corrected through comparison of the detected density and the setor designed density, and the system can achieve mixing of the raw materials of various proportions under the situation that the pump power is not controlled.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

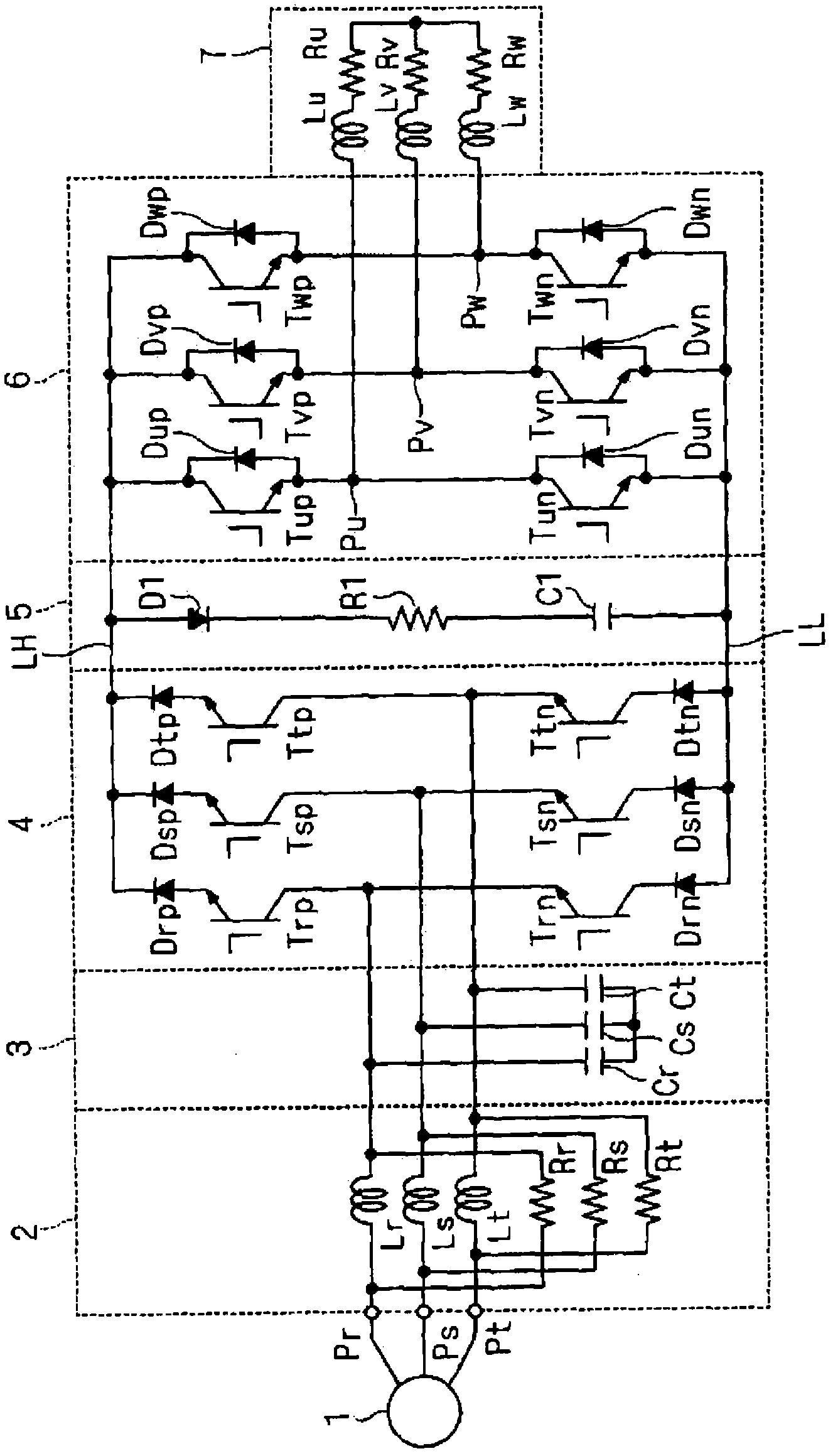

Power converter

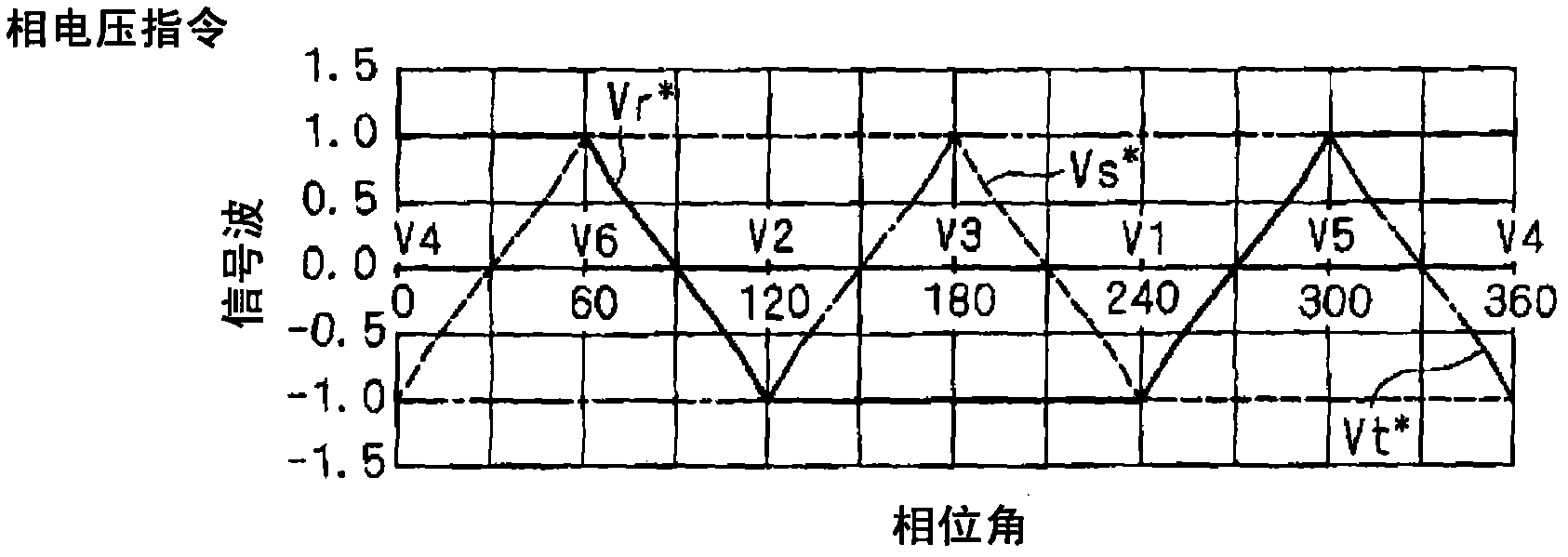

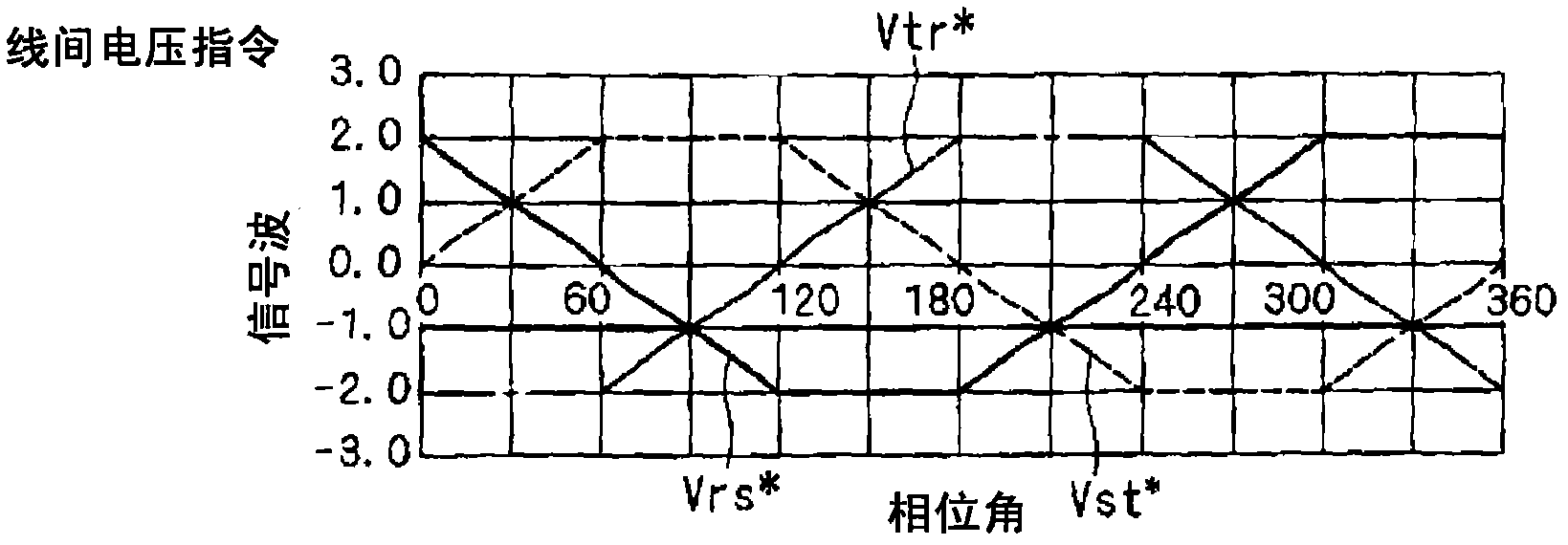

ActiveCN102422518ACurrent limitSuppresses increasing currentAc-dc conversion without reversalAc-ac conversionElectrical resistance and conductanceEngineering

Provided is a power converter which suppresses a current that flows to a capacitor due to a direct current link voltage increase generated by parasitic inductance when a switching a converter is switched in the normal operation. The converter (4) has switching elements, which are connected between a plurality of input terminals (Pr, Ps, Pt) and a direct current power supply line (LH), and switching elements, which are connected between the plurality of input terminals (Pr, Ps, Pt) and a direct current power supply line (LL). A capacitor (C1), a resistor (R1), and a diode (D1) are connected to each other in series between the direct current power supply lines (LH, LL).

Owner:DAIKIN IND LTD

Complete recrystallization of semiconductor wafers

ActiveUS20120164760A1Avoid flowingAfter-treatment apparatusPolycrystalline material growthPhysicsSemiconductor

Owner:STILE

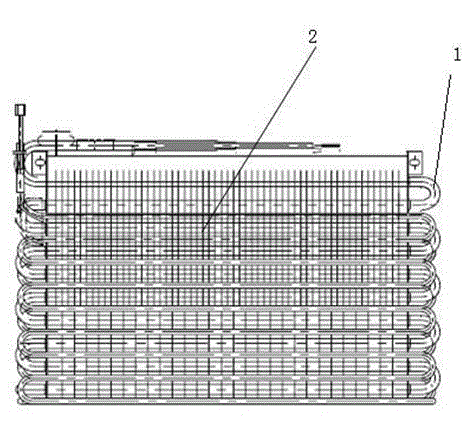

Fin type evaporator and refrigerator with the same

InactiveCN103062960AAvoid flowingImprove cooling effectDomestic refrigeratorsEvaporators/condensersEngineeringRefrigerated temperature

The invention relates to an evaporator, in particular to a fin type evaporator for a refrigerator. The fin type evaporator comprises a pipeline, a fin and two end plates. The fin and the pipeline are assembled in a matching mode, and the end plates are respectively arranged at the left end and the right end of the fin type evaporator. The end plates are respectively provided with a wind screen. The invention further relates to the refrigerator which comprises the fin type evaporator. The fin type evaporator comprises the pipeline, the fin and the two end plates. The fin and the pipeline are assembled in a matching mode, and the end plates are respectively arranged at the left end and the right end of the fin type evaporator. The end plates are respectively provided with one wind screen. The above structure not only has the effects of optimization and wind blocking, but also improves defrosting efficiency and improves the refrigerating effect of the evaporator.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

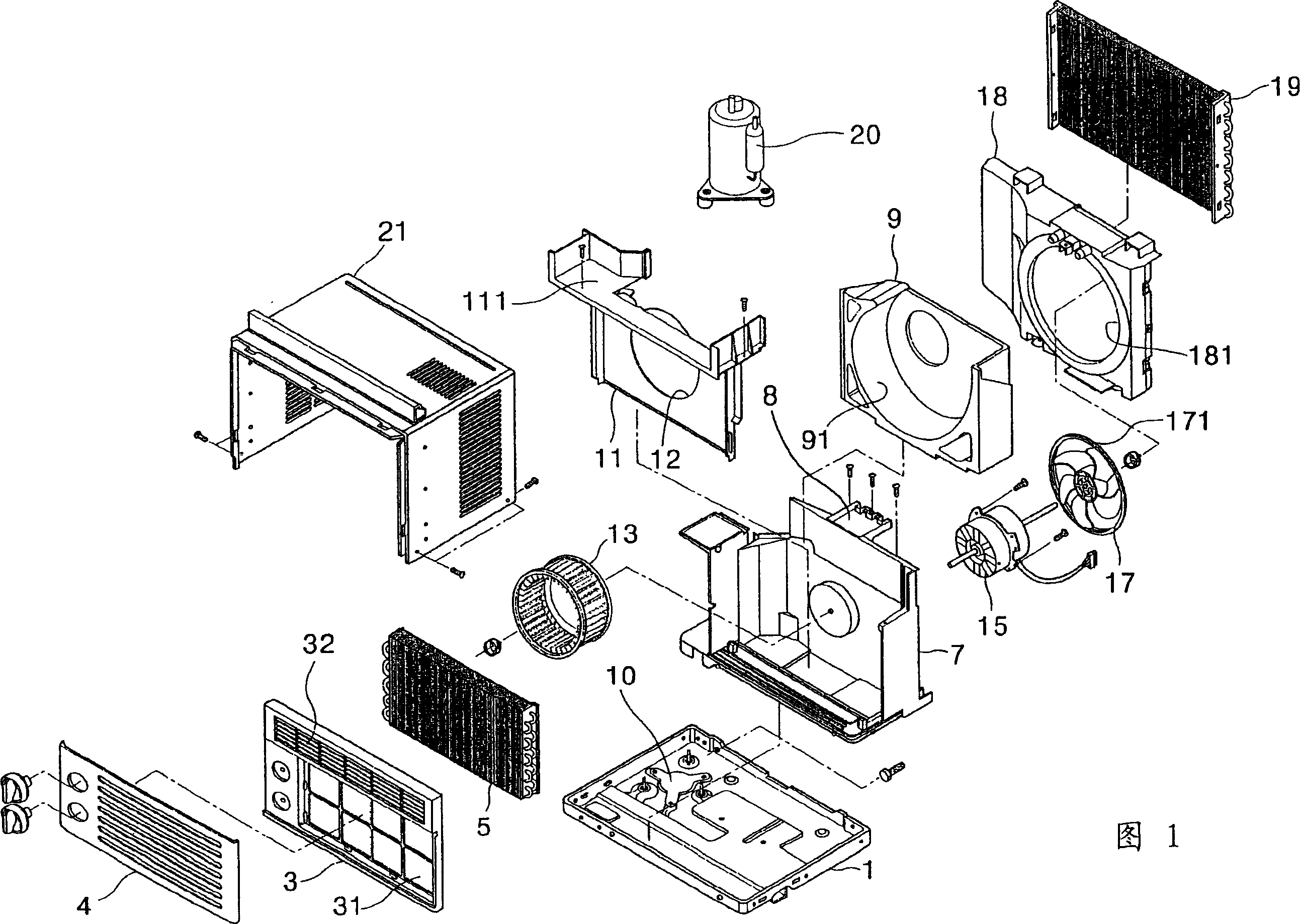

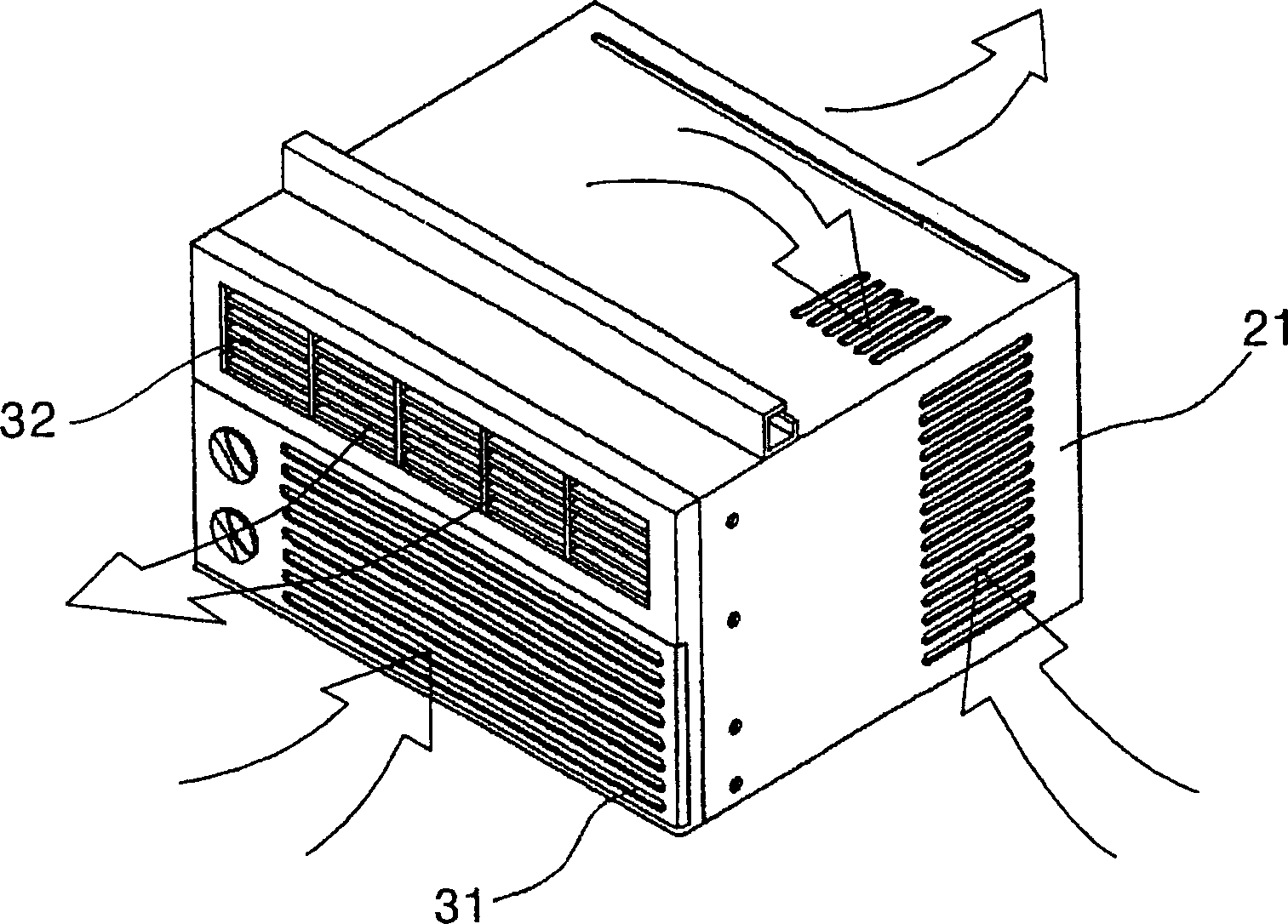

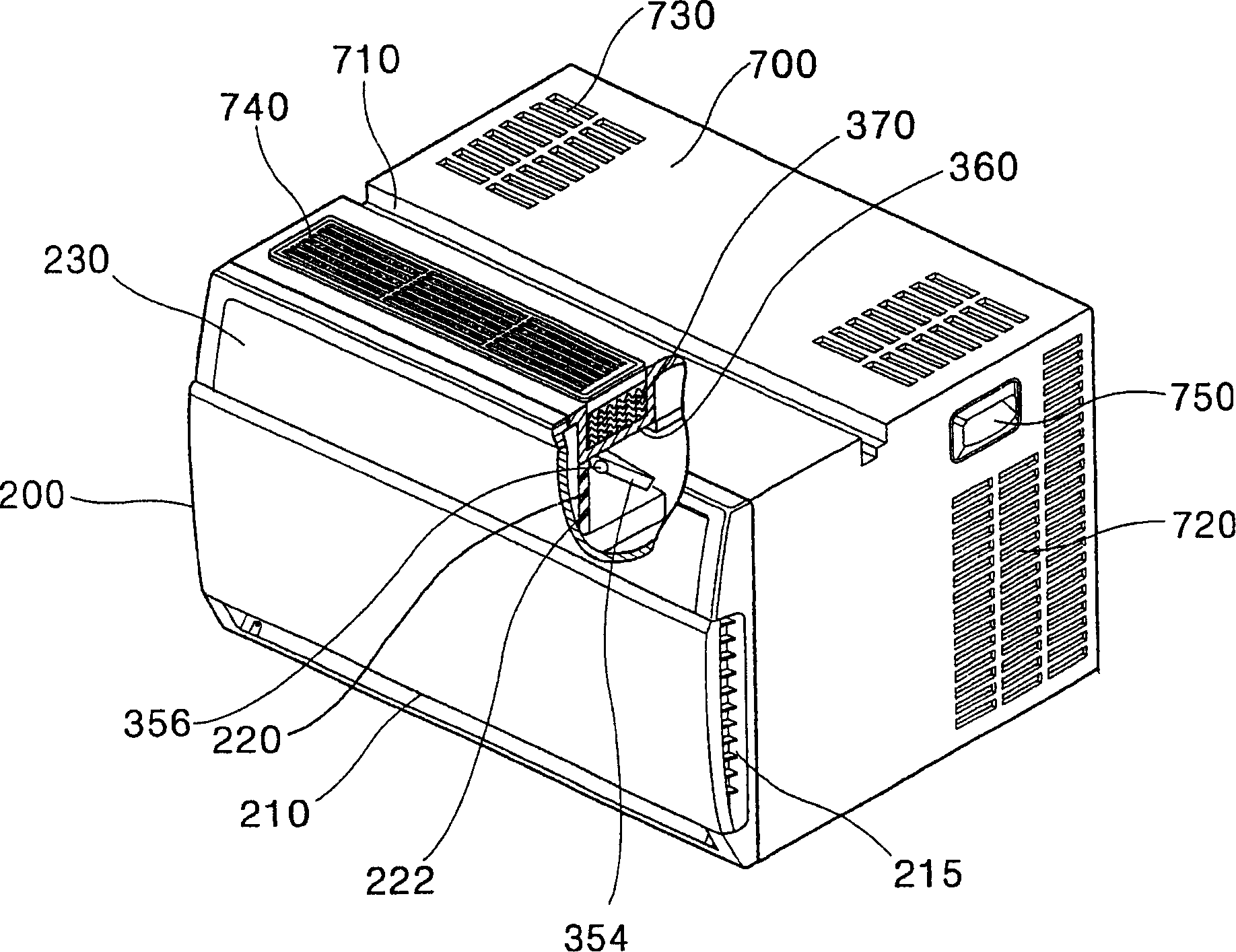

Integral type air conditioner and front panel thereof

InactiveCN1598415AImprove efficiencyImprove aestheticsLighting and heating apparatusHeating and ventilation casings/coversExhaust valveWorking fluid

The invention discloses an integral type air conditioner and a fore plate. The air conditioner comprises a compressor, an air guiding element dividing the air conditioner into an indoor unit and an outdoor unit, an indoor heat exchanger and an outdoor heat exchanger having heat exchange with the outer air by the circulating working fluid of the compressor, a fan near the heat exchanger for forming force airflow and an electric motor and a casing providing rotary power for the fan. The fore plate component comprises a side suction eye at the side, an air vent passing the air inducing to the air conditioner and discharging air and a door open / close device sheltering the exhaust valve of the air vent and for opening / closing the exhaust valve. The inner part of the integral type air conditioner of the invention can not be seen from the outside. When the air conditioner is out of operation, as the exhaust valve shelters the indoor air vent, the appearance of the air conditioner is more beautiful and is convenient for cleaning the fore plate.

Owner:LG ELECTRONICS INC

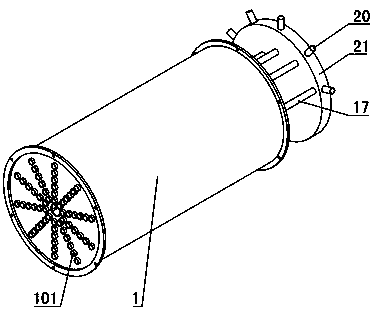

Heat exchanger with brushing function and convenient-to-replace cleaning ball

InactiveCN109269342AEasy to replaceEasy to washFlush cleaningNon-rotary device cleaningButt jointEngineering

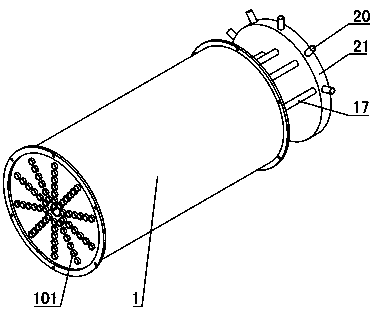

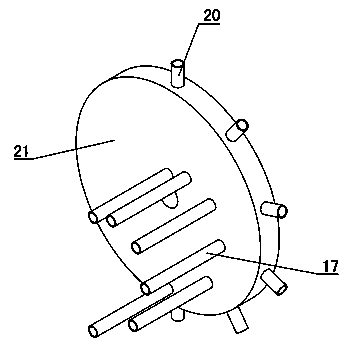

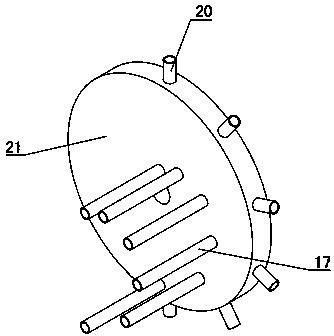

The invention discloses a heat exchanger with a brushing function and a convenient-to-replace cleaning ball, and belongs to the technical field of heat exchangers. The heat exchanger is characterizedthat multiple columns of heat exchange pipes (101) are arranged in the radial direction of the heat exchanger (1), multiple brushing pipes (17) are arranged at the end, close to a water inlet tube, ofa distributing plate (21), the range of each brushing pipe (17) to the center of the distributing plate (21) is the same as the range from the heat exchange pipe (101) in the corresponding position of the brush pipe to the heat exchanger (1), and the brushing pipes (17) are allowed to in butt joint with the heat exchange pipes (101) one by one; a transparent pipe (27) is arranged between a cleaning ball flow returning pipeline and a water outlet end of the heat exchange pipe (101), a return ball valve (28) is arranged between the transparent pipe (27) and the cleaning ball returning pipeline,and a discharging valve (29) is connected with a water outlet end of the transmission pipe (29). The heat exchanger has the advantages that online cleaning of the heat exchanger is achieved by the heat exchanger with the brushing function and the convenient-to-replace cleaning ball, and the replacement of the cleaning ball is convenient.

Owner:SHANDONG UNIV OF TECH

Micro-nano bubble water generating apparatus and water use terminal

PendingCN108285208AEffective limitEffective immobilizationWater aerationSustainable biological treatmentWater useMicro nano

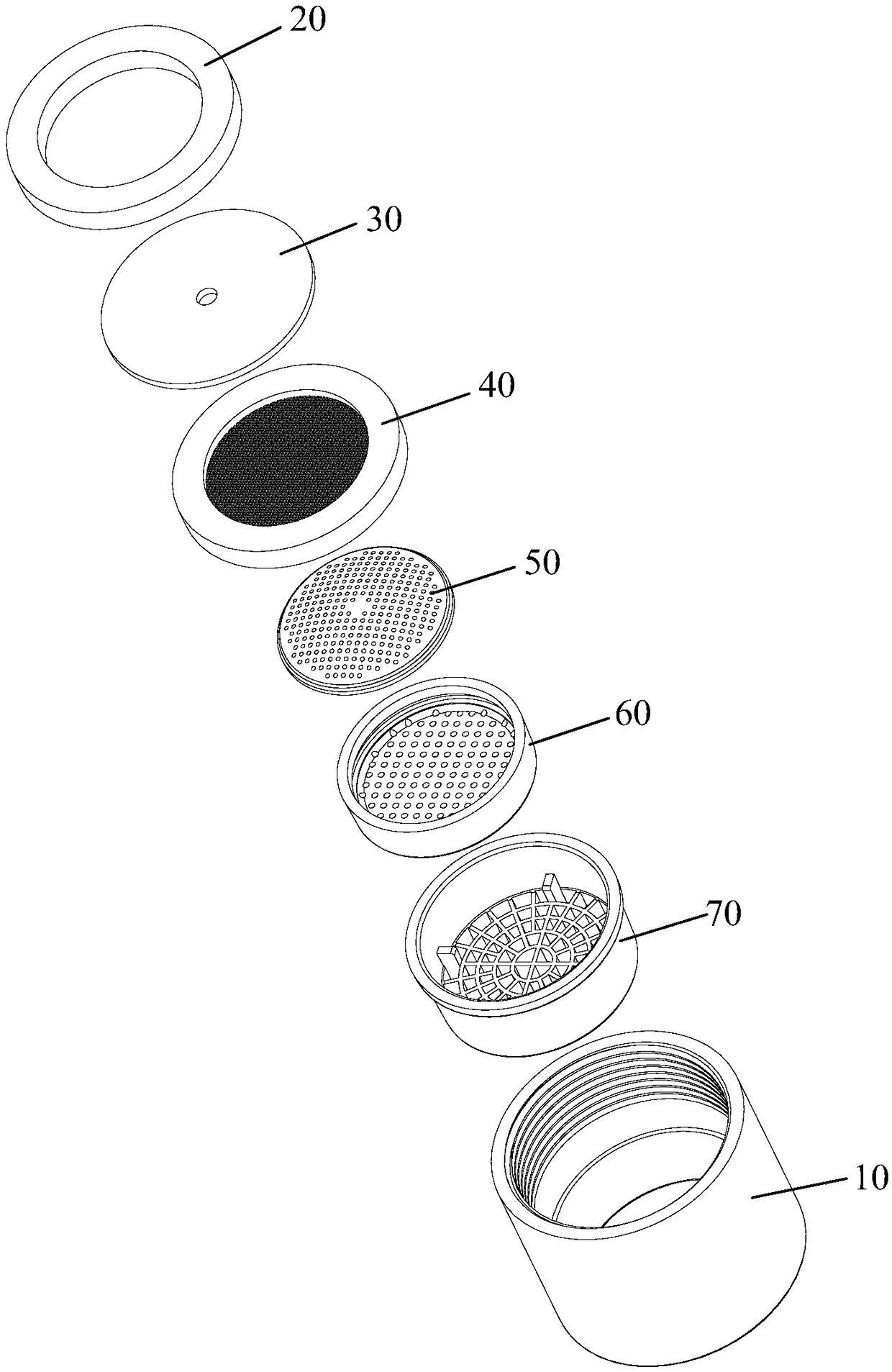

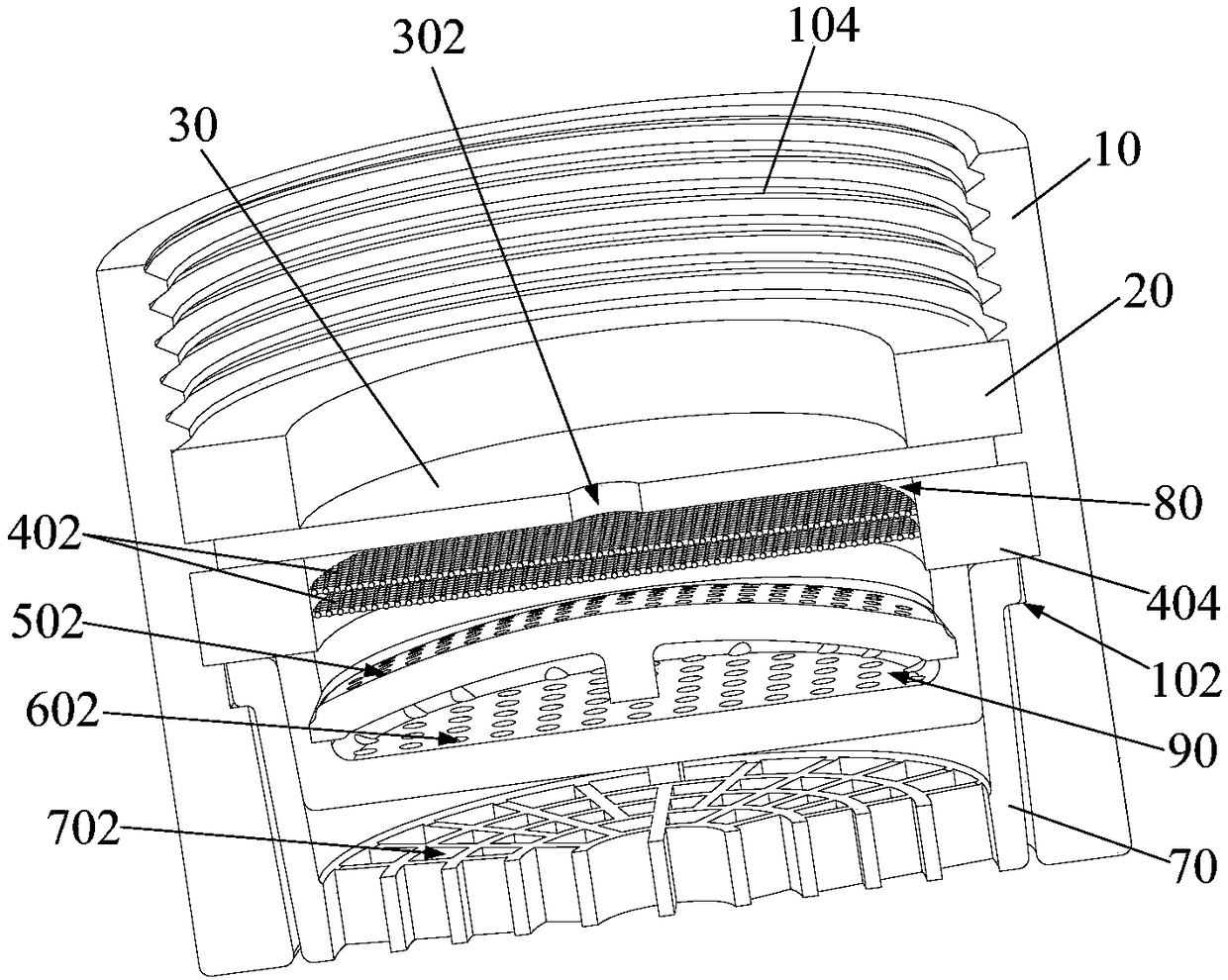

The invention provides micro-nano bubble water generating apparatus and a water use terminal. The generating apparatus comprises a shell, a current limiting device and a foaming device; the shell is provided with a water inlet end and a water outlet end; the current limiting device is arranged in the shell and is provided with a current limiting hole; the foaming device is arranged in the shell and is positioned between the current limiting device and the water outlet end of the shell; the foaming device comprises a filter screen which is arranged oppositely to the current limiting device; anda first micro-nano bubble water generating cavity used for forming micro-nano bubble water is defined between the filter screen and the current limiting device. According to the micro-nano bubble water generating apparatus provided by the invention, the first micro-nano bubble water generating cavity is formed between the current limiting device and the filter screen through the arrangement of the current limiting device and the filter screen; pressure is reduced when high-pressure water containing dissolved gas and entering the shell enters the cavity through the current limiting hole, so that micro-nano bubbles are generated; and the filter screen forms a first layer of obstacle to enable the mixture of the micro-nano bubbles and water to flow at a reduced speed, so that the uniform micro-nano bubble water is formed.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD +1

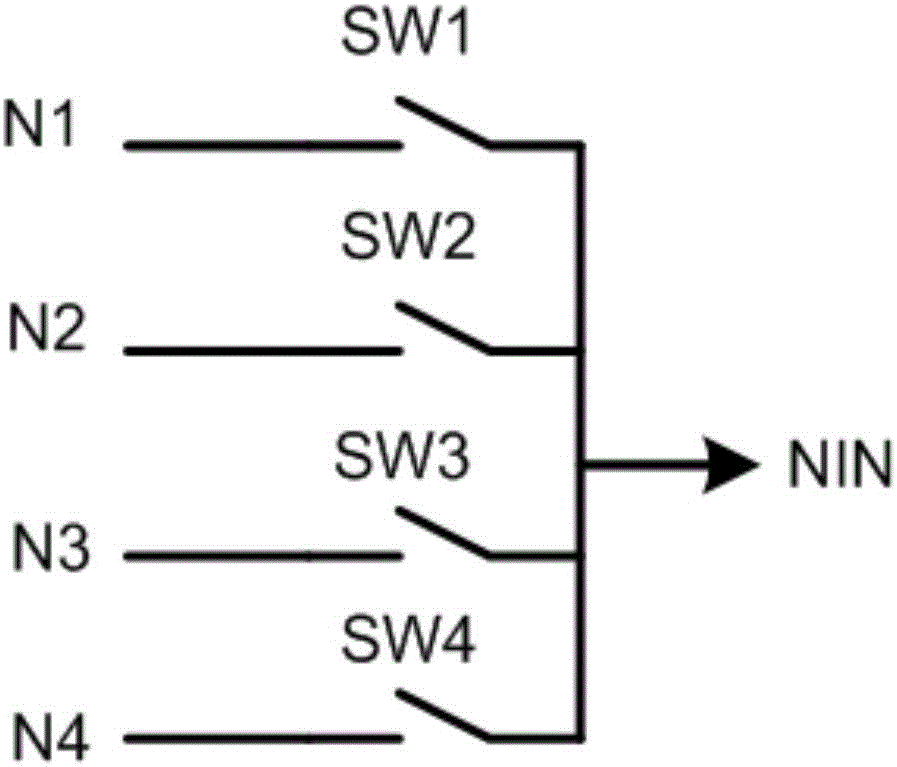

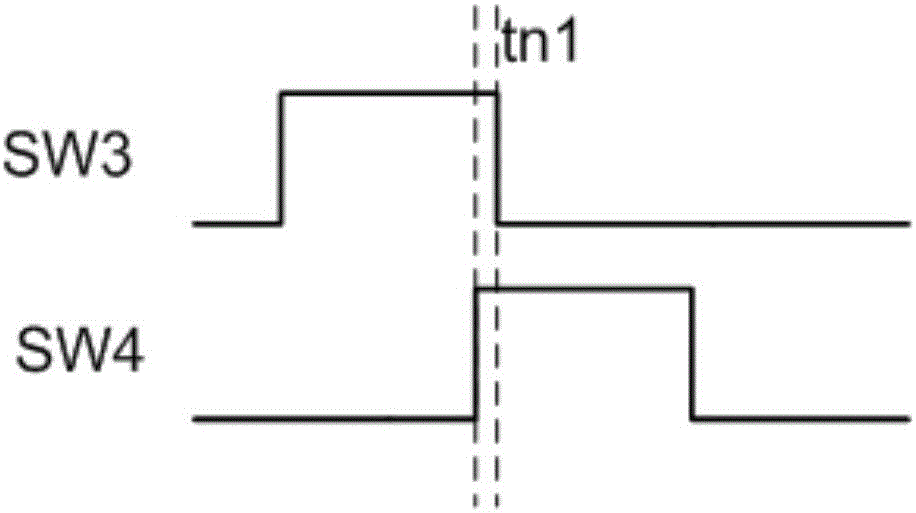

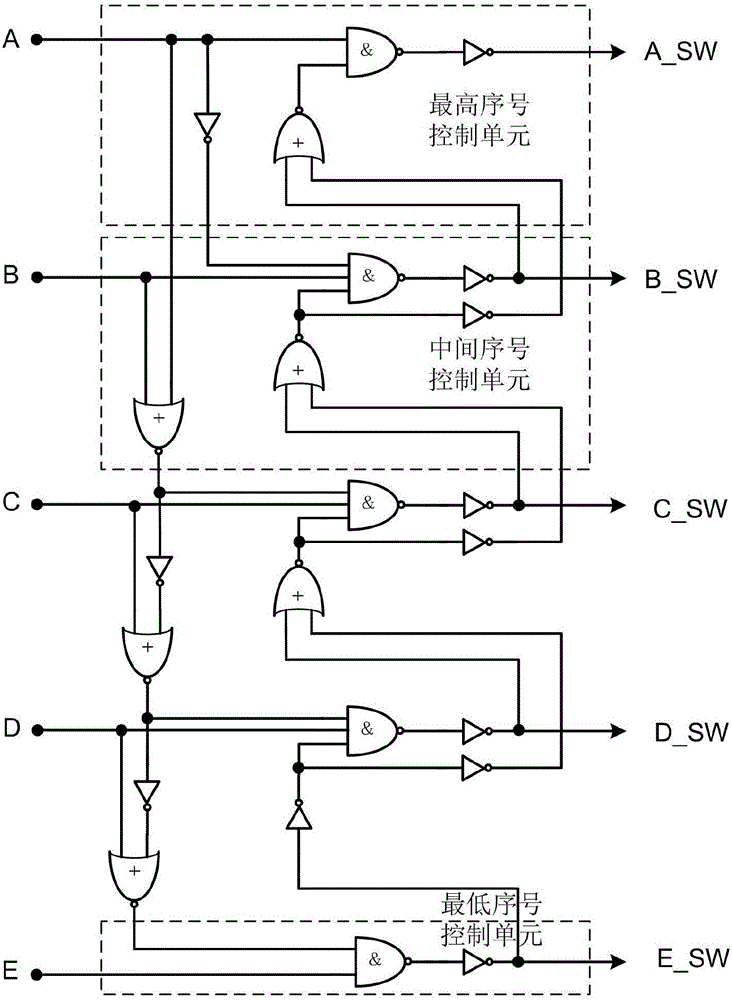

Multipath non-overlapped switching circuit

ActiveCN106452418AImprove scalabilityAvoid flowingReliability increasing modificationsLogic circuits characterised by logic functionPower flowControl signal

The invention discloses a multipath non-overlapped switching circuit, and the circuit comprises a plurality of switches and corresponding switching control signals. Each switching control signal is used for logic control through a logic gate and a phase inverter. Moreover, adjacent multipath switches are connected through the phase inverter and the logic gate, so as to achieve the integrated control of the switching signals, and achieve a purpose that at most one switch is turned on at the same moment. The switching circuit avoids node voltage oscillation caused by the simultaneous switching-on of two switches, and prevents an overlarge current from flowing through the switch. Moreover, the switching circuit is easier to achieve the extension of any non-overlapped switches.

Owner:CHIPSEA TECH SHENZHEN CO LTD

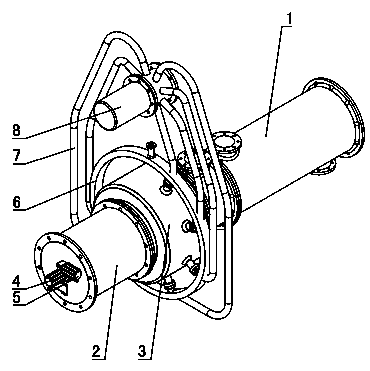

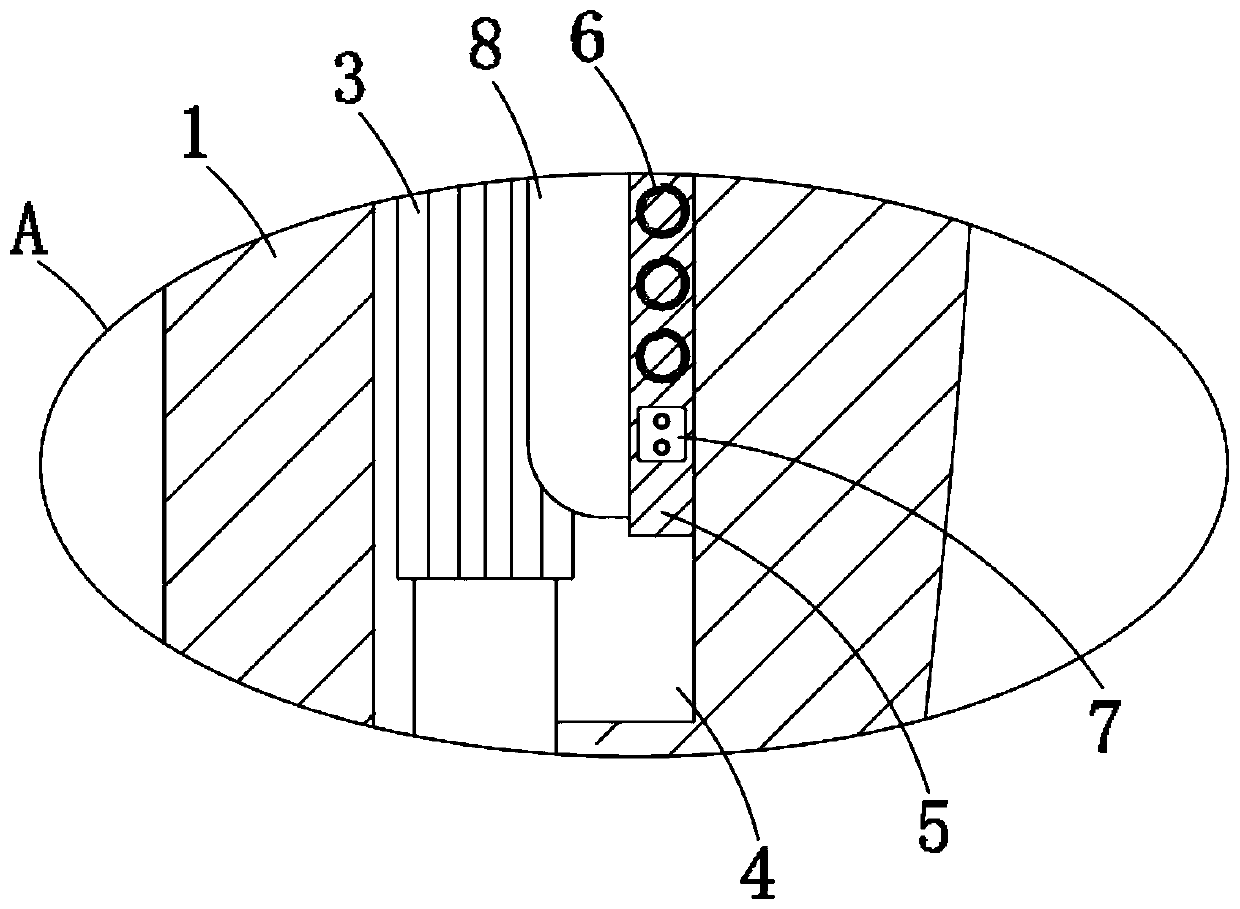

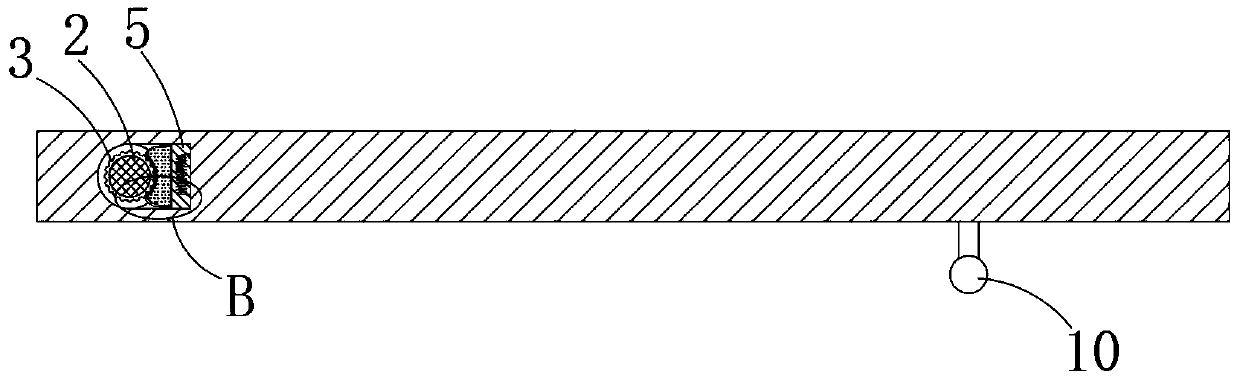

Waterproof plugging device for power cable pipeline

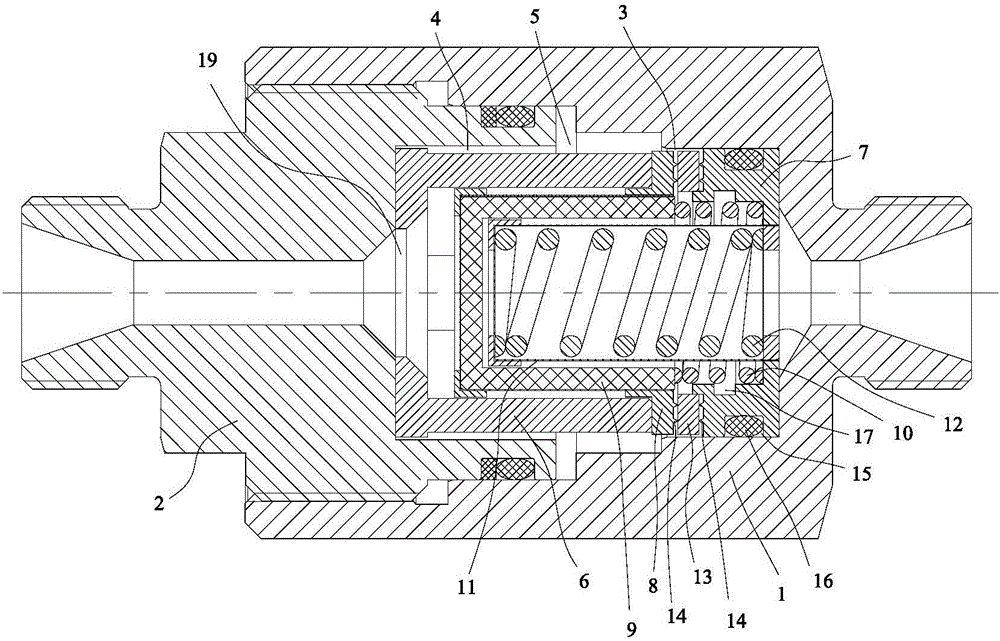

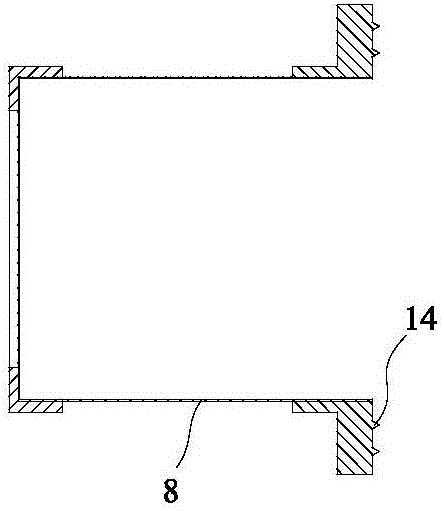

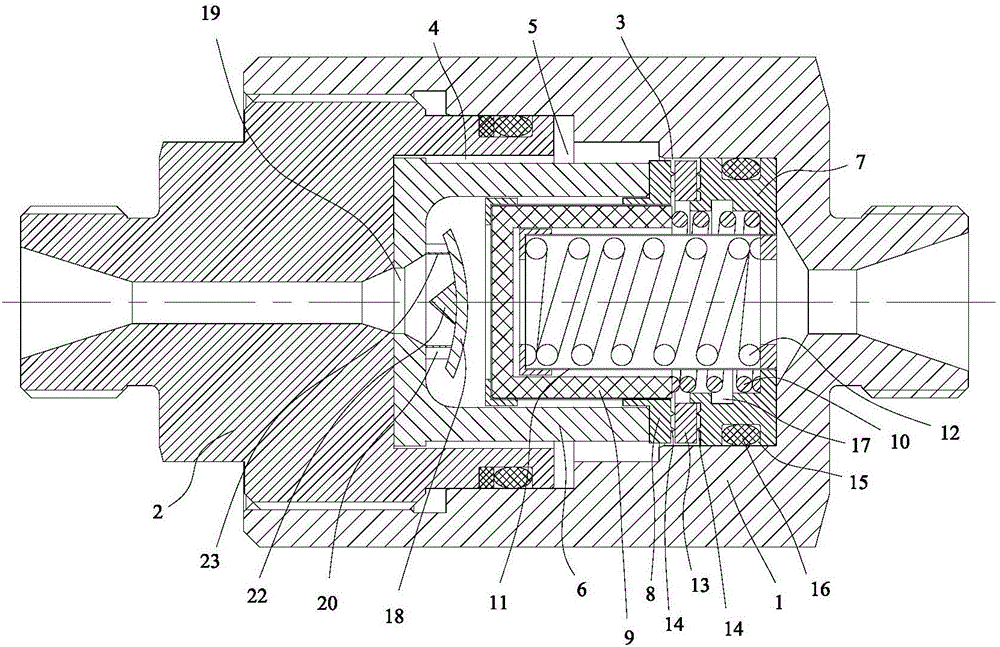

ActiveCN107591769AEffective isolationInfluence phenomenonCable installations in underground tubesCable inlet sealing meansPower cableEngineering

The present invention discloses a waterproof plugging device for a power cable pipeline. The device comprises a pipeline 1, a power cable, a pipeline 2, a plugging housing, a sealing element 1, a sidesealing structure, a pin shaft, an upper cover, an upper plugging structure, a sealing pad, a sealing ring, a lock, a fixed base, a water pumping pipe, a sealing element 2, a water collection cavity,a waterproof separator, a right water pumping channel, screws and a left water pumping channel. The waterproof plugging device for a power cable pipeline is simple and reasonable in structure and lowin production cost, and the waterproof separator is arranged to effectively isolate water between the pipeline 1 and the pipeline 2 so as to avoid a phenomenon of water in a pipeline influencing thewhole pipeline; the right water pumping channel and the left water pumping channel are arranged to facilitate pumping of water generated from the pipeline; the side plugging structure and the upper plugging structure are arranged to effectively perform compression and sealing of the power cable, and the upper side between the connection of pipelines is subjected to tripling compression and sealingto effectively prevent water from flowing through the side surface of the power cable so as to improve a sealing effect.

Owner:YANTAI SANXIN NEW ENERGY TECH CO LTD

Wind-proof door body

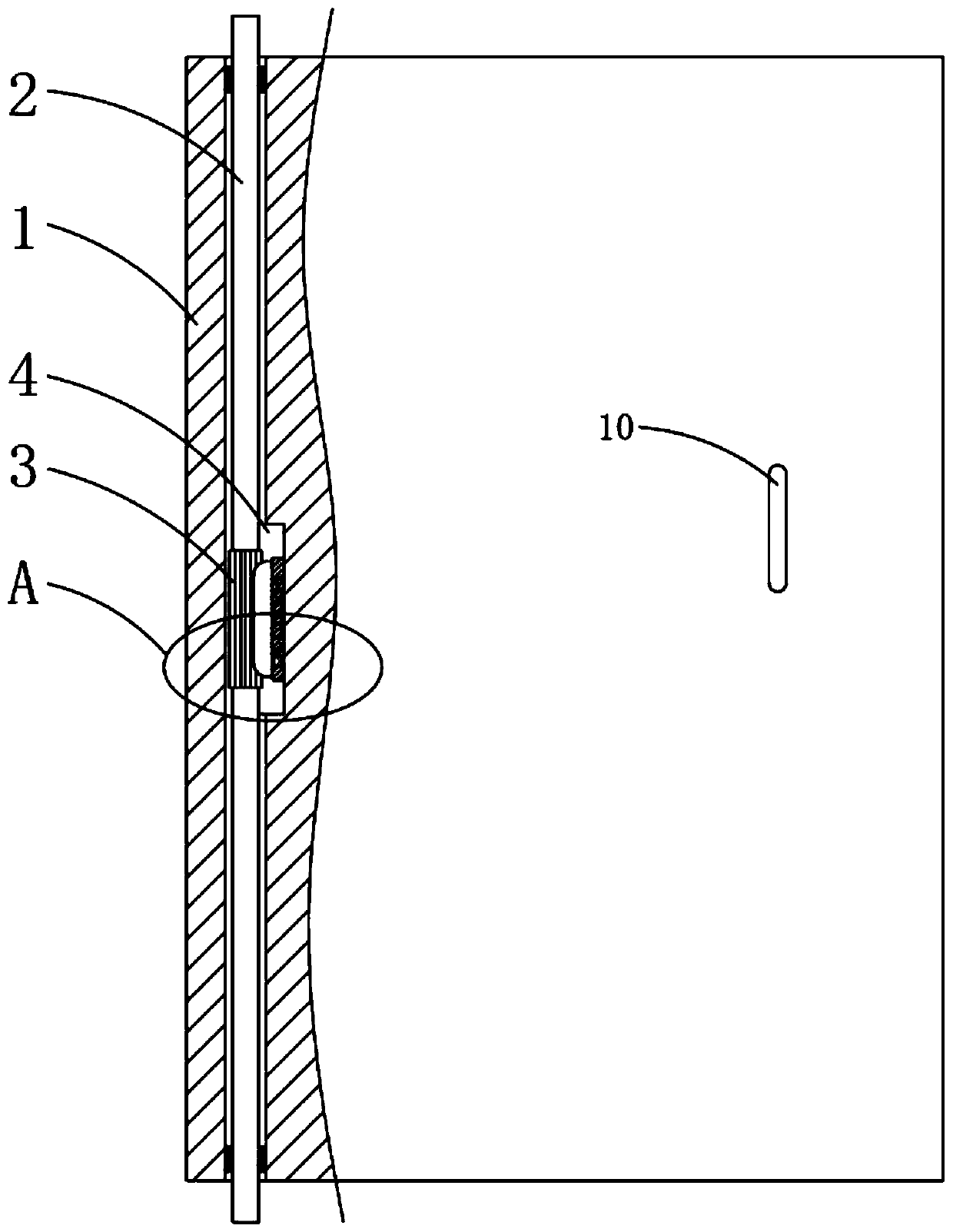

ActiveCN110656851APrevent rotationReduce adverse effectsWing handlesWing knobsStructural engineeringMechanical engineering

The invention discloses a wind-proof door body. The wind-proof door body comprises a door plate and a door shaft, wherein a through hole is formed in one side of the door plate; the door shaft penetrates through the through hole and is rotatably connected with the door plate through a bearing; the door shaft is fixed on an external door frame; a handle is fixedly connected to one side, far away from the door shaft, of the door plate; a groove is formed in the middle of the through hole; a toothed bar is fixedly sleeved in the middle of the door shaft; the section of the toothed bar is of a straight gear-shaped structure; a rubber block is fixedly glued in the groove; a plurality of coils and a first storage battery are embedded in the rubber block; and the coils and the first storage battery are connected in series to form a magnetism generating branch. The wind-proof door body has the advantages that the toothed bar part structure is provided, when the door plate does not need to be rotated, the magnetism generating branch generates a magnetic field to enable a soft bag to be tightly meshed with the toothed bar, so that the door plate cannot rotate, the door plate is prevented from rotating under the action of wind when the door plate does not need to rotate, and the adverse effect of wind blowing on the life of people is greatly reduced.

Owner:ZHEJIANG SHENGNA INTELLIGENT TECH CO LTD

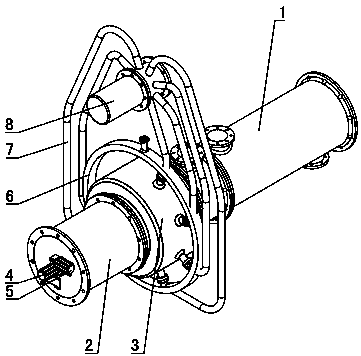

Heat exchanger with washing function

InactiveCN109269326ARinse thoroughlyRealize online cleaningStationary tubular conduit assembliesFlush cleaningEngineeringMicro heat exchanger

The invention relates to a heat exchanger with a washing function and belongs to the technical field of cleaning for heat exchangers. The heat exchanger is characterized in that multiple columns of heat exchange pipes (101) are arranged in the radius direction of a heat exchanger body (1), each column contains the same number of heat exchange pipes (101), and the number of washing pipes (17) of adistribution disc (21) is equal to that of the heat exchange pipes (101) contained in each column; the distance between each washing pipe (17) and the center of the distribution disc (21) is equal tothat between the heat exchange pipe (101) corresponding to each washing pipe (17) and the center of the heat exchanger body (1), water inlets (20) corresponding to the washing pipes (17) one to one are formed in the side of the distribution disc (21), and a pushing mechanism is connected with the distribution disc (21) and drives the distribution disc (21) to move. According to the heat exchangerwith the washing function, online cleaning for the heat exchanger body is achieved, convenience is provided for cleaning, cleaning is complete, the heat exchange efficiency of the heat exchanger is guaranteed, and application of the heat exchanger cannot be hindered when the heat exchange pipes are cleaned.

Owner:SHANDONG UNIV OF TECH

Composite gas filter

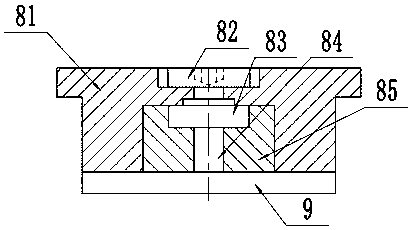

ActiveCN106492549AImprove structural strengthAvoid deformationDispersed particle filtrationTransportation and packagingEngineeringFilter effect

The invention relates to the technical field of filters, and in particular to a composite gas filter which comprises a shell (1) and a connector (2), and further comprises a propping sleeve (6), a bottom ring component (7), a first filtering net component (8), a sintering filter core (9) and a first elastic part (10), wherein a mounting groove (3) is formed inside the shell (1); a groove (4) is formed in the connector (2); the bottom ring component (7) is connected inside the mounting groove (3) in a clamping manner; the propping sleeve (6) is positioned inside the groove (4); the first filtering net component (10) is positioned inside the propping sleeve (6); the top end of the first filtering net component (8) is propped against an end part of the propping sleeve (6); when the connector (2) is tightly screwed with the shell (1), the top end of the first filtering net component (8) is propped against the bottom ring component (7) through the propping sleeve (6); the sintering filter core (9) is positioned inside the first filtering net component (8). By adopting the structure, the composite gas filter that the filtering net component is not liable to damage and thus the filtering effect can be stable is provided.

Owner:NINGBO XINGJIAN SPACE MACHINERY

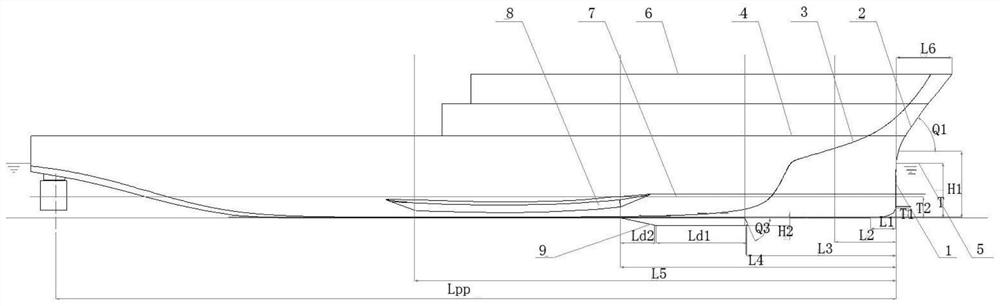

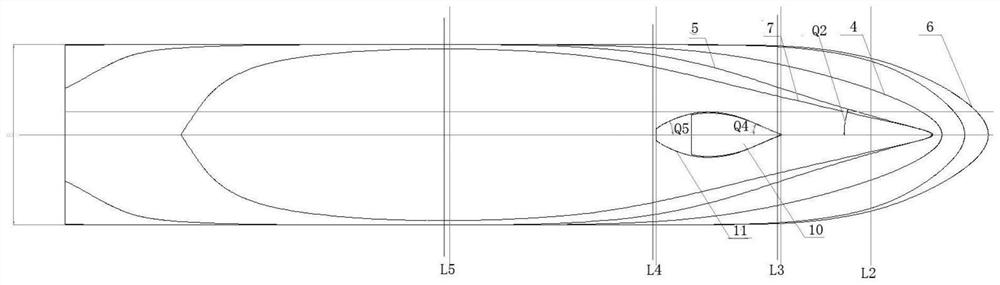

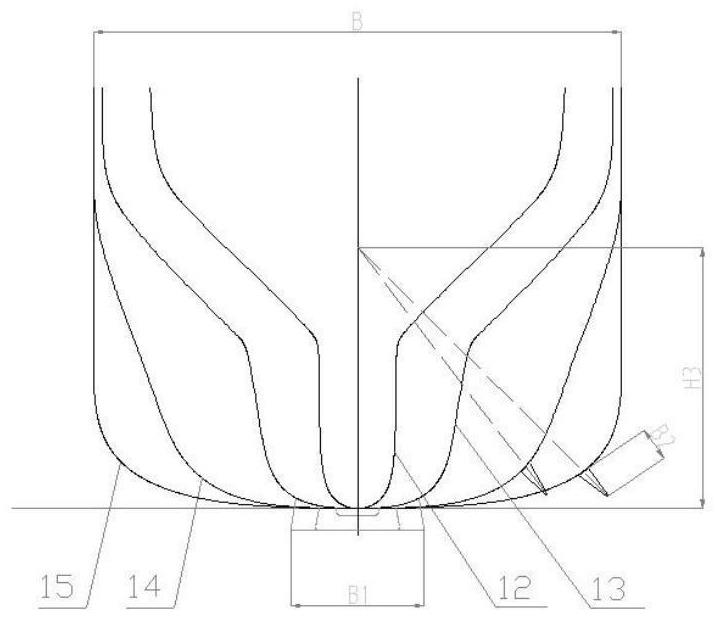

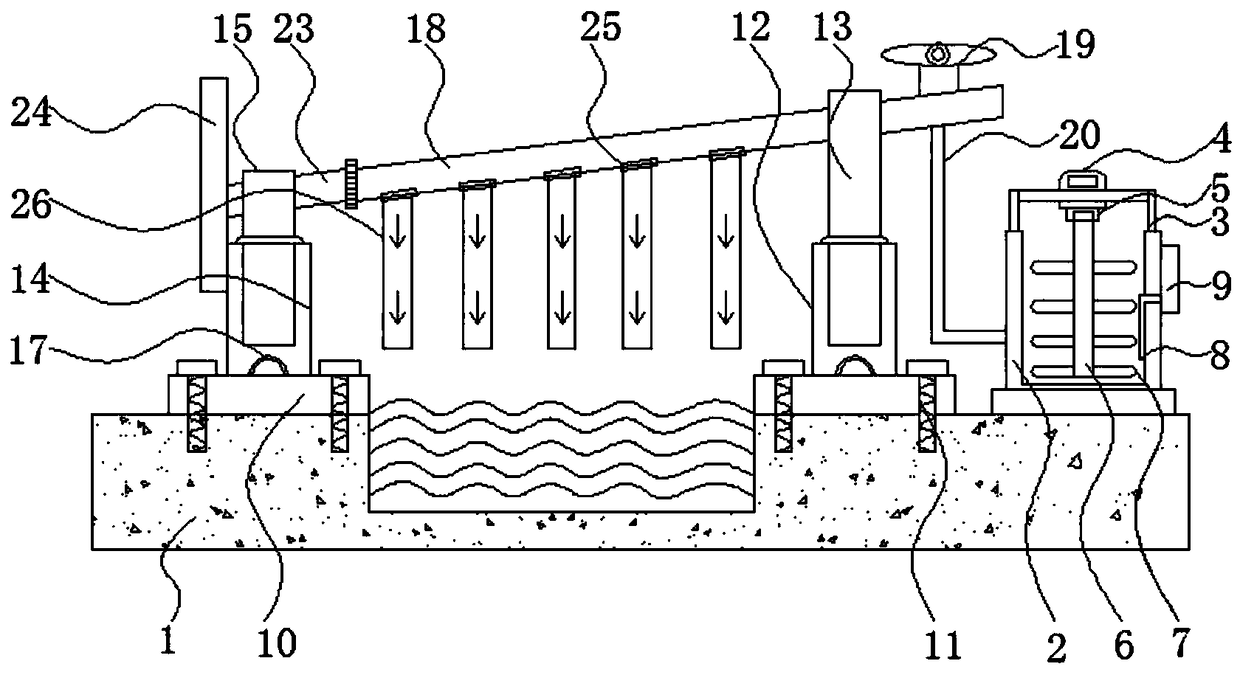

Linear integrated design method for bow and appendage of survey ship with fairing

PendingCN113955037APrevent leakageAvoid flowingWatercraft hull designHull stemsKeelClassical mechanics

The invention relates to an integrated design method for a bow and appendage line type of a survey ship with a fairing, which comprises integrated design of a bow line type, a fairing position and line type, a bilge keel position and line type and the like, and specifically comprises the following steps of: after determining data such as a vertical line length Lpp, a ship width B and a draft T of the ship, designing line type characteristic parameters of the bow and the appendage through the method; bubbles are prevented from being discharged to the surface of the acoustic equipment transducer at the bottom of the ship body along with a streamline, and meanwhile, the streamline is beneficial to reducing resistance and ensuring rapidity.

Owner:CHINA SHIP DEV & DESIGN CENT

High phosphorus content polluted river water treatment method

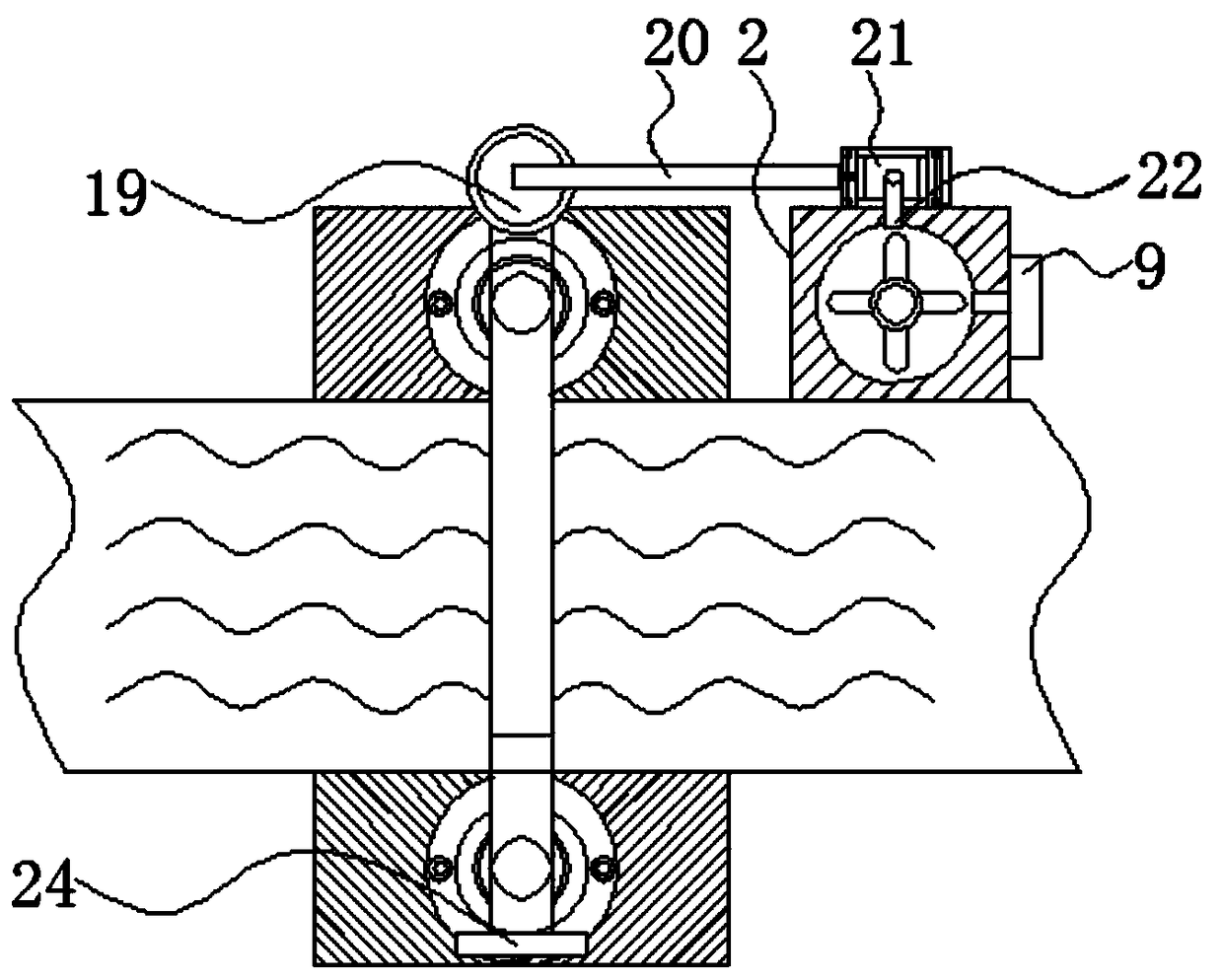

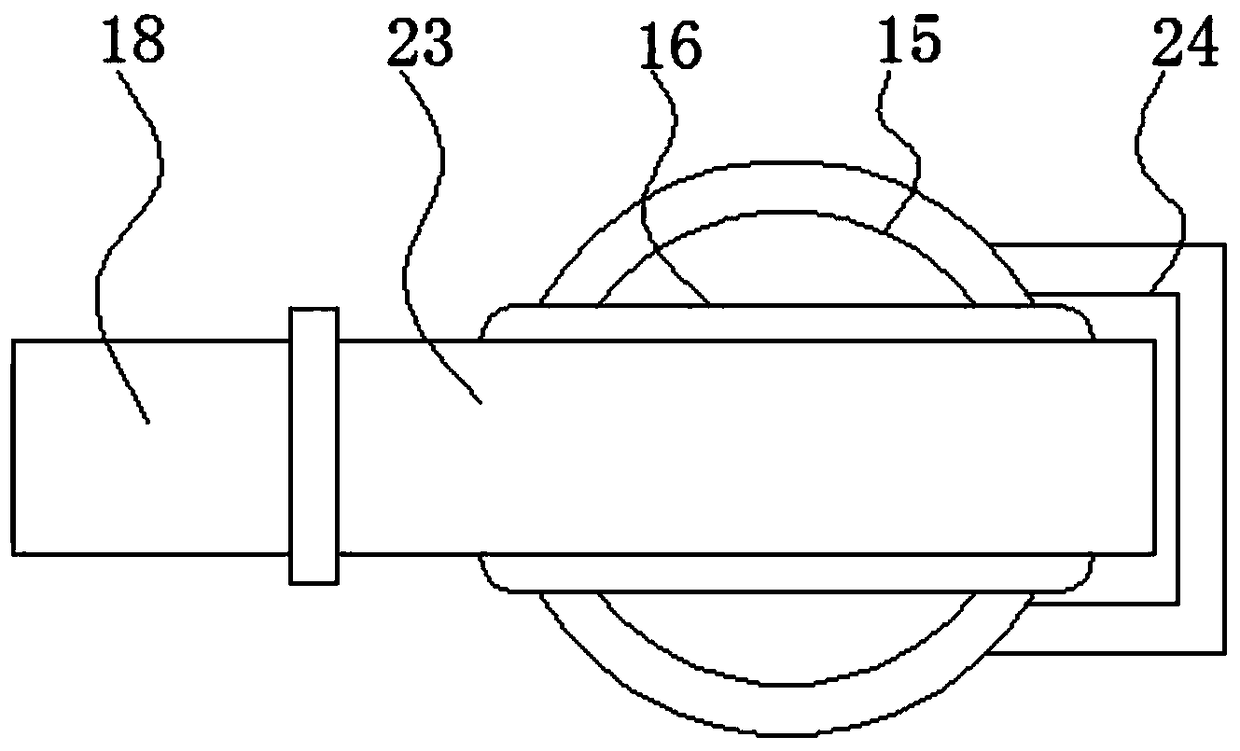

InactiveCN109224967APrevent slidingConcentration detectionRotary stirring mixersTransportation and packagingHigh concentrationDrive shaft

The invention relates to a high phosphorus content polluted river water treatment method and relates to the technical field of river water phosphorus removal. According to the high phosphorus contentpolluted river water treatment method, a riverway soil layer and a bottom frame are specifically utilized, a liquid preparation barrel is arranged above the riverway soil layer, a motor frame is welded to the edge of the upper end of the liquid preparation barrel, a motor is arranged in the motor frame, one end of a transmission shaft is connected to the lower part of the motor, the other end of the transmission shaft is connected with a rotating rod, one end of a through liquid pipe is arranged on an inner wall of the liquid preparation barrel, and a fixed screw penetrates through the insideof the bottom frame. The high phosphorus content polluted river water treatment method disclosed by the invention has the beneficial effects that five liquid discharging pipelines are arranged, so that the liquid discharging pipelines can simultaneously perform high-efficiency phosphorus removal on five areas of river water, and a phosphorus removal agent can be conveniently diffused in the riverwater; thus, the speed of the device for removing excessive phosphorus elements in the river water is improved; the device is provided with a concentration detector, so that the concentration of the phosphorus removal agent can be detected in real time, high-concentration phosphorus removal agents are prevented from being directly injected into river water, and the situation that river water quality becomes bad is avoided.

Owner:FOSHAN UNIVERSITY

An automatic coal discharge control system and method

ActiveCN109763823BMonitor real-time location informationAchieve sharingData processing applicationsUnderground miningThermodynamicsControl system

The present invention discloses an automatic coal drawing control system and method. The system includes: a plurality of movable top coal movement trackers, uniformly arranged in a drill hole on a coal-gangue interface and moved with gangue; a plurality of fixed top coal movement trackers, uniformly fixed on a hydraulic support, and configured to obtain and store second distances between the movable top coal movement trackers near the hydraulic support and the fixed top coal movement trackers, and first distances stored by the movable top coal movement trackers near the hydraulic support; and a central computer, configured to process the first distances and the second distances to obtain real-time position information of each movable top coal movement tracker, and send an instruction according to the real-time position information of each movable top coal movement tracker to control the hydraulic support to open or close a coal drawing port. The automatic coal drawing control system and method can determine the time that gangue is rushed into a coal drawing port massively, and thus determine the time for opening or closing the coal drawing port accurately and implement the high top coal mining rate and the low gangue rate.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Monitoring system, device and method for monitoring standard-exceeding traceability of urban sewage

PendingCN114019120AEasy to recycleWhen it is convenient to recycle the pipe, useVolume/mass flow measurementIndication/recording movementStream flowMonitoring system

The invention discloses a monitoring system, device and method for monitoring standard exceeding traceability of urban sewage, and relates to the technical field of sewage monitoring, the real-time flow direction of the urban sewage can be monitored through a sewage monitoring device, the sewage flow speed is calculated according to the time of the device reaching each detection pipeline, a recording device can know whether the line is blocked or not through the duration of each line, most suspected pollution sources can be excluded through flow direction, flow and flow velocity data, a small number of key pollution nodes are locked, key monitoring is facilitated, a large amount of manpower and cost are saved, and the working efficiency is greatly improved. Furthermore, when the device flows to the recycling pipeline, a user needs to recycle the device for reuse, the user can recycle the device conveniently, and a protective net can prevent the device from flowing through the recycling pipeline; therefore, the use is very convenient.

Owner:深圳自由度科技有限公司 +1

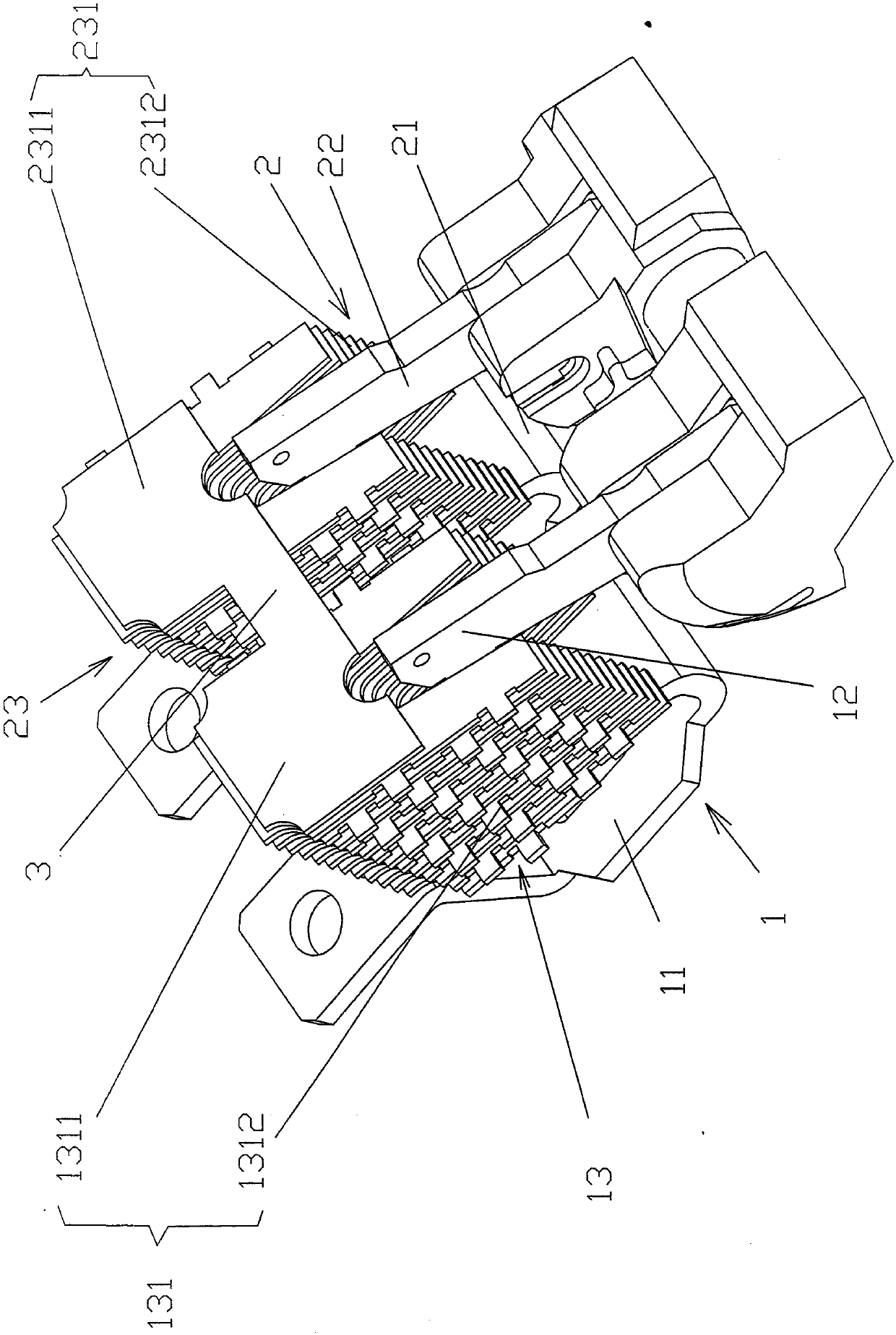

Multi-pole circuit breaker

ActiveCN109559947AShorten burn timeAvoid ablationCircuit-breaking switch detailsElectricityElectric arc

A multi-pole circuit breaker includes at least one first pole unit at least one second pole unit, each first pole unit includes a first static contact, a first movable contact and a first arc extinguishing device, each first arc extinguishing device includes a plurality of first grids, the plurality of first grids are stacked in a spaced state, each second pole unit comprises a second static contact, a second movable contact and a second arc extinguishing device, each second arc extinguishing device comprises a plurality of second grids, and the plurality of second grids are stacked in a spaced state. The multi-pole circuit breaker further comprises an equipotential connection member which is connected with one in the first grids and one of the second grids or connected with one of the first grids and the second static contacts, and the first grids between the equipotential connection member and the first static contacts and / or the second grids between the equipotential connection member and the second static contacts are employed to cut and break the arc between the first static contacts and the second static contacts. The burning time of the arc on the movable contact is shortened, the breaker breaking capacity is improved, and the electric life is prolonged.

Owner:CHANGSHU SWITCHGEAR MFG CO LTD (FORMER CHANGSHU SWITCHGEAR PLANT)

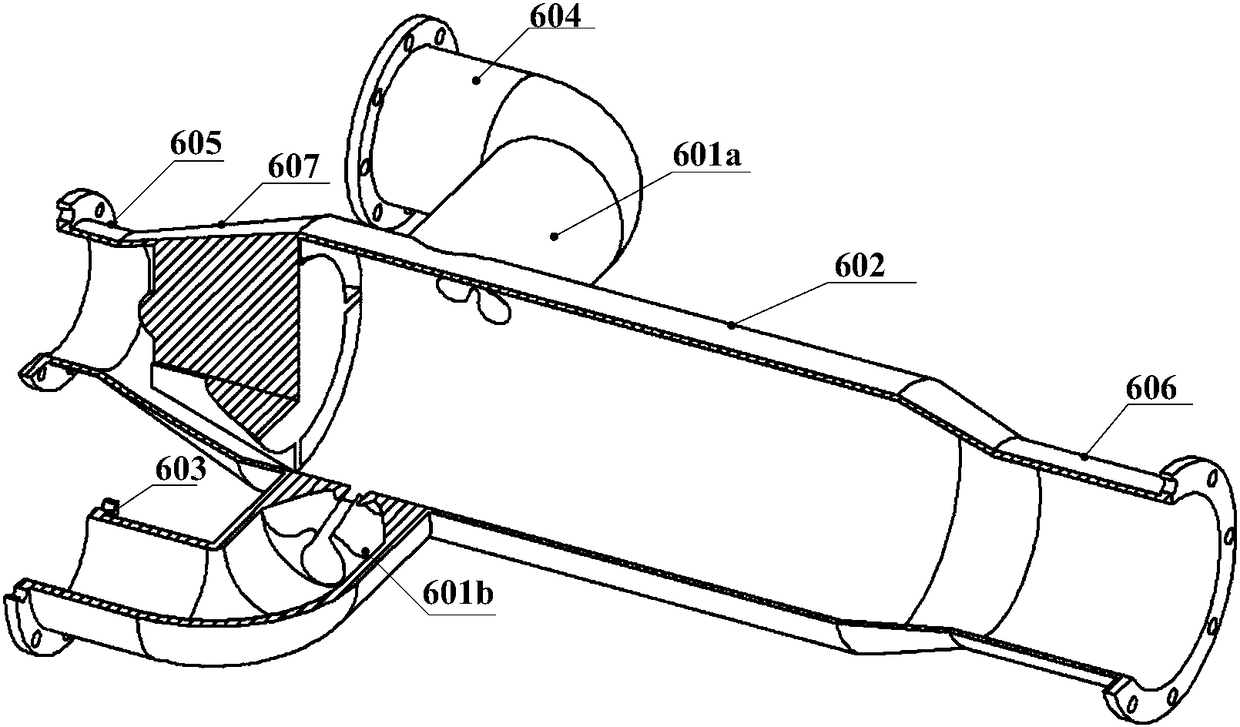

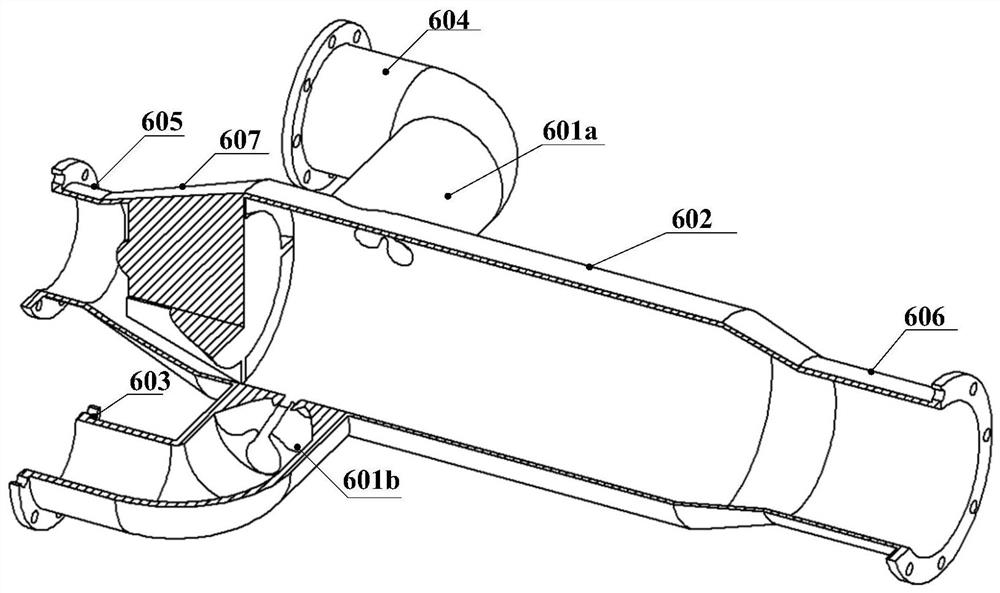

Multiphase System Drilling Fluid Mixer

ActiveCN108176264BIncreased turbulenceIncreased shear contact areaFlow mixersTransportation and packagingWater trapEngineering

Owner:CNPC OFFSHORE ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com