Multiphase System Drilling Fluid Mixer

A multi-phase system and mixer technology, applied in the direction of fluid mixers, mixers, chemical instruments and methods, etc., can solve the problems of high-speed fluid momentum loss, inability to ensure uniform mixing, and affect mixing efficiency, etc., to reduce turbulence The effect of reducing the degree, reducing the volume and reducing the mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

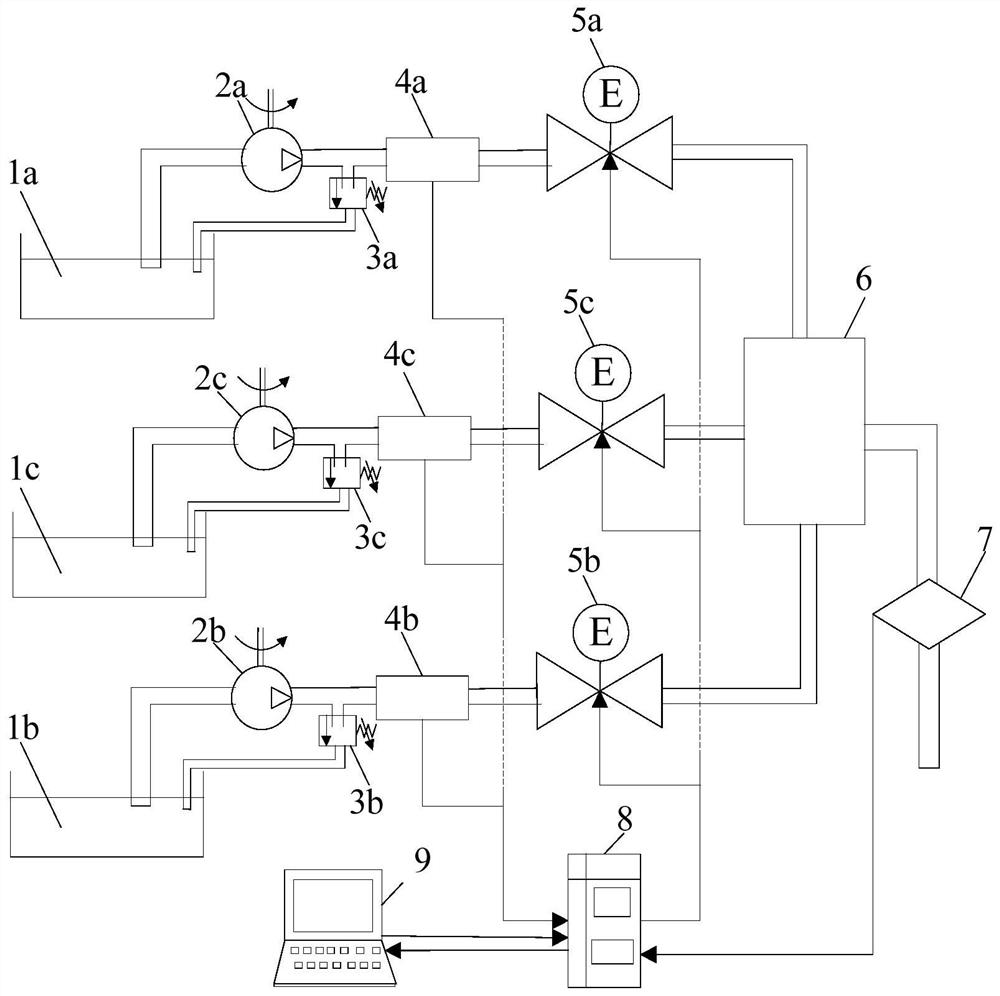

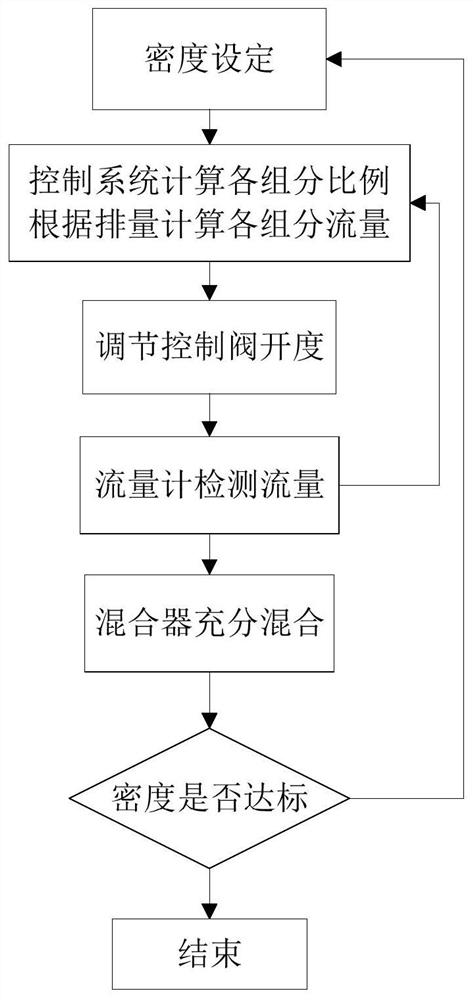

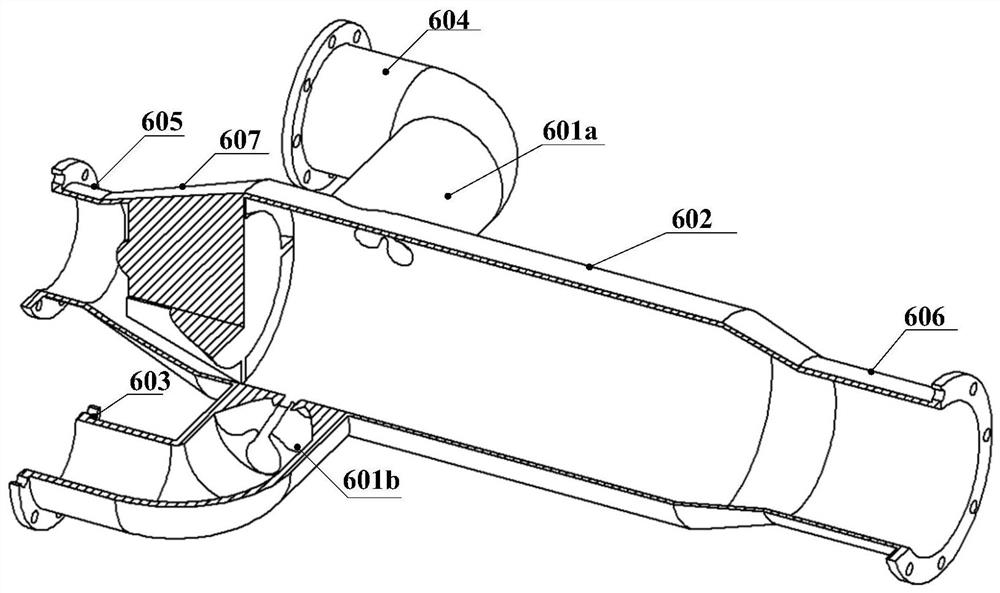

[0023] Such as figure 1 As shown, the self-feedback drilling fluid mixing system includes: a mixer 6, a seawater pool 1a, a base slurry pool 1b, and an additive pool 1c; the seawater pool 1a is connected to the mixer 6 through a first pipeline, and the base slurry pool 1b is connected through a second The pipeline is connected to the mixer 6, and the additive pool 1c is connected to the mixer 6 through a third pipeline; wherein, the seawater pool 1a contains seawater and is used to provide seawater raw materials for the first pipeline; the base slurry pool 1b accommodates the base slurry pool, It is used to provide base slurry raw materials to the second pipeline and destroy the network structure of high-viscosity fluid; the additive pool 1c contains additives and is used to provide additive raw materials to the third pipeline; seawater, base slurry, and additives enter the mixer 6 for mixing After that, it enters the mud pool or the mud pump manifold from the feedback module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com