Matrix addressing vertical cavity surface emitting laser array device

A technology of vertical cavity surface emission and laser array, which is applied in the direction of laser components, lasers, semiconductor lasers, etc., can solve the problems of high process requirements, low reliability and repeatability, and difficult process, and achieve multi-addressing, Avoid the drift of the reflection peak wavelength and the effect of high reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

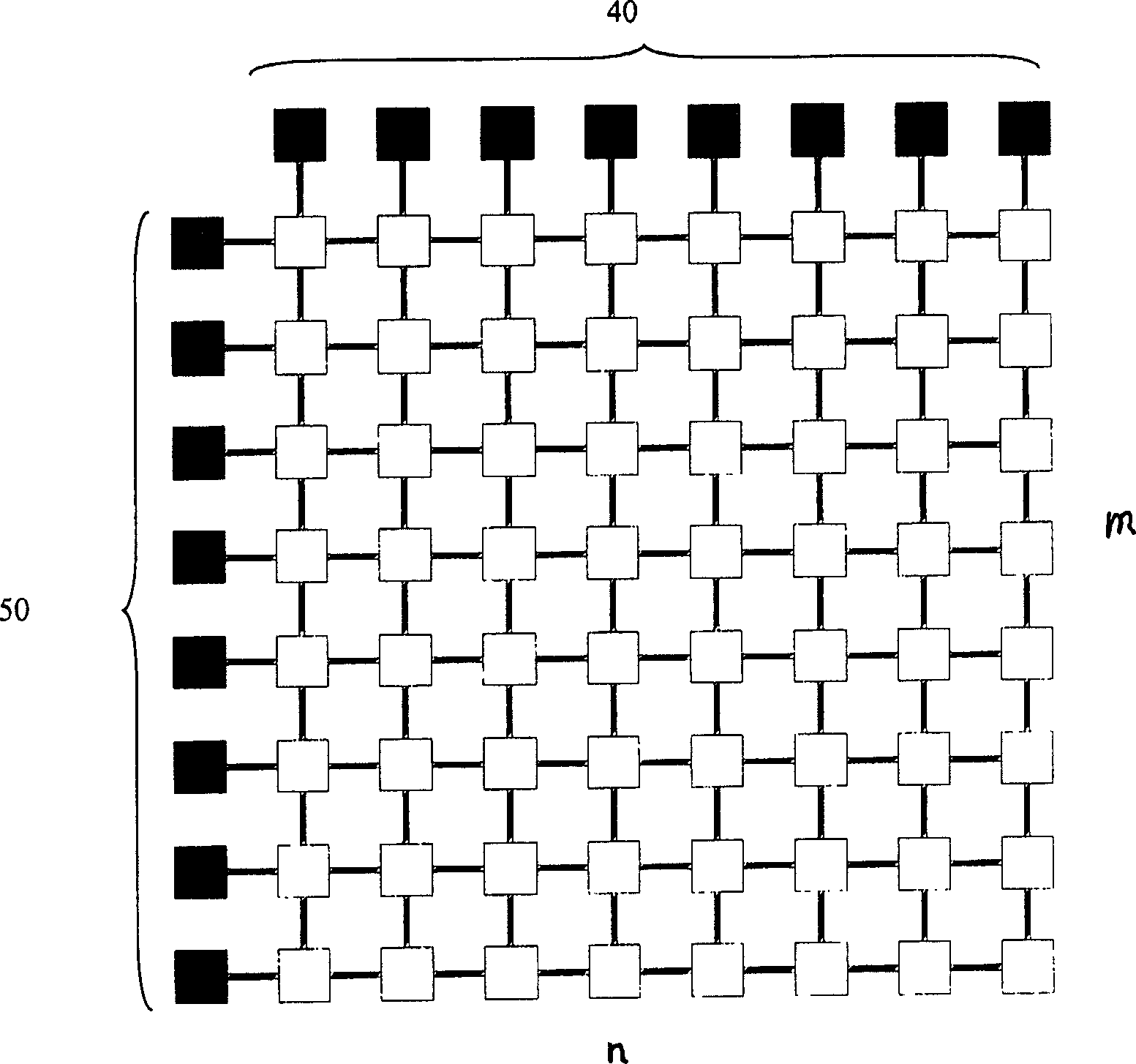

[0043] This embodiment includes a total of 8 rows and 8 columns of 8×8 vertical cavity surface emitting laser units (see attached image 3 );

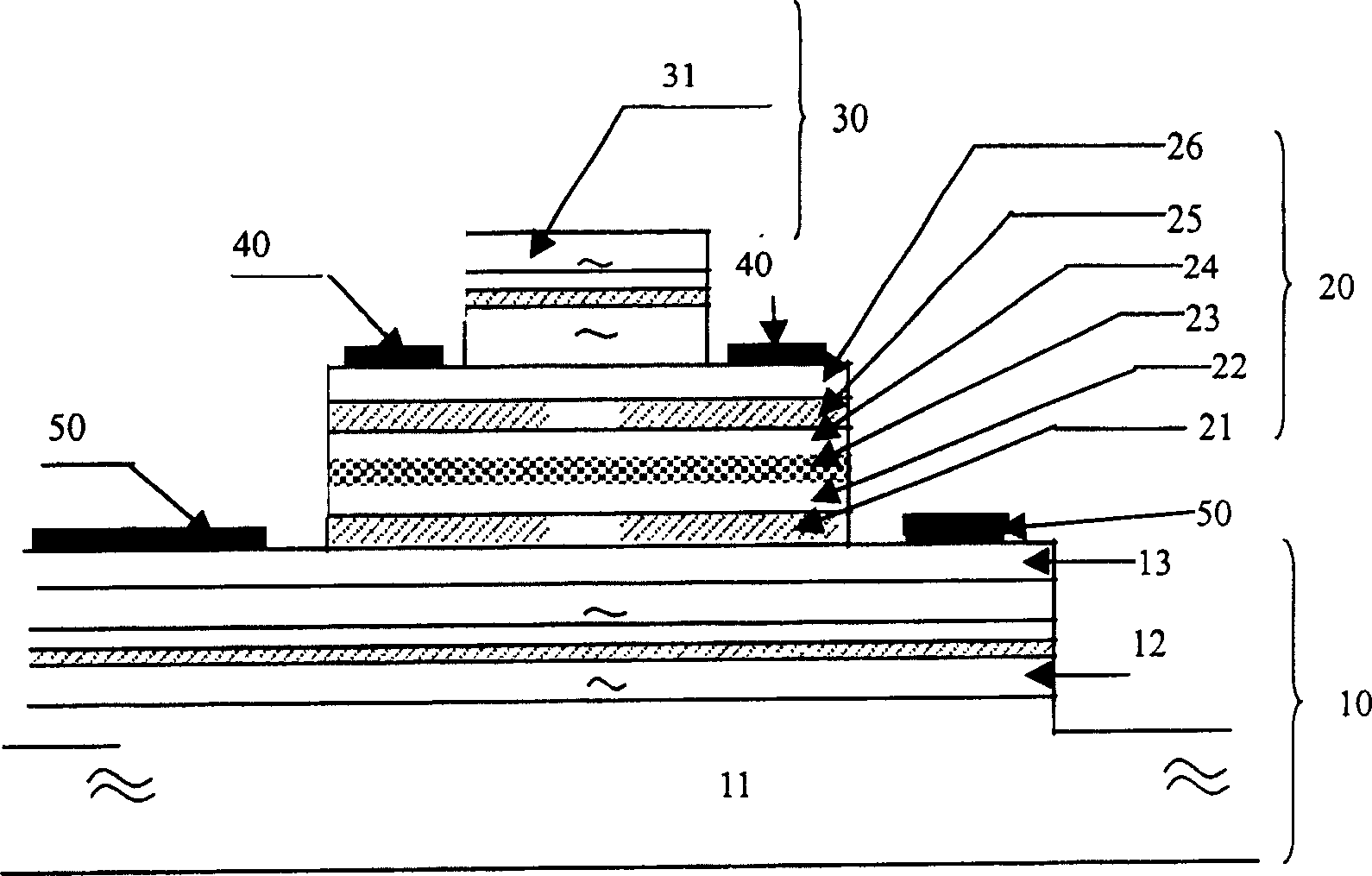

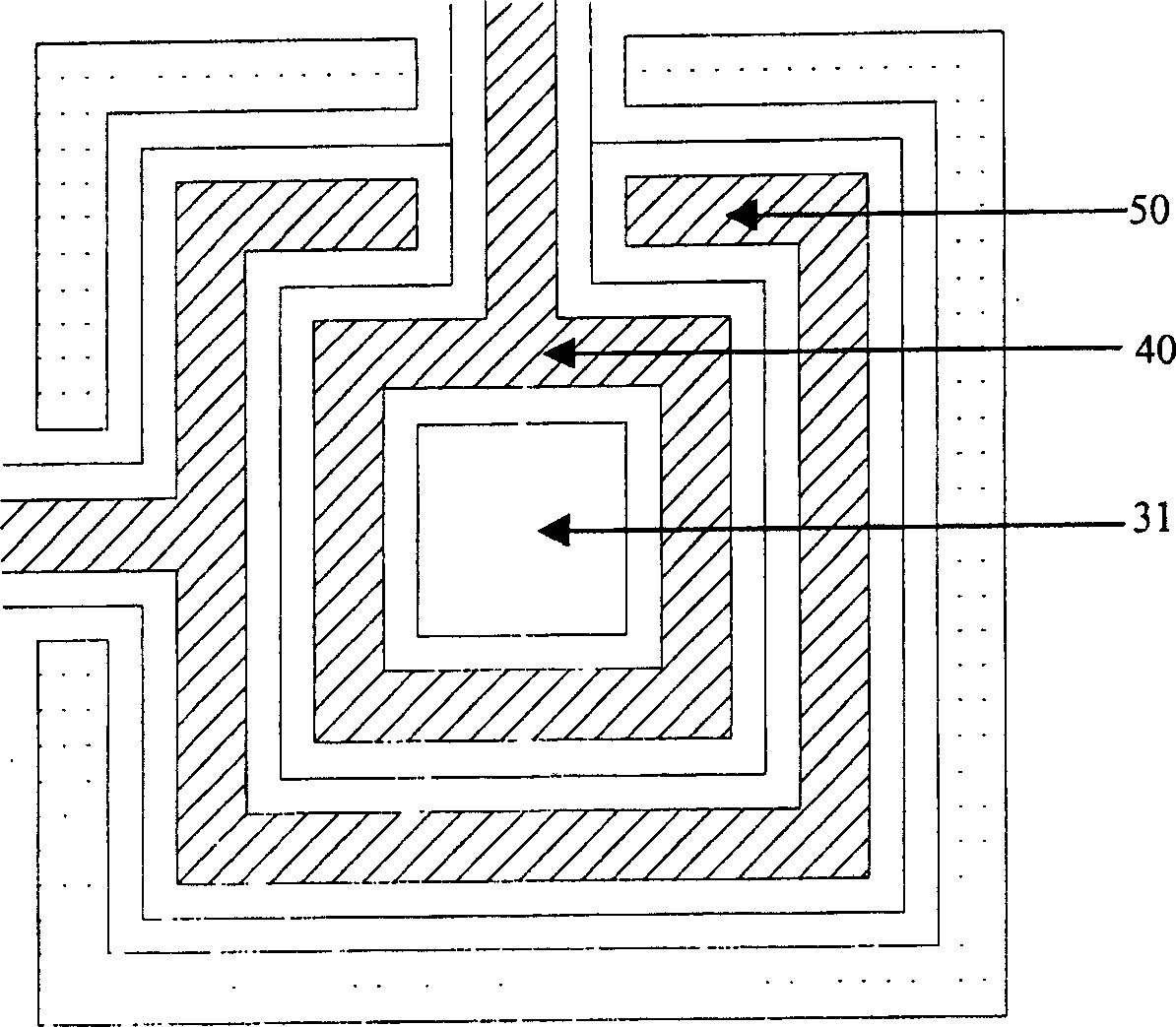

[0044] Combine below figure 1 and figure 2 , to illustrate the basic structure of the embodiment of the present invention.

[0045] Each VCSEL unit includes three stages of decreasing size: a bottom reflection mirror stage 10, an optical cavity stage 20, and a top reflection mirror stage 30, as well as a p-electrode 40 and an n-electrode 50;

[0046] Wherein the bottom reflection mirror stand 10 comprises:

[0047] half of the insulating substrate 11;

[0048] a gallium arsenide / alumina lower Bragg reflector 12;

[0049] An n-type heavily doped gallium arsenide conductive layer 13;

[0050] Optical cavity table 20 comprises:

[0051] An n-type doped AlGaAs layer 21;

[0052] an undoped gallium arsenide lower confinement layer 22;

[0053] An undoped gallium arsenide / aluminum gallium arsenide multi-quantum well active layer 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com