Oil-gas mixed transportation separating flow divider and oil-gas separating flow-dividing method

A technology of oil-gas mixed transportation and oil-gas mixed transportation pump, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, and can solve problems such as impingement flow, gas-liquid vortex, etc., to reduce pressure drop, minimize size, reduce The effect of height and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical solution of the present invention clearer, a specific introduction will be made below in conjunction with the accompanying drawings.

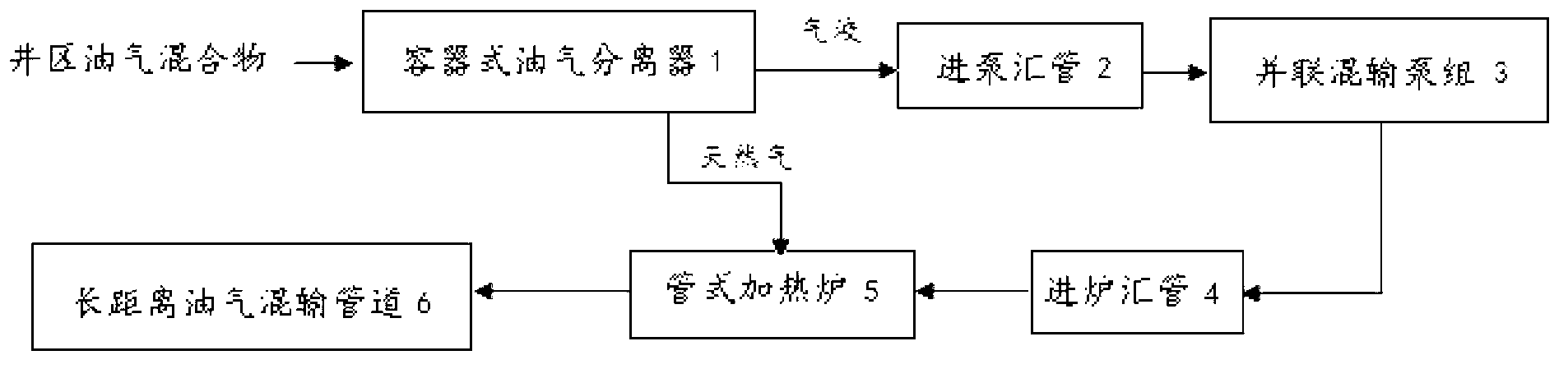

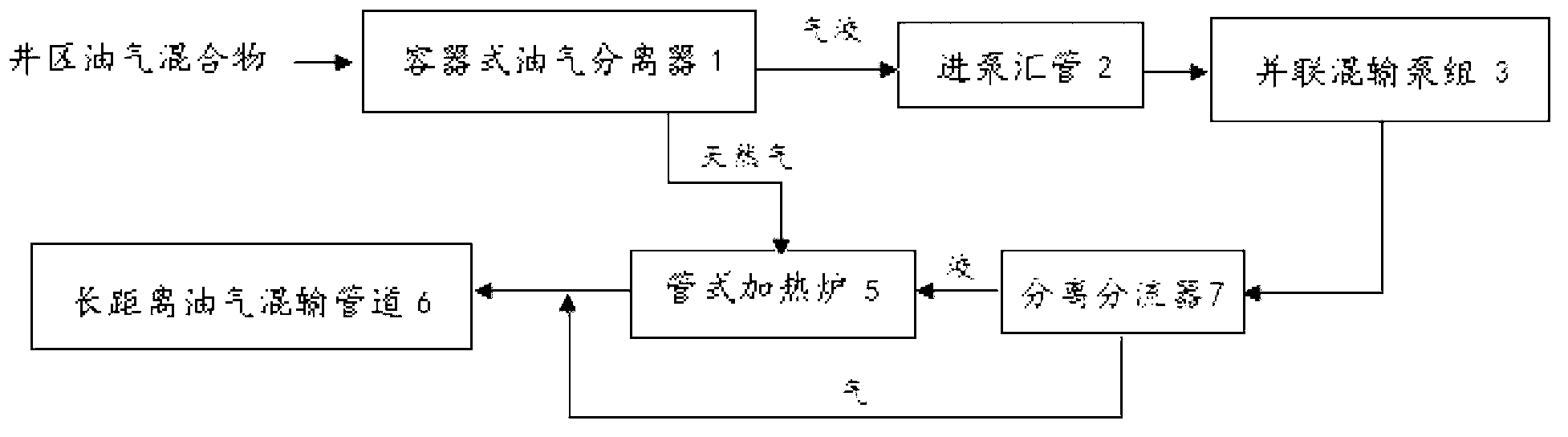

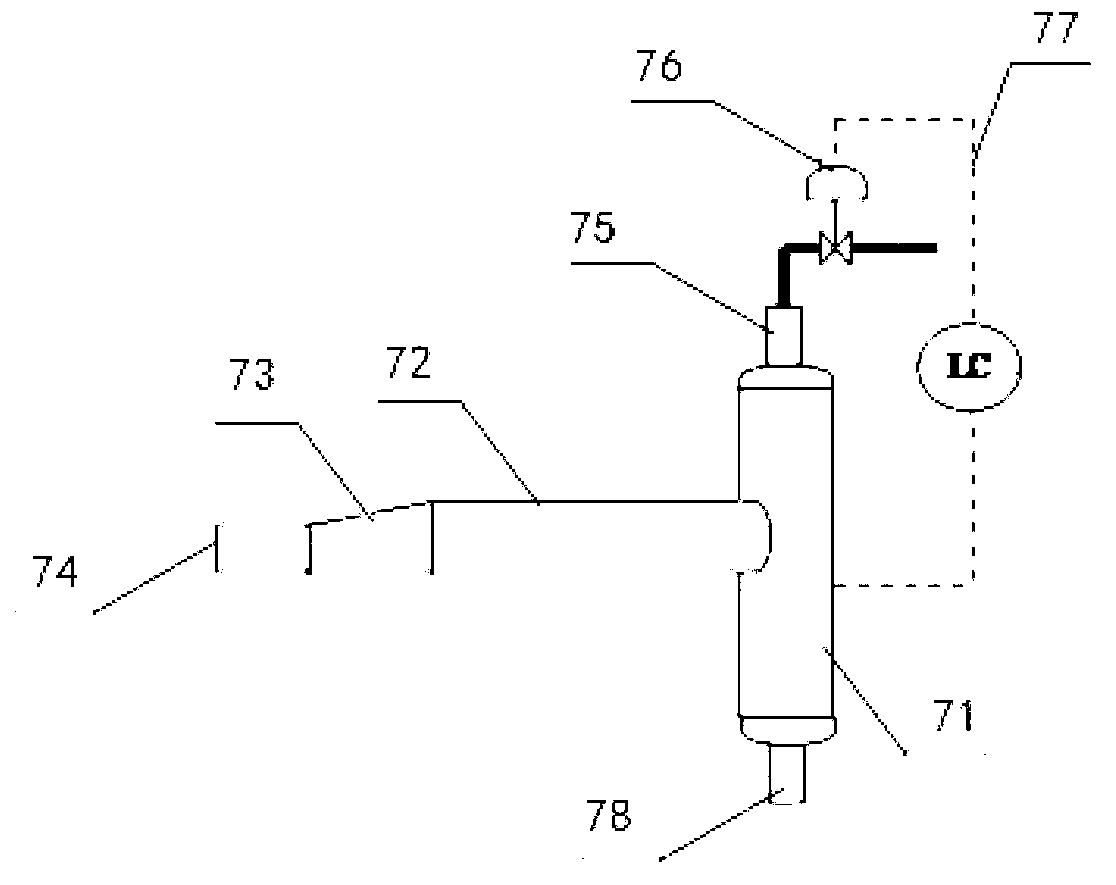

[0026] A gas-liquid mixed fluid separation splitter 7 provided by the present invention can be arranged in figure 2 In the shown oil-gas mixed transportation system and process flow: the inlet of the separation splitter 7 is connected to the outlet of the oil-gas mixed transportation pump unit 3 through a pipeline, and the gas outlet of the separation splitter 7 is connected to the gas-liquid mixing node at the outlet of the heating furnace 5 , the liquid outlet is connected to the heating coil inlet of the heating furnace 5, so as to realize the gas-liquid separation and split flow of all the gas-liquid fluids entering the heating furnace area, so that only the liquid phase enters the heating furnace coil through the heating furnace inlet and the gas phase directly It is mixed with the heated liquid phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com