Efficient electric vehicle direct-current fast charge system

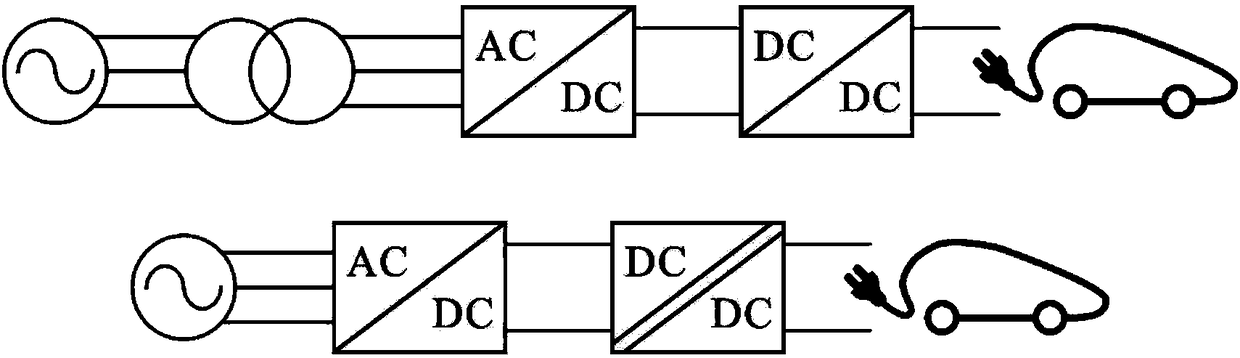

A technology for electric vehicles and DC fast charging piles, applied in electric vehicle charging technology, electric vehicles, efficient vehicle charging, etc., can solve the problems of efficiency loss, inability to meet the typical voltage range of electric vehicle charging, and voltage sine deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

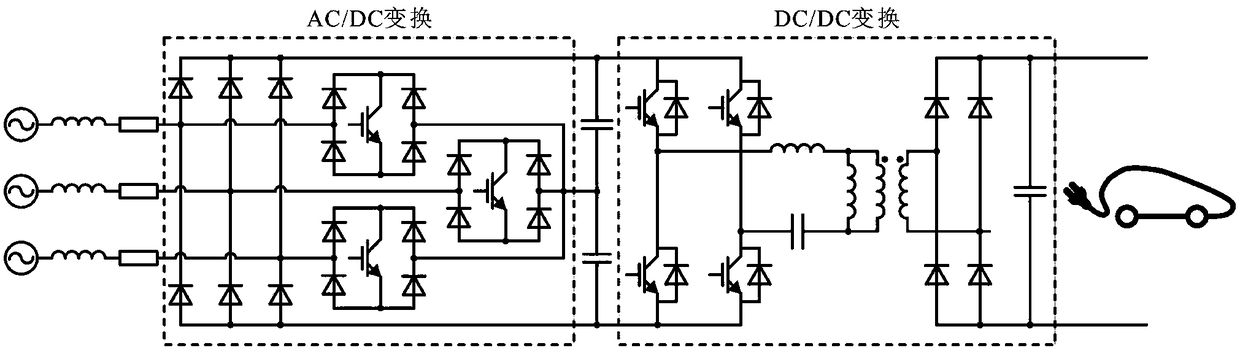

[0035] Embodiment one: Figure 4 It is a basic structural diagram of a DC fast charging system based on single-stage AC / DC power conversion in the present invention. The structure includes a distribution transformer connected to the medium-voltage distribution network, an AC / DC converter, a DC / DC converter, capacitors and charging piles. The primary side of the distribution transformer is connected to the 10kV or 35kV medium-voltage distribution network, and the secondary side (176V non-standard rated voltage) is connected to the AC side of the AC / DC converter. The DC side of the AC / DC converter is connected to the DC bus of the charging pile. One side of the DC / DC is connected to the DC bus of the charging pile, and the other side is a capacitor. The pile body of the charging pile is the interface between the charging system and the power battery pack of the electric vehicle. It integrates a controller inside and communicates with the control system of the electric vehicle an...

Embodiment 2

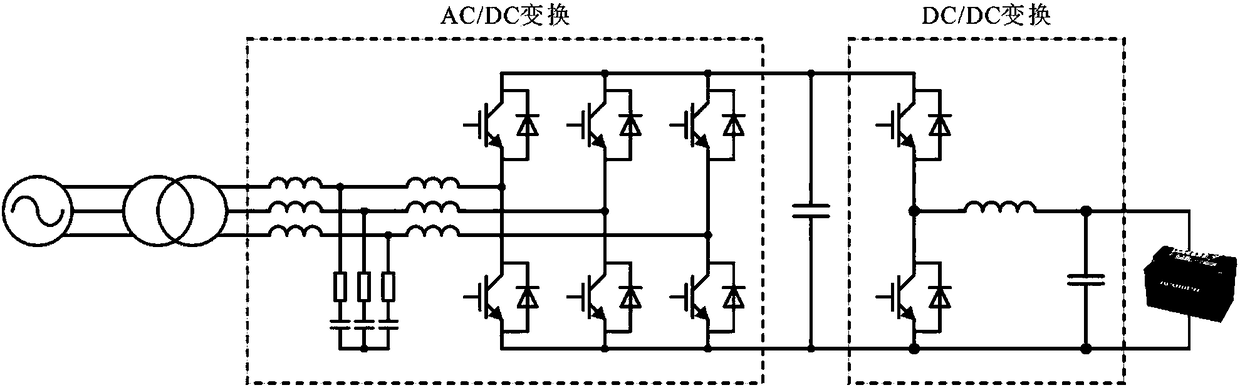

[0042] Embodiment 2: An electric vehicle DC fast charging pile has a power of tens to hundreds of kilowatts, and the maximum charging power of different models is not the same. In order to realize the flexible configuration of power, this embodiment uses multiple single-stage AC / DC The converters are connected in parallel as Figure 10 As shown, here only a low-power DC / DC is connected in parallel to the common DC bus of the charging pile to absorb the harmonic current output by all parallel AC / DC converters. When multiple single-stage AC / DCs are connected in parallel, their respective AC sides need to be isolated. At this time, the 10kV distribution transformer in the DC fast charging station uses a transformer with multiple low-voltage secondary side windings, and the voltage of the secondary side windings is 176V rated or slightly lower. The primary side of the transformer is still connected to the medium-voltage 10kV distribution network, and each independent secondary wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com