Multi-pole circuit breaker

A circuit breaker and multi-pole technology, applied in circuit breaker parts and other directions, can solve the problems of contact ablation, difficulty of arc extinguishing, contact burnout, etc., to avoid ablation, shorten burning time, and prolong electrical life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

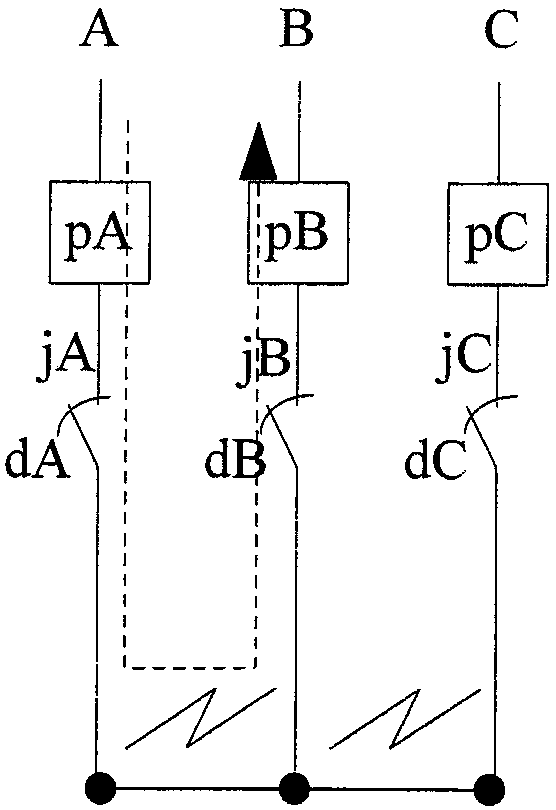

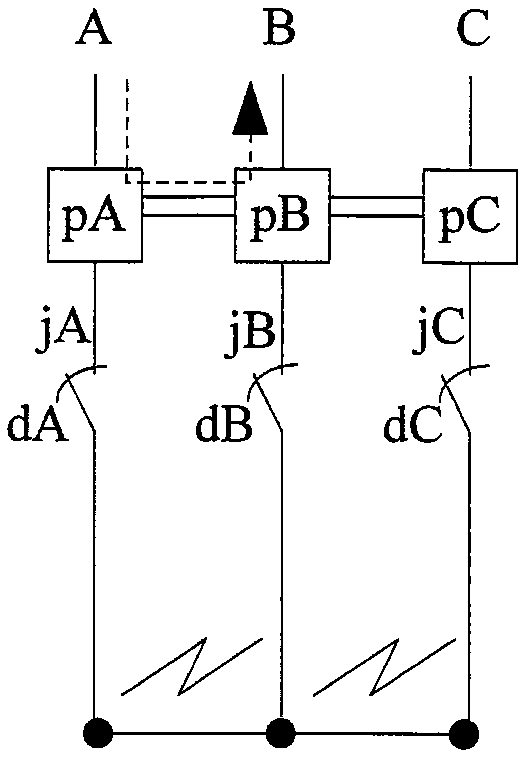

[0028] See figure 2 , figure 2 A, B, and C shown in the figure represent phase A, phase B and phase C of the multi-pole circuit breaker; figure 2 DA, dB and dC shown in the figure represent the A-phase moving contact, B-phase moving contact and C-phase moving contact of the multi-pole circuit breaker respectively; figure 2 The jA, jB and jC indicated in the figure represent the A-phase stationary contact, the B-phase stationary contact and the C-phase stationary contact of the multi-pole circuit breaker respectively; figure 2 The pA, pB and pC shown in the figure respectively represent the A-phase arc-striking grid, the B-phase arc-striking grid and the C-phase arc-striking grid of the multi-pole circuit breaker.

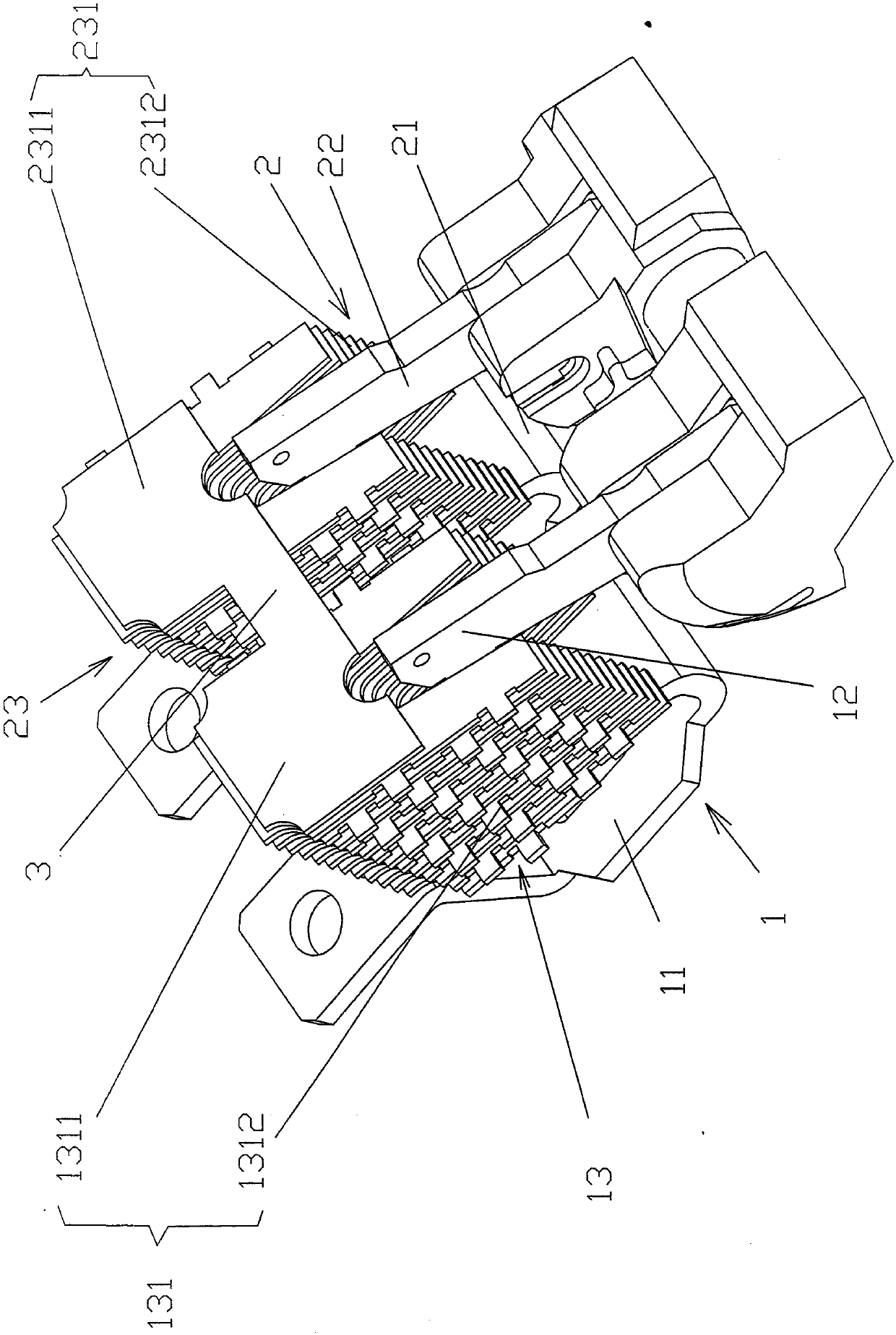

[0029] See image 3 , Shows a first pole unit 1 and a second pole unit 2, which are arranged side by side in a multi-pole circuit breaker. The first pole unit 1 includes a first static contact 11, and a first static contact 11 Contacting or separating the first mova...

Embodiment 2

[0034] See Figure 4 And combine figure 2 In this embodiment, the aforementioned equipotential connecting member 3 is formed by bending upward the edge portion of the first arcing piece 1311 toward the side of the second arcing piece 2311 and the first bending portion 31 formed by The second arcing piece 2311 faces the edge portion of one side of the first arcing piece 1311 and is formed by a second bending portion 32 that is bent upward at a position corresponding to the first bending portion 31. The first and second The two bending parts 31 and 32 are fixedly connected to each other (also called "electrical connection").

[0035] The aforementioned first bending portion 31 and the second bending portion 32 are fixedly connected by the bending portion fixing connecting member 33, specifically by screws, but they can also be fixedly connected by riveting (riveting), or even welding or The first and second bending portions 31 and 32 are fixedly connected in other equivalent ways....

Embodiment 3

[0039] See Figure 5 with Image 6 The plurality of first grid pieces 131 include a first arc-initiating piece 1311 at the top and a plurality of first arc-extinguishing grid pieces 1312 under the first arc-inducing piece 1311. The equipotential connector 3 connects the first arc-striking piece 1311 and the second static contact 21 of the second pole unit 2. due to Figure 5 The meanings of A, B and C, dA, dB and dc, jA, jB and jC, pA, pB and pC are the same as above. figure 2 , So I won’t repeat it.

[0040] The effects of Embodiment 3 are as follows:

[0041] Such as Figure 5 As shown, the A phase is still taken as an example. Since the first arcing piece 1311 of the A phase is connected to the second static contact 21 of the B phase, after the arc on the moving contact is transferred to the arc extinguishing device, the current path no longer passes The moving contact, but from the A-phase terminal, the A-phase static contact (ie the first static contact 11) flows through it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com