Multi-point ignition multi-functional constant volume combustion device

A technology of constant-volume combustion and multi-point ignition, which is applied in chemical analysis by means of combustion, etc., can solve the problems of combustion experiment research with few multi-point ignition of constant-volume incendiary bombs, poor sealing of optical observation windows, and damage to glass sight glass and other problems, to achieve the effect of shortening the burning time, reducing the probability of abnormal burning, and facilitating cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

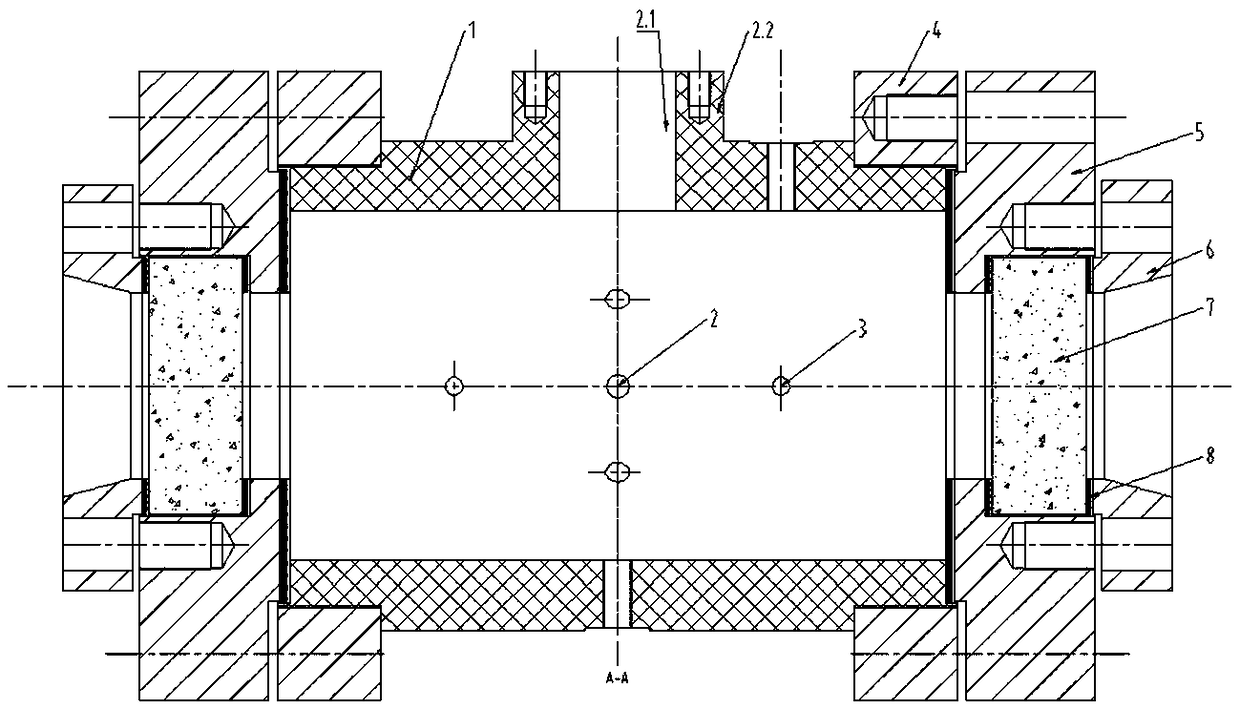

[0046] For common premixed laminar combustion

[0047] see figure 1 , when used in a common premixed combustion test for single-point ignition, the diameter of the quartz glass 7 is 110 mm, which is smaller than the diameter of the constant volume bomb main body 1 . When the constant volume combustion device of the present invention is carrying out common premixed laminar flow combustion, the combustion test under high temperature and high pressure conditions is mainly used, and the device is heated by an additional heating shell (not shown in the figure). The shape and size of the combustion device match. When carrying out the premixed laminar flow test, you only need to place the entire constant volume combustion device in the heating shell. After the heating shell is energized, the heating and heat preservation of the constant volume combustion device can be realized. The inner cavity temperature can be adjusted within 100-400°C. In addition, the initial pressure of the i...

Embodiment 2

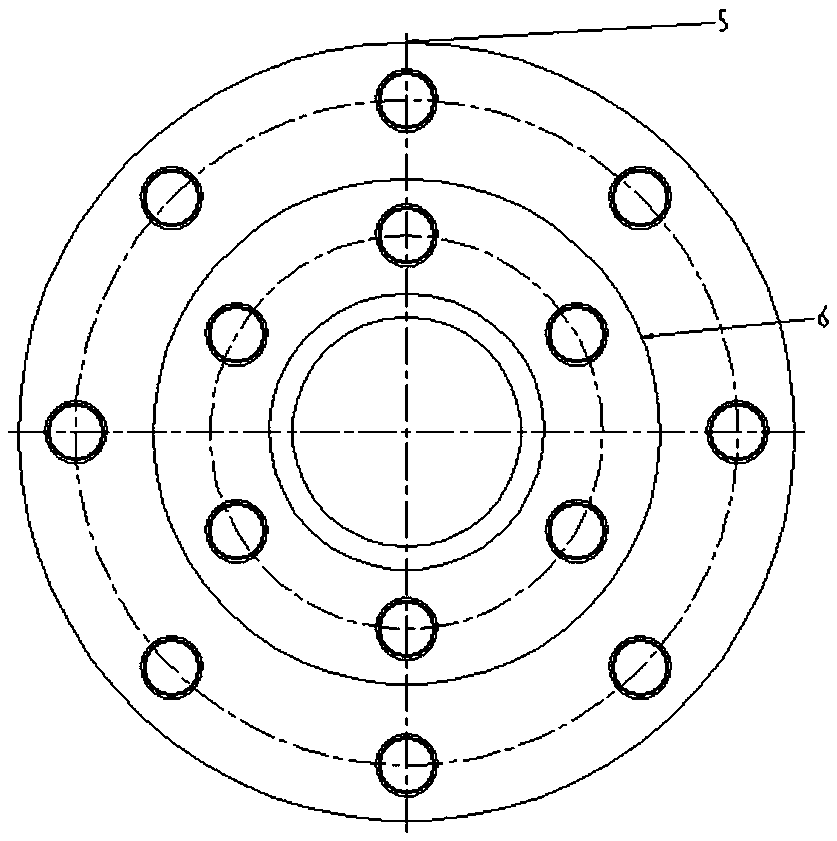

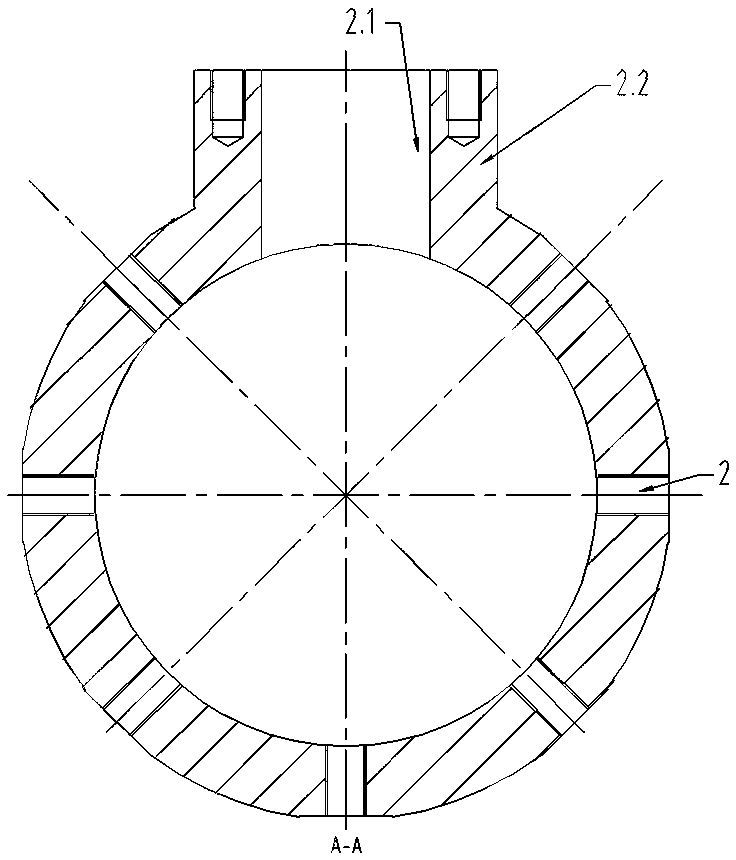

[0055] For multi-point ignition or fuel spray characterization studies

[0056] see Figure 8 , Figure 9 and Figure 10 , when used for common premixed combustion or spray characteristic research tests of multi-point ignition, the diameter of the quartz glass 11 is greater than the diameter of the constant volume bomb main body 1, which is 180 mm; the flange 4, glass base 9 and gland 10 are coaxially fixed together so that the quartz glass 11

[0057] Compression is installed between glass base 9 and gland 10.

[0058] At this moment, both the glass base 9 and the gland 10 are provided with a single-circle through hole, and are tightly connected with the bolt holes on the flange 4 by bolts, and the diameter of the gland 10 is consistent with that of the glass base 9 . This kind of window has a large observation range, and can observe the combustion process near each ignition point in the constant volume bomb main body 1 during multi-point ignition, or when studying the sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com