Method for precisely counting putting quantity of auxiliary cleaning agent

A washing aid and dosage technology, applied in the field of washing machines and automatic washing aid devices, can solve the problems of insufficient water intake time, inaccurate measurement, and complicated volume-fixing process, so as to reduce the running time and the occupied space. , the effect of improving delivery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

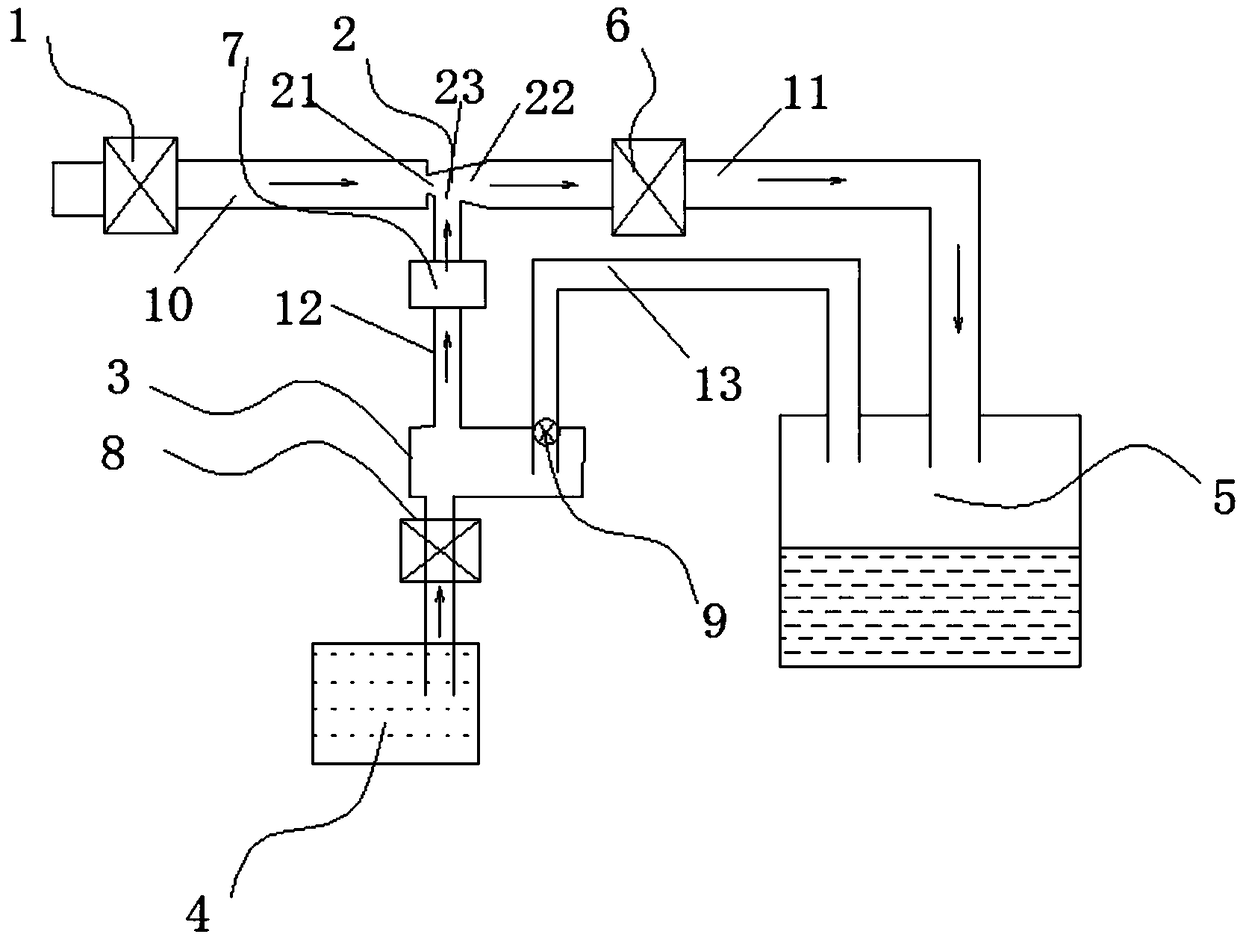

[0035] A method for automatically adding detergent to a washing machine is as follows:

[0036] S1: Open the water inlet valve 1, close the backwash solenoid valve 6 and the washing aid control valve 8, water flows out from the water inlet valve 1, passes through the throat 23 of the Venturi tube 2, and enters the washing aid pipe 12, so that the water metering device 7 Filled with water between the washing aid control valve 8;

[0037] S2: Open the backwash solenoid valve 6, open the water inlet valve 1 and the washing aid control valve 8, the metering device 7 starts to measure, water enters from the water inlet valve 1 through the water outlet 22 of the Venturi tube 2 and the backwash solenoid valve 6 Washing bucket 5, at this time, the washing aid enters the washing aid pipe 12 without passing through the water metering device 7;

[0038] S3: When the water flow through the water metering device 7 reaches the specified amount, and the washing machine controller measures t...

Embodiment 2

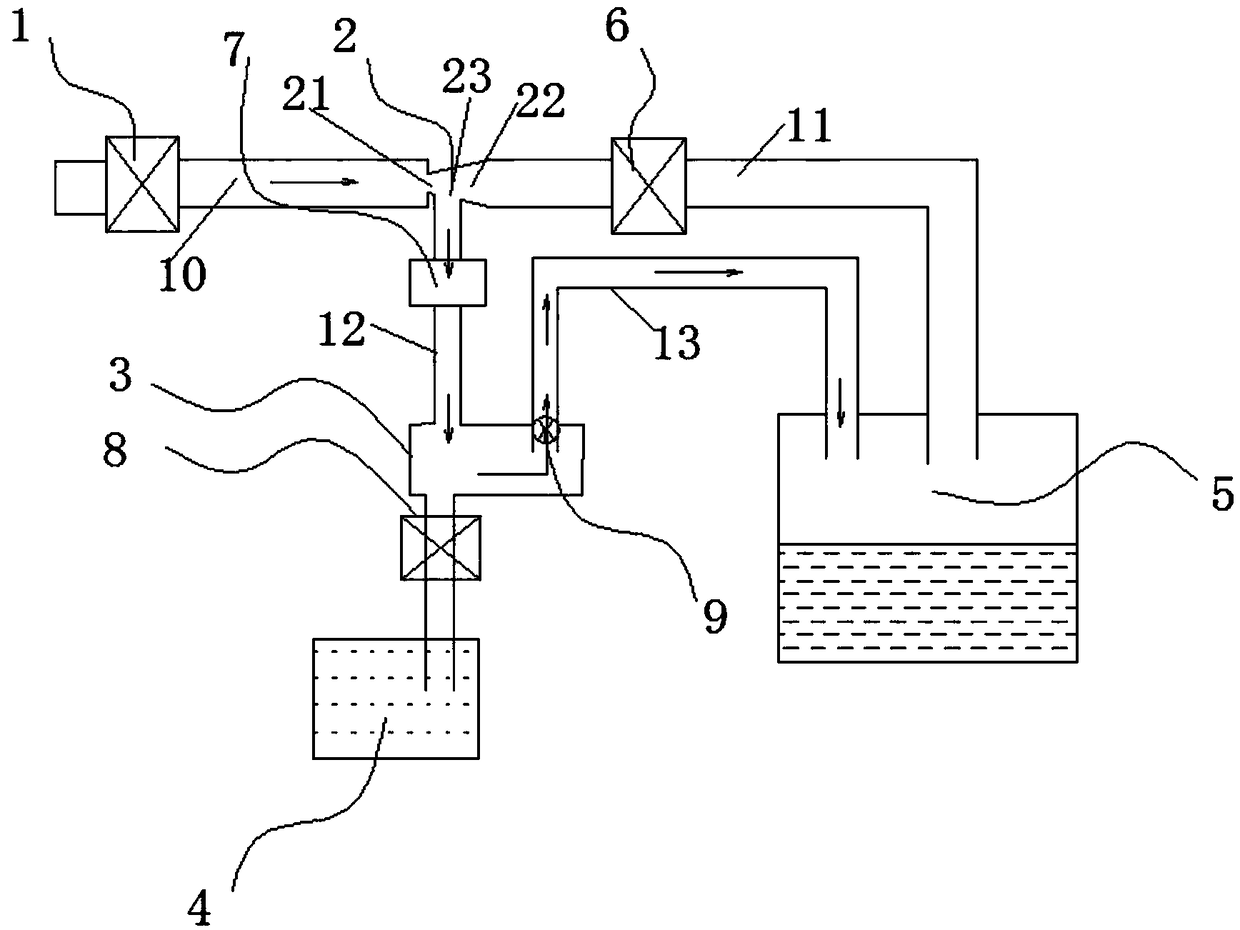

[0041] Others are the same as in Embodiment 1, the difference is that: the pre-storage device 3 provided between the water metering device 7 and the washing aid control valve 8 is a container, so the specific steps are as follows:

[0042] S1: Open the water inlet valve 1, close the backwash solenoid valve 6 and the washing aid control valve 8, water flows out from the water inlet valve 1, passes through the throat 23 of the Venturi tube 2, and enters the washing aid pipe 12, so that the water metering device 7 , the pre-storage device 3, and the washing aid control valve 8 are filled with water;

[0043] S2: Open the backwash solenoid valve 6, open the water inlet valve 1 and the washing aid control valve 8, the metering device 7 starts to measure, water enters from the water inlet valve 1 through the water outlet 22 of the Venturi tube 2 and the backwash solenoid valve 6 Washing bucket 5, at this time, the washing aid enters the pre-storage device 3 without passing through t...

Embodiment 3

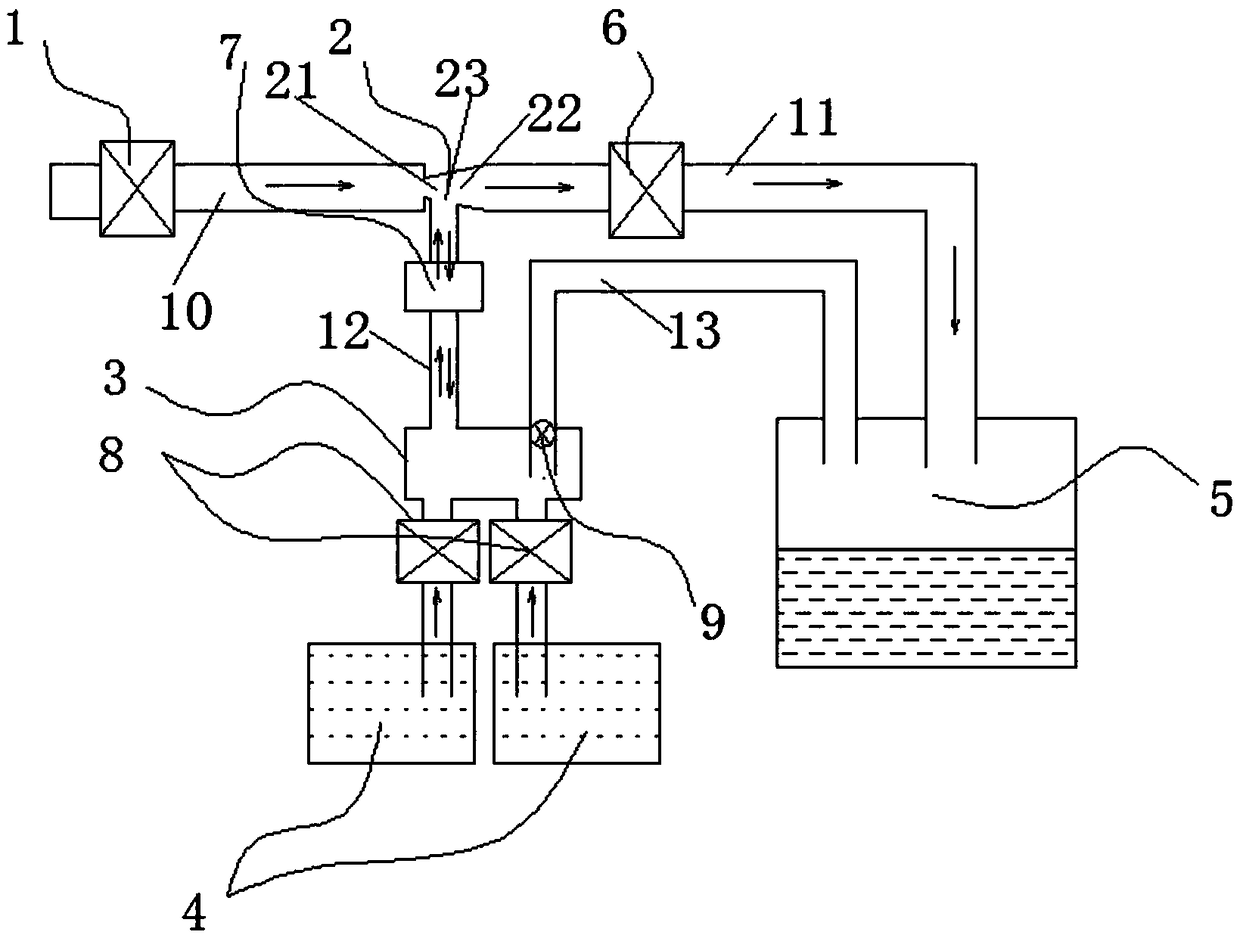

[0047] Others are the same as in embodiment 2, the difference is that in embodiment 2, the washing aid enters the washing tub through the outlet pipe 11, and in this embodiment, the washing aid enters the washing tub 5 through the washing aid branch 13, and the specific steps are as follows:

[0048] When washing, first select the washing mode of the washing machine, and then the specific steps are as follows:

[0049] S1: Open the water inlet valve 1, close the backwash solenoid valve 6 and the washing aid control valve 8, water flows out from the water inlet pipe 10, passes through the throat 23 of the Venturi tube 2, enters the pre-storage device 3, and reaches the pre-storage device 3 full of water;

[0050] S2: Open the backwash solenoid valve 6, open the water inlet valve 1 and the washing aid control valve 8, the metering device 7 starts to measure, and the water enters the washing machine from the water inlet pipe 10 through the water outlet 22 of the Venturi tube 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com