Flyback synchronous rectification control circuit

A synchronous rectification and control circuit technology, which is applied in the direction of electrical components, AC power input conversion to DC power output, output power conversion devices, etc., can solve the problems of low power efficiency and reliability, and large loss of synchronous rectification circuit components. Achieve the effects of improving efficiency, avoiding reverse current flow, reducing loss and voltage stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

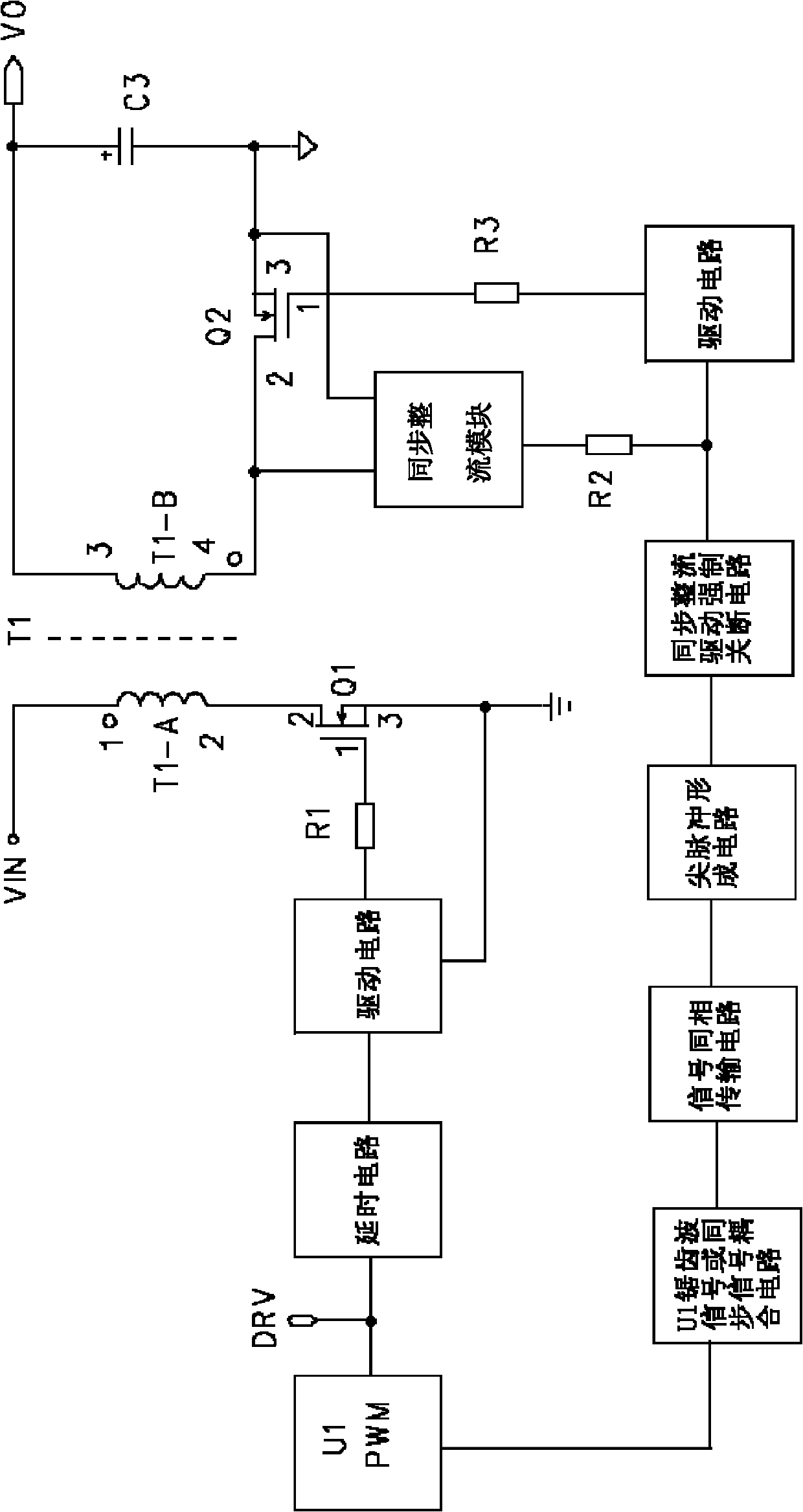

[0023] The flyback synchronous rectification circuit of this embodiment is as figure 2 As shown, it includes a primary switch tube Q1, a synchronous rectifier tube Q2, the primary side of the main transformer T1, the secondary side of the main transformer T1 and a synchronous rectification module, the synchronous rectification module is a synchronous rectification circuit or a control IC; A control circuit composed of a drive circuit 1, a delay circuit 2, a signal in-phase transmission circuit 3, a spike forming circuit 4 and a synchronous rectification forced shutdown circuit 5, the delay circuit 2 and the drive circuit 1 are connected in series, and the delay circuit 1 The other end of the drive circuit 1 receives the PWM signal U1 and the drive signal DRV, the other end of the drive circuit 1 is connected to the gate of the primary switching tube Q1, the signal in-phase transmission circuit 3, the spike forming circuit 4, the synchronous rectification forced shutdown circui...

Embodiment 2

[0026] The flyback synchronous rectification circuit of this embodiment is as image 3 As shown, the difference between it and the foregoing embodiment 1 is that it also includes a drive circuit 6, whose input terminal is connected to the synchronous rectification forced shutdown circuit 5, and is connected to the synchronous rectification module through a resistor R2, and the output terminal is connected to the synchronous rectification module through a resistor R3 It is connected with the gate of the synchronous rectifier Q2.

[0027] In this embodiment, by adding the drive circuit 6 and the protection resistors R2 and R3, the whole circuit can work more stably and reliably.

Embodiment 3

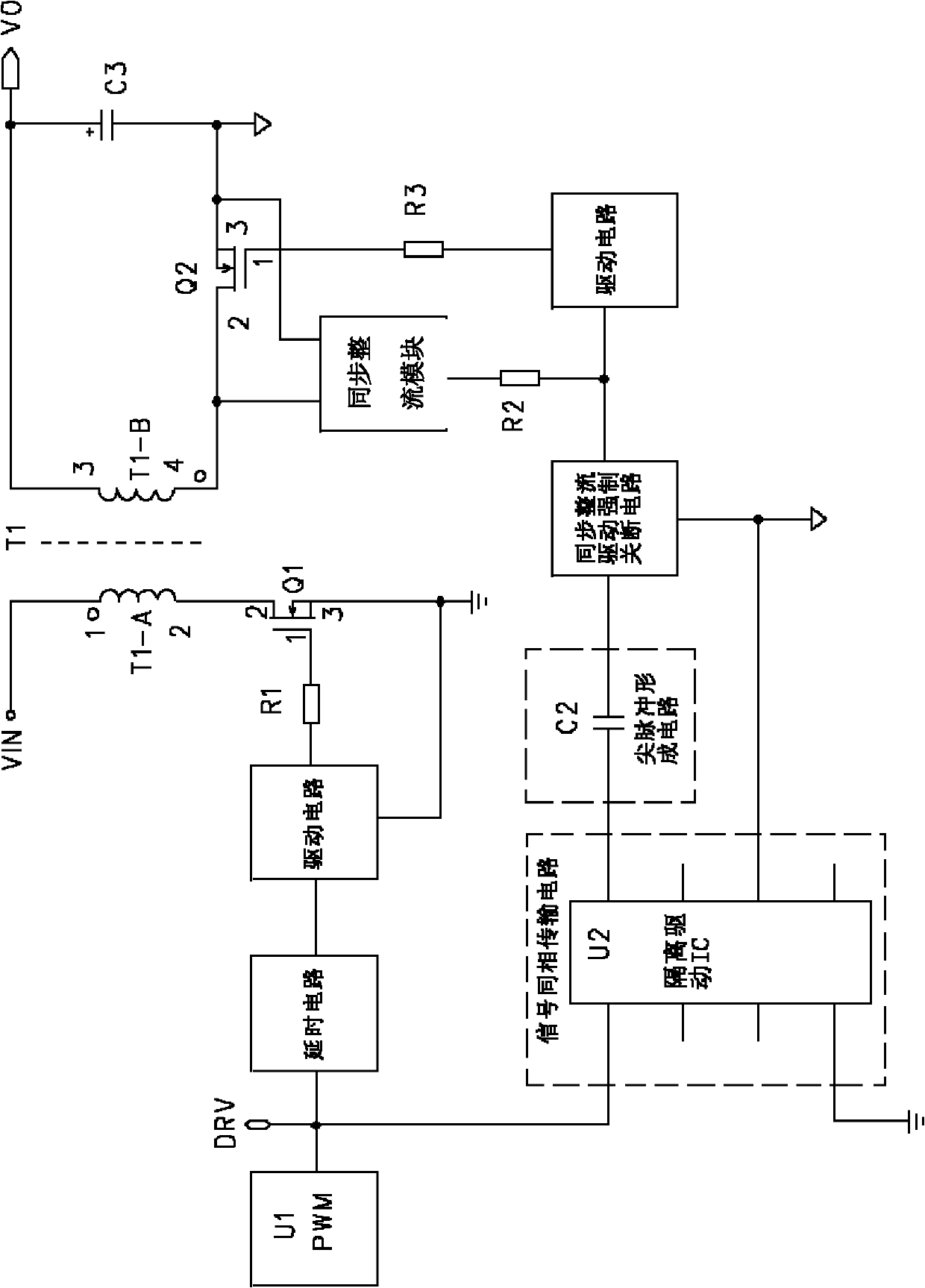

[0029] like Figure 4 As shown, the circuit of this embodiment includes a primary switch tube Q1, a synchronous rectifier tube Q2, a primary side of the main transformer T1, a secondary side of the main transformer T1, and a synchronous rectification module, and the synchronous rectification module is a synchronous rectification circuit or a control IC ; Also comprising a control circuit composed of a drive circuit 1, a time delay circuit 2, a signal in-phase transmission circuit 3, a spike forming circuit 4 and a synchronous rectification forced shutdown circuit 5, the time delay circuit 2 and the drive circuit 1 are connected in series, The other end of the delay circuit 1 receives the PWM signal U1 and the drive signal DRV, the other end of the drive circuit 1 is connected to the gate of the primary switching tube Q1, the signal in-phase transmission circuit 3, the spike forming circuit 4, the synchronous rectification The forced shut-off circuit 5 is sequentially connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com