Front sub-frame of minicar

A front sub-frame and micro-car technology, applied in vehicle parts, substructure, transportation and packaging, etc., can solve problems such as tooling fixtures, welding positioning fixtures, unsuitable for small-scale production operations, and affecting work efficiency. Achieve the effects of reducing labor intensity, improving strength, and facilitating welding positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

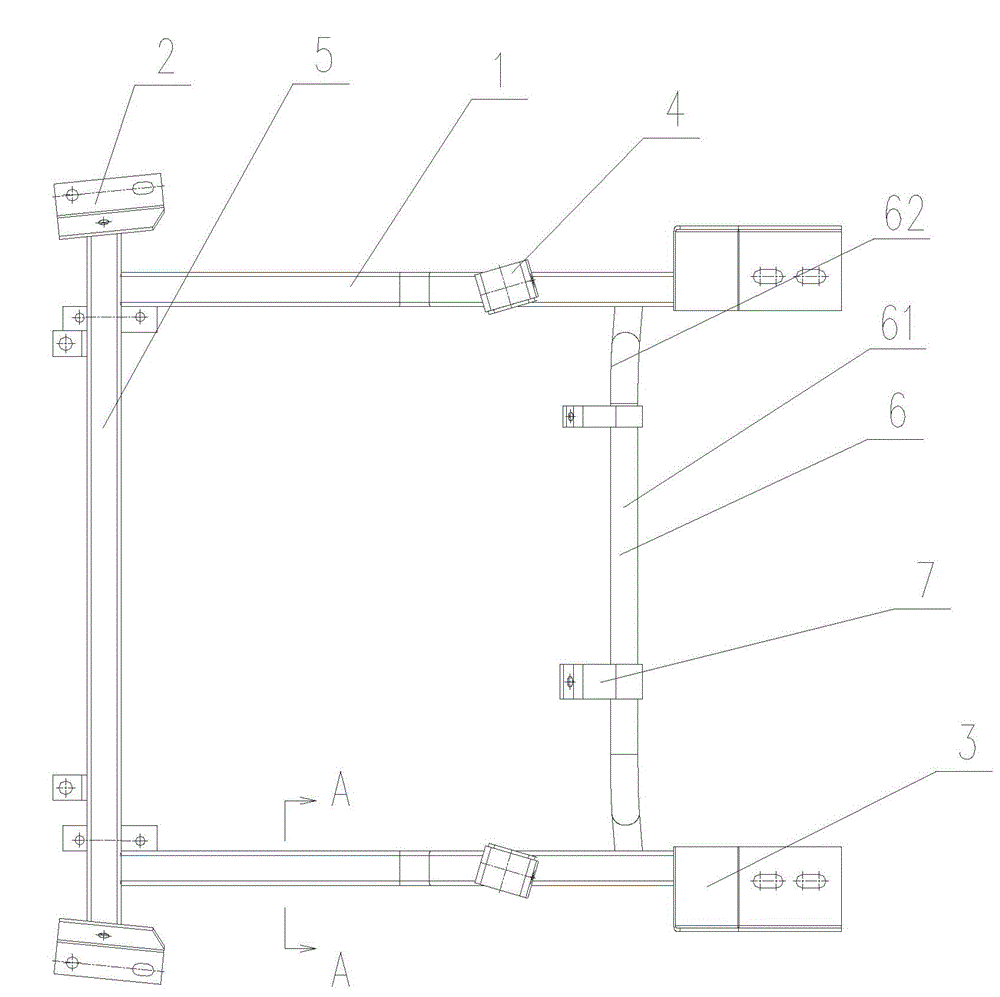

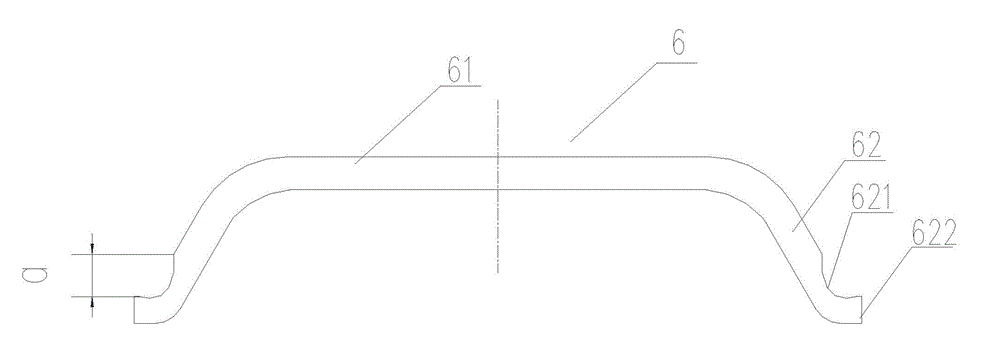

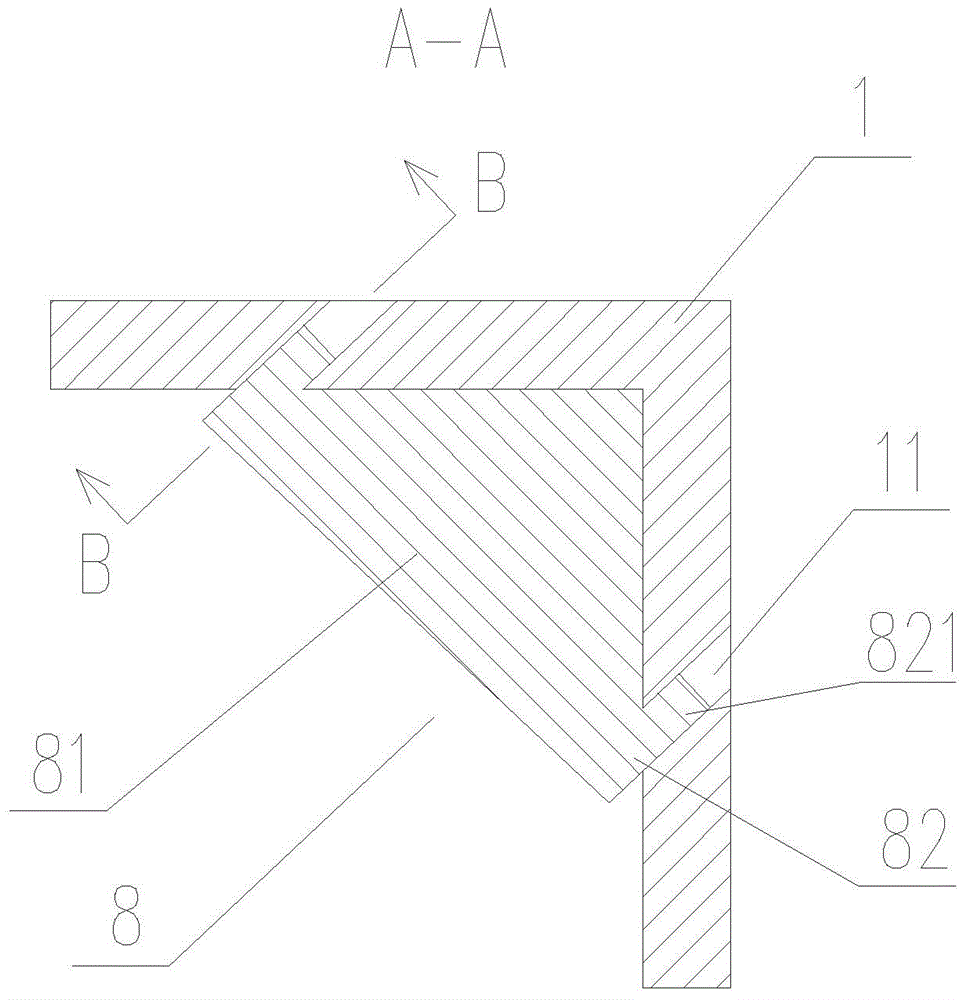

[0018] The present invention as Figure 1-5 As shown, the front sub-frame of the miniature car, the front sub-frame is frame-shaped, including a pair of front longitudinal beams 1, a pair of front brackets 2, a pair of rear brackets 3, a pair of front swing arm brackets 4, and a crossbeam 5 and the steering gear bracket 6, the crossbeam 5 and the steering gear bracket 6 are both arranged between the pair of front longitudinal beams 1, and the pair of front brackets 2 are respectively arranged on the front ends of the pair of front longitudinal beams 1, The pair of rear brackets 3 are respectively arranged on the other end of the pair of front longitudinal beams 1, the pair of front swing arm brackets 4 are symmetrically arranged on the pair of front longitudinal beams 1, and the steering gear bracket 6 A pair of steering gear fixing seats 7 are arranged symmetrically on the top, and the cross-sections of the front longitudinal beam 1 and the cross beam 5 are both L-shaped and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com