Mold for soldering copper mesh

A copper mesh and mold technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor product appearance quality, low copper melting point, difficult welding, etc., to improve production efficiency and welding quality, Fast welding positioning, functional and practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

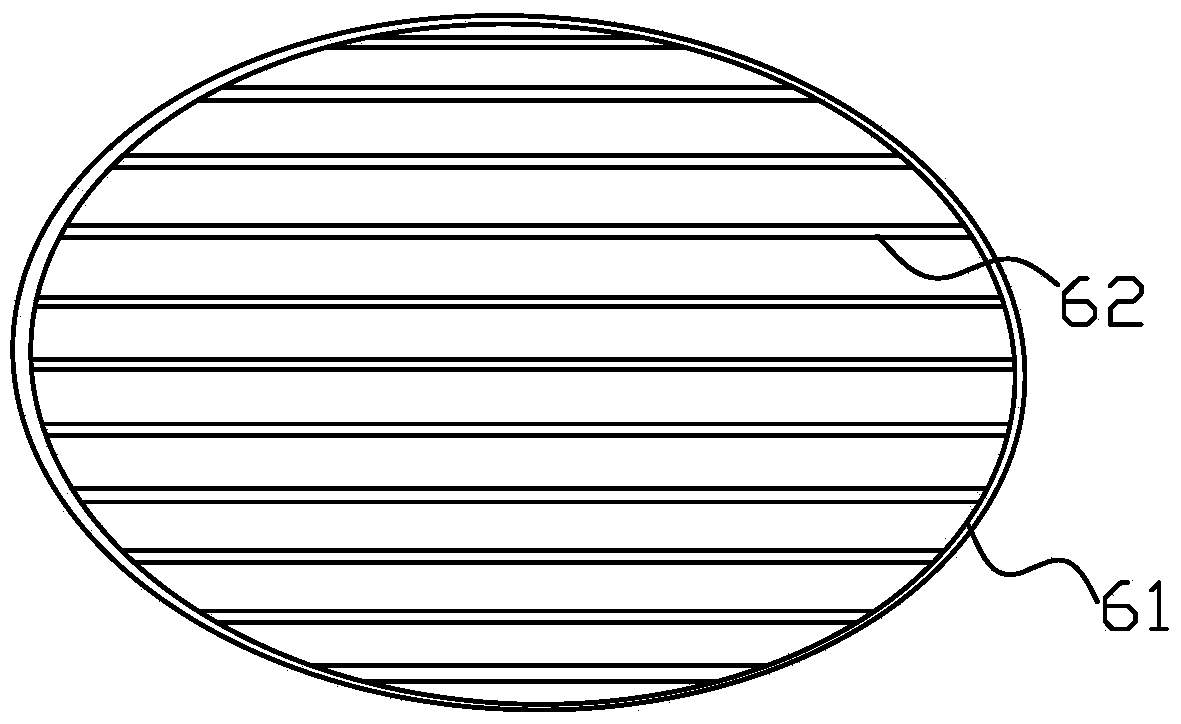

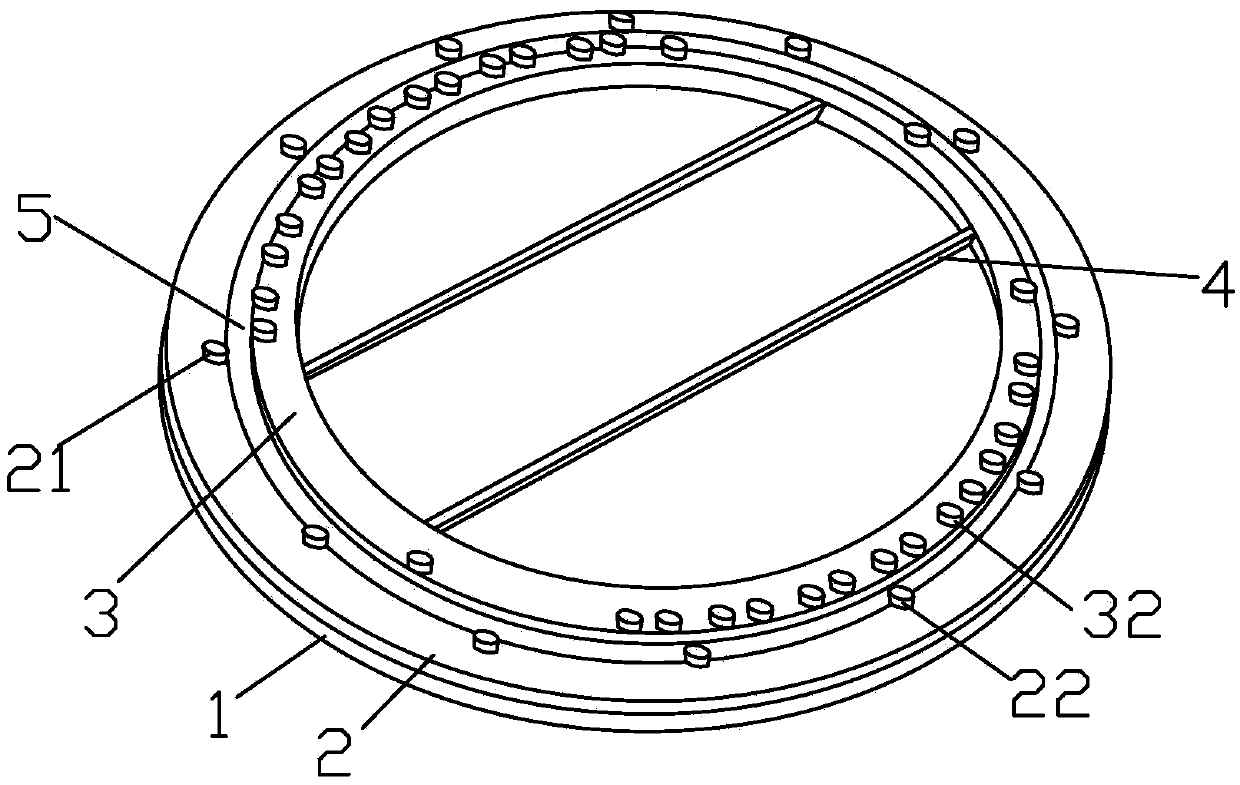

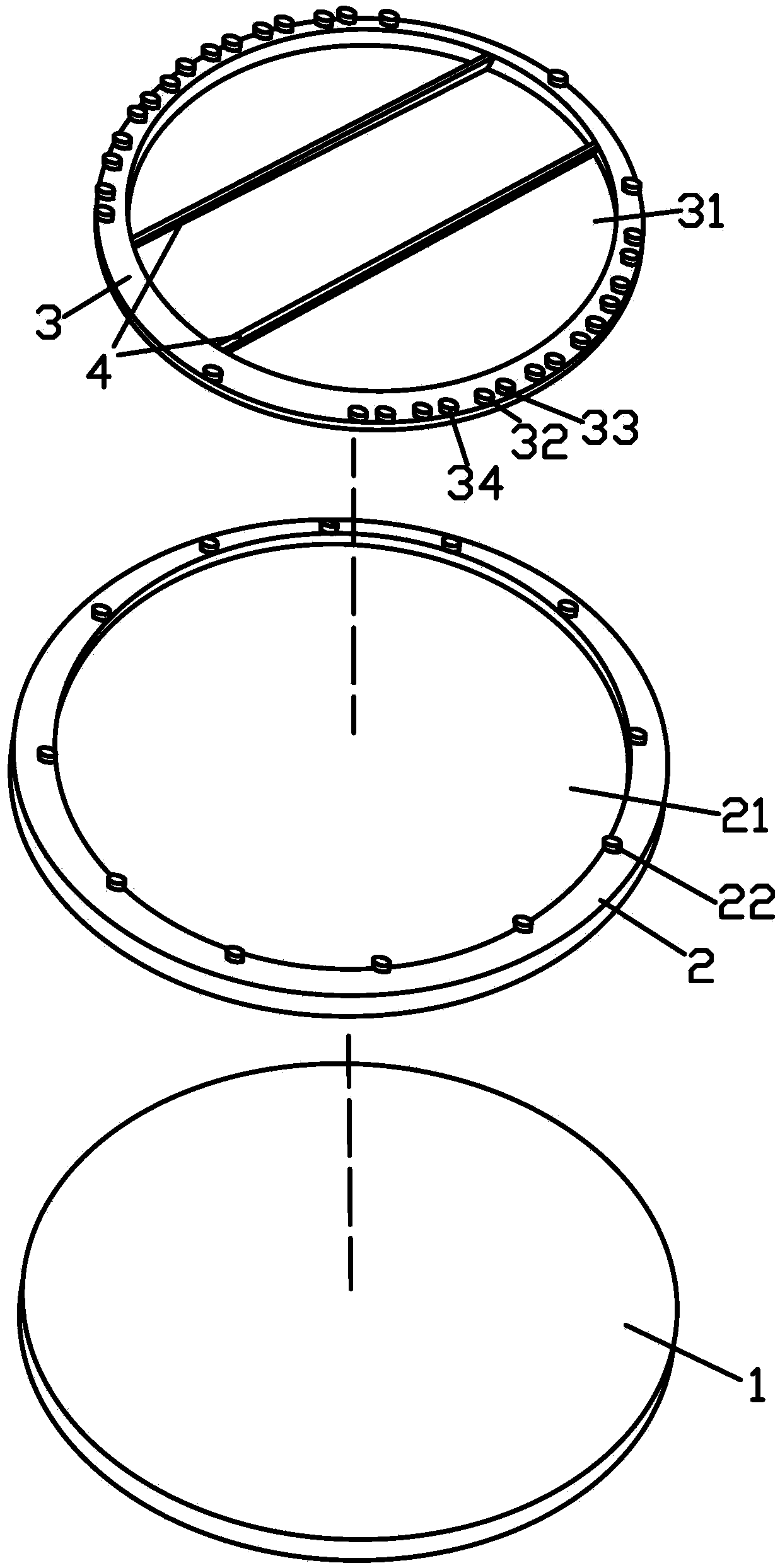

[0018] The present invention proposes a kind of mold that is used for welding copper mesh, and this mold is according to copper mesh (as figure 1 shown) structure to respectively position and fix the copper bars and copper rings of the copper mesh, so as to improve the working efficiency and welding quality of copper mesh welding.

[0019] combine figure 2 and image 3 The structure schematic diagram of the shown embodiment, the mold that the present invention proposes comprises: base plate 1; The first cavity 21 (for example, the copper circle 61 of copper net is circular, and this first positioning part 2 is annular, the middle part of the first positioning part 2 forms the first cavity of circular shape with the same shape structure of the net. 21, and the diameter of the first positioning portion 2 is greater than the diameter of the copper ring 61), and a plurality of first limiting portions 22 (such as the first The limiting part 22 is a steel column welded on the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com