Positioning welding device for anti-jump rail bracket of escalator

An escalator and positioning welding technology, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of low work efficiency, troublesome operation, manual measurement of distance and height, etc., and achieve the effect of convenient and fast positioning welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

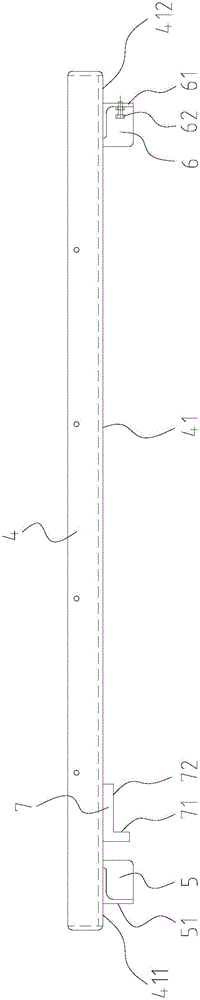

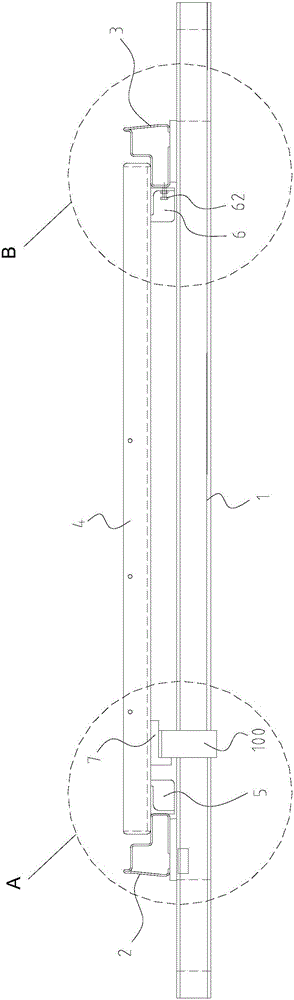

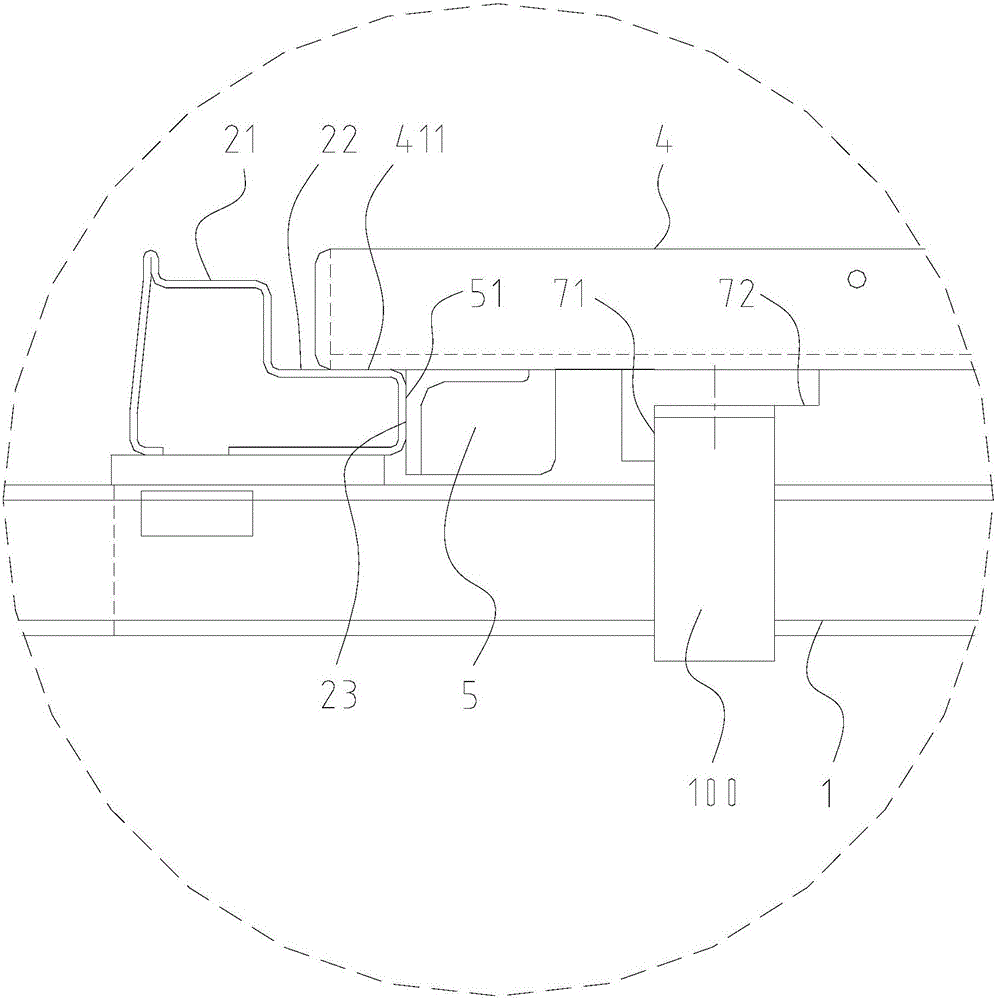

[0014] see Figure 1 to Figure 3 , a positioning welding device for an anti-jumping rail bracket of an escalator according to the present invention is used for positioning welding of an anti-jumping rail bracket 100 on a straight line section of an escalator. The straight section of the escalator has a connecting channel steel 1 arranged along the width direction of the escalator, and left main and auxiliary rails 2 and right main and auxiliary rails 3 respectively arranged on the left and right sides of the connecting channel steel 1 . The left main and auxiliary rails 2 and the right main and auxiliary rails 3 are double-layer stepped, and the upper ends respectively have guide rail surfaces 21, 31 that support the rolling of the step rollers. There is a first horizontal support surface 22 with a height lower than the guide rail surface 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com