Positioning device, welding system and welding method

A technology of positioning device and welding system, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of low welding efficiency and poor welding quality, and achieve the effect of convenient positioning welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

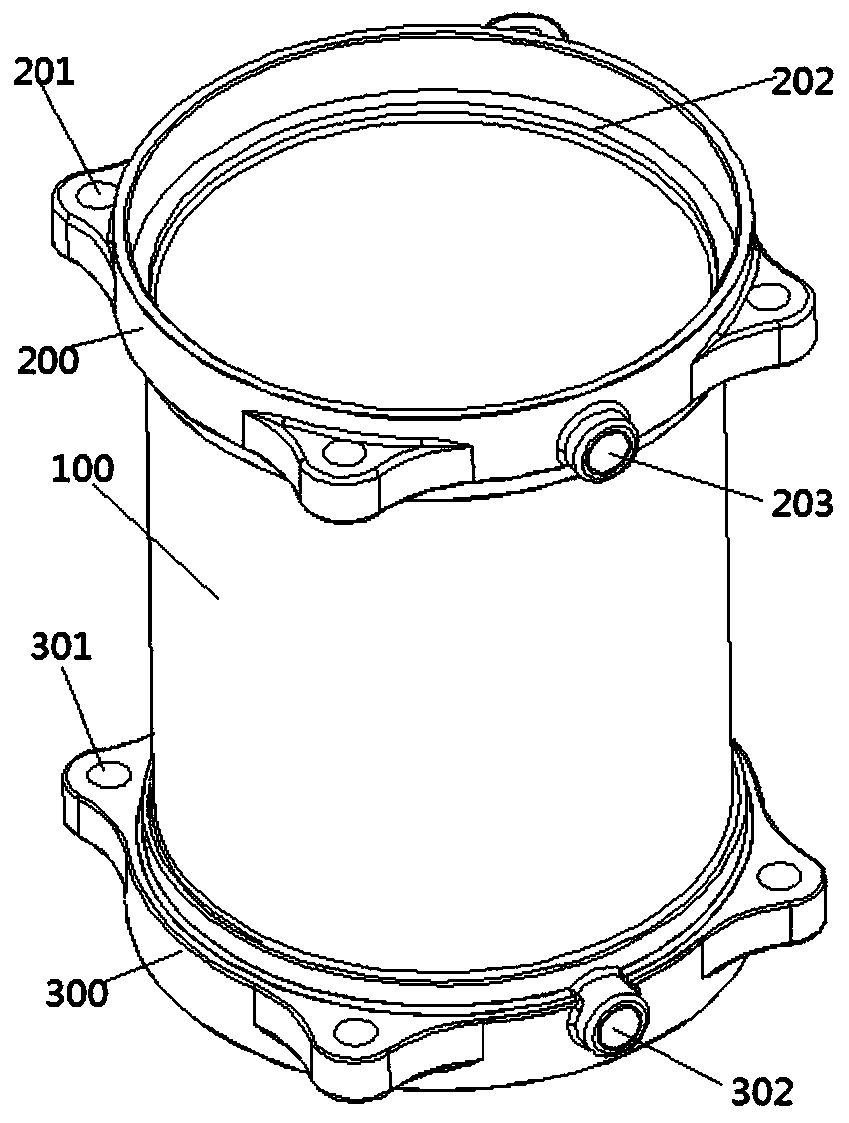

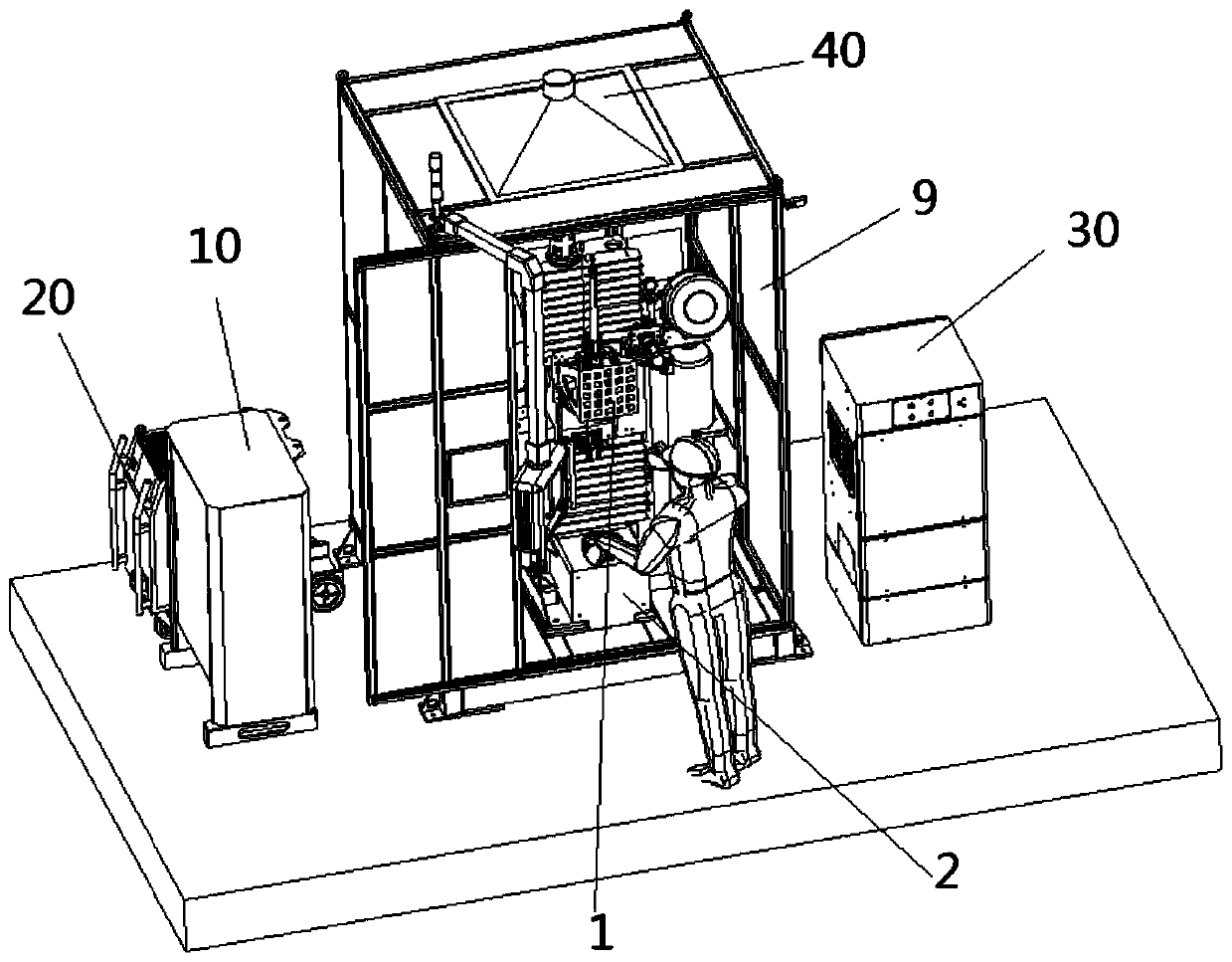

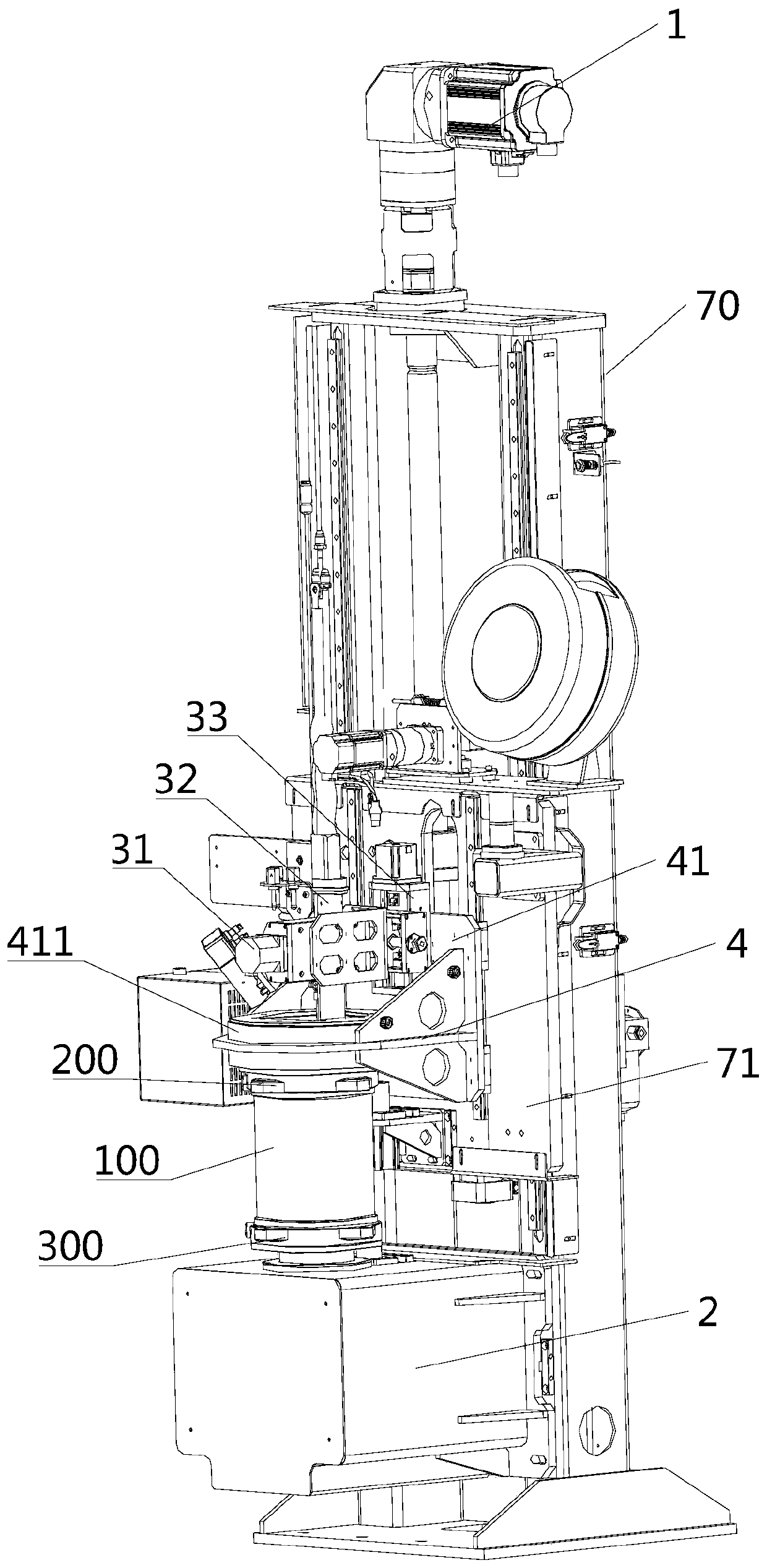

[0054] Embodiments of the present invention: as figure 1 As shown, a welding system for girth welding is disclosed, which is mainly used for welding workpieces whose welding seam is located inside the pipeline, such as welding and fixing flanges on both sides of the shell pipe of a submersible pump. Specifically, such as figure 1 Shown is a shell pipe 100 of a submersible pump to be welded and an upper flange 200 and a lower flange 300 located at both ends of the shell pipe 100. The inner side wall of the upper flange 200 is provided with a flange stop ring 202, and the lower flange The inner side wall of 300 is also provided with a corresponding flange limit ring, one end of the shell tube 100 abuts on the flange limit ring 202 of the upper flange 200, and the other end abuts on the limit r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com