Overturning clamping device

A technology of clamping device and clamping mechanism, which is applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of time-consuming and labor-intensive, and achieve manpower saving, good application prospects, and easy alignment operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

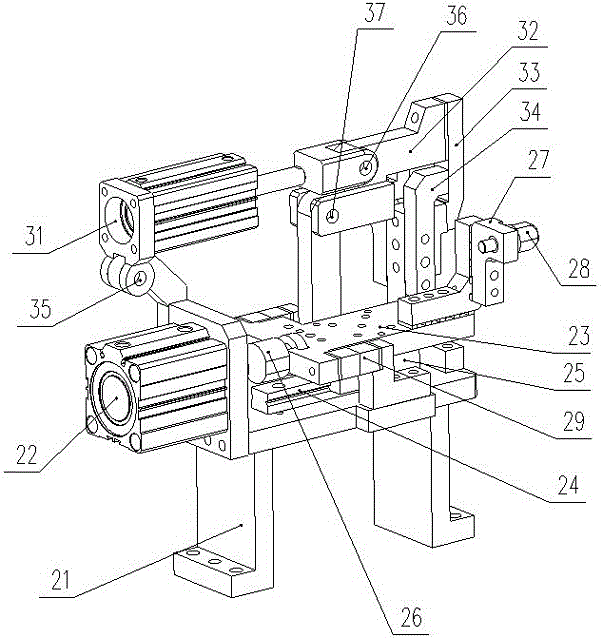

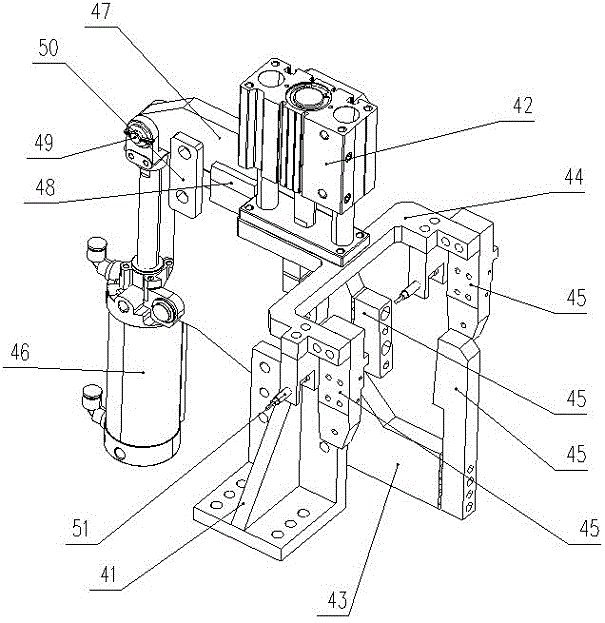

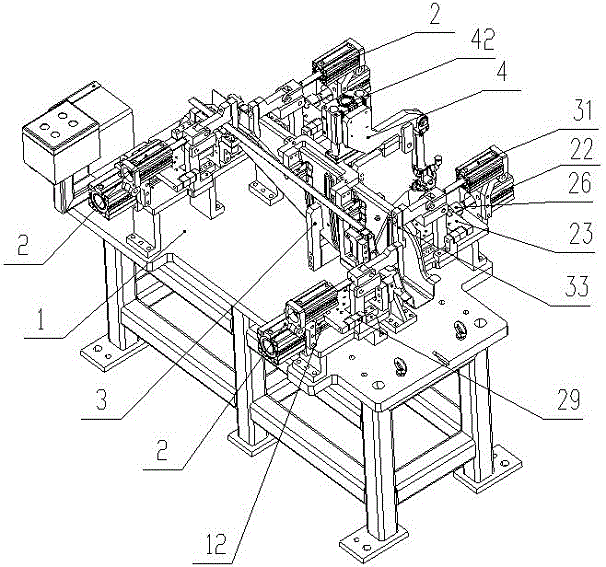

[0025] Embodiment 1: A flipping clamping device, including a workbench 1, a front and back clamping mechanism 2, a side clamping mechanism 4, a foot support I21, and a foot support II41, and the front and back clamping mechanism 2 passes through The foot support I21 is installed on the workbench 1, and the side clamping mechanism 4 is installed on the workbench 1 through the foot support II41, which is characterized in that:

[0026] The front and back clamping mechanisms 2 are provided with two groups, respectively corresponding to the two ends of the parts; each set of front and back clamping mechanisms 2 is composed of two clamping working parts I and two turning working parts I, and in each group The two clamping working parts I are respectively located on the front and back of the part, corresponding to each other;

[0027] The side clamping mechanism 4 is arranged in the middle of the corresponding part; the side clamping mechanism 4 includes a clamping working part II a...

Embodiment 2

[0042] Embodiment 2: A robot welding production line for the rear beam assembly of a passenger car, which uses the overturning clamping device as described in Embodiment 1, and also includes a welding work plate 5, a spot welding robot arm 6 and a safety grating 7; The welding work disk 5 can be rotated, on which at least two groups of flip clamping devices are installed along the circumference, and the spot welding robot hand 6 is arranged in the middle of the welding work disk 5, and its mechanical arm and welding torch can cover all The welding points of the parts clamped by the flip clamping device; the safety grating 7 is set at the passageway for personnel to sense whether people or other objects stay in the working area.

[0043] After the first operator positions and clamps the components of the girder in the welding production line, the spot welding robot 6 is given a start signal through the control button, and the spot welding robot 6 automatically performs spot weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com